How You Execute Project-Specific Manufacturing

The Project-Driven Supply Chain solution provides the ability to execute project-specific manufacturing by creating a work order or through orderless execution, issue components from common or project-specific inventory, and put away the end product into project-specific inventory.

You can create a work order with the project number and task number in Manufacturing. You can also create a work order after the project-specific supply is planned in Supply Planning, and the make planned order is released to Manufacturing.

You can purchase outside processing services, procure material directly for project-specific work orders, and import material and resource costs to the project.

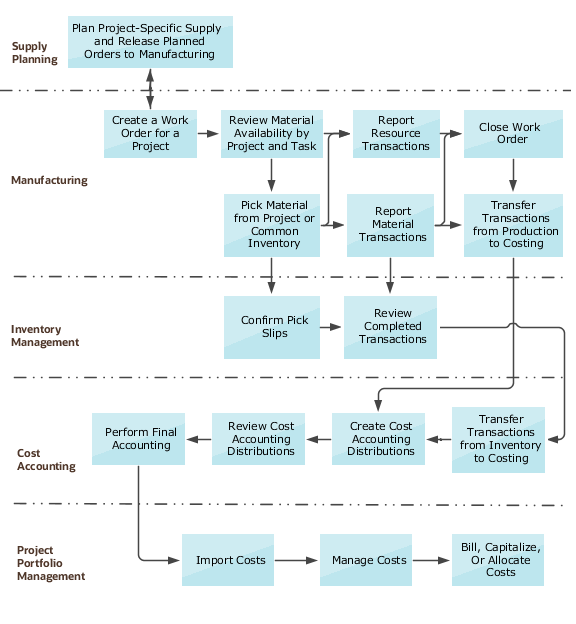

Here's the high-level process flow to execute project-specific manufacturing:

-

Create a work order with the project number and task number in Manufacturing or by using the make planned order released to Manufacturing from Supply Planning.

A work order is saved with the default project costing attributes. You can review and modify the attributes as required.

-

Calculate material availability by project or task and release the work order.

The work order is released only after Project Portfolio Management validates the project costing attributes.

-

Pick material for work order based on project and task.

-

Execute movement requests and review the completed transactions with reference to the project and task in Inventory Management.

-

Interface the material transaction with the project and task references to inventory.

-

Review dispatch list with project and task as additional search attributes.

-

Report resource transactions.

-

Report material transactions and review the completed transactions in Inventory Management.

-

Close the work order.

-

Run the Transfer Transactions from Production to Costing task and transfer the resource transactions to Costing.

-

Run the Transfer Transactions from Inventory to Costing task and transfer the materials transactions to Costing.

-

Create cost accounting distributions and review the project details for accounting distributions. The costs are final accounted and are imported into Project Portfolio Management where they're further managed.

-

Generate project invoices to bill the customer based on the percentage of completion or milestones achieved on the project.

-

If it's a capitalizable cost, you can proceed to execute the capitalization flow. You may also choose to allocate costs to other projects, project tasks, or accounts as appropriate.

Here's an illustration that explains the process flow for creating and executing work orders with project and task details: