Account for Operation Yield in Process Manufacturing

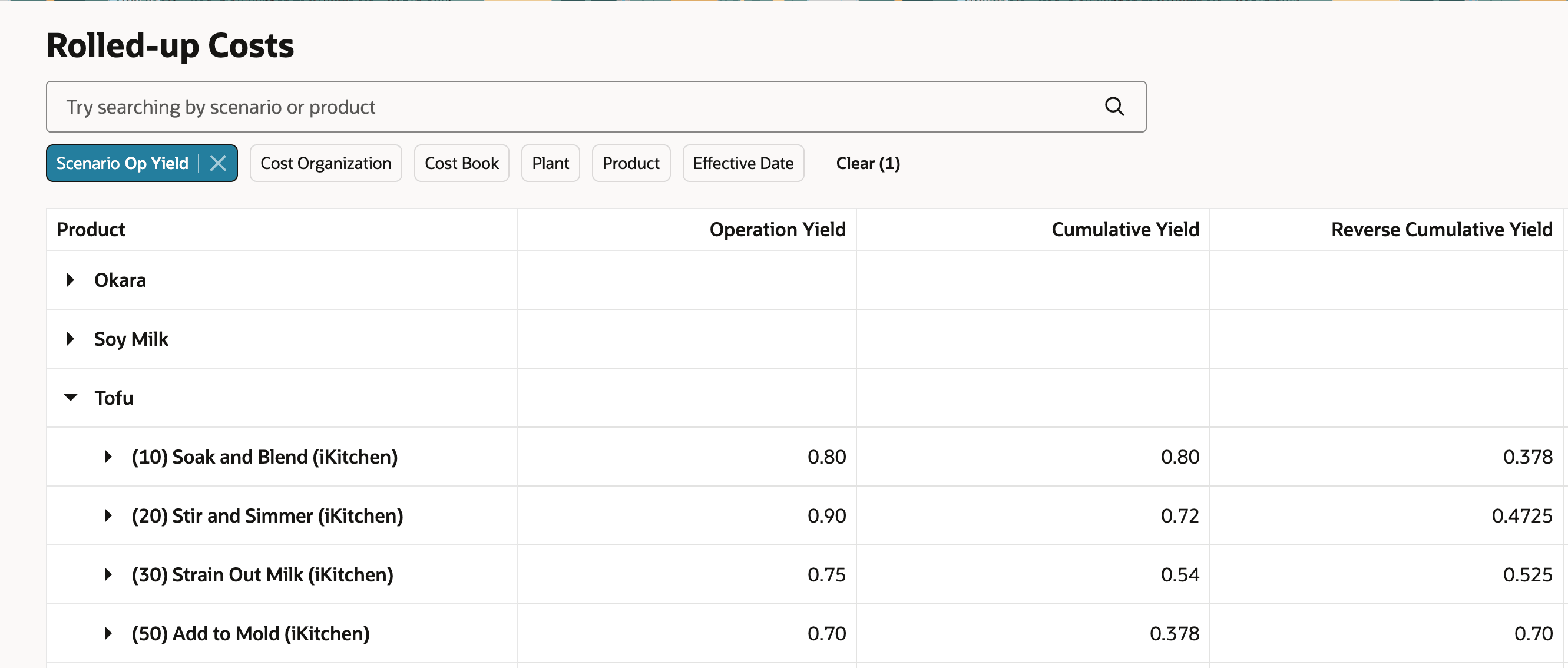

You can now estimate and plan for operation yield in a process manufacturing plant to calculate the costs of your products when using standard cost method to value your inventory. If you use operation yield, you define operation yield in process manufacturing work definition and cumulative yield is calculated based on that.

Impact on the Roll Up Costs Process

The cumulative yield is used by the Roll Up Costs process to calculate the quantity of ingredients and resources needed, which is then used to calculate the costs of products. This attribute is also used to calculate the quantity of products yielded.

Planned quantity for ingredients = {Quantity entered in work definition x Scaling factor/Component yield} x Cumulative yield of prior operation

Planned quantity for resources = {Quantity entered in work definition x Scaling factor} x Cumulative yield of prior operation

Planned quantity of product = {Quantity entered in work definition x Scaling factor} x Cumulative yield of current operation

For process manufacturing calculations, scaling factor = costing batch output size/batch quantity (both attributes are defined in the work definition)

Screenshot of rolled-up costs page showing the operation yield and cumulative operation yield to validate the costs

The rolled-up costs can be published to Cost Accounting to cost transactions from upstream applications.

Cost Accounting Impact

Accumulated Work in Process Balances Calculations

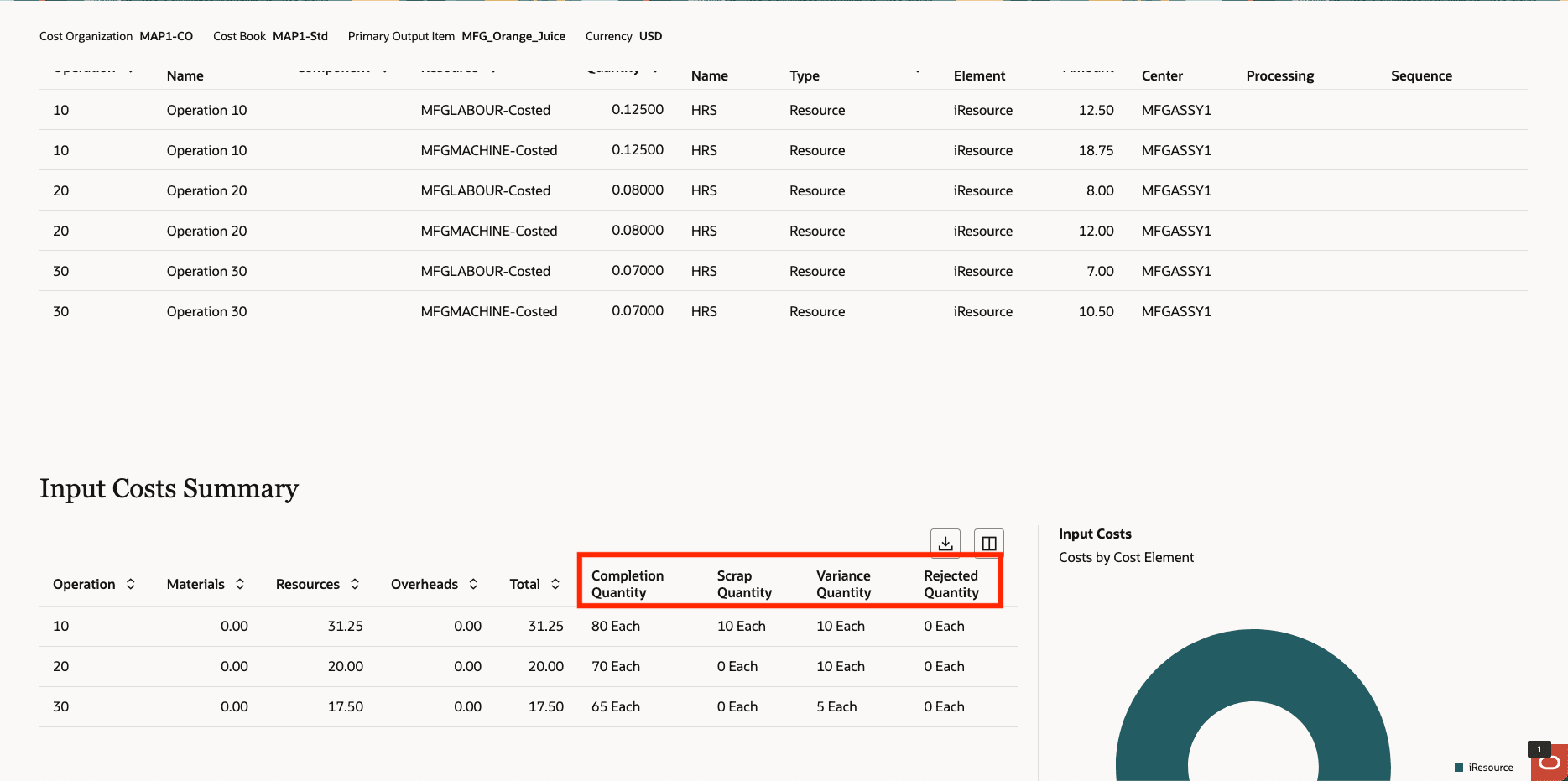

The accumulated work in process balances used for provisional completions will consider the total quantity reported in the operation minus the variance quantity reported in the operation. In the image here of the Input Costs tab on the Work Order Costs page, for the first operation, the total costs will be spread over 90 Ea. The variance quantity of 10 Ea won't be considered for the accumulated work in process balances calculations.

Work order costs page now shows the scrap, variance, and rejected quantity for each operation

Detailed Variances Calculation

For process work orders that have operations with operation yield, the batch quantity used to scale the item and resource requirements will be based on the completion quantity and scrapped quantity in the first operation.

Some of the benefits from this feature include:

- Increasing accuracy by closely tracking the planned and actual production costs.

- Improving efficiency by avoiding offline calculations and using the application to calculate costs based on your real-life production scenarios.

Steps to Enable and Configure

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management No Longer Optional From: Update 26C

Key Resources

- Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Using Supply Chain Cost Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains the following privileges can access this feature:

- Manage Cost Planning Scenario Definition (CST_MANAGE_SCENARIO)

- Perform Cost Rollup (CST_PERFORM_COST_ROLLUP)

- Review Rolled Up Costs (CST_REVIEW_ROLLEDUP_COSTS)

- Allows review of costs and balances by each individual work order. (CST_REVIEW_WORK_ORDER_COSTS_PRIV)