How End Item Substitution and Supersession Are Performed

End item substitution and supersession use the same process that's described in this topic.

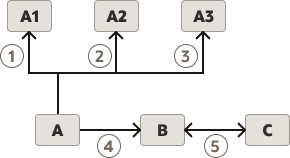

Example for Process of End Item Substitution

Consider a substitution chain in which we have items A, A1, A2, A3, B, and C.

Item A can be substituted by items A1, A2, A3, B, and C, and the ranks of the item relationships are 1, 2, 3, 4, and 5. Moreover, items B and C have a bidirectional relationship.

This figure depicts the substitution chain:

End item substitution is performed for this substitution chain as follows:

- The substitution chain is constructed for item A.

- On Day 1 of the planning horizon, the excess and shortage for items A, A1, A2,

A3, B, and C are calculated.

- If item A has a shortage, then the substitute items are considered

according to the ranks of the item relationships.

Item A1 is checked to see if it has an excess in the excess window. If item A1 doesn't have an excess, then item A2 is considered and so on.

- If item A has a shortage, then the substitute items are considered

according to the ranks of the item relationships.

- If no item has an excess, then item A is checked for the Create Supply

attribute.

If the value is Yes, then supply is created for item A. The Create Supply After attribute is considered.

If the value is No, then the substitute items are considered according to the ranks of the item relationships. The same checks are done for item A1 and so on.

- A planned order is created according to the applicable policy.

- The Substitute Demand and Substitute Supply measures are updated so that the substitution is reflected.

- On each remaining day of the planning horizon, Steps 2 through 5 are repeated.

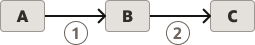

Example for Process of Supersession

Consider a supersession chain in which we have items A, B, and C.

Item A is superseded by item B, item B is superseded by item C, and the ranks of the item relationships are 1 and 2. The relationships among the items are unidirectional.

This figure depicts the supersession chain:

Supersession is performed for this supersession chain as follows:

- The supersession chain is constructed for item A.

- On Day 1 of the planning horizon, the excess and shortage for items A, B, and C

are calculated.

- If item A has a shortage, then the supersession items are considered

according to the ranks of the item relationships.

Item B is checked to see if it has an excess in the excess window. If item B doesn't have an excess, then item C is considered.

- If item A has a shortage, then the supersession items are considered

according to the ranks of the item relationships.

- If no item has an excess, then item A is checked for the Create Supply

attribute.

If the value is Yes, then supply is created for item A. The Create Supply After attribute is considered.

If the value is No, then the supersession items are considered according to the ranks of the item relationships. The same checks are done for item B and so on.

- A planned order is created according to the applicable policy.

- The Substitute Demand and Substitute Supply measures are updated so that the supersession is reflected.

- On each remaining day of the planning horizon, Steps 2 through 5 are repeated.