Example of End Item Substitution and Supersession with Inventory Rebalancing

This topic contains an example of how end item substitution and supersession are performed with inventory rebalancing in a replenishment plan.

In this example, we have a cluster of four locations (organizations), M1, M2, M3, and M4. Also, we have two items, A, and B. Item B is a substitute for Item A.

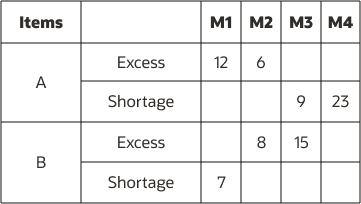

Calculation of Excess Inventory and Inventory Shortage for All Item-Location Combinations

The excess inventory and inventory shortage are calculated for all item-location combinations of the cluster according to the inventory rebalancing logic.

For Item A, Locations M1 and M2 have excess inventory of 12 units and 6 units respectively, and Locations M3 and M4 have an inventory shortage of 9 units and 23 units respectively.

For Item B, Locations M2 and M3 have excess inventory of 8 units and 15 units respectively, and Location M1 has an inventory shortage of 7 units.

The substitution and supersession chains are initially ignored.

The following figure depicts the excess inventory and inventory shortage for the locations:

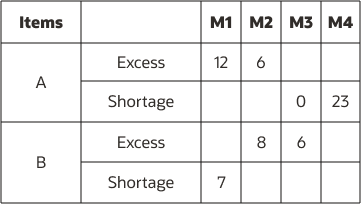

End Item Substitution and Supersession Within Each Location

End item substitution and supersession are then performed within each location.

For Location M3, the inventory shortage of 9 units for Item A is met from the excess inventory of 15 units for Item B because Item B is a substitute for Item A. The substitute supply for Item A is 9 units, and the substitute demand for Item B is 9 units. The remaining excess inventory for Item B is 6 units (15-9).

The following figure depicts the results of end item substitution and supersession within each location:

Inventory Rebalancing Across the Cluster

Inventory rebalancing is then performed for the locations across the cluster, and the substitution or supersession chains are ignored.

For Item A, the inventory shortage is 23 units at Location M4, and the excess inventory is 12 units and 6 units at Locations M1 and M2 respectively. Planned orders are created for transfer of this excess inventory to Location M4, after which the inventory shortage at Location M4 is 5 units.

For Item B, the inventory shortage is 7 units at Location M1, and the excess inventory is 8 units and 6 units at Locations M2 and M3 respectively. A planned order is created for the transfer of the excess inventory from Location M2 to Location M1, after which the excess inventory at Location M2 is 1 unit, and the inventory shortage at Location M1 is 0 units.

The following figure depicts the results of inventory rebalancing across locations of the cluster:

Inventory Rebalancing Across the Cluster with Substitute and Supersession Items

Finally, inventory rebalancing is performed for the locations across the cluster, and the substitute and supersession items are used for meeting inventory shortages.

Location M4 has an inventory shortage of 5 units for Item A, and Location M3 has excess inventory of 6 units for Item B. Therefore, a planned order of 5 units of Item B is created for meeting the inventory shortage of Item A at Location M4 because Item B is a substitute for Item A. The substitute supply for Item A is 5 units, and the substitute demand for Item B is 5 units. After this planned order, the inventory shortage of Item A at Location M4 is 0 units, and the excess inventory of Item B at Location M3 is 1 unit.

The following figure depicts the results of inventory rebalancing across the

locations of the cluster with the use of substitute and supersession items.