Work Areas, Resources, and Work Centers

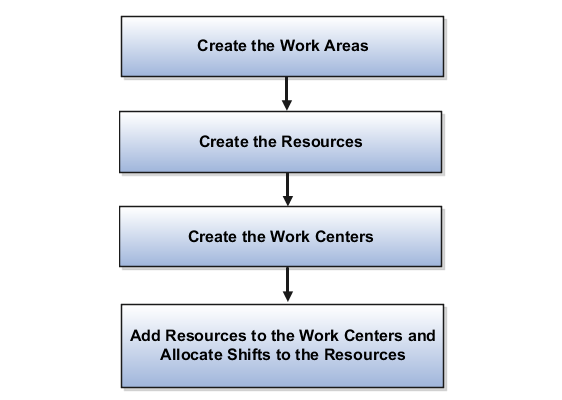

In a maintenance organization, the maintenance activities are carried out in the work centers within the work areas using the resources. So, the required work areas, resources, and work centers must be set up in a maintenance organization before the day to day maintenance activities can be commenced.

Work Areas

First, you must create the required work areas for the maintenance organization. A work area is a specific region allocated for performing the maintenance activities. Every maintenance organization must have at least one work area. However, you can create multiple work areas as per your requirement.

Resources

After creating the work areas, you must create the resources that you need for the maintenance organization. The labor and equipment that you need for performing the maintenance activities are accounted as the resources.

Work Centers

After creating the work areas and resources, you must create the work centers. The production unit consisting of people or equipment is referred as a work center. Add the resources to the work centers where you want to use the resources. You must then allocate shifts for the resources. You can also manage the work center calendars for the resources.