Redwood: Deliver Goods with Robotic Material Handling Equipment

In today's fast-paced and bustling hospital environment, the efficient delivery of medical supplies and equipment is crucial for patient care. Autonomous delivery robots can revolutionize the internal goods delivery process to ensure that various hospital stocking locations receive their resupply requests promptly.

These robots offer a solution to streamline the internal supply chain and enhance the overall operational efficiency of the healthcare facility. By navigating the intricate network of hospital corridors autonomously, they free up up valuable time and resources for materials management and healthcare professionals. Now you can integrate with autonomous delivery robots to complete your receipt deliveries throughout the hospital.

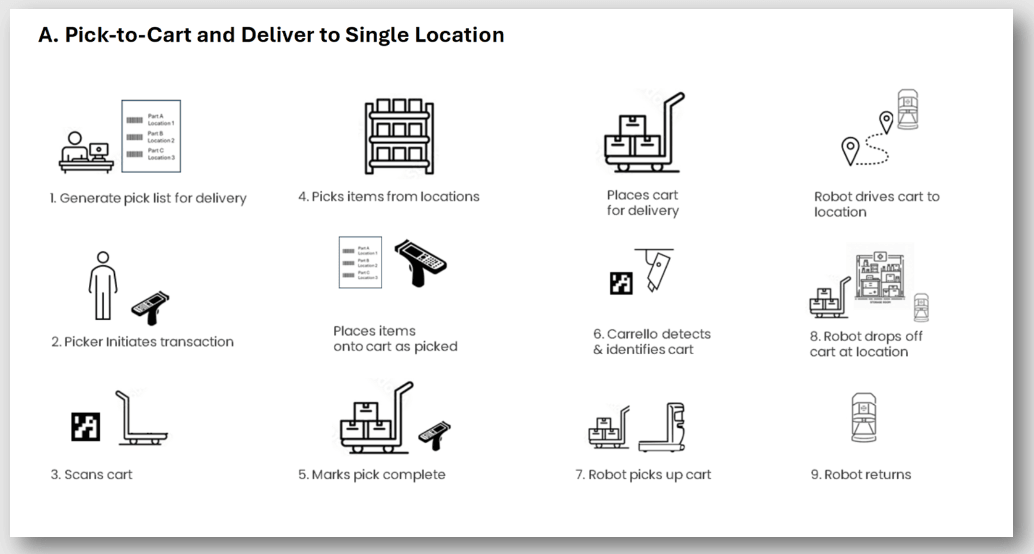

Pick-to-Cart and Deliver to Single Location

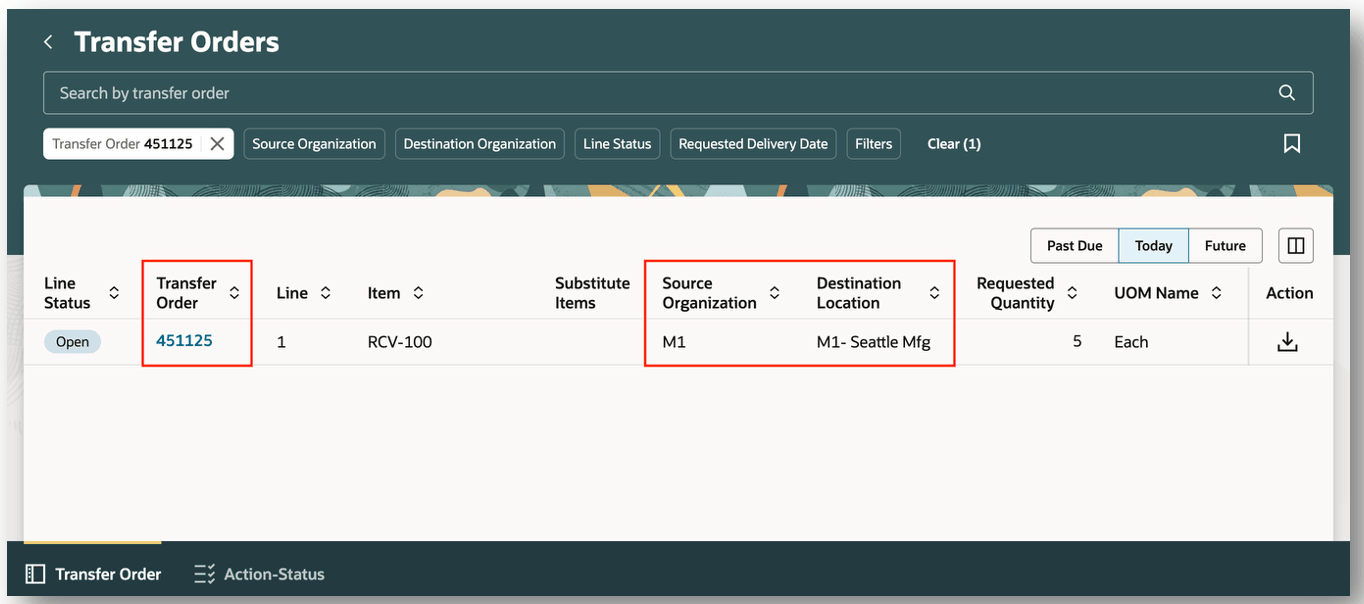

A common use case where autonomous delivery robots are effectively used is when some material needs to be transferred from a storage location to a PAR location. For such activities, organizations uses intraorganization transfer orders to move material from a source subinventory to a PAR location. For example, a PAR location is counted periodically to determine if replenishment is required. In the event of a PAR location replenishment, a transfer order is created to replenish material from a storeroom or storage location. A transfer order contains all the information needed to replenish the PAR location that includes the source and destination location details along with the item and requested quantity.

Transfer Orders

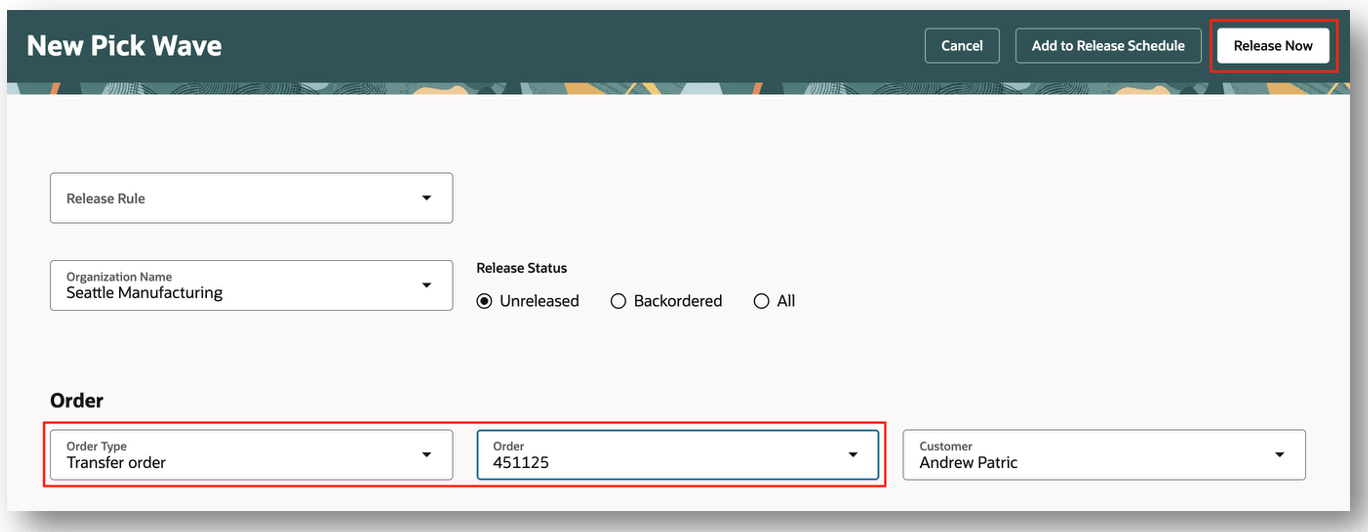

Before you perform picking activities for a transfer order, you must create a pick wave. The pick wave will update the shipment line status to released to warehouse. When releasing a pick wave, it's recommended to enable the automatically ship on manual pick confirm parameter. This parameter is ideal for intraorganization transfers when material is transferred from a central storeroom to PAR locations and the standard ship confirmation is not required.

The automatically ship on manual pick confirm parameter can be enabled on the New Pick Wave, Pick Wave Release Rule, and Shipping Parameters pages. After you have entered or selected the necessary parameters, you can release the pick wave by clicking Release Now.

New Pick Wave

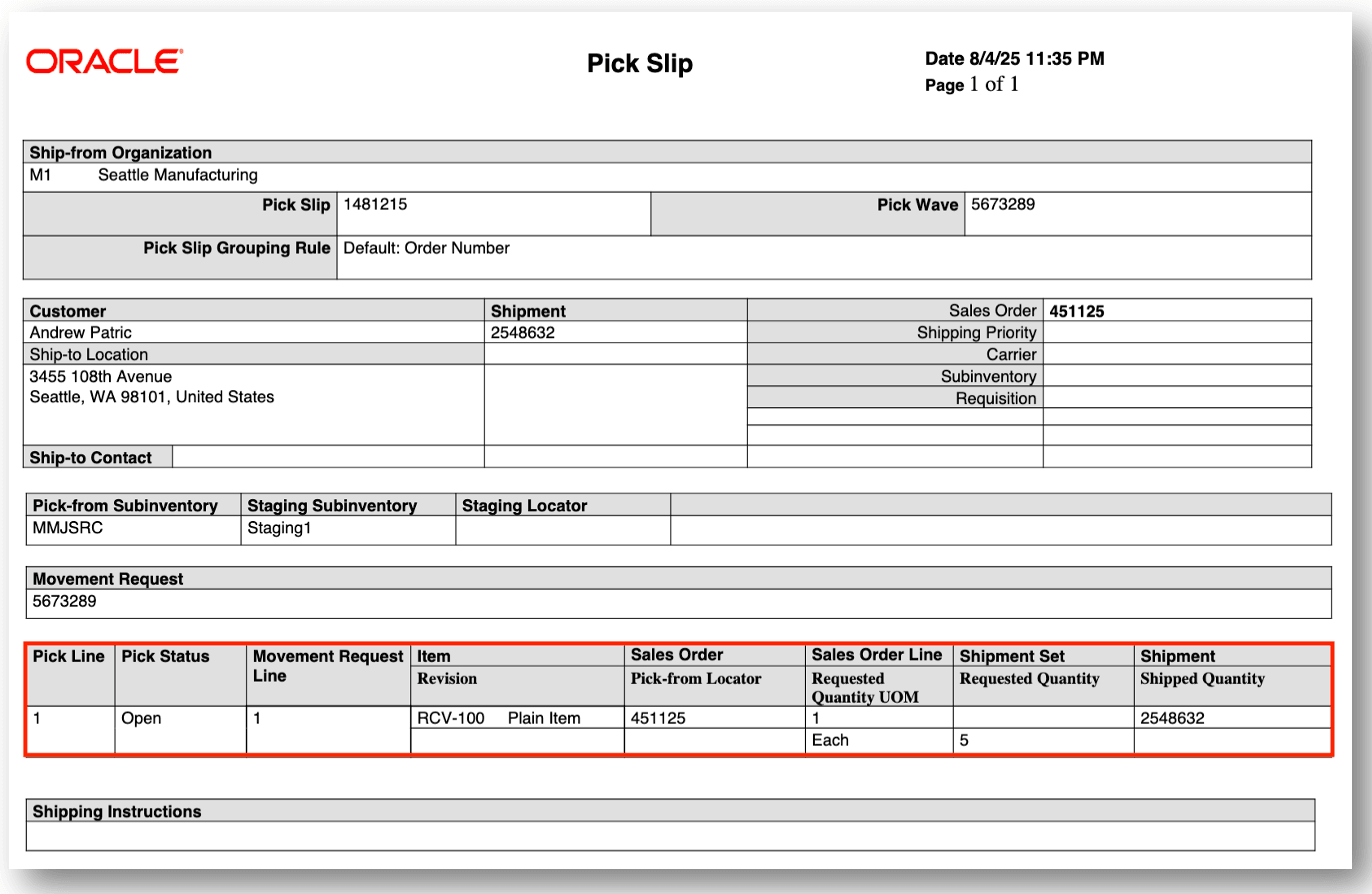

One of the critical documents used when picking material onto the delivery cart is the pick slip report. The pick slip report identifies the material that will be selected and placed onto the delivery cart. This report provide details, such as the pick-from subinventory, transfer order number, item, and quantity.

Pick Slip Report

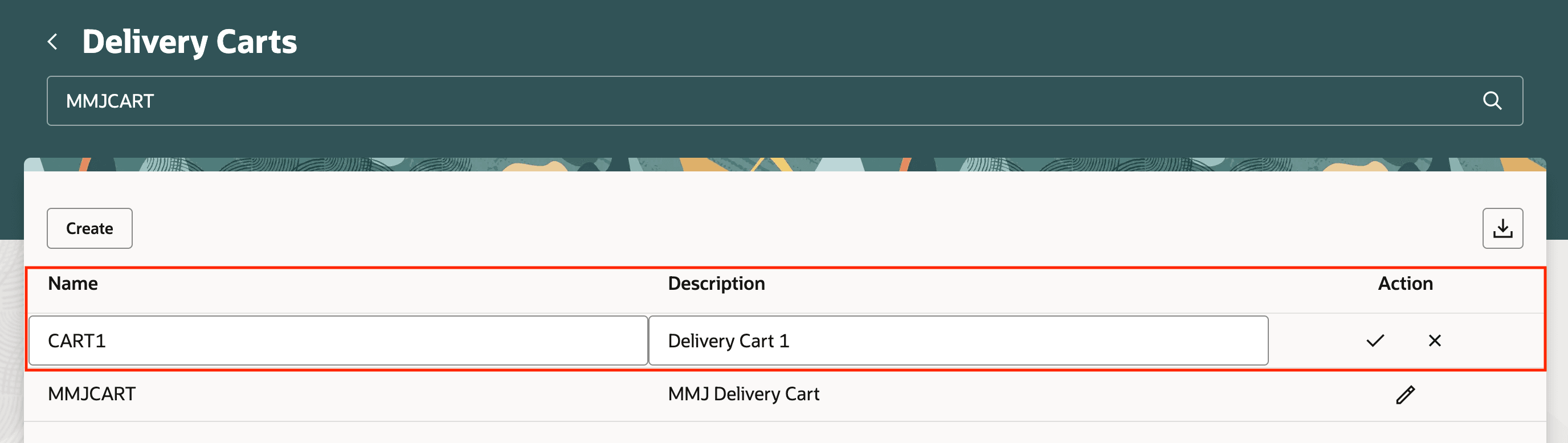

Before you perform picking activities for a transfer order, you must create a delivery cart. Material will be picked onto a delivery cart for pickup by an autonomous delivery robot. You can navigate to the Delivery Carts page from Supply Chain Execution -> Inventory Management -> Receipt Deliveries -> Delivery Carts. When you create a delivery cart, you can specify details, such as the delivery cart name and delivery cart description. Defining a delivery cart is a required prerequisite to select a delivery cart when a pick is confirmed.

NOTE: Once a delivery cart has been created it can't be deleted.

Delivery Carts

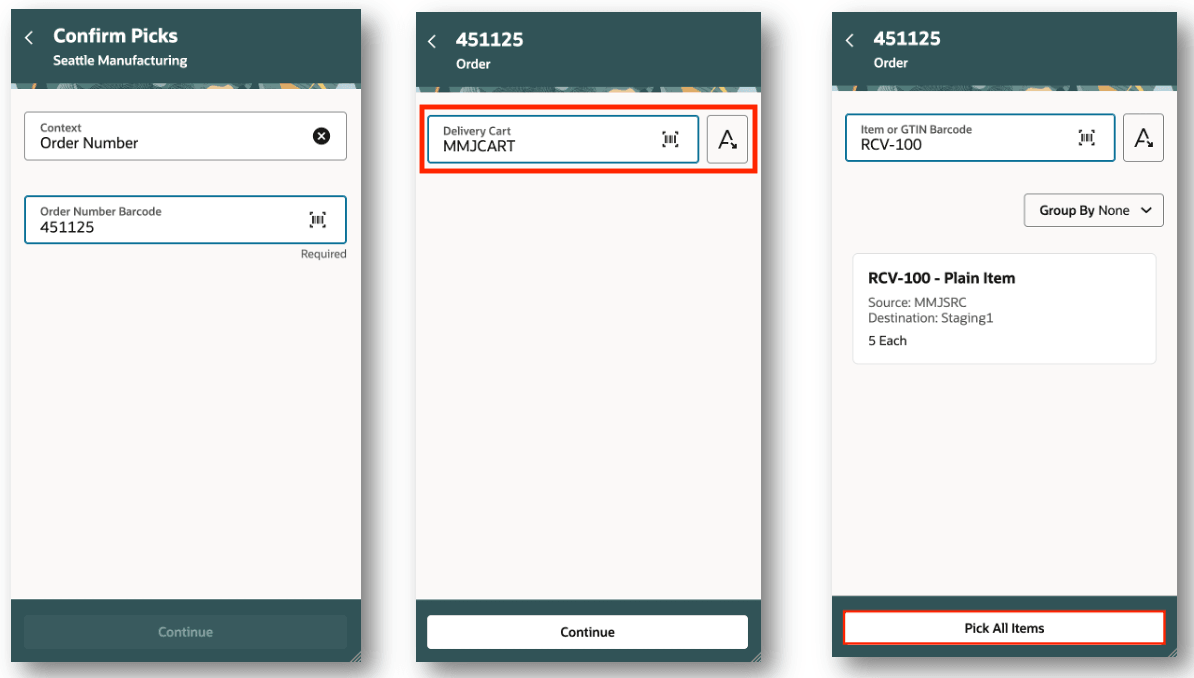

You can navigate to the mobile confirm pick page to pick the items into a delivery cart. The Order Number Barcode field is enabled when you select the Context Order Number. The order number entered represents the transfer order document that is being picked. After you have identified the appropriate transfer order, you can select the delivery cart or scan a barcode associated with the delivery cart.

NOTE: The field Delivery Cart is only enabled when the Advanced Inventory Management parameter Enable deliveries using carts is selected.

Confirm Picks

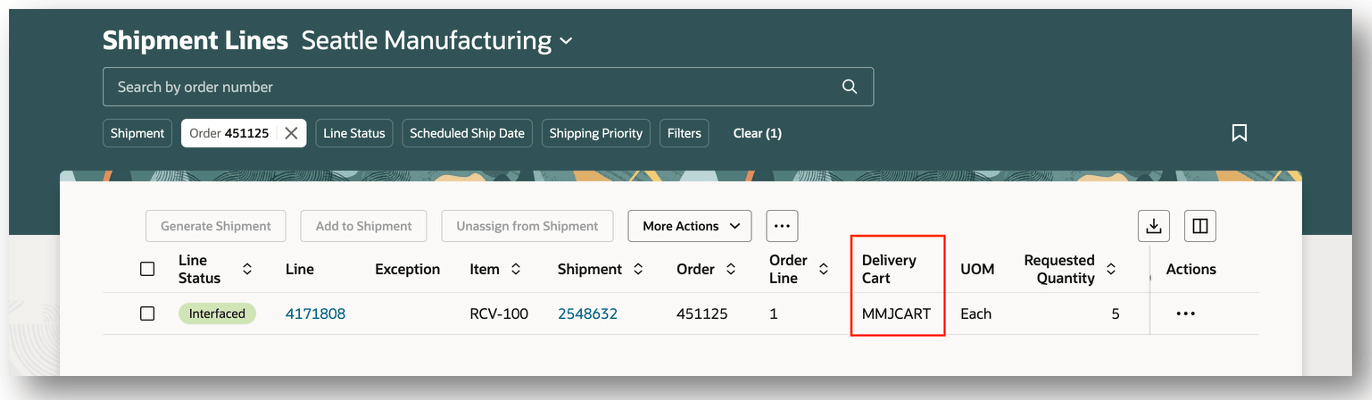

The shipment lines page is enhanced to display the delivery cart. After you complete the picking process, the shipment line will be updated with the associated delivery cart.

Shipment Lines

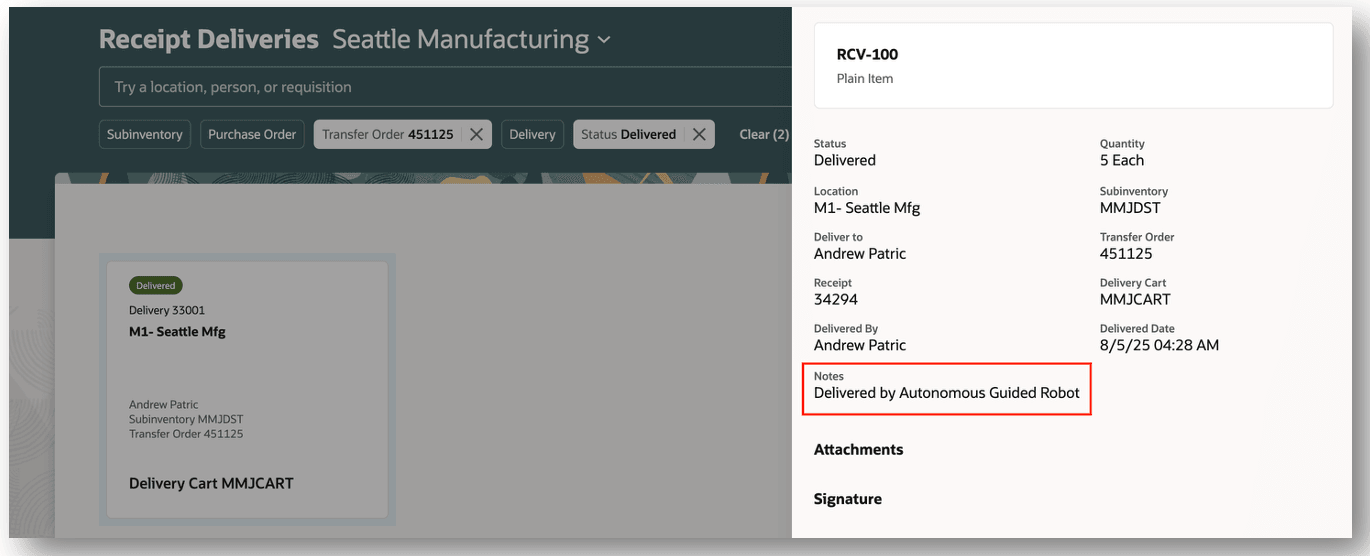

When the autonomous delivery robot drops off the cart at the location, the delivery is updated to delivered. The Notes associated with the receipt delivery indicates Delivered by Autonomous Guided Robot. You can refer back to the Receipt Deliveries and search by status Delivered to see all the completed deliveries. Additionally, you can search by the PAR location to identify the completed deliveries to the PAR location.

This completes the process of delivering a cart to a PAR location using an autonomous delivery robot.

Receipt Deliveries

The adoption of delivery robots can improve response times, reduce the workload for already over burdened staff, and ultimately contribute to a more seamless and reliable hospital supply management system.

Steps to Enable and Configure

NOTE: Before you set up Oracle Fusion Cloud Advanced Inventory Management, see the licensing and enablement information at the beginning of the Advanced Inventory Management section.

Follow these steps to enable material handling equipment:

- In the Setup and Maintenance work area, search for the Advanced Inventory Parameters task.

- On the Advanced Inventory Parameters page, select the following check box.

- Enable deliveries using carts

- Click Save.

Follow these steps to enable delivery management:

- In the Setup and Maintenance work area, search for and select the Receiving Parameters task .

- On the Receiving Parameters page, select one or both of the following check boxes .

- Autocreate deliveries for expense destination receipts

- Autocreate deliveries for PAR location receipts

- After you select these parameters, when a receipt is created, a delivery will be scheduled automatically.

- Click Update.

Follow these steps to create a delivery cart:

- In the Inventory Management Landing page, select the Receipt Deliveries task.

- Select the More Actions icon and click Delivery Carts

- Click Create.

- Enter the delivery cart name

- Enter the delivery cart description

- Click Apply.

Tips And Considerations

- The Delivery Cart field on the Confirm Picks page is only enabled when the Advanced Inventory Management > Enable deliveries using carts is enabled parameter is enabled.

- After you create delivery cart, it can't be deleted.

- The delivery cart name defined in Oracle should match the delivery cart name in the partner system.

- The Automatically Ship on manual pick confirm parameter can be enabled on the New Pick Wave, Pick Wave Release Rule, and Shipping Parameters pages.

- To automatically create deliveries for receipts at PAR locations, you need to enable the Autocreate deliveries for PAR locations receipts option in the receiving parameters.

- To automatically create deliveries for receipts at expense destinations, you need to enable the Autocreate deliveries for expense destination receipts option in the receiving parameters.

Key Resources

- Oracle Fusion Cloud SCM: Using Inventory Management guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Using Receiving guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Using Shipping guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Scheduled Processes for SCM, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Security Reference for Manufacturing and Supply Chain Materials Management on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these duty roles can access this feature:

- Monitor Receipt Deliveries Using Responsive Receiving Duty (ORA_RCV_MONITOR_RECEIPT_DELIVERIES_PWA_DUTY)

These duty roles were available prior to this update.

To set up this feature, you'll need a configured job role that contains this new duty role, which is not assigned to any predefined job roles:

- Advanced Inventory Management Administration Duty (ORA_INV_ADVANCED_INVENTORY_MANAGEMENT_ADMINISTRATION_DUTY)

This duty role was available prior to this update.