Execute Production Without Defining Workstations

Manufacturing teams working with complex operations and dynamic shopfloor environments need a flexible, efficient option to execute production, without requiring a physical workstation location to record production data.

This update enables operators to optionally execute work order operations without configuring workstations in the work center. This enhancement introduces greater flexibility in the manufacturing process, especially for operations not tied to a physical workstation on the shop floor.

With this new capability, operators can:

- Record completed and rejected quantities efficiently, which helps provide accurate updates on the production progress.

- Track execution status in real time, which helps address issues faster.

- Automatically report resource usage for each work order operation, which reduces manual entry and helps support accurate labor and material tracking.

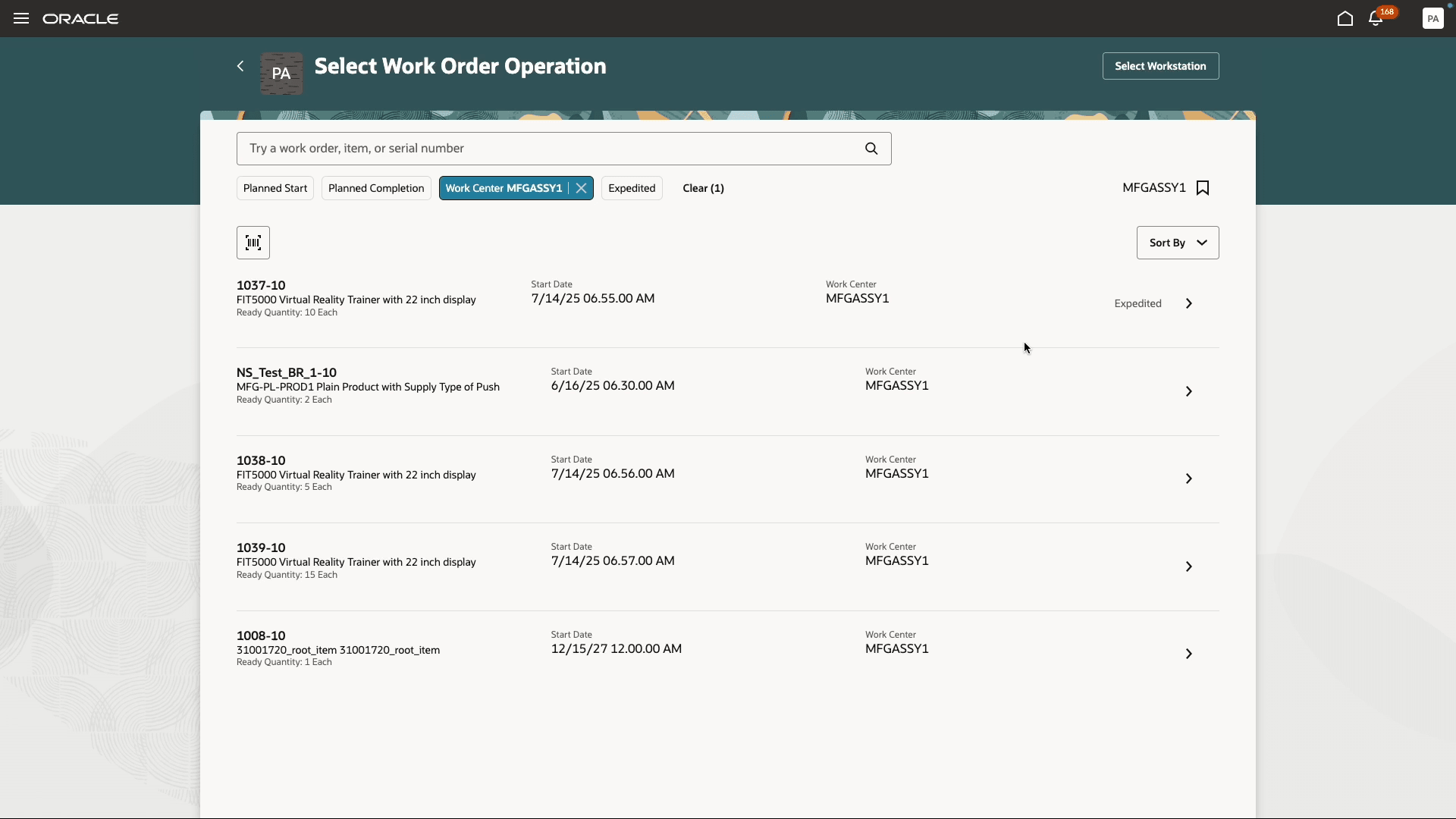

Select Work Order Operation for Execution

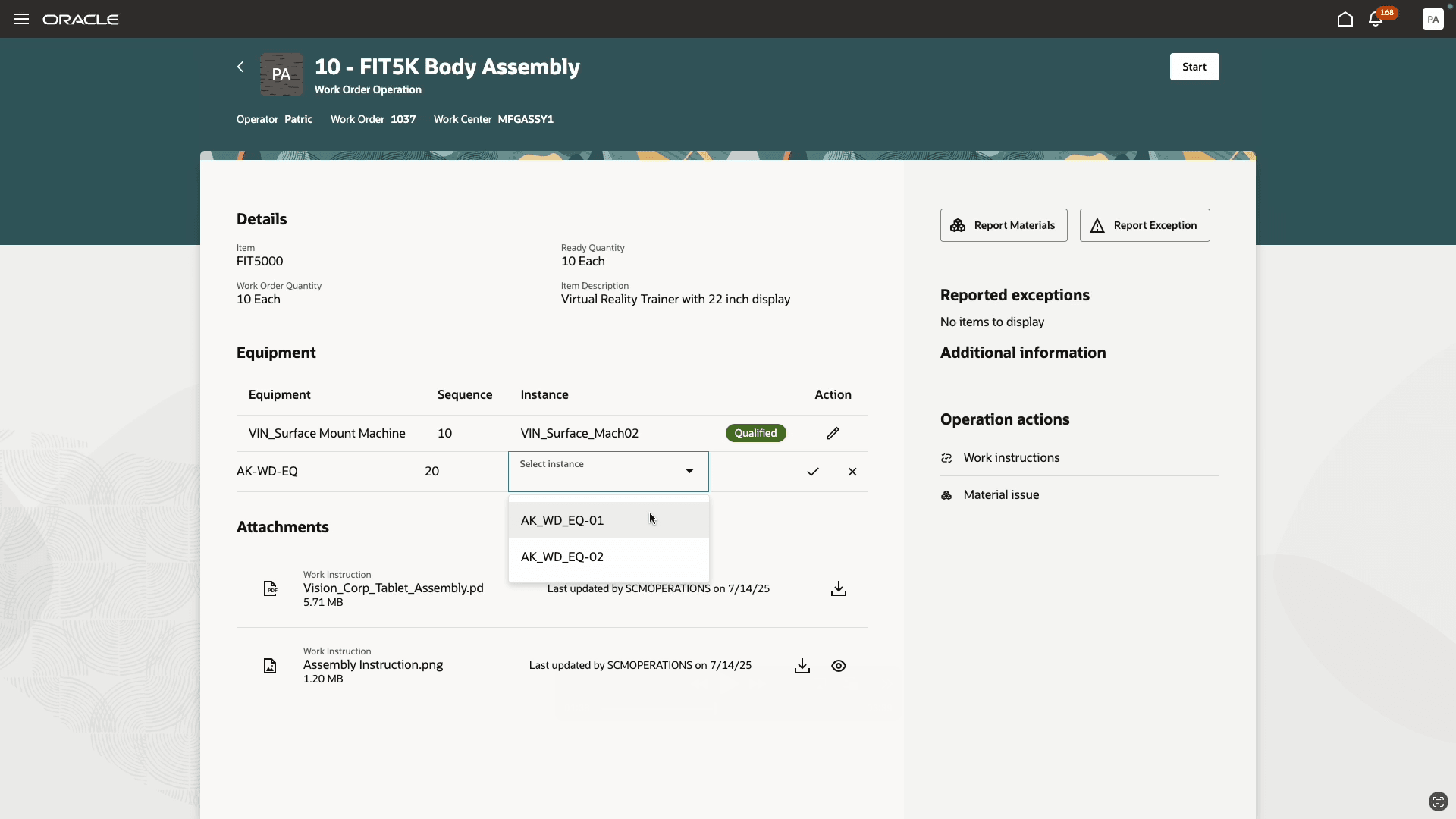

View Details of the Work Order Operation and Qualify Equipment Before Starting Execution

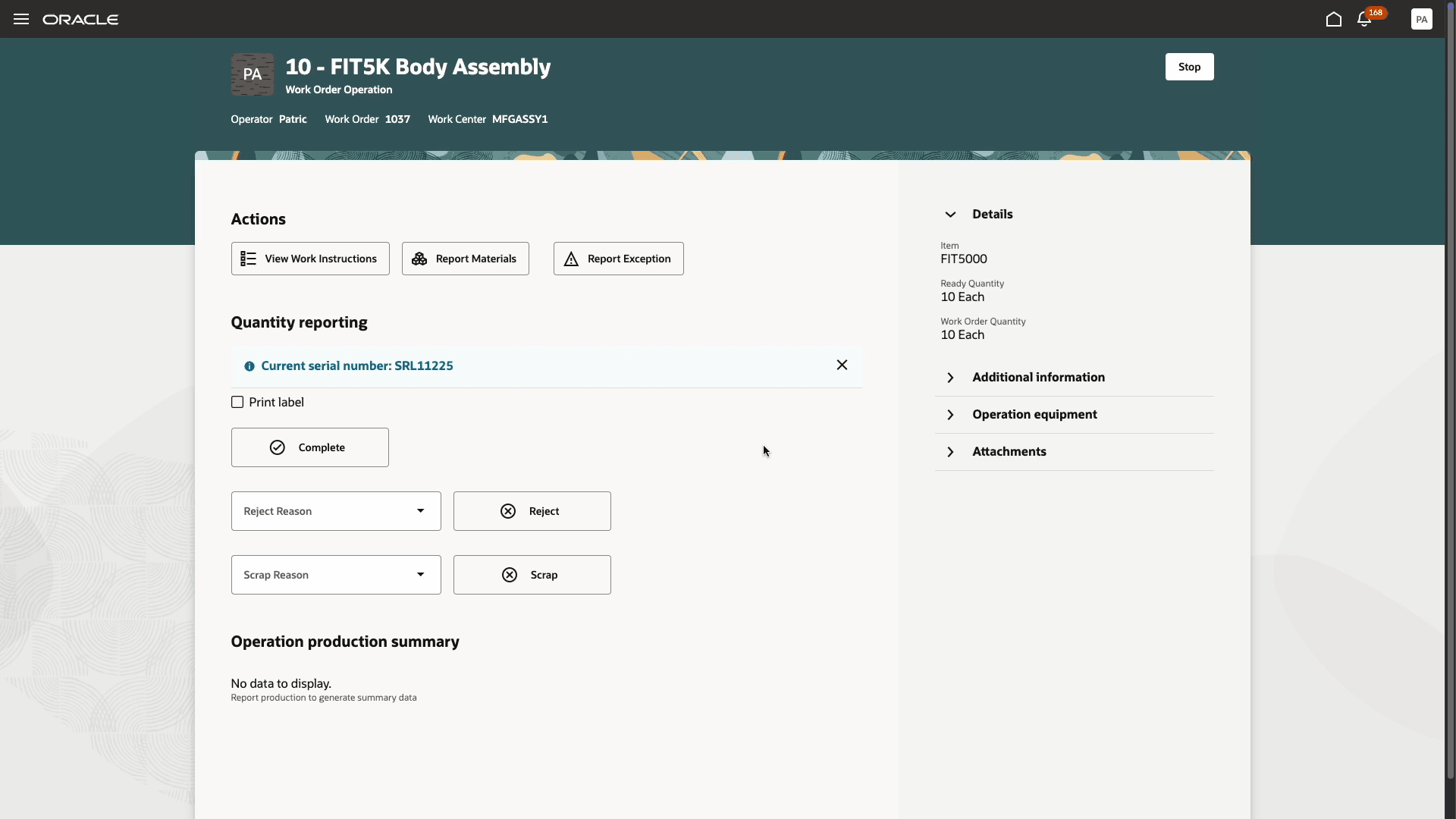

Report Progress Made During Execution

- Increased Flexibility: Support non-traditional manufacturing environments where tasks are not restricted to specific workstations.

- Improved Data Accuracy: Capture operation progress, outputs, and exceptions as they occur, which helps maintain up-to-date records.

- Streamlined Execution: Minimize administrative overhead by automating resource reporting during work order execution.

- Enhanced Visibility: Provide real-time insights into the production status across all work order operations.

Here's the demo of these capabilities:

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management No Longer Optional From: Update 26B

Tips And Considerations

- Once this feature is enabled, the action Execute production at a workstation in the Work Execution work area changes to Production Execution.

- Upon launching the Production Execution action, if you have workstations defined in your organization, then you can select and check in to a workstation, as usual.

Optionally, you can click Select Work Order Operation and view the list of work order operations available for execution. - If operators have been assigned workstations using the Production Supervision page, and operator assignment is enforced in Smart Operations Configurations, then operators can only check in to assigned workstations to execute production.

- To make the Select Work Order Operation button always visible, set the Select Work Order Operation Button page property for the Select Workstation page to true in Visual Builder studio.

- Use saved search to preselect the filter criteria when viewing the Select Work Order Operations page.

- Before starting work execution, you can select the equipment instance that will be used as the work order operation resource. If qualification of the equipment instance is required, then you must select a qualified equipment instance to enable the Start button.

- After starting the execution, you can report execution progress or stop execution. Currently, you cannot pause execution of a work order operation.

- Upon stopping execution, resource transactions for resources of type manual, and the labor resource charge for the operator executing the operation, are automatically submitted.

- Connected equipment signals cannot be used to report progress when execution is performed without the context of workstations.

Key Resources

- Watch the feature demo for Execute Production Without Defining Workstations.

- Watch the feature demo for Inspect Flow Schedules at the End of the Production Line Using the Operator Workbench.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges can use this feature:

- Report Operation Transactions (WIP_REPORT_OPERATION_TRANSACTIONS_PRIV)

- Report Material Transactions (WIP_REPORT_MATERIAL_TRANSACTIONS_PRIV)

- Edit Inspection Results (QA_EDIT_INSPECTION_RESULTS_PRIV)

- View Inspection Results (QA_VIEW_INSPECTION_RESULTS_PRIV)

- Execute Production at a Workstation (WIP_EXECUTE_WORKSTATION)

Guided Journeys: Role Codes

- Use REST Service - Guided Journeys Read Only (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

- Use REST Service - Guided Journey Responses (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)