Manage Supply Requests for Projects

You can manage supply requests that include project data in Supply Chain Orchestration.

You can manage:

-

Transfer requests across different organizations that include project data from Self Service Procurement.

-

Transfer requests within a single organization or across different organizations that include project data from the Supply Request REST API.

-

Purchase requests that include project data for outside processing from Manufacturing. Supply Chain Orchestration gets default values for project data and validates cost transactions for each project.

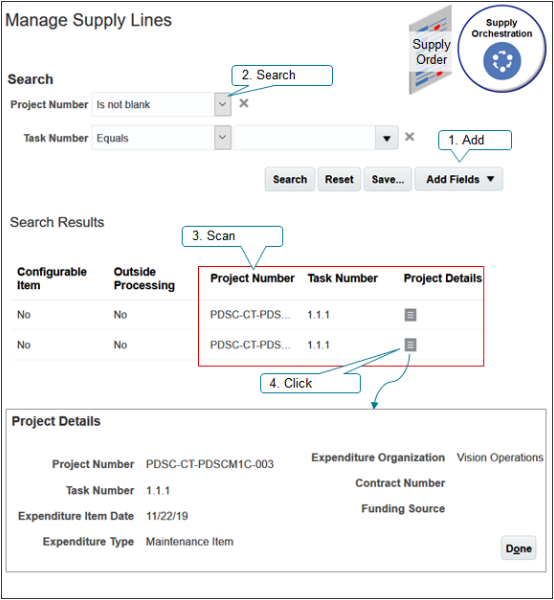

Examine Project Details

Go to the Supply Orchestration work area, then in the Search area, click Add Fields to add the Project Number and Task Number, then use these attributes to search for supply requests that include project data.

You can do your search on various pages in the Supply Orchestration work area.

-

Manage Supply Lines

-

Supply Order Details

-

Manage Supply Request Exceptions

View the full set of project data on each supply line, such as Project Name, Task Number, Expenditure Item Date, Expenditure Type, Expenditure Organization, Contract Number, and Funding Source.

For example, view them on the Manage Supply Lines page.

Points to Consider

-

If you use the Supply Request REST API.

-

You can capture project data only for transfer requests.

-

You can capture only the project number and task number, or you can capture the full set of project data. If you capture only the project number and task number, or only part of the full set of project data, then Supply Chain Orchestration keeps the values that you capture and gets default values for the project attributes that you don't capture.

-

-

If validation fails for the project cost transaction, or if a setup or technical error happens, then you can manually correct the error and use the Supply Orchestration work area to resubmit the supply request.

For example, if the expenditure type isn't active during the expenditure item date, then use the Manage Expenditure Types page to validate the expenditure type date. Resubmit the supply request so orchestration can successfully process the transfer request for the project.

Use Supply That's Specific to Each Project

Use this feature in your back-to-back fulfillment flow for each item that's too expensive to maintain as on-hand inventory when you must fulfill a sales order that has project details.

-

Use this feature to make sure the project expenditures that you see in inventory are accurate.

-

Your purchase order, transfer order, or work order can include project details from the sales order. Inventory Management uses these details to fulfill the item from inventory that's specific for the project, so you can accurately apply the cost that you incur for carrying inventory to each project.

-

If you don't use this feature, then Inventory Management uses common inventory to fulfill the item, and costs get averaged for all items that are in common inventory regardless of whether they're part of a project. This situation can result in project expenditures that aren't accurate because costs aren't specific to the project, and it might affect your project margins.

Enable the Feature

-

Go to the Setup and Maintenance work are, then select the Manufacturing and Supply Chain Materials Management offering.

-

Click Change Feature Opt In.

-

In the row that contains Manufacturing and Supply Chain Materials Management in the Name column, click the pencil.

-

On the Edit Features page, in the row that contains Create Supply in Back-to-Back Flows for Sales Orders That Include Project Details in the Feature column, add a check mark to the box in the Enable column.

How it Works

-

You create a sales order in Oracle Order Management that includes project details.

-

Order Management sends a supply request that includes project details to Supply Chain Orchestration.

-

Supply Chain Orchestration gets a supply recommendation from Global Order Promising according to the sourcing rules that you set up for your back-to-back fulfillment for the item.

-

Supply Chain Orchestration uses the supply recommendation to create a supply order.

-

Supply Chain Orchestration sends the sales order details to Inventory Management.

-

Inventory Management creates shipment lines to fulfill the item.

-

Your back-to-back fulfillment uses a buy, make, transfer, or on-hand flow to create supply. There are some unique differences for each of these flows.

Buy Orders

-

Supply Chain Orchestration creates a purchase requisition that includes project details from the sales order.

-

Oracle Procurement converts the requisition into a purchase order.

-

Inventory Management receives the item and adds it to inventory that's specific for the project.

-

You can't update the project attributes on a back-to-back purchase order.

Make Orders

-

Supply Chain Orchestration creates a back-to-back work order that includes project details form the sales order.

-

Inventory Management finishes the item and adds it to inventory that's specific for the project.

-

You can't update the project and task on the work order that's reserved for the sales order, but you can update other project attributes for a work order that isn't released.

Transfer Orders

-

Supply Chain Orchestration creates back-to-back supply that includes project details, then sends these supply details to Inventory Management.

-

Inventory Management creates a transfer order that includes the project details, then sends the transfer order to the warehouse.

-

The warehouse uses the project details that are on the transfer order to identify the project-specific inventory it will use to fulfill the item, then picks and ships the item.

-

You can't update project attributes on the transfer order.

On Hand Supply

-

You can use the on-hand flow when on-hand supply is available in the fulfillment warehouse that you use for the back-to-back item.

-

Global Order Promising examines the supply chain, then sends a recommendation to reserve on-hand supply.

-

Supply Chain Orchestration uses project details from the sales order to reserve on-hand supply for the back-to-back order.

-

Inventory Management reserves the on-hand supply.

Notes

-

Global Order Promising doesn't consider project details.

-

Use the Supply Chain Availability promising mode when set up your available-to-promise rule for each item that you fulfill in a back-to-back flow.

-

Consider excluding on-hand supply for your back-to-back item. This will help to avoid a reservation failure for your project-specific inventory.