Define and Run Zero Acceptance Sampling

In high-risk and safety-critical industries, regulatory mandates and customer requirements often demand zero tolerance for defects.

Traditional acceptance plans, which allow even a small number of defects, fall short of these stringent standards.

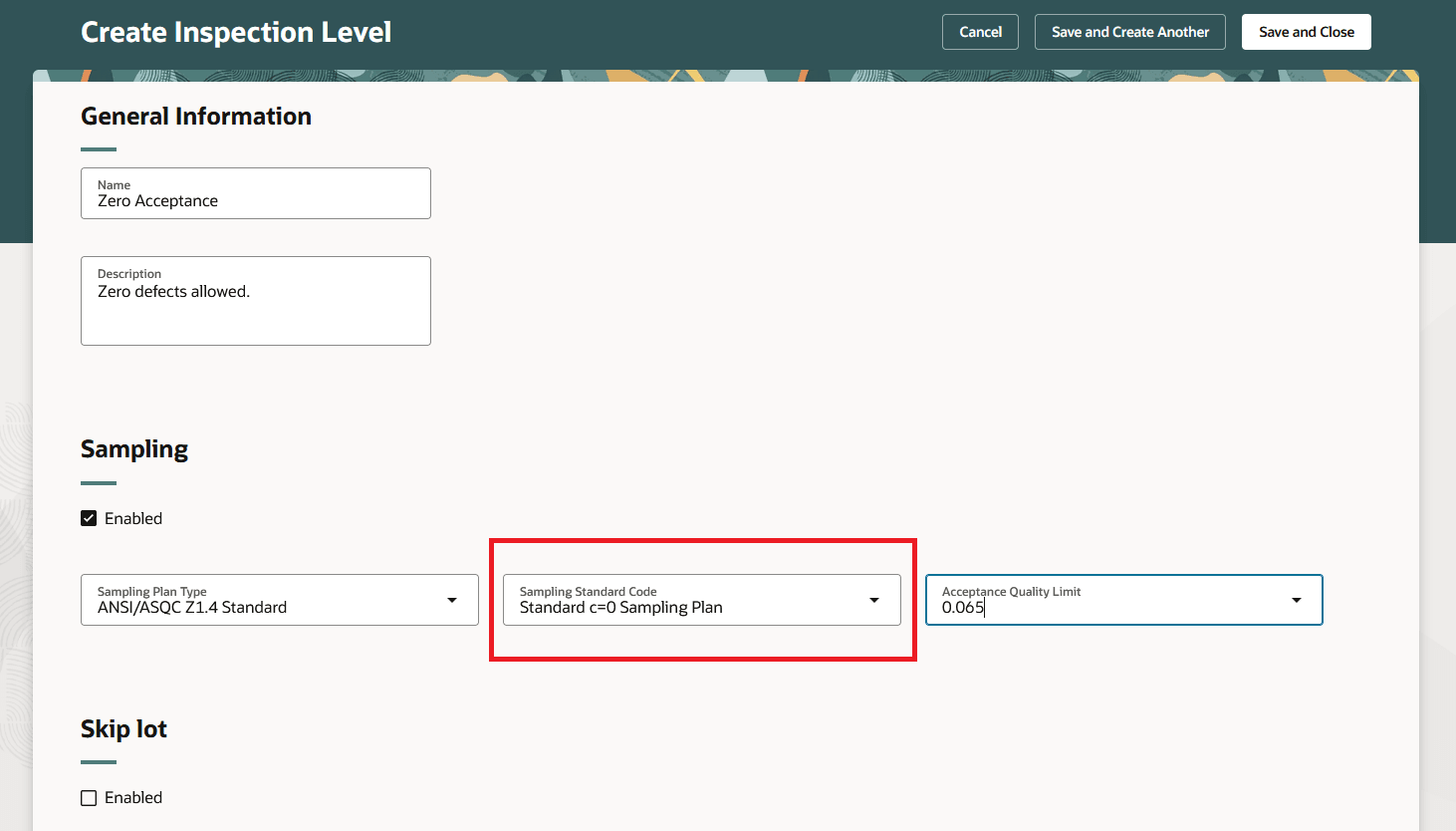

With this release, you can now configure Zero Acceptance Sampling Plans (C=0) directly within an inspection level.

Define a Standard C=0 Sampling Plan inspection level

This ensures lots are only accepted when all sampled units pass inspection, giving quality engineers and inspectors the ability to enforce the strictest standards of compliance and product reliability.

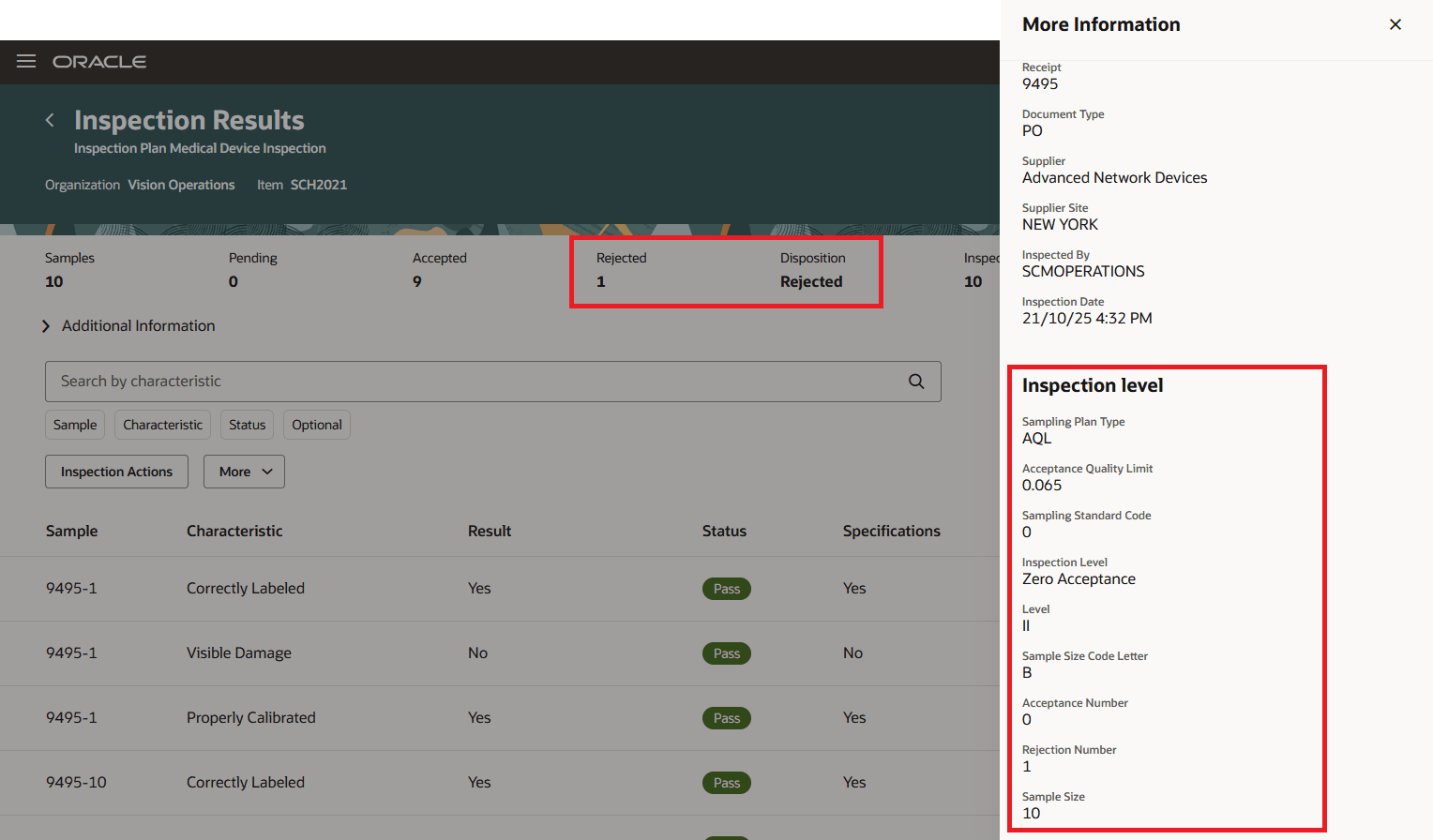

Inline inspection using an inspection plan leveraging a C=0 inspection level

Zero acceptance sampling benefits highly regulated industries by:

- Enforcing zero-defect tolerance in inspections

- Aligning with regulatory requirements and industry best practices

- Strengthening quality assurance controls for critical products

Here's the demo of these capabilities:

Steps to Enable and Configure

You don't need to do anything to enable this feature.

Tips And Considerations

The ability to define a zero acceptance inspection level is only available from the Redwood version of the Create Inspection Characteristic page.

Access Requirements

Users who are assigned a configured job role that contains these privileges and codes can access this feature:

Quality Inspection Management Privileges :

- Edit Characteristics (QA_EDIT_CHARACTERISTICS)

- Edit Inspection Results (QA_EDIT_INSPECTION_RESULTS)