Calculate Product Completion Cost for Same Output Completed on Multiple Operations

You can now add co-products and by-products to different operations in a work definition or work order, with enhanced support for accurate cost calculations. When co-products or by-products are specified at the operation level, the application automatically apportions costs based on the cost allocation basis defined in the work definition.

Standard Cost Calculation

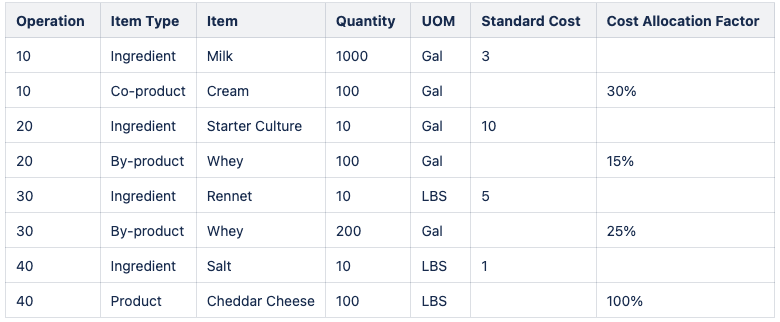

The standard cost calculation now uses multiple instances of co-products and by-products in a work definition and their cost allocation percentages to calculate a blended standard cost. Let's review an example of a work definition where a by-product is yielded in different operations.

Work Definition Used for Cost Calculation Example

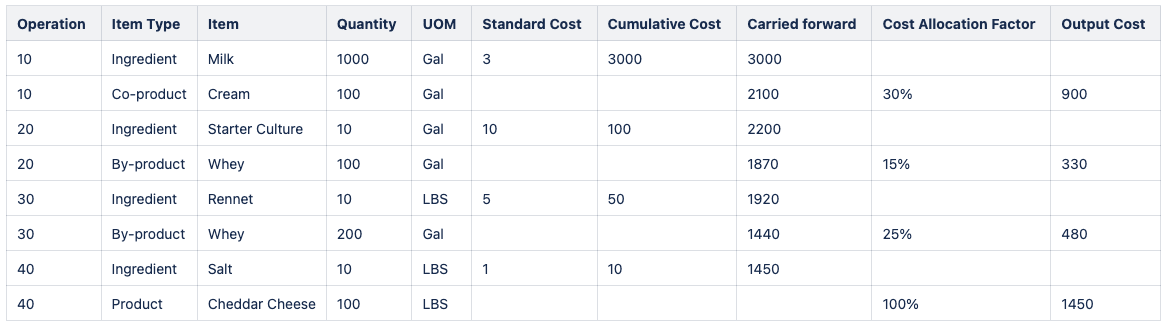

Cost Calculations

Standard Cost Rollup Calculations

Standard cost = Output cost / Quantity

Standard cost of Cream = 900/100 = $9

Standard cost of Whey = (330+480)/(100+200) = $2.7

Standard cost of Cheddar Cheese = 1450/100 = $14.5

Both the product completions for Whey will be costed using this calculated standard cost that's $2.7.

Actual, Average, and Periodic Average Cost Methods

If you've set the provisional completion option to Use Accumulated Work in Process Balances, each of the product completions will be calculated based on the accumulated work in process balances till that operation. When the work order is closed, the cost processor will calculate a single cost for product completions and will create a product cost adjustment for the difference between the product completion cost and cost calculated at work order close.

This ensures that the total production costs are distributed appropriately across all outputs, providing precise and transparent cost tracking. As a result, you can achieve more accurate inventory valuation, improved profitability analysis, and better alignment with operational realities in complex manufacturing scenarios.

Steps to Enable and Configure

You don't need to do anything to enable this feature.

Tips And Considerations

The cost allocation factor basis needs to be same for the same item across different operations. This validation is enforced when you create a work definition and when you add the same item in different operations in a work order.

Key Resources

- Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Using Supply Chain Cost Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains the following privileges can access this feature:

- Manage Cost Planning Scenario Definition (CST_MANAGE_SCENARIO)

- Perform Cost Rollup (CST_PERFORM_COST_ROLLUP)

- Review Rolled Up Costs (CST_REVIEW_ROLLEDUP_COSTS)

- Allows review of costs and balances by each individual work order (CST_REVIEW_WORK_ORDER_COSTS_PRIV)

These privileges were available prior to this update.