Create a Process Manufacturing Work Definition Based on a Formula

Create a Process Manufacturing Work Definition Based on a Formula

Before this update, a process manufacturing work definition could optionally be created with a reference to an item structure for the list the ingredients and updated through an automated scheduled process that synchronizes item structure changes. Co-products and by-products could be added and scaled manually in the work definition, so that the work definition includes all the outputs of the production process.

With the introduction of formulas in Oracle Fusion Product Management, you can now leverage formulas in the creation of process manufacturing work definitions. A formula can be produced with one or more process manufacturing work definitions based on varying batch sizes, production resources, process parameters, and work instructions.

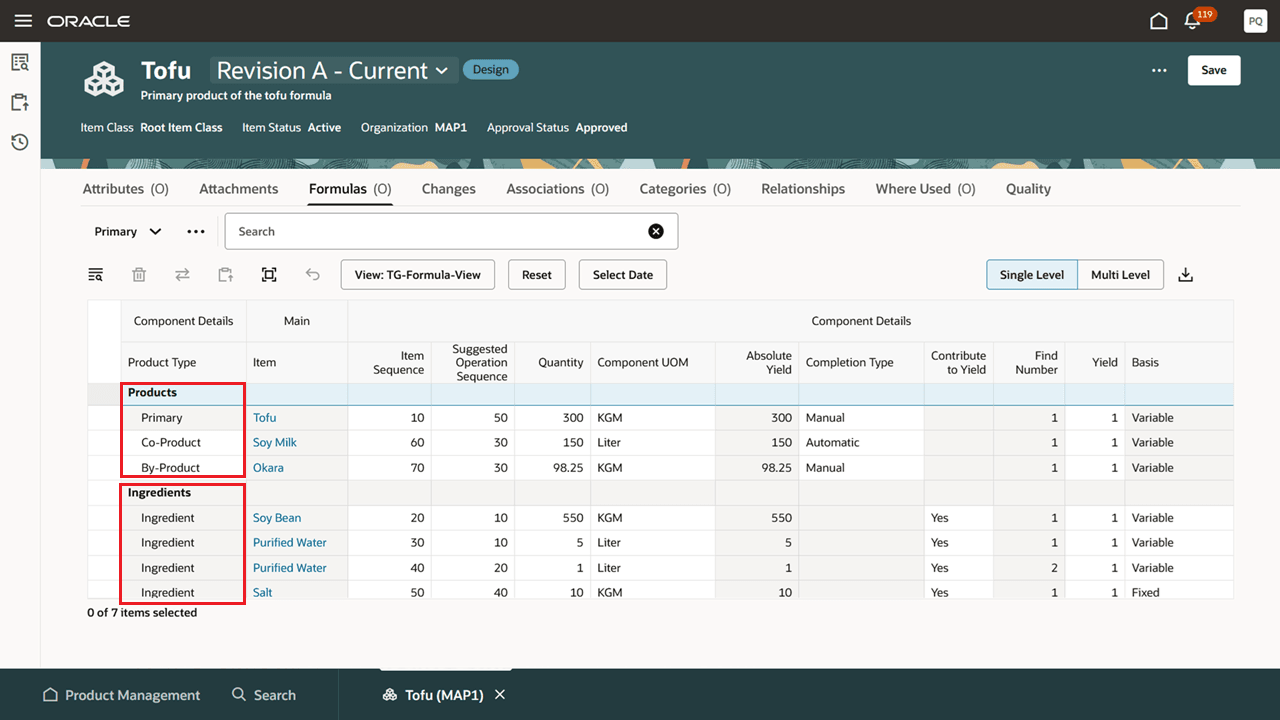

The following screenshot of the Formula page shows the formula products and ingredients for the primary product, Tofu:

Formula for Tofu

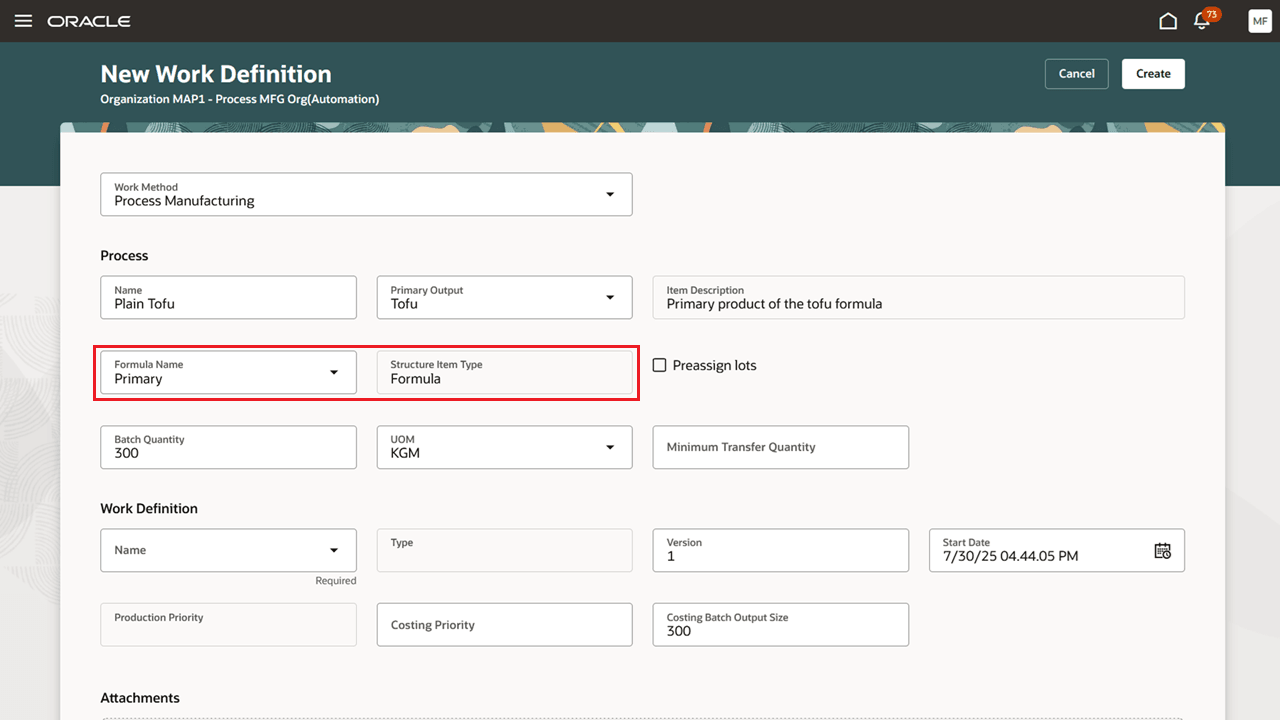

The following screenshot of the Create Work Definition page shows how a formula name can be specified for the process manufacturing work method:

Create a Process Manufacturing Work Definition Based on a Formula

By referencing formulas directly when creating work definitions, manufacturing engineers can easily assign input and output items to operations without manually recalculating quantities for batch sizes. You can also automatically assign formula ingredients and products to process manufacturing work definition operations using the suggested operation sequence. Formula ingredients and products have effective start dates and end dates for controlling changes, so you can view them in the context of operation effective start and end dates to understand the planned requirements as of a specific date in the work definition. With the Override Item Structure Components in Work Definition privilege, you can add ad hoc items in the process manufacturing work definition.

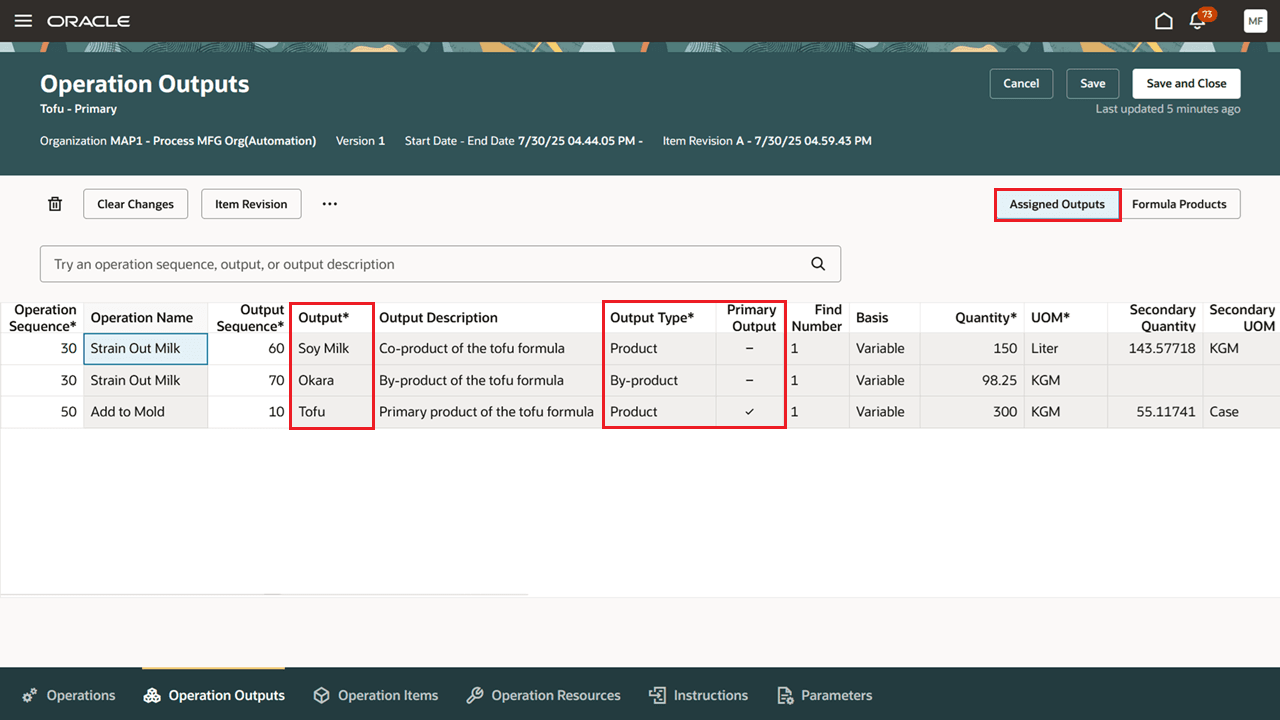

The following screenshot of the Assigned Outputs page shows the formula products assigned to work definition operations as outputs:

Formula Products as Assigned Outputs

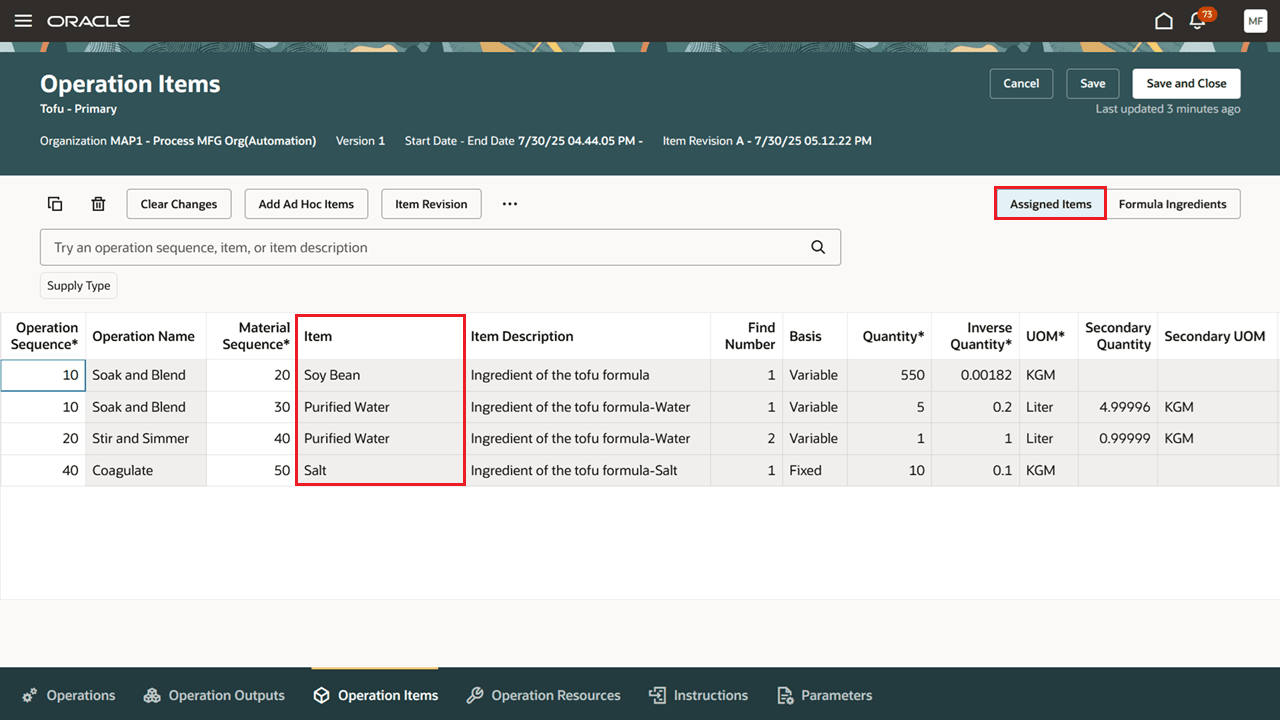

The following screenshot of the Assigned Items page shows the formula ingredients assigned to work definition operations as inputs:

Formula Ingredients as Assigned Items

Formula information as part of the process manufacturing work definition also supports approvals using electronic records and electronic signatures, audit trails, and analysis reporting using BICC and the Work Definition OTBI subject area.

File-Based Data Import (FBDI) Changes:

The FBDI process work definition template, ProcessWorkDefinitionTemplate.xlsm, has been enhanced to enable the creation of a process manufacturing work definition based on a formula. A new column Start Date has been added to the Operation Outputs worksheet. Use the latest template after upgrade to 25D.

REST API Changes:

You now can create a process manufacturing work definition based on a formula using the Work Definition Requests REST API.

Modeling formula ingredients and products as a reference for process manufacturing work definitions provides a more streamlined product development process that ensures integrity between formula and recipe management.

Here's the demo of these capabilities:

Steps to Enable

If you want to use the Create a Process Manufacturing Work Definition Based on a Formula feature, then you must opt in to its parent feature: Redwood: Create and Edit Formulas. If you’ve already opted in to this parent feature, then you don’t have to opt in again.

Tips And Considerations

- This feature is available only with the Redwood experience, which can be enabled using the profile option, Redwood Work Definitions Enabled.

- The following considerations apply when deciding between using a formula vs an item structure in a process manufacturing work definition:

- The formula streamlines the transfer of information to a process manufacturing work definition, which now includes the list of products as outputs.

- The absolute yield of the primary product from the formula, which is its quantity multiplied by yield, is defaulted to the batch quantity in the work definition.

- You can continue to create and use process manufacturing work definitions with or without item structures. You can evaluate whether to use formulas in creating process manufacturing work definitions going forward.

- You can't add a formula to an existing process manufacturing work definition. An item can only have one structure item type in PIM. If an item already has an item structure, you can't update the structure item type from standard to formula. Therefore, you may have to consider creating a new item.

- You can't use negative quantity components in an item structure or negative quantity ingredients in a formula as a co-product or by-product in a process manufacturing work definition. Instead, model co-products and by-products natively as products in a formula and outputs in a process manufacturing work definition.

- You can't automatically scale or edit quantities for formula ingredients or products to align with the batch quantity in the process manufacturing work definition. The formula ingredient and product quantities default to the process manufacturing work definition and can't be overridden, so you should account for the batch quantity when defining the formula.

- You can use the Override Item Structure Components in Work Definitions privilege to add ad hoc items. You can't add ad hoc outputs to a process manufacturing work definition that references a formula.

- You can't automatically synchronize formula changes to process manufacturing work definitions using the scheduled process at this time. Instead, you can search process manufacturing work definitions by item revision and formula, and make the changes manually by deleting the specific operation item or operation output and reassigning it to an operation.

- You can't use the Product Yield and Contribute to Yield attributes in the formula for process manufacturing work definitions and work orders at this time.

Key Resources

- Watch the Create a Process Manufacturing Work Definition Based on a Formula demo.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

- Refer to the 25D feature Redwood: Create and Edit Formula in Oracle Fusion Product Management for more information about formulas.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Manage Work Definitions (WIS_MANAGE_WORK_DEFINITIONS_PRIV)

- View Work Definitions (WIS_VIEW_WORK_DEFINITIONS_PRIV)

- Get Work Definitions by Service (WIS_GET_WORK_DEFINITIONS_SERVICE_PRIV)

- Manage Work Definitions by Service (WIS_MANAGE_WORK_DEFINITIONS_SERVICE_PRIV)

- Get Manufacturing Plant Set Up Data by Service (WIS_GET_MFG_PLANT_SETUP_SERVICE_PRIV)

These privileges were available prior to this update.