Configure Order-Based Exceptions for Constrained Supply Plans

You can configure order-based exceptions as user-defined exceptions for constrained supply plans. In this topic, we discuss the predefined order-based exceptions that are available for unconstrained supply plans, but aren't available as predefined exceptions for constrained supply plans.

Configure Exceptions That Are Order Based

Use these general steps to configure exceptions for constrained supply plans that are order based.

-

Open a constrained supply plan and access the Supplies and Demands table.

-

In the Search section, click the Advanced button.

-

Click the Add Fields button and select an order attribute from the list of values.

-

Define a condition and value for the order attribute.

-

To save the search, click the Save button.

-

In the Create Save Search dialog box, enter a name.

-

Click OK.

-

-

In the Supplies and Demands table, click Search.

The Supplies and Demands table displays the records that conform to the defined condition.

The following sections provide specific details for some user-defined exceptions that you can configure for constrained supply plans.

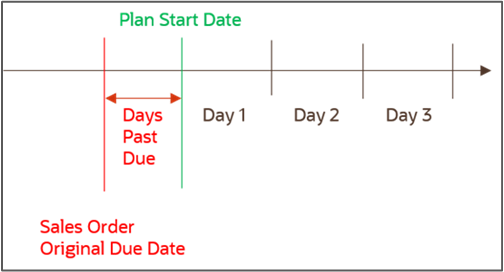

Past Due Sales Orders

In an unconstrained supply plan, the planning process generates the Past Due Sales Orders exception when it detects that the scheduled date of the sales order is earlier than the plan horizon start date. A past due sales order line is a sales order line with a scheduled date earlier than the plan horizon start date.

To see demand where quantity isn't met in your constrained supply plan, follow these steps:

-

Open the Supplies and Demands table.

-

In the Search section, click the Advanced button.

-

Click the Add Fields button and select Days Past Due.

-

In the Order Type field:

-

Set the operation to Equals

-

For the value, select Sales order

-

-

In the Days Past Due field:

-

Set the operation to Greater than

-

Set the value to 0 (zero)

-

-

Click the Search button.

All past due sales orders appear in the Search Results section in the Supplies and Demands table.

Late Replenishment for Forecast

The planning process generates the Late Replenishment for Forecast exception when it detects supplies that peg against independent forecast demand that's satisfied late. Through this exception, you can quickly detect which supplies are pegged against a late forecast.

A sales order becomes past due when it hasn't been satisfied by the time you run the plan. In other words, the Original Due Date of the sales order falls before the Plan Start Date. This exception usually occurs because of a material constraint, resource constraint, or a planning time fence.

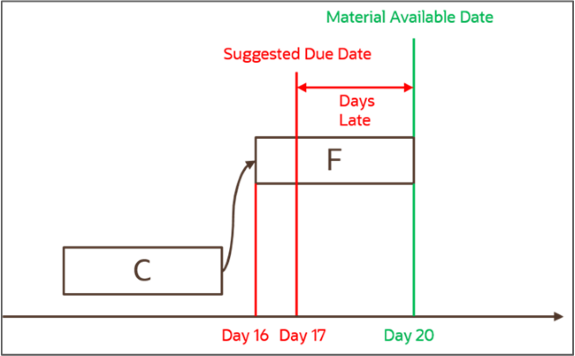

Let's work through an example to see all late replenishments for forecasts in your constrained supply plan using the following criteria:

-

Component C feeds end item F.

-

There's a forecast for end item F with a due date of Day 17.

-

Due to manufacturing constraints, the component is available on Day 16. As a result, the Material Available Date for end item F is Day 20.

In this example, the availability of material is late with respect to the due date. As a result, the planning process generates a Late Replenishment for Forecast exception for end item F.

To see all late replenishments for forecasts in your constrained supply plan, follow these steps:

-

Open the Supplies and Demands table.

-

In the Search section, click the Advanced button.

-

Click the Add Fields button and select Days Late.

-

In the Order Type field:

-

Set the operation to Equals

-

For the value, select Forecast

-

-

In the Days Late field:

-

Set the operation to Greater than

-

Set the value to 0 (zero)

-

-

Click the Search button.

All late replenishments for forecasts appear in the Supplies and Demands table.

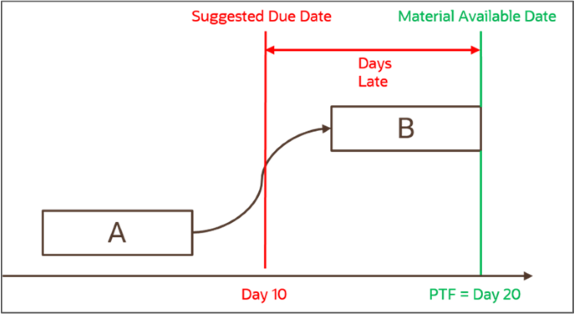

Late Replenishment for Sales Orders

The planning process generates a Late Replenishment for Sales Order exception when it detects that the supplies for a sales order line are due later than the sales order line's scheduled date. In other words, the Material Available Date is after its Suggested Due Date. This exception typically occurs due to any of these issues:

-

There's a resource constraint

-

Planning time fences are enabled

-

A reserved supply is firmed late

Let's work through an example to see all late replenishments for sales orders in your constrained supply plan using the following criteria:

-

Component A feeds end item B

-

End item B planning time fence is Day 20

-

There's a sales order for end item B with a due date of Day 10

-

Due to the item B planning time fence, item B can't be planned before Day 20. As a result, the Material Available Date for the end item B is Day 20.

In this example, the availability of material is late with respect to the due date. As a result, a Late Replenishment for Sales Order exception is generated for the end item B.

To see all late replenishment for sales orders in your constrained supply plan, follow these steps:

-

Open the Supplies and Demands table.

-

In the Search section, click the Advanced button.

-

Click the Add Fields button and select Days Late.

-

In the Order Type field:

-

Set the operation to Equals

-

For the value, select Sales order

-

-

In the Days Late field:

-

Set the operation to Greater than

-

Set the value to 0 (zero)

-

-

Click the Search button.

All late replenishments for sales orders appear in the Supplies and Demands table.

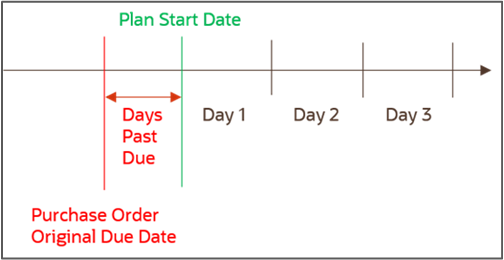

Past Due Orders

The planning process generates the Past Due Orders exception when it detects purchase orders, transfer orders, or work orders that have order due dates before the plan horizon start date. If the order is firm, the planning process retains the order's firmed duration as it schedules all of its operations beyond the planning horizon start date. For supply orders that aren't firm, the planning process also issues an Orders to be rescheduled out exception message.

The calculation for the Days Past Due exception is:

Plan Start Date - Order Original Due Date, when Plan Start Date is after the Order Original Due Date

To see past due orders in a constrained supply plan, follow these steps:

-

Open the Supplies and Demands table.

-

In the Search section, click the Advanced button.

-

Click the Add Fields button to add the following attributes to the search section:

-

Old Due Date

-

Days Past Due

-

Action

-

-

Set the operations and values for the following fields in the Search section:

Field

Operation

Value

Note

Order Type

Equals

All supplies

N/A

Old Due Date

Is not

NULL

Planned order is NULL

Days Past Due

Greater than

0 (zero)

N/A

Action

Is not

Canceled

You must select all values except Cancel

-

Click the Search button.

All past due orders are displayed in the Supplies and Demands table.

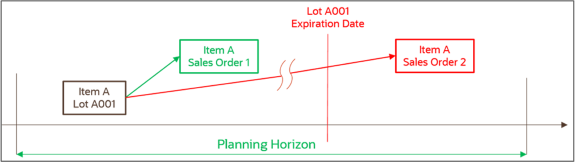

Items with Expired Lots

The planning process generates an Items with Expired Lots exception when it detects a potential expired lot. Item lots can satisfy demands before their expiration dates. A potential expired lot:

-

Has a lot expiration date during the planning horizon.

-

Isn't pegged to a demand that results in its use before its lot expiration date.

This exception occurs against items under full lot control.

In addition to reporting this exception, the planning process plans for you to flush the inventory on its lot expiration date. This process prevents you from using the lot after its lot expiration date to satisfy demands.

The calculation for Items with Expired Lots is: Lot Receipt Date + Shelf Life Days

In the following example, lot A001 of item A can only satisfy sales order 1 with a due date before the lot A001 expiration date.

To see all items with expired lots in your constrained supply plan, follow these steps:

-

Open the Supplies and Demands table.

-

In the Order Type field in the Search section:

-

Set the operation to Equals

-

For the value, select Expired lot

-

-

Click the Search button.

All items with expired lots appear in the Search Results section in the Supplies and Demands table.

Demand Quantity Not Satisfied

The planning process generates a Demand Quantity Not Satisfied exception when there isn't enough supply available. The planning process finds demand pegged to supplies and the supply quantities are less than the demand quantity. The planning process issues this exception for demands at all levels of the supply chain bill of materials.

This exception typically occurs due to inconsistent setups. For example, a configured item can't be sourced because too many option-specific exclusions prevent any source from being used.

To see demand where quantity isn't met in your constrained supply plan, follow these steps:

-

Open the Supplies and Demands table.

-

In the search section, click the Advanced button.

-

Click the Add Fields button and select Unmet Demand Quantity.

-

In the Unmet Demand Quantity field:

-

Set the operation to Greater than.

-

Set the value to 0 (zero).

-

-

Click the Search button.

All demand quantities that aren't satisfied appear in the Search section in the Supplies and Demands table.