Send Equipment Set Points and Program Information to Connected Equipment Using Bidirectional Communication

This update supports advanced bidirectional communication with factory robots and connected equipment on the factory floor. You can now define set points in a work definition operation, which are used by the equipment to execute the operation for an item corresponding to the work definition. During execution, operators can trigger the set points and any program information, such as the program file name, to be sent to the equipment without having to manually load them into the equipment, through IoT based communication. Operation quantities, such as completions and rejections, are automatically recorded in the system based on real-time equipment signals.

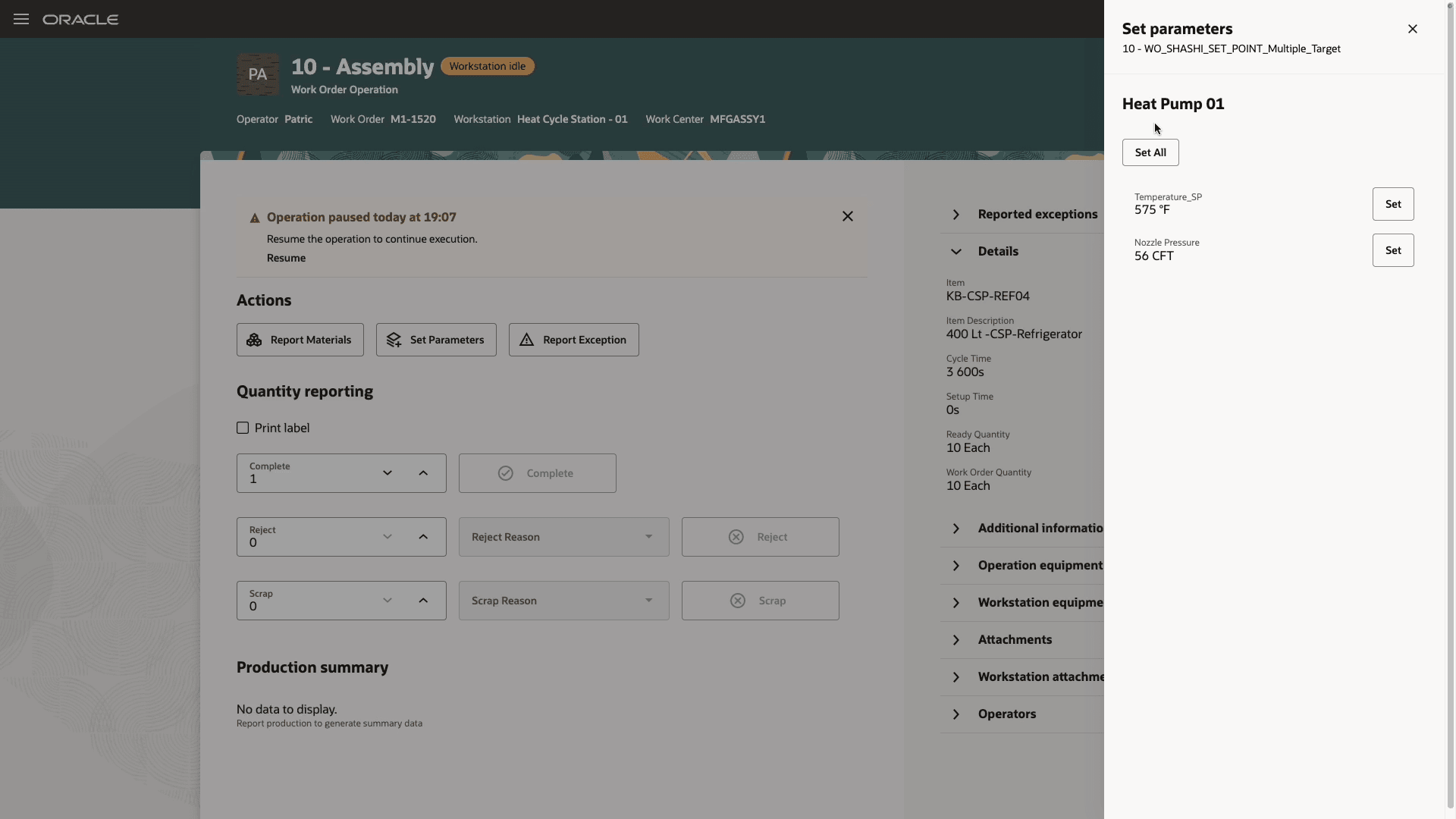

Send Set Points to Connected Equipment During Execution

- Enhanced Automation: Automate key steps in the setup and execution process, reducing reliance on manual data entry and intervention.

- Seamless Integration: Exchange critical information, such as set points and program files, directly with connected equipment ensuring correct machine configuration before execution.

Here's the demo of these capabilities:

Steps to Enable

To enable this feature you need to log a Service Request (SR).

- Select Product Module - Oracle Fusion Manufacturing Cloud Service.

- Select Category - Work Execution.

- Select Subcategory - Manage Work Orders.

- Select Component: Installation Issue (INSTALL).

- Copy and paste this text into the Description area of the SR: Enable the SCM Core Service-Smart Operations.

This feature requires the SCM Core Service-Smart Operations service to be provisioned on your instance. Please note that this service can be enabled only on pods that are available in Oracle Public Cloud regions. Once this service is enabled, you can access the user guide and the implementation guide for Manufacturing Cloud to learn more about this feature and how to set it up.

The high-level setups required to use this feature are as follows:

- Use the Opt In UI to enable this feature.

For instructions, refer to the Optional Uptake of New Features section of this document. This feature is a child feature of the feature "Record Process Data for an Operation When Executing Production at a Workstation" and is no longer optional from 26A.

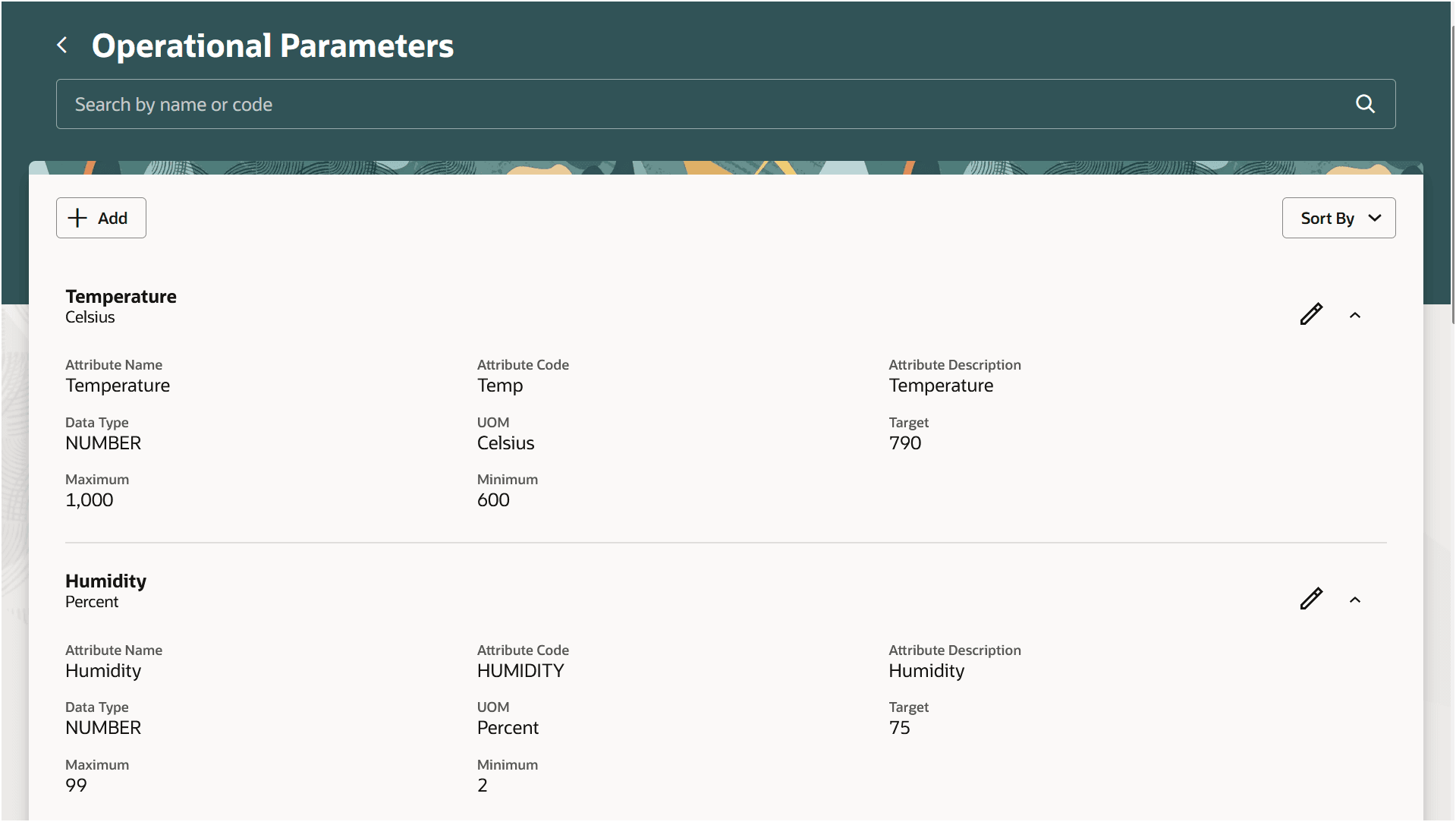

- Define Operational Parameters.

- Navigate to the Work Definition work area, and select the Operational Parameters task.

- Create the parameter by specifying details such as the parameter name, data type, target value, minimum and maximum value.

- Save the parameter.

Define Operational Parameters

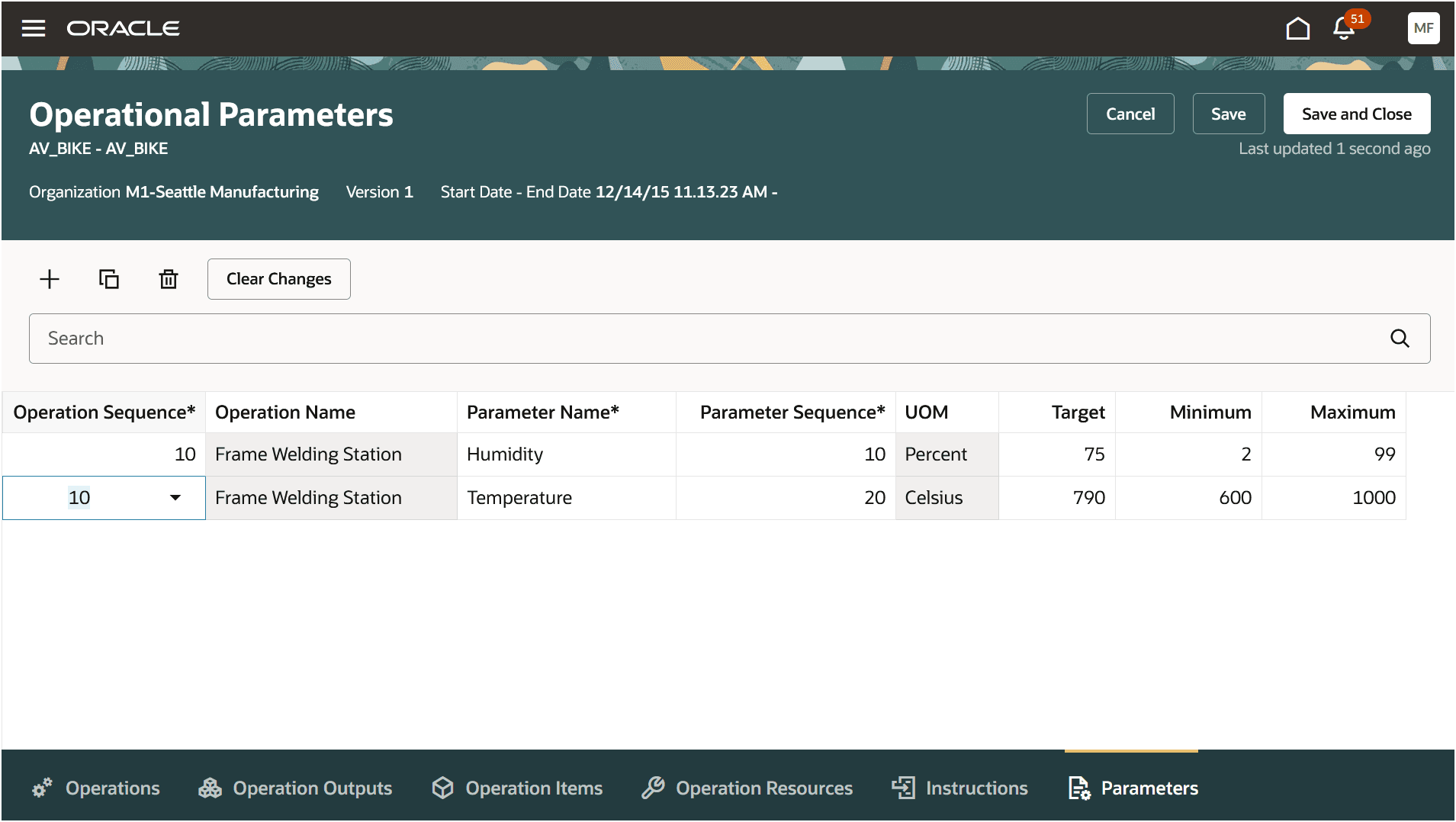

- Associate Operational Parameters with the work definition.

- In the Work Definition work area, select the Manufacturing Work Definitions task, and switch to the Parameters tab.

- Associate the parameters with the operation sequence.

- Save the work definition.

Associate Operational Parameters with the Work Definition Operation

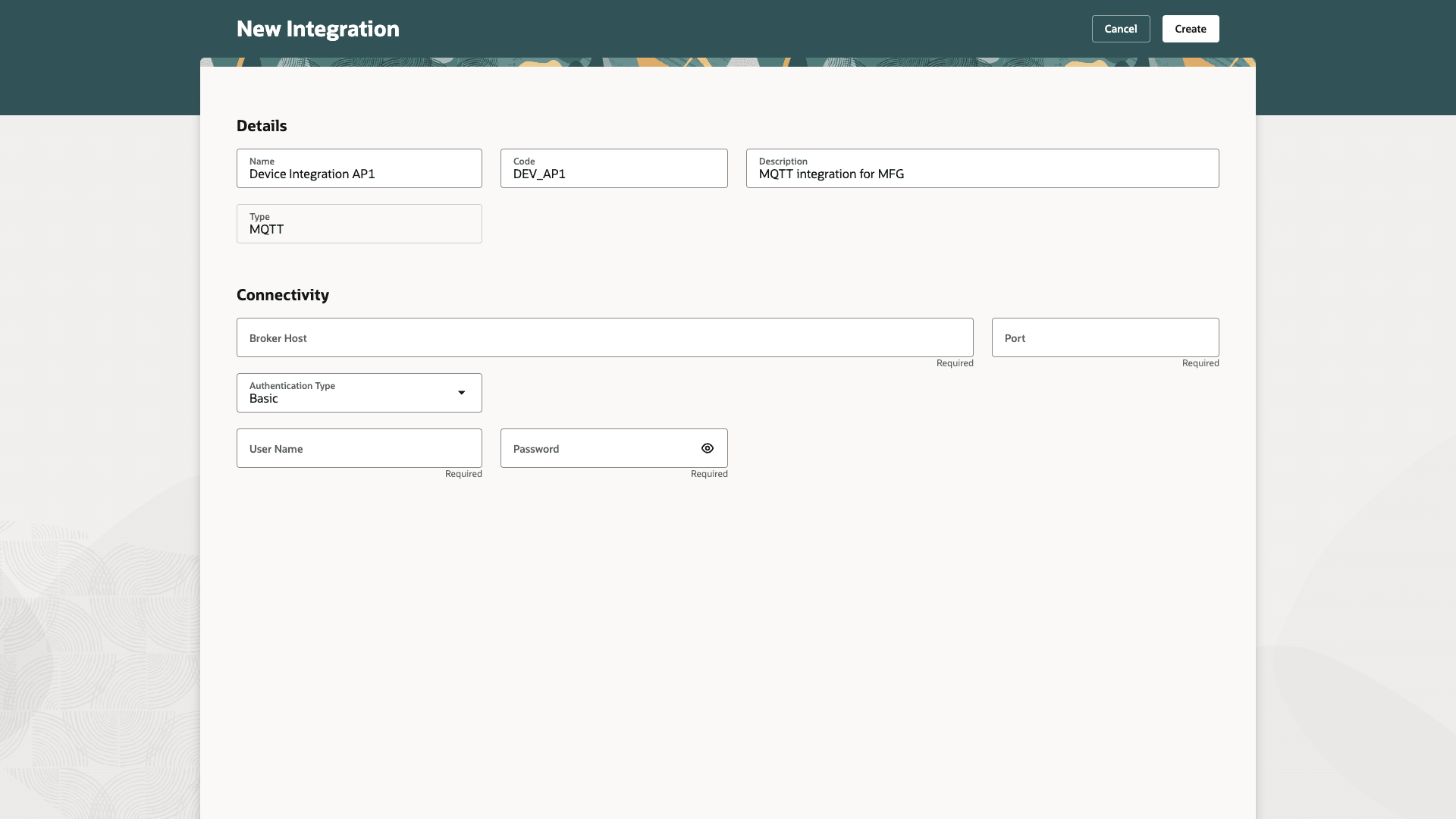

- Configure an Integration in Smart Operations Configurations

- In the Work Execution work area, select the Smart Operations Configurations action, and switch to the Integrations tab.

- Configure an Integration for bidirectional connectivity with the device.

Configure an Integration in Smart Operations Configurations

Tips And Considerations

- Operational parameters are organization-agnostic and can be used in the work definition for items in any organization.

- Operational parameters are added to work definitions in the "Parameters" tab. The data types supported for operational parameters are string and number. To send set points to a connected equipment, define a target value for the number data type. Setting a target for the string data type is currently not supported.

- An operational parameter with targets can be defined more than once for a work definition operation, provided the target values are unique.

- You need to configure an integration of type MQTT in Smart Operation Configurations to send set points to the connected equipment.

- Set points sent to an equipment can be viewed using the "Operational Data" task in the Work Execution work area.

Key Resources

- Watch the feature demo for Send Equipment Set Points and Program Information to Connected Equipment Using Bidirectional Communication.

- Watch the feature demo for Collect Operational Process Data from Connected Equipment When Executing Production at a Workstation.

- Watch the feature demo for Record Process Data for an Operation When Executing Production at a Workstation.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains the following privileges and duty roles can use this feature:

- Execute Production at a Workstation (WIP_EXECUTE_WORKSTATION)

- View Operational Events (SMO_VIEW_EVENT_LOGS_PRIV)

- View Operational Events (ORA_DR_SMO_VIEW_OPERATIONAL_EVENTS_MFG_DUTY)

- Manage Operational Rules and Events (ORA_DR_SMO_MANAGE_OPERATIONAL_RULES_AND_EVENTS_MFG_DUTY)

- Manage Operational Parameters (SMO_MANAGE_OPERATIONAL_PARAMETERS_PRIV)

- View Operational Parameters (SMO_VIEW_OPERATIONAL_PARAMETERS_PRIV)

- View Operational Commands (SMO_VIEW_OPERATIONAL_COMMANDS)

- Send Operational Commands (SMO_SEND_OPERATIONAL_COMMANDS)

Guided Journeys: Role Codes

- Use REST Service - Guided Journeys Read Only (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

- Use REST Service - Guided Journey Responses (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)