Account for Operation Variances in Process Manufacturing Work Order

Due to the variability of ingredients and processing in a process manufacturing work order, it's possible that you can't complete the entire planned quantity in an operation or work order. You can now report the quantity completed and mark the operation as complete to continue to the next operation for a process manufacturing work order. The difference between the planned and actual output quantities is automatically captured in a new variance dispatch status to facilitate cost analysis and production efficiency improvements. You can also effectively track this difference between the planned and actual quantities produced without inflating material requirements in subsequent operations. Marking the last operation as complete in the process manufacturing work order also completes the work order, so that no additional actions are required to resolve any remaining quantity compared to the work order batch quantity.

Let's understand the impact on accumulated work in process balances calculation logic using this example.

Work Order Operations with Completion Quantities

| Operation | Start Quantity | Completed Quantity | Variance Quantity | Marked as Complete? | Work in Process |

|---|---|---|---|---|---|

| 10 | 100 | 80 | 20 | Yes | $1800 |

| 20 | 80 | 70 | 10 | Yes | $1000 |

| 30 | 70 | 50 | 0 | No | $500 |

Let's assume that a by-product is reported at operation 20 with a cost allocation factor of 50% and the primary product gets rest of the cost and is completed in operation 30. The accumulated work in process balances will calculate the cost as follows:

Accumulated Work in Process Balance Calculations

| Operation | WIP Value Added | Cost Allocation Factor | Accumulated Work in Process Balance | Cost Allocation for Product | Completed Quantity | Per Unit Cost at Operation |

|---|---|---|---|---|---|---|

| 10 | $1800 | 0 | $1800 | 80 |

$1800/80 = $22.5 |

|

| 20 | $1000 | 50% | $2800 (1800+1000) | $1400 | 70 |

$1400/70 = $20 |

| 30 | $500 | 100% |

$1500 (1000+500) (Carry Forward Cost + Current Operation WIP) Carry Forward Cost = Quantity Completed in Current Operation * Per unit cost till prior operation = 50 * 20 |

$1500 | 50 |

$1500/50 = $30 |

If scrap is reported in any of the operation, it would use the cost as shown in the Per Unit Cost at Operation column.

For detailed variances calculations, the existing logic uses the completed quantity in the last operation to scale the item and resource requirements. With this new feature, the detailed variances will be calculated by using the completed quantity in the first operation as the basis for calculations.

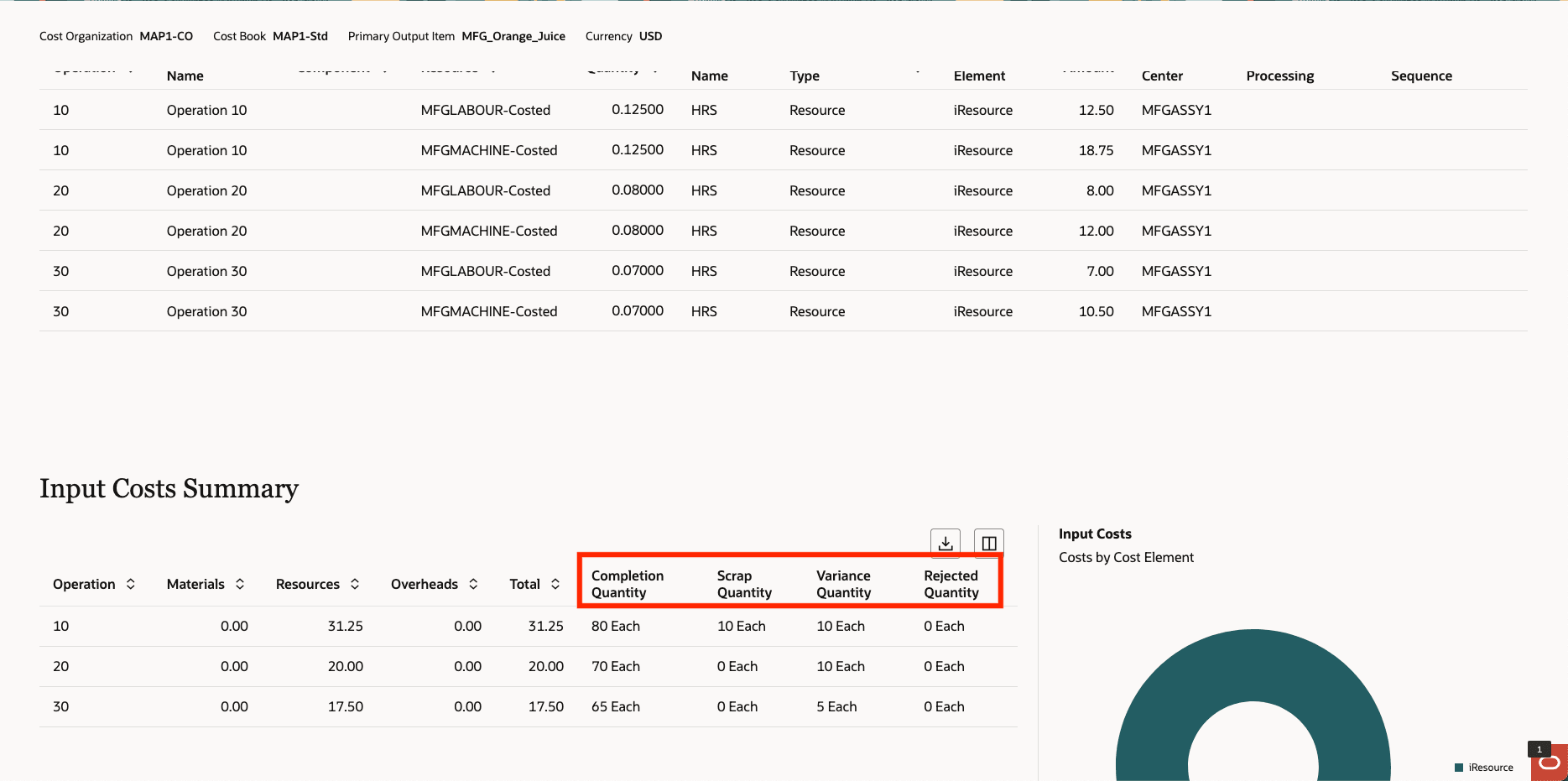

The Work Order Costs page now shows the quantity completed, rejected, scrapped, and the variance reported for each operation to help you understand the cost calculations.

Work Order Costs shows the newly introduced variance quantity

With this feature, you will now be able to indicate the process losses in each operation and calculate the costs of products and scrap based on the actual completion in each operation.

Steps to Enable and Configure

Set up the plant parameters to enable this feature:

- In the Setup and Maintenance work area, search for and select the Manage Plant Parameters task.

- On the Manage Plant Parameters page, select the required inventory organization.

- In the Plant Details tab, ensure that the Enable process manufacturing option is enabled.

- In the Work Execution tab, under Execute Production, enable the Report operation completion and variance on process work orders checkbox.

Tips And Considerations

You can complete a work order operation with variance and automatically complete a process manufacturing work order using this feature. It doesn't apply to discrete manufacturing work orders, flow schedules, or orderless transactions.

Key Resources

- Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Using Supply Chain Cost Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains the following privilege can access this feature:

- Allows review of costs and balances by each individual work order. (CST_REVIEW_WORK_ORDER_COSTS_PRIV)