Schedule a Flow Manufacturing Production Line

With this update, all flow schedules on a production line within the schedule horizon are sequenced, considering the takt time of the production line along with item attributes and corresponding volume. Flow schedules with certain attributes are spread throughout a scheduling bucket to balance the production line.

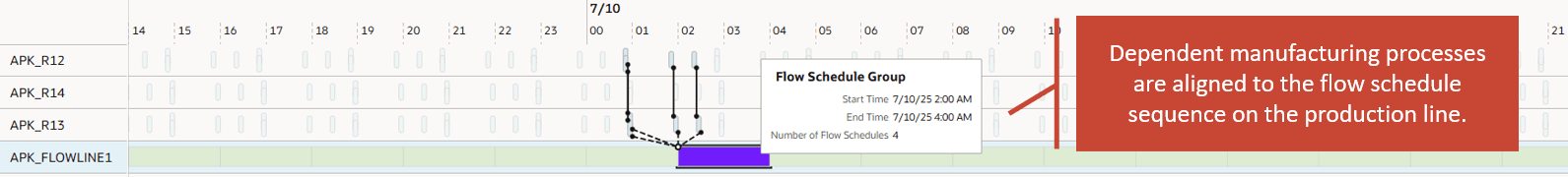

Upstream and downstream manufacturing processes are aligned to the flow schedule sequence, and material constraints are considered.

Aligning Production to Flow Schedules Across Production Stages

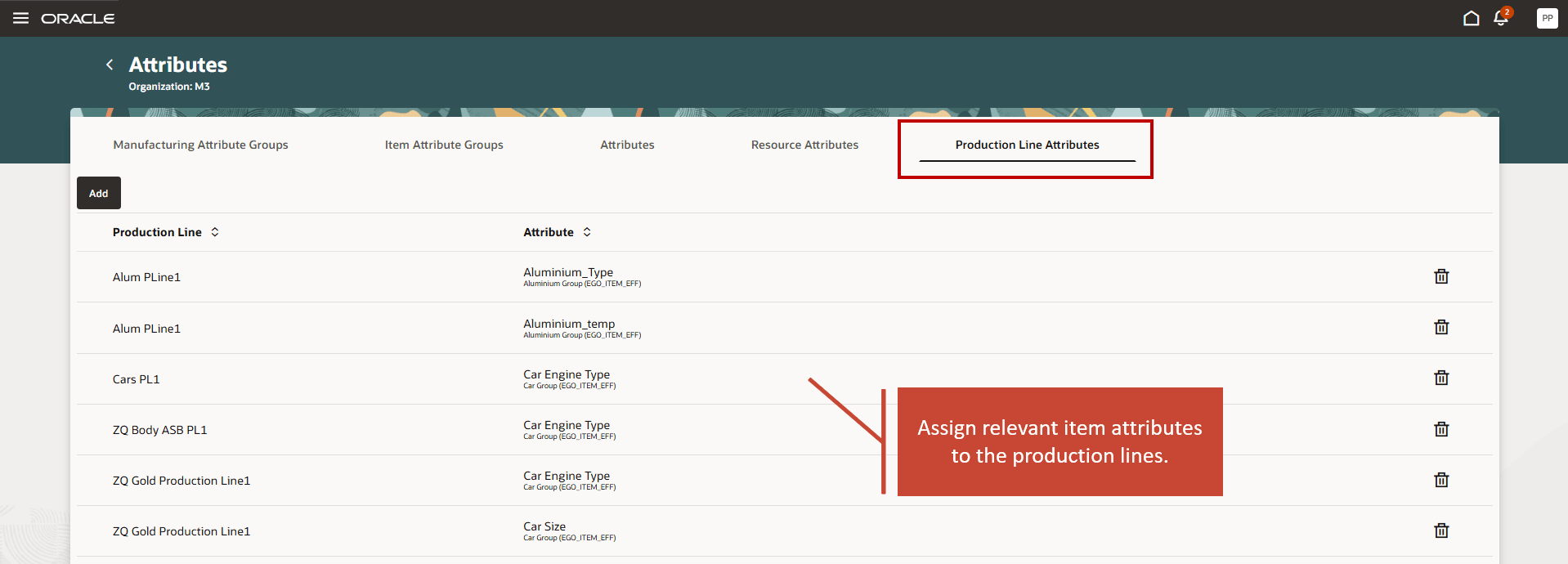

Production Scheduling uses item attributes maintained as item extensible flex fields when making sequencing decisions. Only those attributes that are assigned to a production line are considered during sequencing. You can assign attributes to a flow production line in the Scheduling Organization data setups. If you wish to spread by item name, then you must populate an item extensible flex field with the name of the item and treat that like any other custom attribute.

Assigning Item Attributes to Flow Production Lines for Consideration During Sequencing

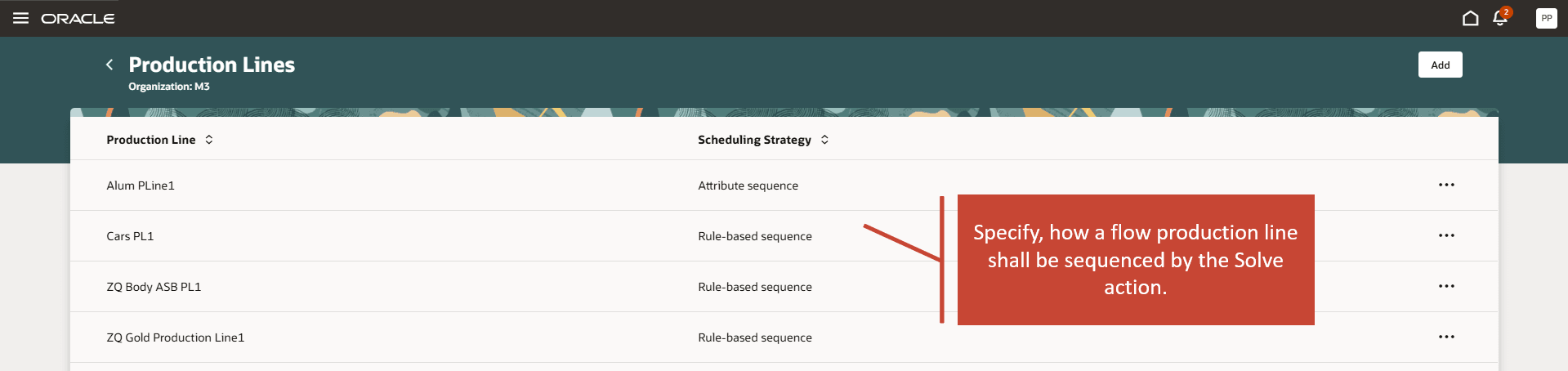

The Solve action applies one of the two alternate approaches to how flow schedules on a production line are sequenced. Either a user-defined attribute sequence is followed, or flow sequencing rules will be applied. You specify this setting on the Production Lines UI page within the Scheduling Organization data setups.

Defining the Scheduling Strategy for Production Lines

For both the approaches, Attribute sequence and Rule-based sequence, the completion date is used to allocate the flow schedules into scheduling buckets. You can use the Completion Date Override option to allocate flow schedules into a different scheduling bucket to influence the sequencing decisions. It can be edited directly in the Flow Schedules table or via mass-edit. Upon schedule release, the Scheduled Completion Date and Scheduled Build Sequence Numbers as calculated by the solve or repair actions are used to update the flow schedules’ completion dates and build sequence numbers in Oracle Fusion Manufacturing, as it was prior to this update.

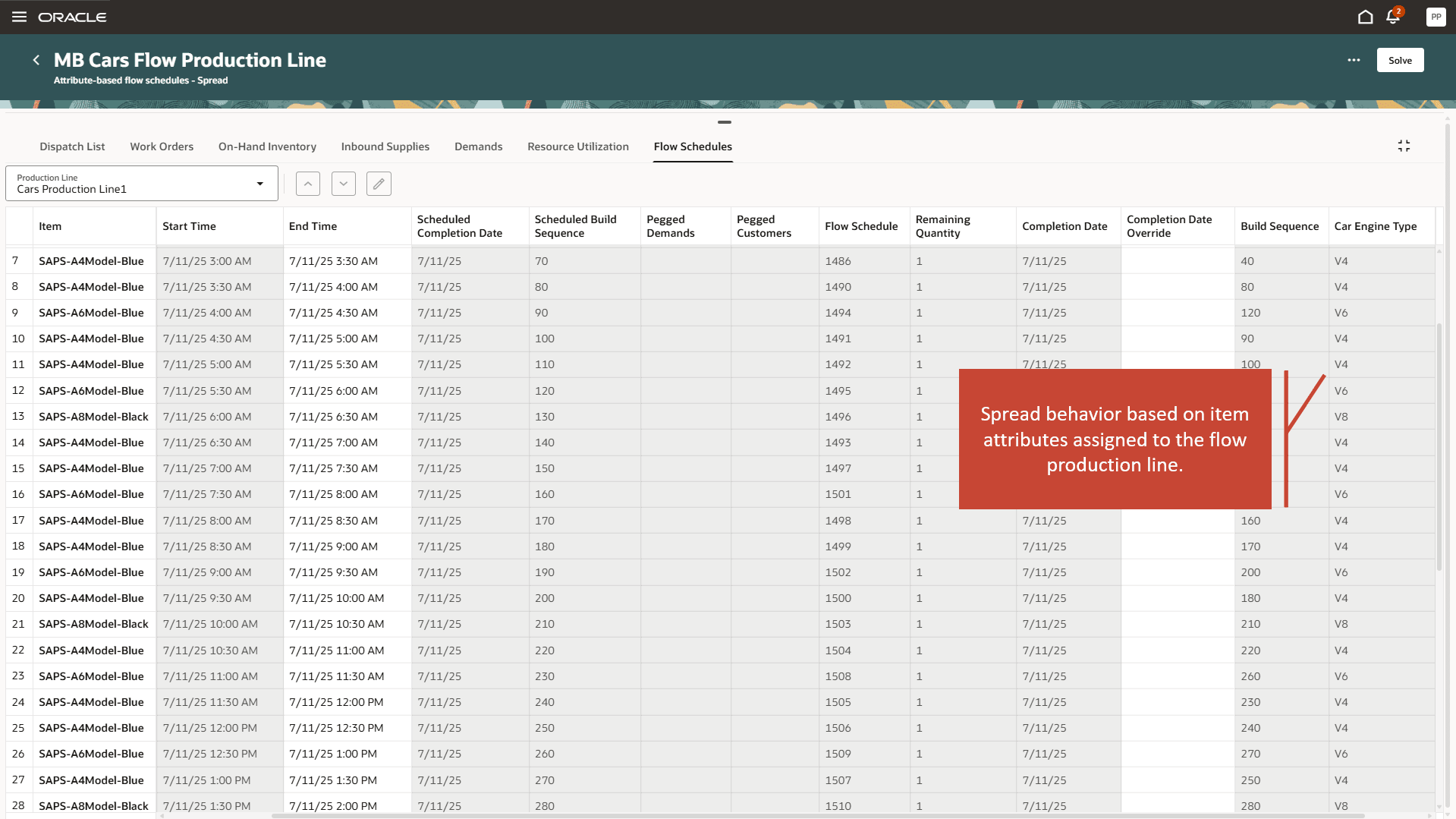

Rule-based sequence has one rule that is applied by default. This rule distributes flow schedules within a scheduling bucket based on item attributes. It ensures that appearance ratios and run sizes align with the volume of flow schedules with specific attribute values, relative to the total volume in the bucket. In subsequent releases additional flow sequencing rules will be added.

Let’s understand this with an example.

In the following example, the volume of flow schedules with attribute Car Engine Type set to V4 is about double the volume of V6 and four times the volume of V8.

The spread of flow schedules is accordingly:

- Flow schedules for items with attribute value V4 is often run in pairs of two and in higher frequency.

- Flow schedules with attribute values V6 and V8 are scheduled as single units.

- Items with attribute value V6 being scheduled more frequently than those with attribute value V8.

Spreading Flow Schedules Based on Attribute Car Engine Type Assigned to the Flow Production Line

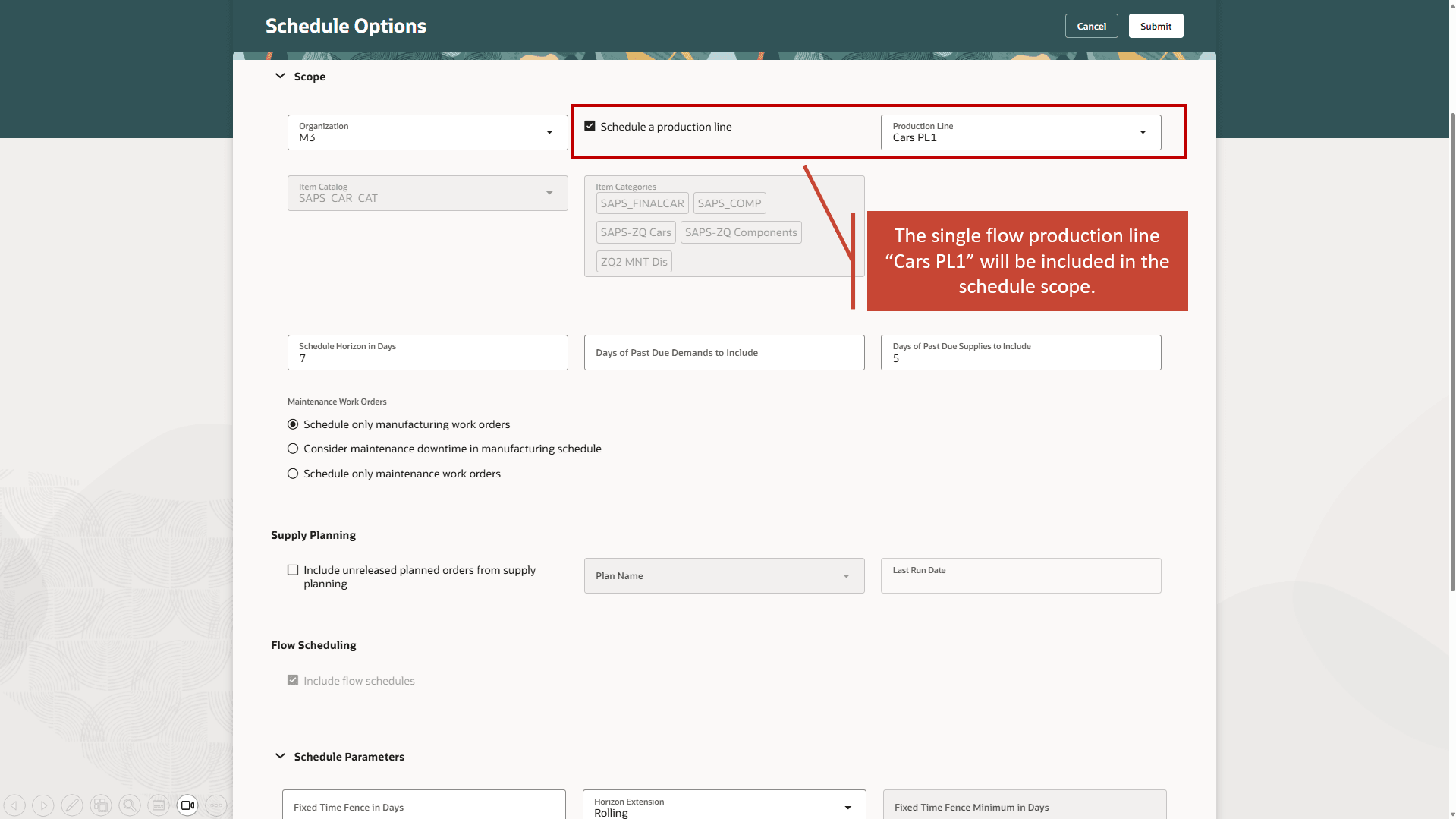

In situations when upstream and downstream manufacturing and material constraints aren't considered, you can schedule a single production line only. If the option Schedule a production line in the schedule options scope section is selected, then you must specify a production line, and the item catalog and item categories are disabled and won’t be considered. The schedule refresh and solve actions exclusively sequence all flow schedules on that production line within the schedule horizon. If the option Schedule a production line isn’t selected, then you must specify item catalog and item categories just as you did before. In this case, select the option Include flow schedules (please refer to the 25C What’s New document) to also schedule flow schedules for items that belong to the selected item categories, align upstream and downstream manufacturing, and consider material constraints.

Scheduling a Single Flow Production Line

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Supply Chain Planning

Tips And Considerations

If you want to use the Schedule a Flow Manufacturing Production Line feature, then you must opt in to its parent feature: Production Scheduling. If you’ve already opted in to this parent feature, then you don’t have to opt in again.

Key Resources

- Visit https://redwood.oracle.com/ for more information about the Redwood experience.

Access Requirements

Users who are assigned a configured job role that contains this privilege can access this feature:

- Edit Production Schedule (MSC_EDIT_PRODUCTION_SCHEDULE_PRIV)

This privilege was available prior to this update.