Consider Your Lead Times

Consider how your lead times affect promising.

The Create Bills of Resources scheduled process populates the Lead Time Offset attribute for each item.

If you set the sourcing rule for your item to Make At, then the Lead Time Offset will include the time it takes to process and post process the item. If you specify that the item is critical, and if the item resides in more than one level below the manufactured item, then your lead time offset will account for the lead times of the intermediate items, even if they aren't critical.

Assume your lead times will include Taiwan, Los Angeles, and Denver.

- Taiwan transfers the critical CM153 chip to Los Angeles.

- Los Angeles uses the CM153 that it gets from Taiwan to assemble the noncritical AS301 motherboard.

- Los Angeles assembles the AS301 motherboard into the AS54888 computer, which is the final assembled item.

The lead time will include:

- Processing lead time and postprocessing lead time that Taiwan needs to make the CM153 chip, plus:

- Transfer lead time to get the CM153 chip from Taiwan to Los Angeles according to the default shipping method that you set up between Taiwan and Los Angeles, plus:

- Processing and postprocessing lead time that Los Angeles needs to install the CM153 chip onto the AS301 motherboard, plus:

- Processing and postprocessing lead time that Los Angeles needs to install the AS301 motherboard into the AS54888 computer, plus:

- Transfer lead time to get the AS54888 from Los Angeles to Denver.

In summary, the lead time is different depending on what you're doing.

| What You're Doing | How Long it Takes |

|---|---|

| Assemble an item in the same organization where you make it |

|

| Assemble the item and its subassemblies at the same organization |

|

| Transfer an item from an upstream organization to a downstream organization |

|

| Transfer the assembly and subassemblies from an upstream organization to a downstream organization |

|

Detailed Lead Time Example

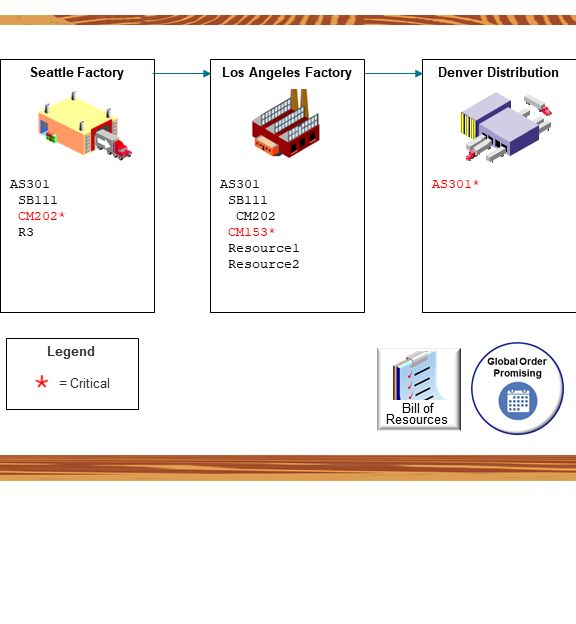

Consider this flow.

Note

- The assembled AS301 item is critical in the Denver Distribution Center.

- Subassembly SB111 in the Los Angeles Factory isn't critical.

- The CM202 item in the Seattle Factory is critical, and it is two levels below the AS301.

- The CM153 item in Los Angeles is critical, and it is one level below the AS301.

- You have done all the required Promising setups, such as sourcing rules, assignment sets, ATP rules, and so on.

Here are your transit times between facilities.

| From | To | Transit Time |

|---|---|---|

| Los Angeles | Denver | 2 |

| Seattle | Los Angeles | 3 |

Here are your lead times.

| Item | Organization | Critical | Processing Lead Time | Postprocessing Lead Time |

|---|---|---|---|---|

| AS301 | Denver | Yes | 2 days | 4 days |

| AS301 | Los Angeles | No | 2 days | 3 days |

| SB111 | Los Angeles | No | 1 day | 1 day |

| SB111 | Seattle | No | 1 day | 1 day |

Here are the lead times that the scheduled process creates in your bill of resources.

| Assembly | Assembly Organization | Component | Component Organization | Lead Time |

|---|---|---|---|---|

| AS301 | Denver | CM202 | Seattle | 17 days |

| AS301 | Denver | CM153 | Los Angeles | 11 days |

Here's the calculation for the CM202's 17 day lead time.

| Lead Time Calculation for the CM202 | Running Total |

|---|---|

| 1 day processing plus 1 day postprocessing for the SB111 in Seattle equals 2 days | 2 |

|

3 days transit time to get from Seattle to Los Angeles

|

2 + 3 = 5 |

| 1 day postprocessing for the SB111 in Los Angeles | 5 + 1 = 6 |

| 2 days processing plus 3 days postprocessing for the AS301 in Los Angeles equals 5 more days | 6 + 5 = 11 |

| 2 day transit time to get from Los Angeles to Denver | 11 + 2 = 13 |

| 4 days postprocessing for the AS301 in Denver | 13 + 4 = 17 |

Here's the calculation for the CM153's 11 day lead time.

| Lead Time Calculation for the CM153 | Running Total |

|---|---|

| 2 days processing plus 3 days postprocessing for the AS301 | 5 |

| 2 days transit time to get from Los Angeles to Denver | 5 + 2 = 7 |

| 4 days postprocessing for the AS301 | 7 + 4 = 11 |