How You Create a Configured Item Work Definition

Configure to Order (CTO) is the process of ordering and fulfilling configured products. The configured products, also referred as configured items, are either procured or made to order. The configured item work definition defines the manufacturing process to build the configured item.

Process to Create a Configured Item Work Definition

When Oracle Manufacturing receives a request to create a work order for the configured item:

-

First, it creates the configured item work definition.

-

Then, based on the configured item work definition, it creates the configured item work order

A configured item work definition is created dynamically using the primary ATO model work definition, selected options, and transactional item attributes. Unlike the ATO model work definition, the configured item work definition isn't saved in the database. Also, you can't create a work definition for a configured item manually or search for it in the user interface.

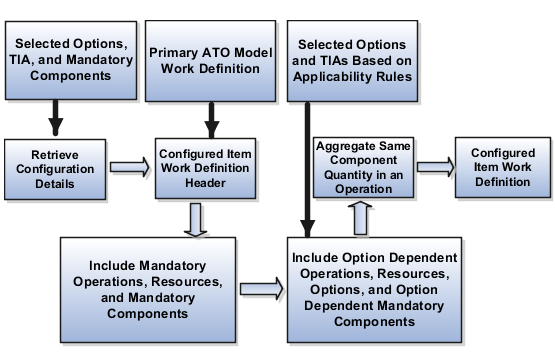

The following figure illustrates the steps to create a configured item work definition dynamically. First, the application retrieves the configuration details that include the selected options, TIA, and mandatory components. Then, the application creates the configured item work definition header based on the base ATO model work definition header. It includes all the mandatory operations, mandatory components, and related resources. Based on the options and transactional item attributes that are selected during the configuration process, it includes the corresponding option-dependent operations along with the optional components and related resources. The application also explodes standard items with supply type as phantom for the ATO model and includes the components that make up the phantom according to the item structure. A configured item work order is then created based on the configured item work definition. The parameter Phantom Operation Inheritance is applicable for standard item work order creation and not for configured item work order creation.

Example to Create a Configured Item Work Definition

The following example illustrates how a configured item work definition is created.

The following shows how a configured item is created from the item structure:

-

ATO MODEL 1

-

OPTION CLASS 1

-

OPTION 11: (selected option: Y)

-

OPTION 12

-

MANDATORY COMP 13

-

-

OPTION CLASS 2

-

OPTION 21: (selected option: Y)

-

OPTION 22

-

MANDATORY COMP 23 (Phantom)

-

-

-

MANDATORY COMP 23

-

COMP 231

-

COMP 232

-

The following table illustrates the various attributes of the work definition for ATO Model 1:

|

Operation Sequence |

Operation Name |

Option Dependent |

Operation Item |

Applicability Rule |

|---|---|---|---|---|

|

10 |

Assembly |

N |

MANDATORY COMP 3 OPTION CLASS 1 |

Blank |

|

20 |

Hand insertion |

Y |

OPTION CLASS 2 |

Blank |

|

30 |

Performance Test A |

Y |

Blank |

If OPTION 21 is selected |

|

40 |

Performance Test B |

Y |

Blank |

If OPTION 22 is selected |

|

50 |

Pack |

N |

MANDATORY COMP 4 |

Blank |

The following table illustrates the various attributes of the work definition for configured item ATO Model 1:1:

|

Operation Sequence |

Operation Name |

Operation Item |

|---|---|---|

|

10 |

Assembly |

MANDATORY COMP3 OPTION 11 |

|

20 |

Hand insertion |

OPTION 21 COMP 231 COMP 232 |

|

30 |

Performance Test A |

Blank |

|

50 |

Pack |

MANDATORY COMP 4 |

-

The quantity recorded on the sales order is the quantity that's used for selected options and child ATO models.

-

The quantity defined in Oracle Fusion Product Model is the quantity that's used for mandatory component.