Overview of End Item Substitution and Supersession

End item substitution and supersession enable you to increase customer satisfaction while minimizing excess and obsolete inventory.

These are brief descriptions of end item substitution and supersession and their applicability to replenishment plans:

- End item substitution substitutes one item for another item during demand fulfillment for your replenishment plan. The substitute item's supply is used, and a replenishment order isn't created for the demanded item.

- Supersession replaces an item with a newer or more advanced version during demand fulfillment for your replenishment plan. The supply of the supersession item is used, and a replenishment order isn’t created for the demanded item.

In the Product Information Management work area, on the Manage Item Relationships page, you specify the substitution or supersession relationship between the items. The type of the relationship between the items is Substitute for a substitution relationship and Superseded for a supersession relationship. The relationships can be unilateral or bilateral. By extending the substitution or supersession relationship between two items to other items, you can create a substitution or supersession chain, which can be specific to an organization or all child organizations under a master organization. The substitution or supersession chain contains all organizations to which the source item, substitute item, and supersession item are assigned. You also can import substitution and supersession relationships using the file-based data import (FBDI) template named Supply Chain Planning Item Substitute (ScpItemSubstituteImportTemplate.xlsm).

By implementing end item substitution and supersession, you get these benefits:

- You can optimize inventory costs by minimizing excess and obsolete inventory.

By designing your substitution or supersession chain and assigning ranks, you can ensure that the excess of the substitute or superseded item is used before orders are placed for the item.

If no excess is available, a replenishment order is placed for the item.

- If the sourcing rule for the item is Buy from, the order is placed according to your selection in the Create Supply field and date in the Create Supply After field for the item in the Product Information Management work area. Or, the imported values are checked for the equivalent columns in the import template named Supply Chain Planning Items (ScpItemImportTemplate.xlsm).

- If the sourcing rule is Transfer from, the replenishment order is always placed.

- You can improve customer satisfaction.

For example, during a period of high demand in the retail industry, you can configure item B as a substitute for item A. If the supply for item A on a particular day is three units, and the demand is four units, then one unit of item B is used for fulfilling the demand for item A.

- You can configure analysis hierarchies for items with bidirectional relationships.

An analysis hierarchy is a Product dimension hierarchy that consists of a catalog,

categories (primes), and associated items. You can use these categories in tables

and graphs to view the results of replenishment planning at the aggregate (prime)

level for your substitution or supersession chains.

The analysis hierarchy feature is especially useful in the service parts industry.

Additional Things to Consider When You Implement End Item Substitution and Supersession

When you implement end item substitution and supersession, here are some additional things to consider:

- In a replenishment plan that's enabled for incremental planning and end item substitution and supersession, if an item with a change in net supplies and demands is a part of a substitution or supersession chain, the entire chain is replanned.

- If you enable your replenishment plan for end item substitution and supersession and simulate a change to the policy parameters, policy values, supplies and demands, or attributes for an item-location combination, the entire substitution or supersession chain is replanned.

- You can use the feature for end item substitution and supersession in a plan

that's enabled for multiechelon replenishment planning.

The supply of the substitute or supersession item at a source location can be used for meeting the requirement for the demanded item at the destination location. A planned order is created for moving the substitute or supersession item from the source location to the destination location. At the destination location, substitute supply is created for the demanded item, and substitute demand is created for the substitute or supersession item.

The item relationship at the destination location is respected. If the item relationship at the destination location isn't the same as that at the source location, then substitution or supersession isn't performed.

- These are the two order types that represent supplies and demands for end item

substitution and supersession in the Supplies and Demands table:

- Substitute supply

- Substitute demand

The Firm Date, Firm Quantity, and Firm Status columns in the table aren't editable for these order types.

- You can view information about end item substitution and supersession in these

columns in the Supplies and Demands table:

- Requested Item

- Requested Item Description

- Supplied Item

- Supplied Item Description

- For a substitution or supersession chain, Oracle Replenishment Planning builds

implied relationships so long as the relationships in the chain are only

substitution relationships or only supersession relationships. Replenishment

Planning doesn't build implied relationships for a chain that contains both

substitution and supersession relationships.

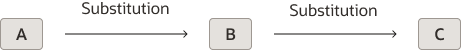

Consider a substitution chain with items A, B, and C, in which B is a substitute of A, and C is a substitute of B. The following figure depicts this substitution chain:

For this substitution chain, Replenishment Planning builds an implied substitution relationship between C and A.

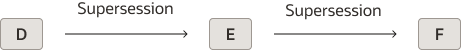

Consider a supersession chain with items D, E, and F, in which E supersedes D, and F supersedes E. The following figure depicts this supersession chain:

For this supersession chain, Replenishment Planning builds an implied supersession relationship between F and D.

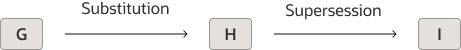

Consider a chain with items G, H, and I, in which H is a substitute for G, while I supersedes H. The following figure depicts this chain:

For this chain, Replenishment Planning won't build any implied relationship between I and G. However, Replenishment Planning builds the substitution relationship between H and G and supersession relationship between I and H.

- The items belonging to the substitution or supersession chain can belong to different segments of the segment group for your replenishment plan.

- If the end date for an item revision is before the plan start date, then the item revision is ignored by the replenishment plan. The affected substitution or supersession chain isn't considered by the replenishment plan, and the items are individually planned.