Example of Supply Chain Cost Rollup for Discrete Manufacturing

This example illustrates how the unit cost of an item in discrete manufacturing is calculated by the Roll up Costs process when using supply chain cost rollup.

Scenario

Organization ZQD is manufacturing the item SC_FP01. To manufacture this item, you need various other items. The items, their sourcing rules, and quantities are listed in this table:

| Item | Organization | Sourcing Rule | Source Organization | Allocation | Quantity |

|---|---|---|---|---|---|

| SC_FP01 | ZQD | Make | N/A | 100% | 1 |

| SC_F1 | ZQD | Buy | N/A | 100% | 10 |

| SC_SubPhantom1 | ZQD | Make | N/A | 100% | 5 |

| SC_Ph1 | ZQD | Buy | N/A | 100% | 25 |

| SC_Ph2 | ZQD | Buy | N/A | 100% | 25 |

| SC_SubAsmb1 | ZQD | Transfer | M1 | 100% | 1 |

The item SC_SubAsmb1 in the above table is made in the organization M1. The corresponding sourcing rules are listed in this table:

| Item | Organization | Sourcing Rule | Source Organization | Allocation | Quantity |

|---|---|---|---|---|---|

| SC_SubAsmb1 | M1 | Make | N/A | 100% | 1 |

| SC_A1 | M1 | Buy | N/A | 100% | 5 |

| SC_A2 | M1 | Buy | N/A | 100% | 5 |

As you can gather from the tables, the organization ZQD requires the items listed here to manufacture the finished item SC_FP01:

-

SC_F1 – ZQD buys this item and a standard or buy cost must be defined for this item.

-

SC_SubPhantom1 – ZQD makes this item and needs these items:

-

SC_Ph1 – ZQD buys this item and a standard or buy cost must be defined for this item.

-

SC_Ph2 – ZQD buys this item and a standard or buy cost must be defined for this item.

-

-

SC_SubAsmb1 – ZQD sources this from M1, which manufactures it with these items:

-

SC_A1 – M1 buys this item and a standard or buy cost must be defined for this item.

-

SC_A2 – M1 buys this item and a standard or buy cost must be defined for this item.

-

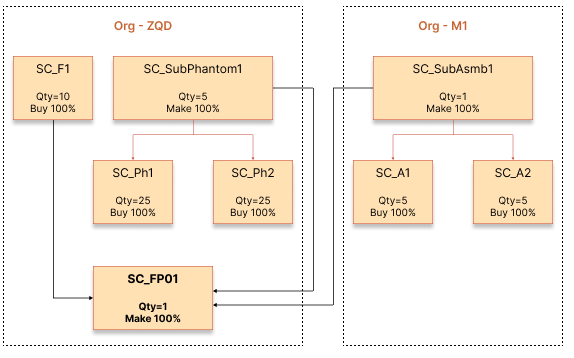

Apart from these materials, you also require various other resources to manufacture this item. Here's an image illustrating the overall manufacturing flow for the finished item SC_FP01.

For this item, you create the work definitions.

| Item | Work Definition Name | Version | Date |

|---|---|---|---|

| SC_FP01 | ZQD_Final | 1 | 11/1/2023 |

| SC_SubAsmb1 | Main | 1 | 11/1/2023 |

Let's assume that the batch size of the work definition output is 1 each (primary UOM of these items).

Cost Scenario, Standard Costs, Resource Rates, and Overhead Rates

Now, to calculate the unit cost of SC_FP01, you start by creating a cost scenario. You must make sure that the effective start date of the cost scenario is same as or later than the work definition start date. Also, ensure that the settings listed here are made in the cost scenario:

-

Enable Supply Chain Cost Rollup – Select this option.

-

Organization Context – Group

-

Cost Rollup Group – Select a cost rollup group that you've created with the cost organization and cost book combinations for the ZQD and M1 organizations respectively.

-

Effective Date – 11/1/2023

-

Assignment Set Name – Select the assignment set in which you have set the sourcing type for all the items. Also, ensure that you’ve defined the various sourcing rules. The sourcing rules must be planning enabled and linked to the assignment set. Also, check whether active supply sourcing rules with total allocation of 100% exist as of the scenario effective date.

Note: You must run the Extract Supply Sources process for the assignment set before running the Roll up Costs process. -

Transfer Charge Rule Set – Select the rule set with the transfer charge rule for transfer from M1 to ZQD. Let’s assume you've defined a 2% transfer charge rule.

-

Rollup Scope – Select Items. Add the items listed here:

-

SC_SubAsmb1

-

SC_SubPhantom1

-

SC_FP01

-

-

Use Latest Work Definitions – Select this option to use the latest version of active work definition in the manufacturing organization.

Next, you must define the standard costs for the materials used, the rates for the various resources used when manufacturing the item, and the overheads incurred.

Standard Costs

| Item | Valuation Unit | Buy Cost | Cost Element | Cost Element Type | Expense Pool | Unit Cost ($) |

|---|---|---|---|---|---|---|

| SC_F1 | ZQD-Org1 | Yes | ||||

| P2P-Material | Material | 9.80 | ||||

| P2P-OH | Overhead | P2P_Exp_Pool | 1.43 | |||

| 11.23 | ||||||

| SC_Ph1 | ZQD-Org1 | No | ||||

| P2P-Material | Material | 10.00 | ||||

| P2P-OH | Overhead | P2P_Exp_Pool | 2.15 | |||

| 12.15 | ||||||

| SC_Ph2 | ZQD-Org1 | Yes | ||||

| P2P-Material | Material | 5.35 | ||||

| P2P-OH | Overhead | P2P_Exp_Pool | 1.45 | |||

| 6.80 | ||||||

| SC_A1 | M1-Org1 | Yes | ||||

| P2P-Material | Material | 2.65 | ||||

| P2P-OH | Overhead | P2P_Exp_Pool | 0.75 | |||

| 3.40 | ||||||

| SC_A2 | M1-Org1 | Yes | ||||

| P2P-Material | Material | 20.00 | ||||

| P2P-OH | Overhead | P2P_Exp_Pool | 2.00 | |||

| 22.00 |

-

For SC_Ph1, Buy Cost isn't selected. You are defining a standard cost for this item that can be used to cost inventory transactions in Cost Accounting. When you select Buy Cost, the buy cost will be used by the Roll up Costs process to calculate the standard cost of the item only if the cost scenario is enabled for supply chain cost rollup and a buy sourcing rule exists for the item in the sourcing assignment. The buy cost is never used to cost inventory transactions in Cost Accounting.

-

Ensure that you select the appropriate cost organization and cost book combination for the items made or used by the ZQD and M1 organizations respectively.

Resource Rates

| Resource | Plant | Cost Element | Cost Element Type | Expense Pool | Unit Cost ($) |

|---|---|---|---|---|---|

| SC_ZQD_Res1 | ZQD-Mfg | ||||

| P2P-Resource | Resource | P2P_Res_Pool | 7.00 | ||

| Res-OH-2 | Overhead | RS_OH_Exp | 2.99 | ||

| 9.99 | |||||

| SC_M1_Res1 | M1-Mfg | ||||

| P2P-Resource | Resource | P2P_Res_Pool | 5.00 | ||

| Res-OH-2 | Overhead | RS_OH_Exp | 0.35 | ||

| 5.35 |

Overhead Rates

| Plant | Overhead Rate Type | Item | Cost Element | Expense Pool | Absorption Type | Rate |

|---|---|---|---|---|---|---|

| M1-Mfg | Work center overhead | SC_SubAsmb1 | Res-overhead | WC-OH | Percentage | 10% |

| ZQD-Mfg | Plant overhead | N/A | Plant_OH | P1-OH | Fixed | $50.00 |

| ZQD-Mfg | Plant overhead | N/A | Plant_OH | P1-OH | Percentage | 20% |

Analysis

After you define the cost scenario and the corresponding standard costs, resource rates, overhead rates, run the Roll up Costs process for the cost scenario.

Rolled Up Costs

Let's start with identifying the costs for the items SC_SubAsmb1, SC_SubPhantom1, and SC_FP01.

The item cost calculation for SC_SubAsmb1 is as shown here.

| Operation Sequence | Component/Resource | Cost Element Type | Unit Cost | Quantity | Amount |

|---|---|---|---|---|---|

| SC_SubAsmb1 | 138.70 | 1 | 138.70 | ||

| 10 | SC_A1 | Material | 2.65 | 5 | 13.25 |

| Overhead | 0.75 | 5 | 3.75 | ||

| 10 | SC_A2 | Material | 20.00 | 5 | 100.00 |

| Overhead | 2.00 | 5 | 10.00 | ||

| 10 | SC_M1_Res1 | Resource | 5.00 | 2 | 10.00 |

| Overhead | 0.35 | 2 | 0.70 | ||

| 10 | Work center overhead | Overhead | 1.00 | 1 | 1.00 |

The item cost calculation for SC_SubPhantom1 is as shown here.

| Operation Sequence | Component/Resource | Cost Element Type | Unit Cost | Quantity | Amount |

|---|---|---|---|---|---|

| SC_SubPhantom1 | 160.10 | 1 | 160.10 | ||

| 10 | SC_Ph1 | Material | 10.00 | 5 | 50.00 |

| Overhead | 2.15 | 5 | 10.75 | ||

| 10 | SC_Ph2 | Material | 5.35 | 5 | 26.75 |

| Overhead | 1.45 | 5 | 7.25 | ||

| 10 | Plant overhead | Overhead (Fixed) | 50.00 | 1 | 50.00 |

| 10 | Plant overhead | Overhead (Percentage) | 15.35 | 1 | 15.35 |

The percentage plant overhead in the table is defined at 20%. That's 20% of the material cost. The material cost equates to sum of the material cost multiplied by the quantity.

Overhead = 0.2 * [5 * (10.00 + 5.35)]

Overhead = 0.2 * [76.75] = 15.35

The item cost calculation for the final product SC_FP01 is as shown here.

| Operation Sequence | Component/Resource | Cost Element Type | Unit Cost | Quantity | Amount |

|---|---|---|---|---|---|

| SC_FP01 | 817.10 | 1 | 817.10 | ||

| 10 | SC_F1 | Material | 9.80 | 10 | 98.00 |

| Overhead | 1.43 | 10 | 14.30 | ||

| 10 | SC_Ph1 | Total cost from phantom | 60.75 | 5 | 303.75 |

| 10 | SC_Ph2 | Total cost from phantom | 34.00 | 5 | 170.00 |

| 10 | SC_SubAsmb1 | Total cost from subassembly + transfer charge rule | 141.47 | 1 | 141.47 |

| 10 | SC_ZQD_Res1 | Resource | 7.00 | 2 | 14.00 |

| Overhead | 2.99 | 2 | 5.98 | ||

| 10 | Plant overhead | Overhead (Fixed) | 50.00 | 1 | 50.00 |

| 10 | Plant overhead | Overhead (Percentage) | 19.65 | 1 | 19.60 |

The percentage plant overhead in the table is defined at 20%. That's 20% of the material cost. The material cost equates to sum of the material cost multiplied by the quantity.

Overhead = 0.2 * [10 * (9.8)]

Overhead = 0.2 * [98] = 19.60

Also, the cost for the item SC_SubAsmb1 must include the 2% transfer charge. So the item cost is,

1.02 * 138.70 = 141.47

When you view the rolled up cost for the product, you'll notice that the phantom subassembly isn't shown directly, instead the phantom is expanded to show its components as if they're going into the higher-level assembly.