Automate Operation Completion and Exception Reporting Using Equipment Events for Process Manufacturing Work Orders

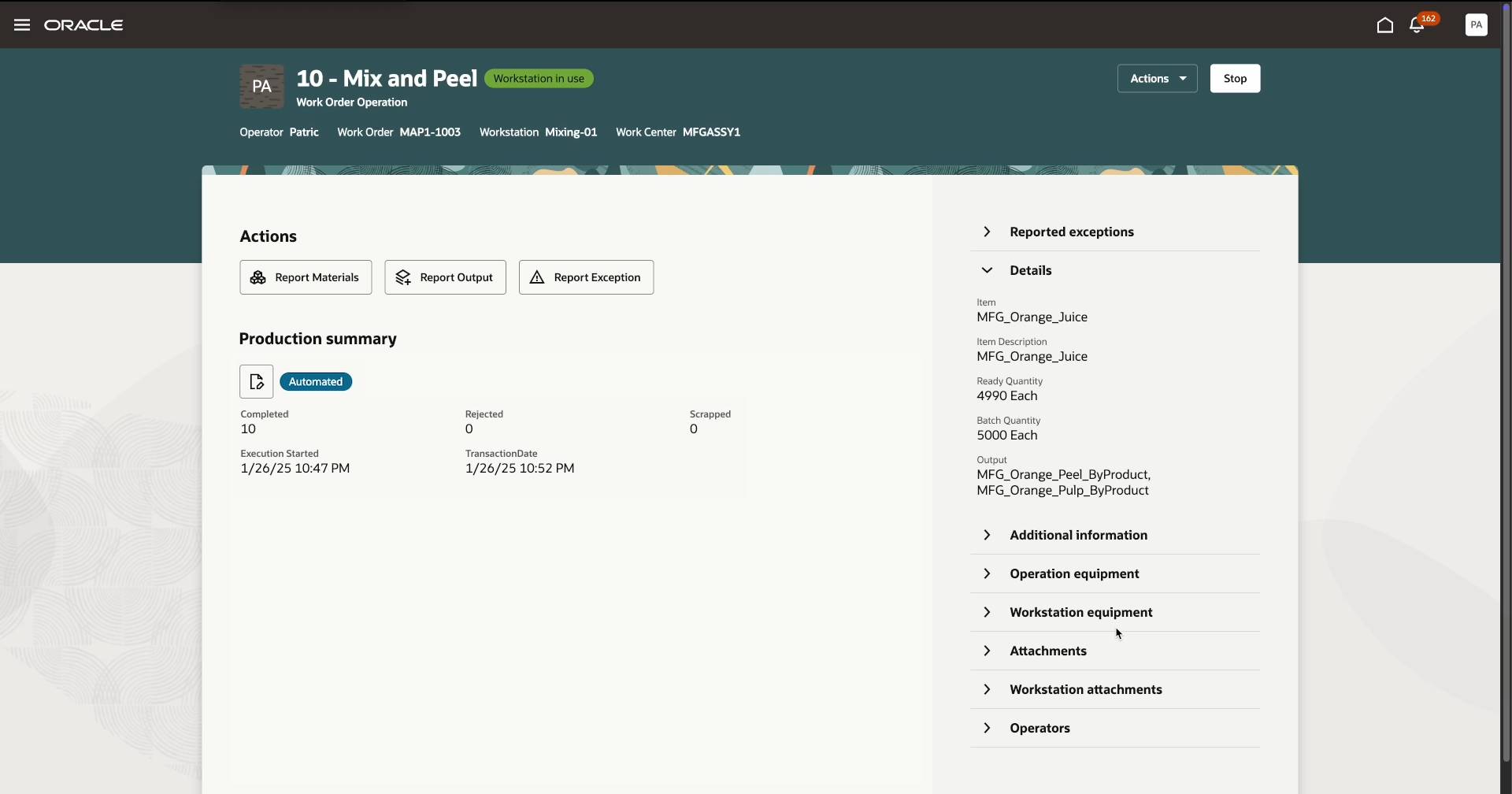

In process manufacturing plants, connected equipment can generate valuable machine events, such as quantities produced during an operation. With this update, you can now leverage IoT communications to automatically record the completion or rejection of operation quantities when executing process manufacturing work orders at workstations. When workstations use IoT-enabled equipment, machine signals can be used to start and end work order operations automatically. Machine signals can also trigger production exceptions for any break down events received during production.

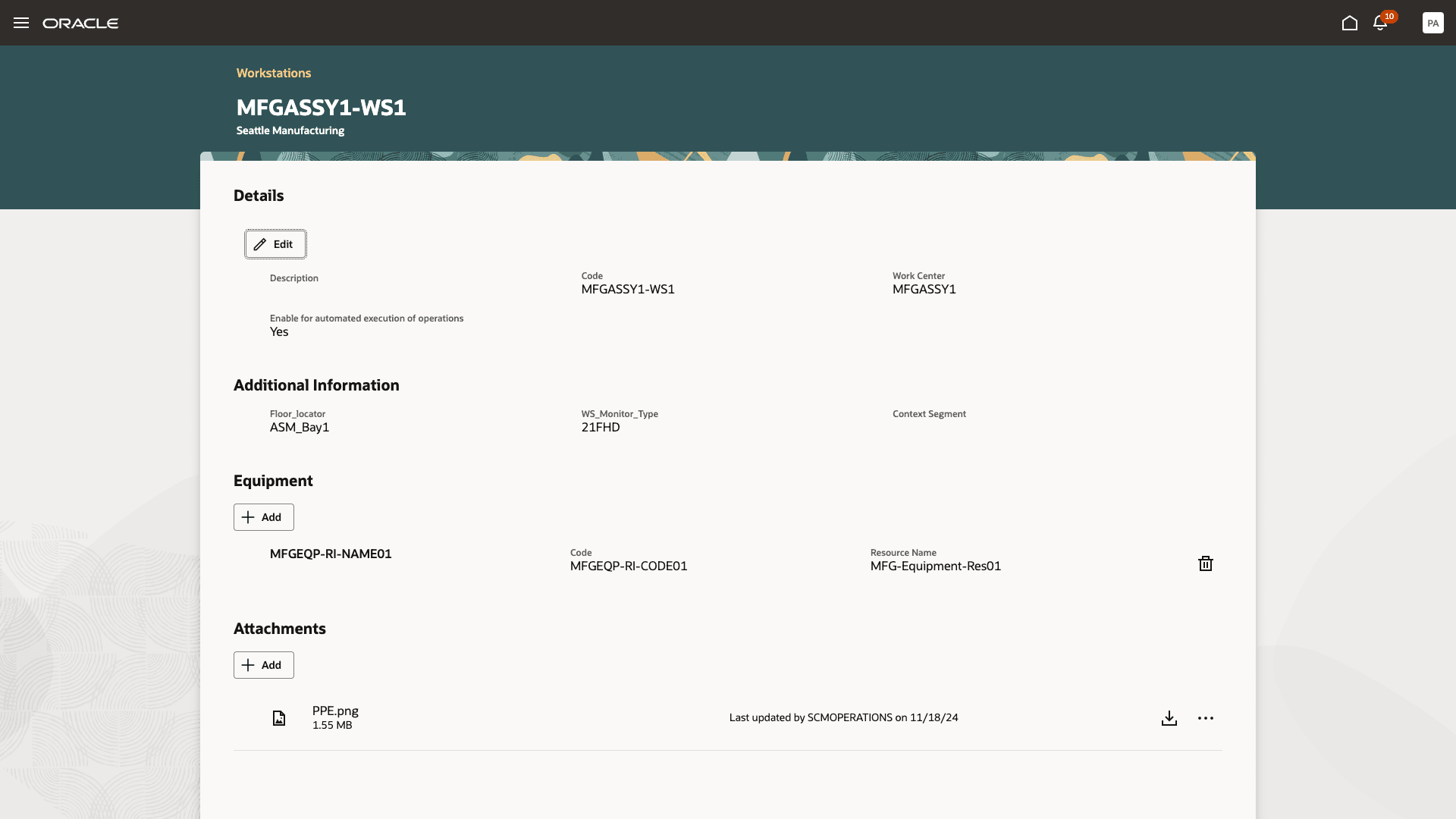

Enable Workstation to Support Automated Execution of Operations

View Connected Equipment's Execution Progress

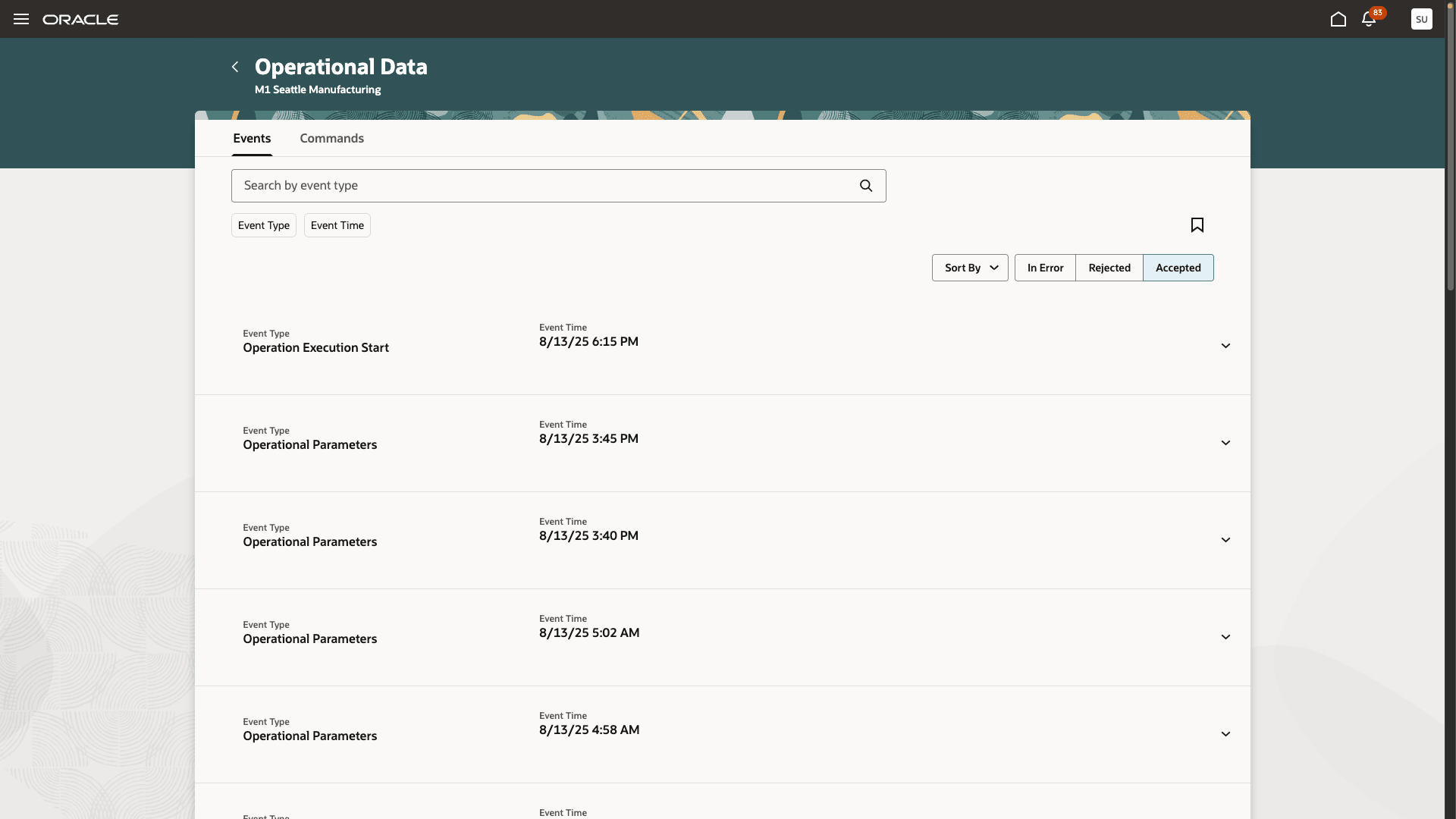

View Operational Events History

- Ensures that quantity completions and rejections are captured directly from equipment, reducing manual entry errors.

- Minimizes operator intervention by using machine events to initiate and complete work order operations automatically.

- Instantly updates operation progress in the system, providing supervisors with up-to-date production data.

- Streamlines production workflows by integrating equipment signals with process manufacturing operations, resulting in faster, more reliable recording of work execution events.

This feature builds on the capabilities introduced in 25A for Discrete Manufacturing, where equipment events could be leveraged to automate operation completion and exception reporting. The same functionality is now extended to Process Manufacturing work orders, with similar event-driven automation and reporting. For a demonstration of the feature, please watch this 25A demo: Complete Work Order Operations Automatically Using Equipment Signals at Workstations, which illustrates the behavior now applicable to both Discrete and Process Manufacturing.

Steps to Enable

To enable this feature you need to log a Service Request (SR).

- Select Product Module - Oracle Fusion Manufacturing Cloud Service.

- Select Category - Work Execution.

- Select Subcategory - Manage Work Orders.

- Select Component: Installation Issue (INSTALL).

- Copy and paste this text into the description area of the SR: Enable the SCM Core Service-Smart Operations.

This feature requires the SCM Core Service-Smart Operations service to be provisioned on your instance. Please note that this service can be enabled only on pods that are available in Oracle Public Cloud regions. Once this service is enabled, you can access the user guide and the implementation guide for Manufacturing Cloud to learn more about this feature and how to set it up.

Tips And Considerations

- If a signal received from an equipment cannot be processed, the reason for the failure to process can be viewed using the Operational Events task in the Work Execution work area.

- Once the feature "Record Process Data for an Operation When Executing Production at a Workstation" is enabled, the action Operational Events in the Work Execution work area changes to Operational Data.

- Equipment instances capable of communicating through industrial communication protocols can send the following signals to Fusion Manufacturing Cloud:

- Operation execution start.

- Operation execution stop.

- Asset or equipment resource instance status change to idle, in-use, or down.

- Quantity reporting for completed and rejected quantities, and quality inspection results.

- Asset or equipment resource instance fault with fault code and fault type details.

- Send set points and capture operational parameters.

- Enable a workstation for automated execution of work order operations by setting the Enable for automated execution of operations flag for the workstation.

- To enable equipment resource instances for connected execution, they need to be associated with an asset configured in Oracle Fusion Maintenance Cloud. The asset's location organization should be the same as the equipment resource instance's manufacturing organization.

- Equipment instance signals received through industrial communication protocols need to be converted to a REST payload that Fusion Manufacturing Cloud can ingest and take actions on. The accepted payload specifications are documented here: REST API for Oracle Fusion Cloud SCM.

Key Resources

- Watch the feature demo for Automate Operation Completion and Exception Reporting Using Equipment Events for Process Manufacturing Work Orders.

- Watch the feature demo for Complete Work Order Operations Automatically Using Equipment Signals at Workstations.

- Watch the feature demo for Execute Production at a Workstation and Automate Resource Transactions.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains the following privileges and duty roles can use this feature:

- View Operational Events (SMO_VIEW_EVENT_LOGS_PRIV)

- View Operational Events (ORA_DR_SMO_VIEW_OPERATIONAL_EVENTS_MFG_DUTY)

- Manage Operational Rules and Events (ORA_DR_SMO_MANAGE_OPERATIONAL_RULES_AND_EVENTS_MFG_DUTY)

The preceding duty role is introduced in this update.

Guided Journeys: Role Codes

- Use REST Service - Guided Journeys Read Only (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

- Use REST Service - Guided Journey Responses (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)