Collect Source System Data

Order Management uses various data, such as units of measure, currency, and currency conversions, from the Order Orchestration and Planning Data Repository. You must collect data for these entities so your set up can receive source orders.

Sourcing rules in Global Order Promising reference the Organization Parameter entity. You must collect organization parameters before you set up your sourcing rules.

Assume you must set up collections for the AS54888 Desktop Computer.

Note

-

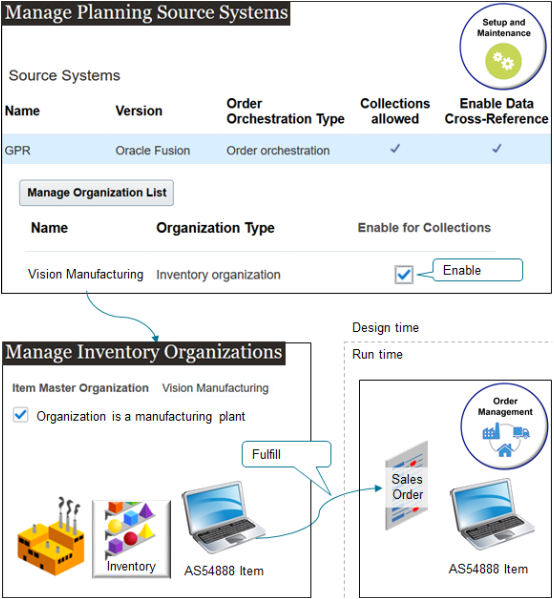

You use the Manage Planning Source Systems task to specify Oracle Order Orchestration And Planning as your source system, to specify Vision Manufacturing as the inventory organization for the AS54888, and to enable Vision Manufacturing for collections.

-

You use the Manage Inventory Organizations task to specify Vision Manufacturing as a manufacturing plant.

-

At run time, Order Management uses the inventory in Vision Manufacturing to fulfill the AS54888.

Summary of the Set Up

-

Set up the item.

-

Set up the inventory organization.

-

Collect data from source systems.

Set Up the Item

Set up your item so it supports order promising.

-

Go to the Product Information Management work area, then open item AS54888 for editing.

-

Click Specifications, click Planning, then set the value.

Attribute

Value

Planning Method

Set it to MPR Planning or MPS Planning.

You must use one of these values. If you use any other value, then the item won't be available for promising and fulfillment will likely fail.

-

Click Sales and Order Management, then set the values.

Attribute

Value

Check ATP

Material and Resource

Shippable

Yes

-

Refresh the order promising server.

Entities

Value

Items

Contains a check mark.

For details, see Refresh the Order Promising Server for Order Management.

Set Up the Inventory Organization

Set up your inventory organization so it supports order promising.

-

Go to the Setup and Maintenance work area, then go to the task.

-

Offering: Manufacturing and Supply Chain Materials Management

-

Functional Area: Facilities

-

Task: Manage Inventory Organizations

-

-

On the Manage Inventory Organizations page, search for your inventory organization.

Attribute

Value

Organization Name

Vision Manufacturing

-

In the search results, click that row that has your organization, then click Manage Organization Parameters.

-

On the Manage Inventory Organization Parameters page, in the Additional Usages area, set the value.

Attribute

Value

Organization is a Manufacturing Plant

Contains a check mark.

-

Go to the task.

-

Offering: Manufacturing and Supply Chain Materials Management

-

Functional Area: Manufacturing Master Data

-

Task: Manage Plant Parameters

-

-

Verify that the value in the Manufacturing Calendar attribute is the correct calendar.

For details, see How to Create a Calendar used by Order Management and Global Order Promising (Doc ID 2204151.1).

-

Collect planning data and refresh the order promising server.

-

Select all entities when you do the Collect Planning Data task.

-

Select all entities when you refresh the server.

For details, see Collect Planning Data for Order Management.

-

Collect Data From Source Systems

-

Collect data from your source system.

-

In the Setup and Maintenance work area, go to the task.

-

Offering: Supply Chain Planning

-

Functional Area: Supply Chain Planning Configuration

-

Task: Manage Planning Source Systems

-

-

On the Manage Planning Source Systems page, in the Source Systems list, locate your Oracle system, then set the values.

Attribute

Value

Version

Fusion

Collections Allowed

Contains a check mark

Order Orchestration Type

Order Orchestration

Enable Data Cross-Reference

Contains a check mark

-

Set the values for each system that your set up must integrate, such as an order capture system or fulfillment system.

Attribute

Value

Version

Others

Collections Allowed

Contains a check mark

Enable Data Cross-Reference

Contains a check mark

For details, see Manage Planning Source Systems for Data Collections.

-

-

Collect data for Vision Manufacturing, which is the organization that contains the inventory you plan to use to fulfill the item.

-

Select your source system in the Source Systems list, then click Manage Organization List.

-

In the Manage Organization List dialog, click Refresh Organization List.

-

Add a check mark to the Enable for Collections option for each organization that you use to fulfill the item, then click Save and Close.

Attribute

Value

Name

Vision Manufacturing

Enable for Collections

Contains a check mark

-

-

Collect planning data. You must do the Collect Planning Data task each time after you do the Manage Planning Source Systems task. Here are your values for this example.

Parameter

Value

Source System

OPS

Collection Type

Targeted

Reference Data

Move the Items entity and the Organizations entity to the Selected Entities window.

For details, see Collect Planning Data for Order Management.

-

Refresh the Order Promising Server for Order Management.

Parameters

Value

Items

Contains a check mark.

Organizations

Contains a check mark.

For details, see Refresh the Order Promising Server for Order Management.