Consider Under-Completion Tolerance for Process Work Orders

In process manufacturing, actual yields often vary from expected yields due to the inherent variability in production processes. In cases, where the actual yield is less than the expected yield, you can specify an under-completion tolerance so that the planning system doesn’t continue to plan for the remaining quantity that was expected. This update enables you to specify the under-completion tolerance in Oracle Manufacturing and Oracle Supply Planning will honor this specification when planning for the WIP orders.

As a production operator, you may need to report the completion of a quantity within the permissible under-completion tolerance so that the work order operation can be marked as complete without taking additional steps in the system, even if there's a shortfall in the required quantity.

Supply Planning Impact from Work Order with Variance

With this feature, you can now post variance at the operation level by enabling the option Mark as Complete while executing process manufacturing work orders. When this option is enabled, any remaining quantity at that operation is moved to the Variance Quantity, setting the Open Quantity to zero for that operation.

As a result:

- The Operation Start Quantity for the next operation is reduced by the cumulative variance quantity from the previous operation.

- The work order demand for components at the operation is calculated based on the estimated open operation start quantity.

- The resource requirements for that operation are also based on the estimated open operation start quantity.

- The supplies for by-products, co-products, and the primary product are determined using the estimated operation end quantity, which factors in the variance.

Example:

Let’s assume we have a work definition where the Batch Quantity is greater than the Primary Product Quantity.

| Batch quantity | 100 | ||||||

|---|---|---|---|---|---|---|---|

| Operation | Component | Initial Quantity | Output Item | Output item quantity | Product type | Resource | Resource required(hrs) |

| 10 | PPS-EIR-CPU | 111.25 | PPS-EIR-R1 | 100 | |||

| 20 | PPS-EIR-Monitor | 111.25 | PPS-EIR-R2 | 100 | |||

| 30 | PPS-EIR-KeyBoard | 111.25 | PPS-EIR-ByProduct/ PPS-EIR-CoProduct | 20/20 | By product/Co product | PPS-EIR-W1 | 100 |

| 40 | PPS-EIR-Mouse | 111.25 | PPS-EIR-COMPUTER | 50 | Primary | PPS-EIR-W2 | 100 |

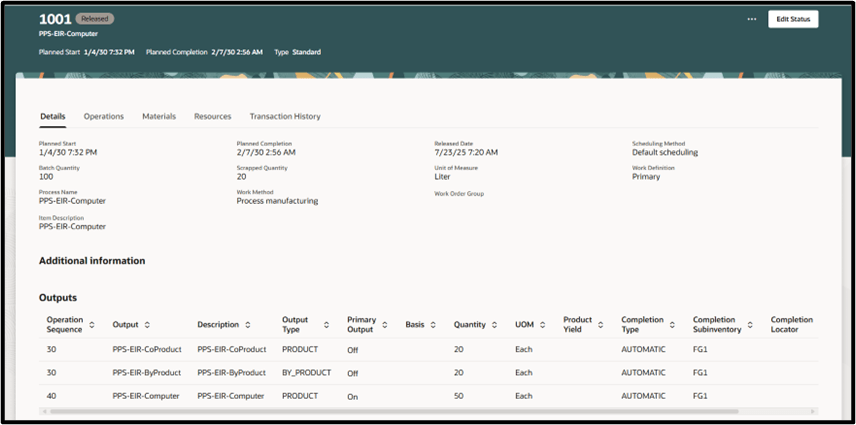

Work Order in Oracle Fusion Manufacturing

Work Order

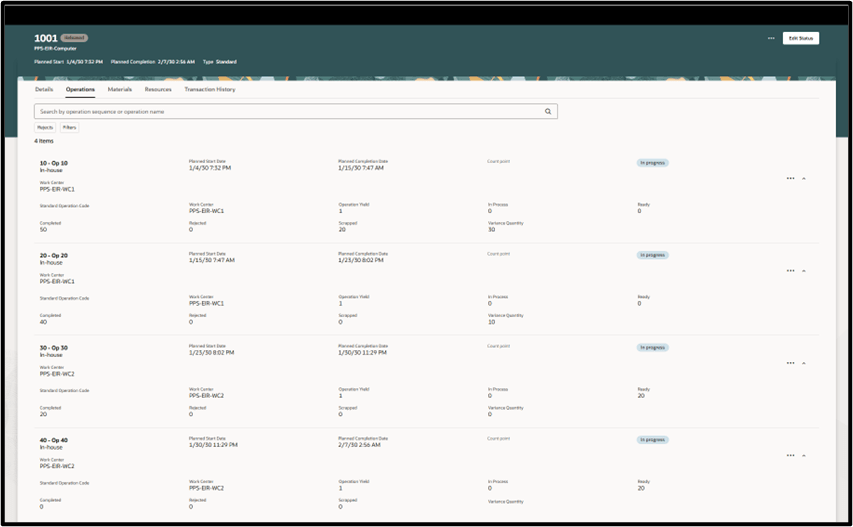

In-Progress Work Order Status:

The status of Operation 10 is recorded as follows across multiple transactions:

Transaction 1

- Completed Quantity: 50

- Scrap Quantity: 20

- Variance Quantity: 30

Transaction 2

- Completed Quantity: 40

- Scrap Quantity: 0

- Variance Quantity: 10

Transaction 3

- Completed Quantity: 20

- Scrap Quantity: 0

- Variance Quantity: 0

Transaction 4

- Completed Quantity: 0

- Scrap Quantity: 0

- Variance Quantity: 0

Additional Context:

Component Consumption Rate:

Each component is consumed at 1.001 units per batch unit of the primary product.

Resource Usage Rate:

The operation requires 1 hour of resource time per batch unit.

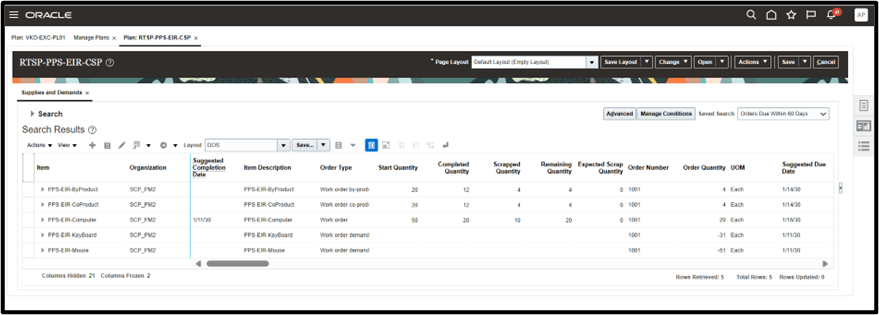

In Progress Work Order

Once the work order is collected and the supply plan is executed, the Work Order Supplies for by-products, co-products, and primary products are calculated based on the estimated open operation end quantity for the operation.

The formula used is:

Order Quantity = Initial Start Quantity – Quantity Per Product × (Cumulative Variance Quantity + Cumulative Scrap Quantity + Completed Quantity)

Supplies Calculation

- By-Product Supply for

PPS-EIR-ByProduct

= 20 – 0.2 × (40 + 20 + 20)

= 20 – 0.2 × 80 = 4 units - Co-Product Supply for

PPS-EIR-CoProduct

= 20 – 0.2 × (40 + 20 + 20)

= 20 – 0.2 × 80 = 4 units - Primary Product Supply for

PPS-EIR-Computer

= 50 – 0.5 × (40 + 20)

= 50 – 0.5 × 60 = 20 units

Component Demand Impact by Operation

- Operations 10 and 20:

No component demand is generated since there is no open quantity remaining for these operations. - Operations 30 and 40:

Component demand is based on the estimated open operation start quantity:

Order Quantity = Initial Quantity – Quantity Per Product × (Cumulative Variance + Scrap + Completed Qty)

Component Demand Calculation

- For

PPS-EIR-KeyBoard

(Op 30)

= 111.25 – 1.001 × (40 + 20 + 20)

= 111.25 – 1.001 × 80 = 31.17 units - For

PPS-EIR-Mouse

(Op 40)

= 111.25 – 1.001 × (40 + 20)

= 111.25 – 1.001 × 60 = 51 units

Work Order Supplies and Demand

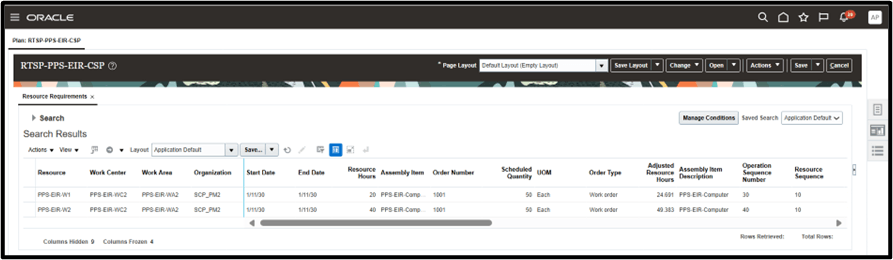

Resource Requirements Impact

For the given work order:

- Operations 10 and 20:

No Resource Requirements are generated since these operations are marked as complete. - Operations 30 and 40:

Resource Requirements are calculated based on the open operation start quantity, using the following formula:

Resource Hours = Initial Resource Hours – Resource Usage × (Cumulative Variance Quantity + Cumulative Scrap Quantity + Completed Quantity)

Example Calculations

- For PPS-EIR-W1 (Operation 30)

= 100 – 1 × (40 + 20 + 20)

= 100 – 1 × 80 = 20 hours - For PPS-EIR-W2 (Operation 40)

= 100 – 1 × (40 + 20)

= 100 – 1 × 60 = 40 hours

Resource Requirements

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Supply Chain Planning

Tips And Considerations

If you want to use the Consider Under-Completion Tolerance for Process Work Orders feature, then you must opt in to its parent feature: Production Scheduling. If you’ve already opted in to this parent feature, then you don’t have to opt in again.

In 25D, Variance Quantity is captured under the Completed quantity field in Supply Planning. Production Scheduling will schedule work orders and their operations as specified in Oracle Manufacturing at time of schedule refresh.

Key Resources

Access Requirements

No separate privilege is required to access this feature.