Roll up of Recall Notice Status to Pending Closure on Completion of Tasks

With this release, recall notices are no longer automatically marked as Closed once all recall tasks are completed. Instead, the application retains the notices in a Pending Closure status. This change allows continued tracking of any incoming shipments of recalled parts that may still be circulating in the supply chain.

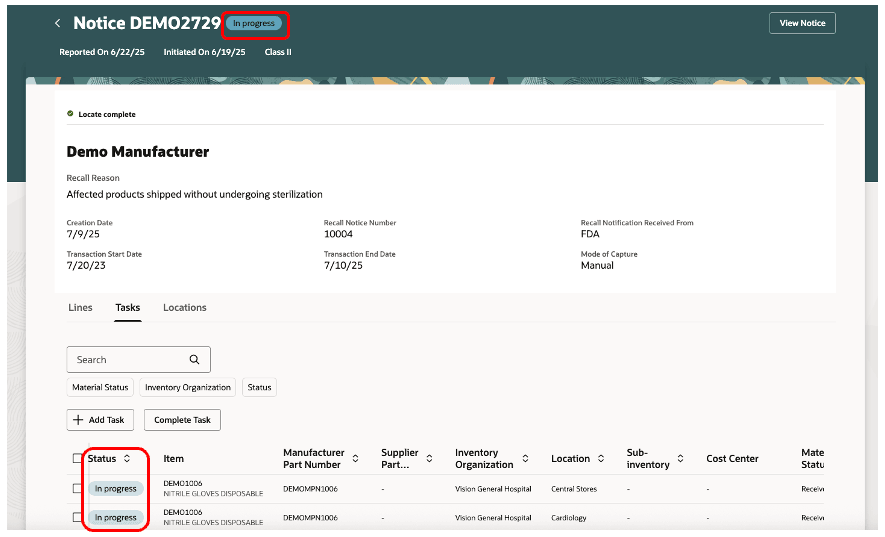

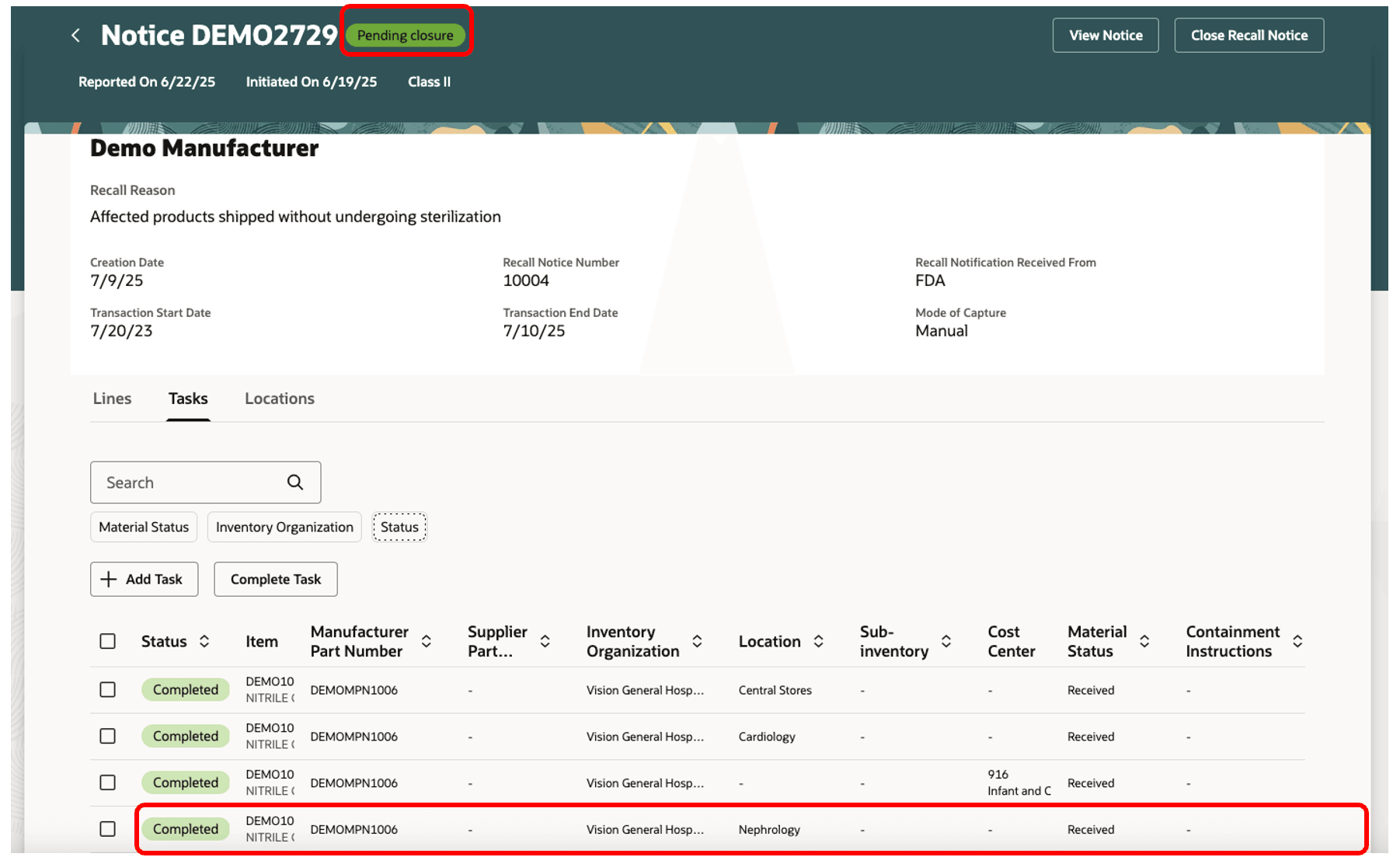

Recall notice and tasks in progress

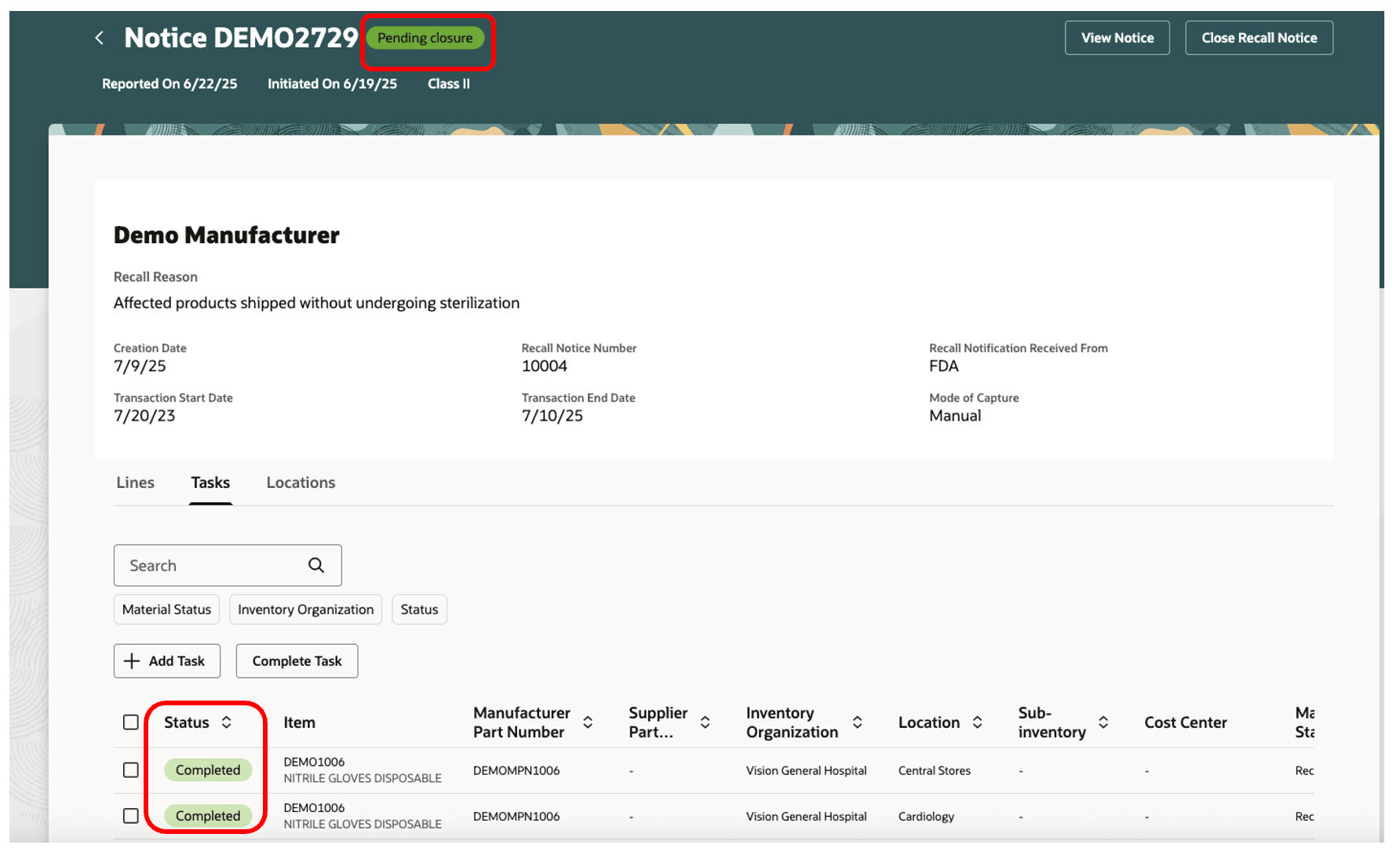

Recall notice in Pending Closure status

As shipments of recalled parts are received while the recall notice remains in the Pending Closure status, the application automatically generates new recall tasks. This allows you to continue monitoring and addressing defective products within the supply chain. You can take appropriate containment actions on these incoming materials and complete the associated tasks.

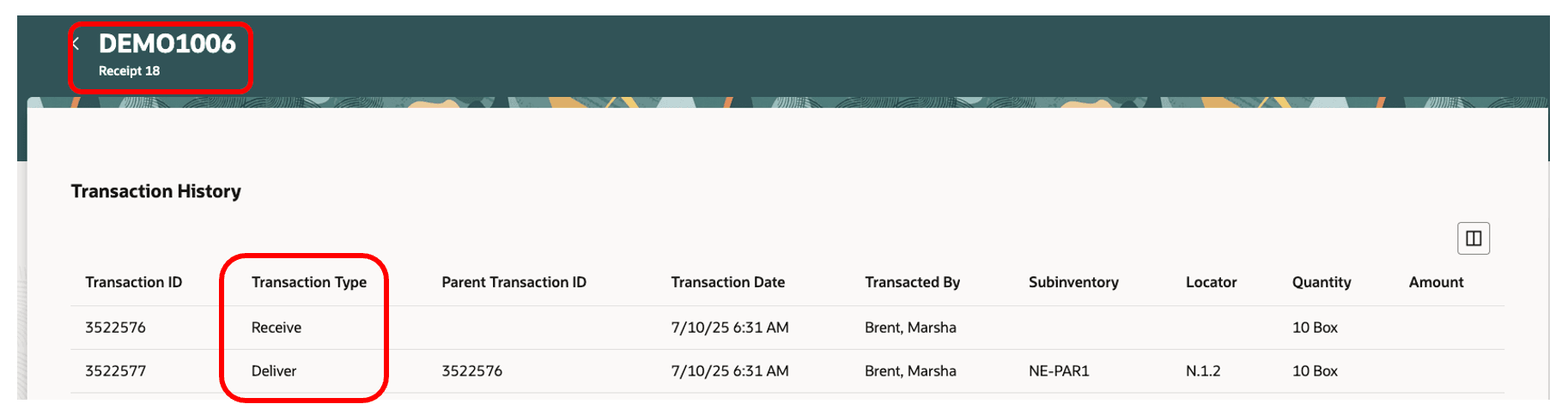

Receipt of in-transit shipment

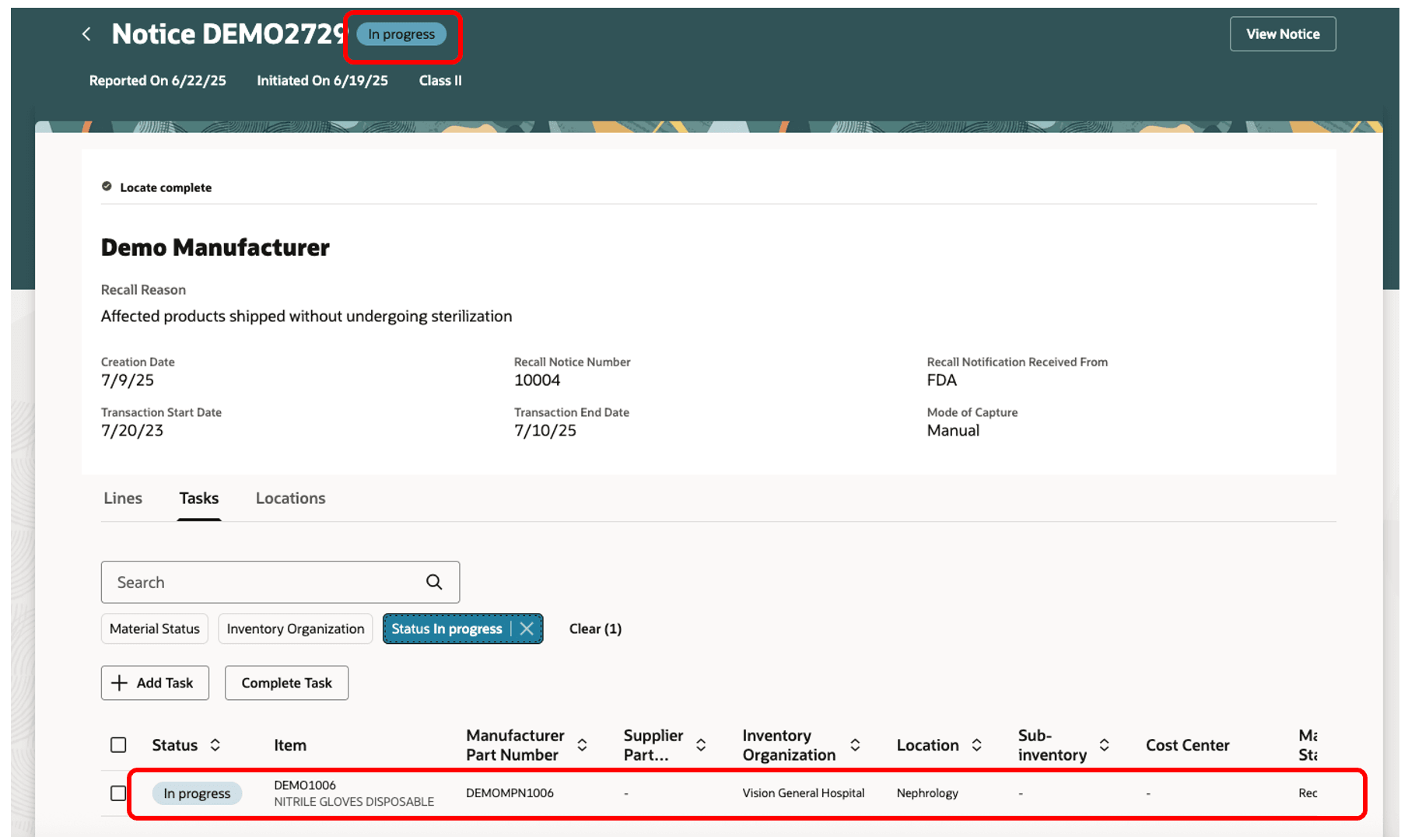

Generation of new task

Status after the task is completed

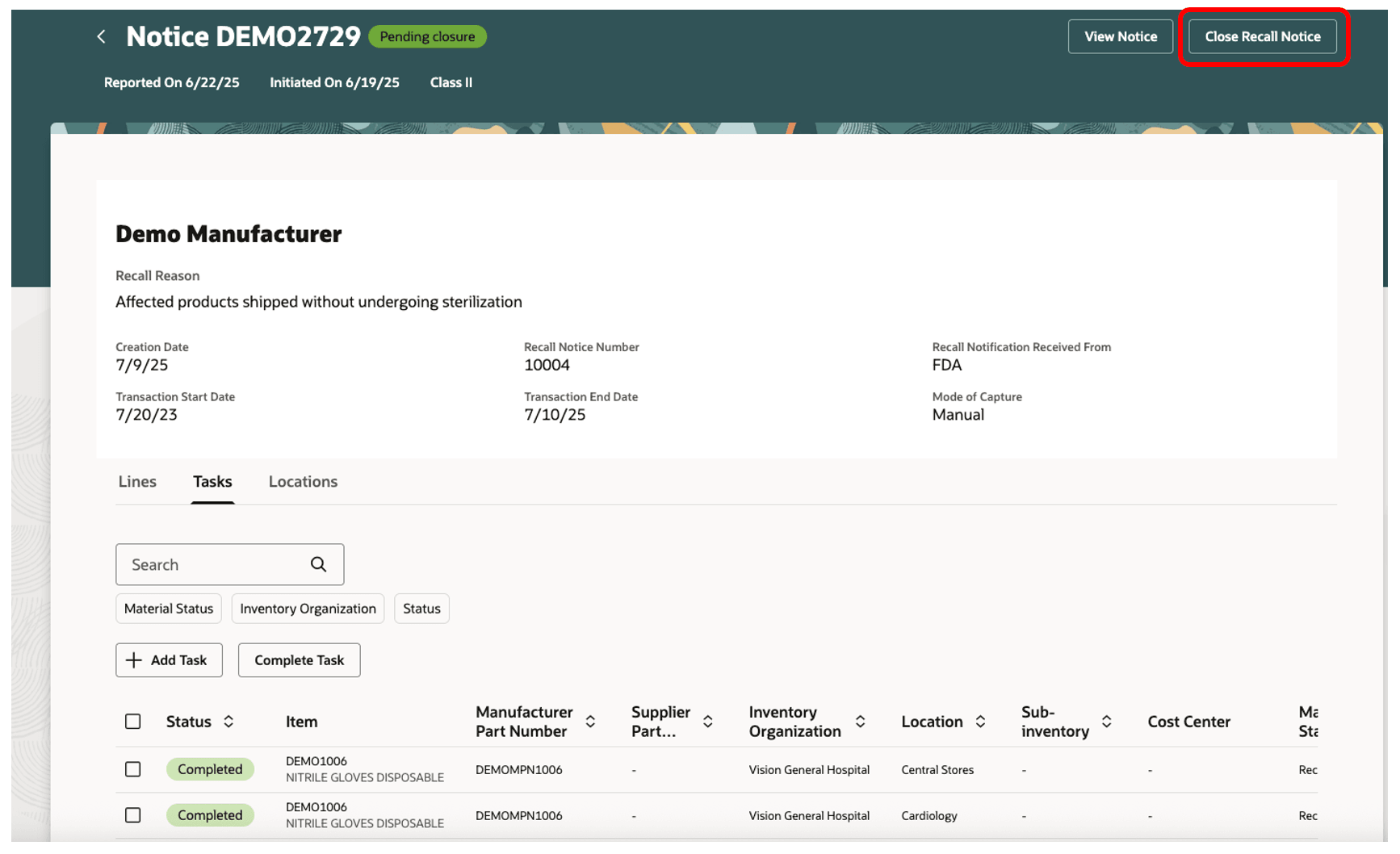

You can permanently close the recall notice when you manually confirm closure with the recalling firm or when you have sufficient evidence that the recall event has concluded. Once closed, the application stops tracking incoming shipments related to that recall.

Manual closure of recall notice

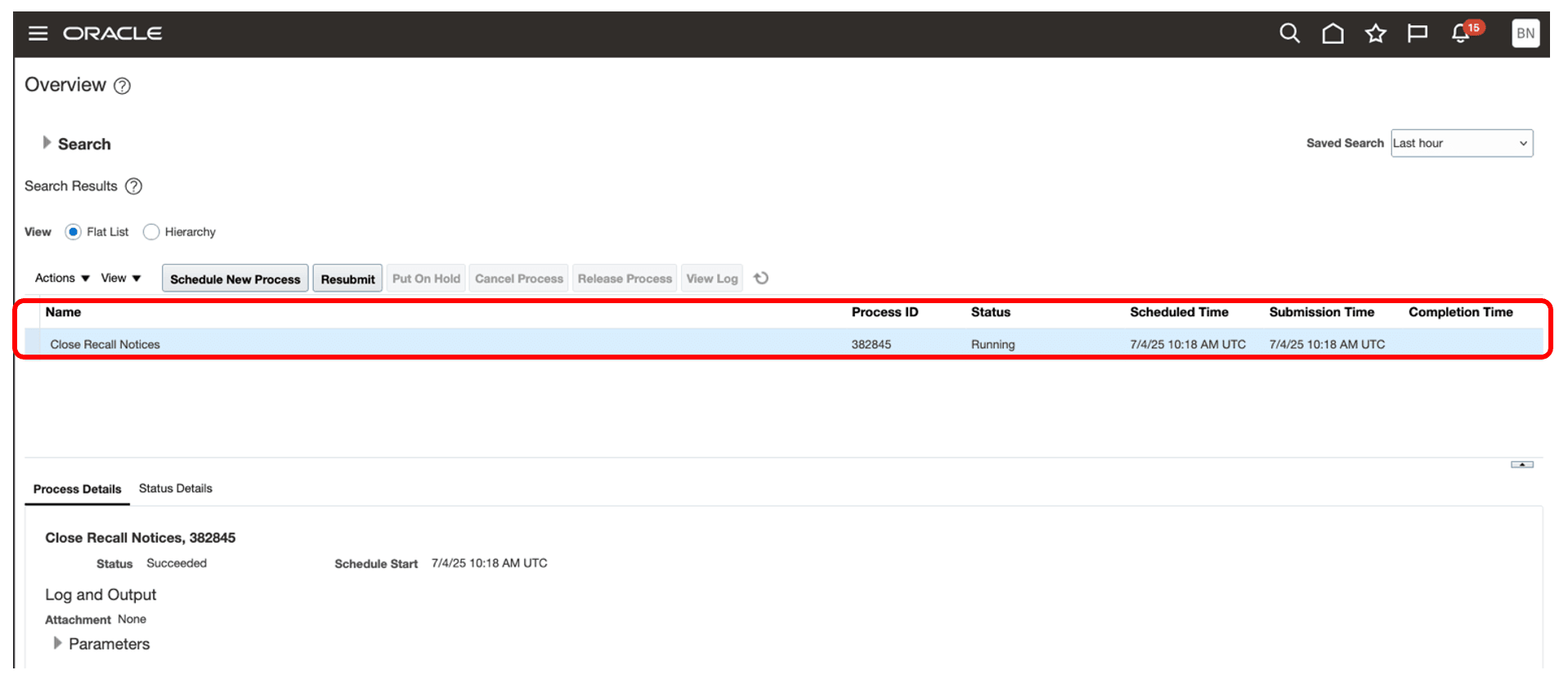

For added flexibility, you can configure the application to automatically transition recall notices in the Pending Closure status to Closed after a defined period. You do this by setting a time fence and scheduling the Close Recall Notices process to run at a specific interval.

For example, if the time fence is set to 180 days and the recall notice moves to the Pending Closure status on January 15, 2025, it is automatically closed on July 14, 2025.

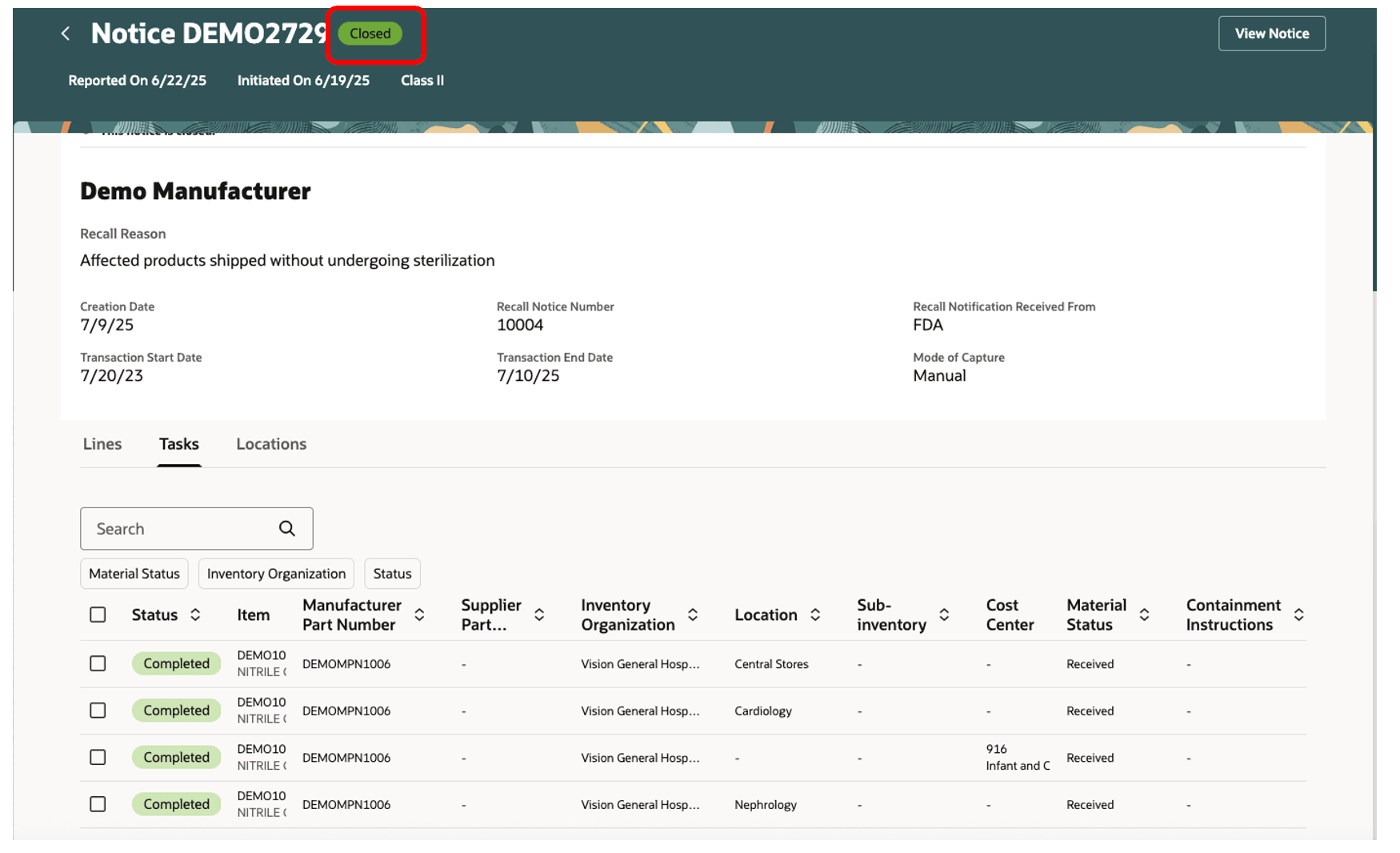

Scheduled process to close recall notice automatically

Auto closure of recall notice

- Extended recall coverage: Ensures that all recalled items, including those in transit or received after task completion, are properly tracked and addressed before the recall is permanently closed.

- Reduced risk of defective product usage: Prevents premature closure of recalls, helping avoid the inadvertent use or distribution of defective or non-compliant materials.

- Greater control over closure timelines: Offers the flexibility to manually close recall notices based on operational readiness or official confirmation from the initiating party.

- Efficiency through automation: Allows configuration of time-based rules to automatically transition notices to closed status, reducing manual follow-up while maintaining control.

- Enhanced supply chain resilience: Identifies and allows corrective actions on recalled parts from late shipments, minimizing downstream disruptions and ensuring business continuity.

Steps to Enable and Configure

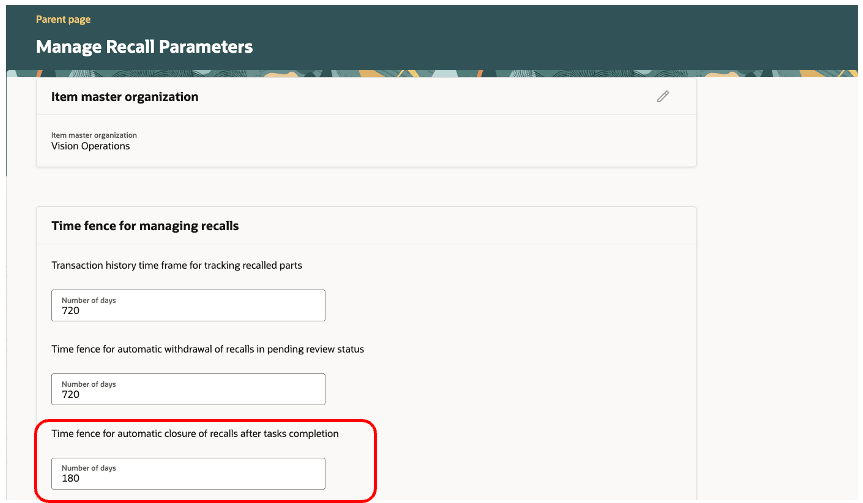

To roll up the recall notices in Pending closure status to Closed status automatically, configure the recall parameters as mentioned below.

- In the Setup and Maintenance work area, go to the following:

- Offering: Manufacturing and Supply Chain Materials Management

- Functional Area: Product Recall Management

- Task: Manage Product Recall Parameters

- Set the time fence for automatic closure of recalls after tasks completion in the Time fence for managing recalls section under Global tab and save the record.

Configure time fence in Recall Parameters

Key Resources

- Oracle Supply Chain Management guide, Using Product Recall Management guide, available on the Oracle Help Center.

- Oracle Supply Chain Management guide, Implementing Product Recall Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned with configured job role that contains the following privileges can access this feature:

- Manage Product Recall Notices (ENQ_MANAGE_PRODUCT_RECALL_NOTICES)