Complete an Operation with Variance in a Process Manufacturing Work Order

Sometimes, process manufacturers expect variable yield at each operation due to the inherent gain or loss during the production process, such as evaporation. Currently, an operation is considered complete when the full batch quantity is reported, and extra manual steps are required for handling the variance, slowing down operator efficiency and resulting in planning and costing inaccuracies for the remaining quantity. Subsequent operations after completions with variance also recalculate the required material quantities, which make it difficult for variance tracking.

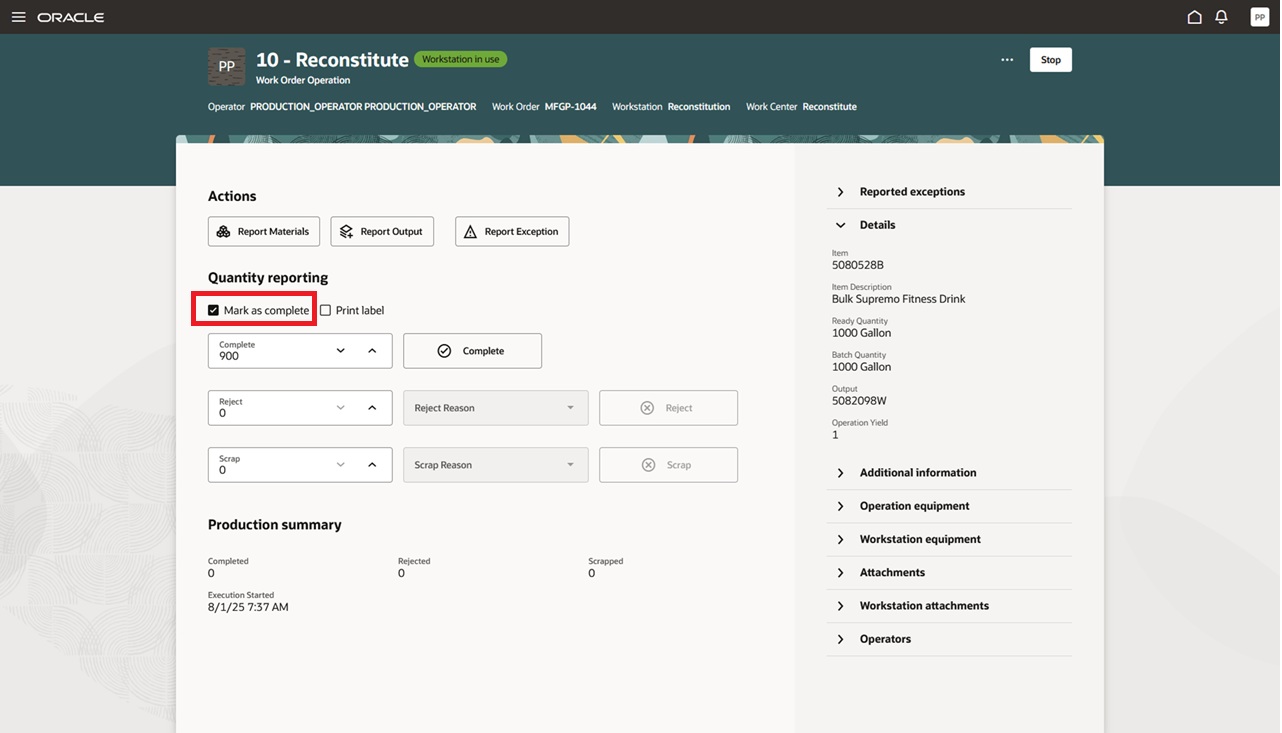

In a process manufacturing work order, you can now report the quantity completed and mark the operation as complete to continue to the next operation using the dispatch list or a workstation. The difference between the planned and actual output quantities is automatically captured in a Variance dispatch status to facilitate cost analysis and production efficiency improvements. You can also effectively track this variance without inflating material requirements in subsequent operations. Marking the last operation as complete in the process manufacturing work order also completes the work order, so that no additional actions are required to resolve any remaining quantity compared to the work order batch quantity.

Report a Process Work Order Operation as Complete

With a direct acknowledgement for operation completion, production operators can easily report overcompletion or undercompletion for more streamlined production reporting and automatic work order completion.

Here's the demo of these capabilities:

Steps to Enable

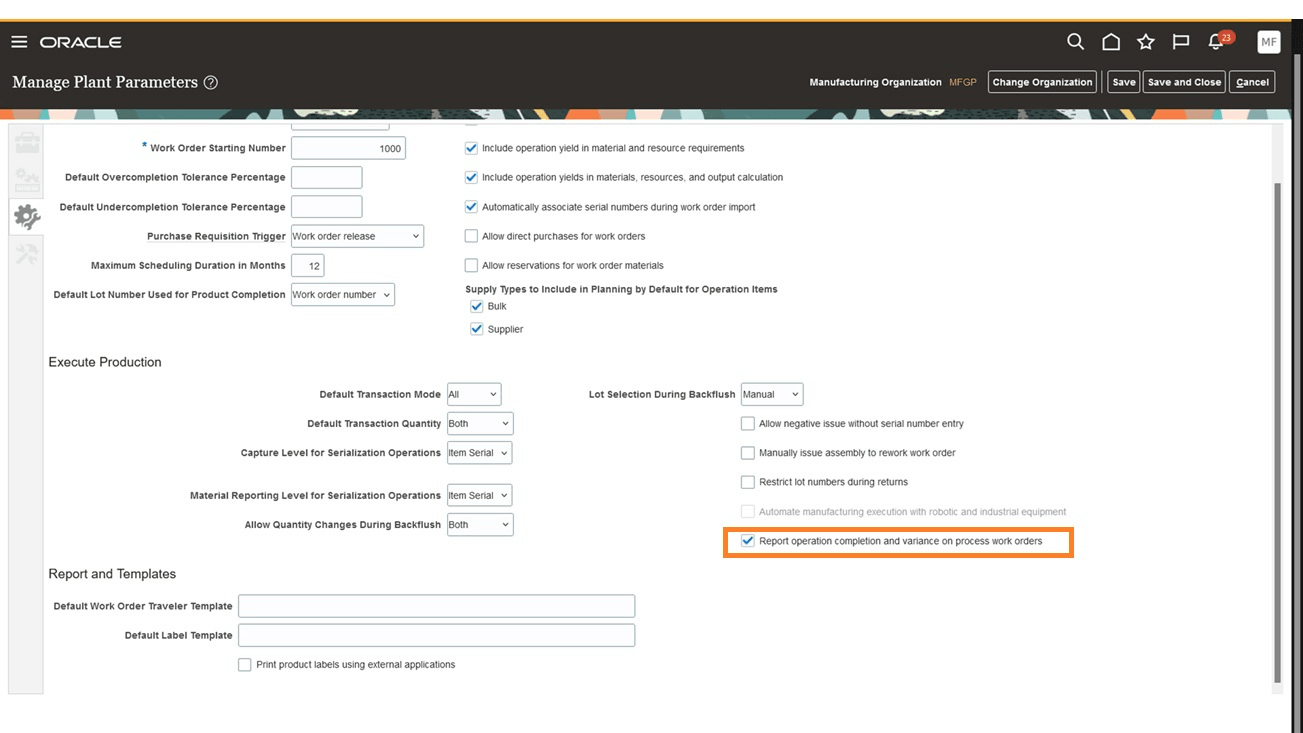

Set up the plant parameters to enable this feature:

- In the Setup and Maintenance work area, search for, and select the Manage Plant Parameters task.

- On the Manage Plant Parameters page, select the required inventory organization.

- In the Plant Details tab, ensure that the Enable process manufacturing option is enabled.

- In the Work Execution tab, under Execute Production, enable the Report operation completion and variance on process work orders checkbox.

Plant Parameter to Enable Variance Reporting for Process Work Order Operations

Tips And Considerations

- You can complete a work order operation with variance and automatically complete a process manufacturing work order using this feature. It doesn't apply to discrete manufacturing work orders, flow schedules, or orderless transactions.

- You can't mark an operation as complete if the operation is set as automatically transact or optional, or if there is no quantity completed, rejected, or scrapped.

- You can't mark an operation as complete if the operation has some quantity in reject dispatch state.

- You can't report additional operation transactions once an operation is marked as complete, except for a return or reverse transaction.

Key Resources

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains the following privilege can access this feature:

- Manufacturing Privilege :

-

Report Operation Transactions (WIP_REPORT_OPERATION_TRANSACTIONS_PRIV)

-

This privilege was available prior to this update.