Examples of Project Netting

These examples help you understand how the planning process nets available supplies to project demands and creates planned orders for unmet demands:

-

Example 1 explains how the planning process performs project netting across different projects in a project group.

-

Example 2 explains how the planning process performs attribute-based netting with multiple project groups.

Example 1: Project Netting Across Different Projects in a Project Group

Let's assume that you have these setups for your attribute-based netting rule, item attributes, and project group:

| Item Attributes | ||

| Item Attribute | Value | |

| Hard pegging Level | Project and task | |

| Allow Use of Common Supplies | Yes | |

| Attributes for Planned Orders | ||

| Demand Grouping | Striping | |

| Project Group | Project Group | |

| Project | Project | |

| Task | Task | |

| Project Group | ||

| Project Group | Project | Task |

| Project Group 1 | Project P1 | Task P1T1 Task P1T2 |

| Project P2 | Task P2T1 | |

| Sequence Number | Demand Attribute | Demand Operator | Supply Attribute | Supply Operator |

| 1 | Project Group | Any | Project Group | Matches Demand Value |

| Project | Any | Project | Matches Demand Value | |

| Task | Any | Task | Matches Demand Value | |

| 4 | Project Group | Any | Project Group | Blank |

| Project | Any | Project | Blank | |

| Task | Any | Task | Blank |

Based on the netting sequences and their order defined in this example, the planning process has these options for project netting:

-

The planning process applies the first netting sequence step of attribute-based netting rule, Net project task supply, defined in your netting rule to allocate supplies to demands with matching project and task attributes. This means that the supplies with project P1 and task P1T1 can only be allocated to a demand with project P1 and task P1T1.

-

When no matching project and task supplies are available, the process applies the second netting sequence step of attribute-based netting rule to allocate the available common supply to project demands.

-

For unmet demands, the process recommends planned orders.

The planning process applies the netting sequences in the same order in each time bucket for attribute-based netting throughout the plan horizon.

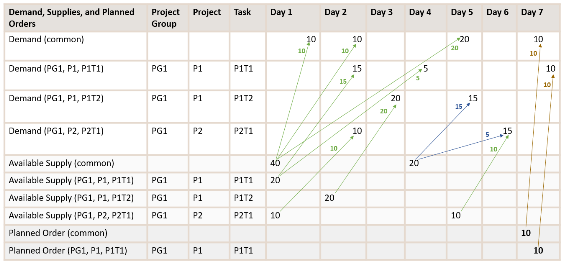

Here's a simple plan output that represents pegging of available supplies to demands and recommended planned orders.

Let's analyze the netting of supplies and demands in each time bucket.

|

Day |

Project Netting |

|---|---|

|

Day 1 |

The planning process pegs 10 units of common supply to 10 units of common demand (a demand without any project and task attributes). The remaining common supply after this pegging is 30 units. |

|

Day 2 |

The process identifies 20 units of (P1, P1T2) supply. The process pegs 10 units of common supply to 10 units of common demand. The remaining common supply after this pegging is 20 units. The process applies the first netting sequence step of the attribute-based netting rule to identify supplies and demands with matching project and task attributes. It pegs 15 units of (P1, P1T1) supply to 15 units of (P1, P1T1) demand. The remaining (P1, P1T1) supply after this pegging is 5 units. The process also pegs 10 units of (P2, P2T1) supply to 10 units of (P2, P2T1) demand. This pegging completely consumes the (P2, P2T1) supply. |

|

Day 3 |

The process applies the first netting sequence step of the attribute-based netting rule to peg 20 units of (P1, P1T2) supply to 20 units of (P1, P1T2) demand. This pegging completely consumes the (P1, P1T2) supply. |

|

Day 4 |

The process identifies an additional common supply of 20 units. The process applies the first netting sequence step of the attribute-based netting rule to peg 5 units of (P1, P1T1) supply to 5 units of (P1, P1T1) demand. This pegging completely consumes the (P1, P1T1) supply. |

|

Day 5 |

The process pegs 20 units of common supply to 20 units of common demand. The remaining common supply after this pegging is 20 units. The process applies the second netting sequence step of the attribute-based netting rule for 15 units of (P1, P1T2) demand but doesn't find any supplies with matching project and task attributes. The process then applies the second netting sequence step of the attribute-based netting rule and pegs 15 units of the common supply to 15 units of (P1, P1T2) demand. The remaining common supply after this pegging is 5 units. |

|

Day 6 |

The process applies the first netting sequence step of the attribute-based netting rule to peg 10 units of (P2, P2T1) supply to 15 units of (P2, P2T1) demand. This pegging completely consumes the (P2, P2T1) supply. The process then applies the second netting sequence step of the attribute-based netting rule to peg 5 units of common supply to the remaining 5 units of (P2, P2T1) demand. This pegging completely consumes the common supply. |

|

Day 7 |

The process applies the second netting sequence step of the attribute-based netting rule for 10 units of (P1, P1T1) demand but doesn't find any supplies with matching project and task attributes. The planning process also applies the Net common supply netting sequence but doesn't find any common supplies. The process then recommends a common planned order for the unmet common demand and a project planned order for the unmet project demand. It then assigns the project and task values to the project planned order. |

Example 2: Project Netting with Multiple Projects

Let's assume that you have these setups for your attribute-based netting rule, item attributes, and project groups:

| Item Attributes | ||

| Item Attribute | Value | |

| Hard pegging Level | Project and task | |

| Allow Use of Common Supplies | Yes | |

| Fixed Order Quantity | 20 | |

| Attributes for Planned Orders | ||

| Demand Grouping | Striping | |

| Project Group | Project Group | |

| Project | ||

| Task | ||

| Project Group | ||

| Project Group | Project | Task |

| Project Group 1 | Project P1 | Task P1T1 Task P1T2 |

| Project P2 | Task P2T1 | |

| Project Group 2 | Project P3 | Task P3T1 |

| Sequence Number | Demand Attribute | Demand Operator | Demand Attribute Value 1 | Supply Attribute | Supply Operator |

| 1 | Project Group | Any | Project Group | Matches Demand Value | |

| Project | Any | Project | Matches Demand Value | ||

| Task | Any | Task | Matches Demand Value | ||

| 2 | Project Group | Any | Project Group | Matches Demand Value | |

| Project | Any | Project | Matches Demand Value | ||

| Task | Any | Task | Any | ||

| 3 | Project Group | Any | Project Group | Matches Demand Value | |

| Project | Any | Project | Any | ||

| Task | Any | Task | Any | ||

| 4 | Project Group | Equals | PG1 | Project Group | Blank |

| Project | Any | Project | Blank | ||

| Task | Any | Task | Blank |

Based on the netting sequences and their order defined in this example, the planning process has these options for project netting:

-

The planning process applies the first netting sequence step of the attribute-based netting rule, Net project task supply, defined in your netting rule to allocate supplies to demands with matching project and task attributes. This means that the supplies with project P1 and task P1T1 can only be allocated to a demand with project P1 and task P1T1.

-

When no matching project and task supplies are available, the process applies the second netting sequence step of the attribute-based netting rule. Because the Reservation Level in the rule is Project group, the planning process nets supplies that belong to any task in the same project group. This means that the supplies of any tasks of P1 can be allocated to any tasks of P1 because they're in the same group PG1.

- When no matching task supplies are available within the same project, the process applies the sequence number 3 netting step of attribute-based netting rule to net the supplies that belong to any project or any task within the same group. This means that the supplies of any tasks of P1 can be allocated to any tasks of P2 because they are in same group.

-

In the absence of any excess supplies within the project group, the process applies the fourth netting sequence step of the attribute-based netting rule to allocate the common supply to project demands.

-

For unmet demands, the process recommends planned orders.

The planning process applies the netting sequences in the same order in each time bucket for attribute-based throughout the plan horizon.

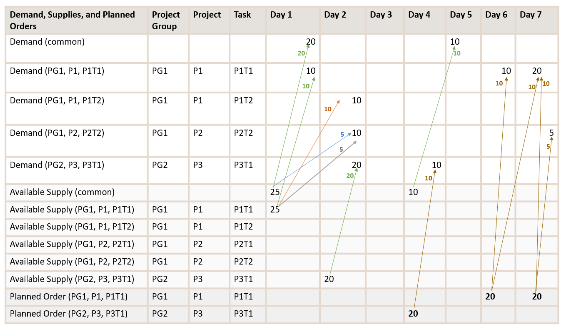

Here's a plan output that represents pegging of available supplies to demands and recommended planned orders.

Let's analyze the netting of supplies and demands in each time bucket of this plan.

|

Day |

Attribute-Based Netting |

|---|---|

|

Day 1 |

The planning process pegs 20 units of common supply to 20 units of common demand (a demand without any project and task attributes). The remaining common supply after this pegging is 5 units. The process applies the first netting sequence step of the attribute-based netting rule to identify supplies and demands with matching project and task attributes. It pegs 10 units of (P1, P1T1) supply to 10 units of (P1, P1T1) demand. The remaining (P1, P1T1) supply after this pegging is 15 units. |

|

Day 2 |

The process identifies 20 units of (P3, P3T1) supply. The process applies the first netting sequence step of the attribute-based netting rule to peg 20 units of (P3, P3T1) supply to 20 units of (P3, P3T1) demand. This pegging completely consumes the (P3, P3T1) supply. The process then applies the second and third netting sequence steps of the attribute-based netting rule to identify excess supplies from a project and task within the same project group. It pegs 10 units of (P1, P1T1) supply to 10 units of (P1, P1T2) demand. It also pegs 5 units of (P1, P1T1) supply to 10 units of (P2, P2T2) demand. This pegging completely consumes the (P1, P1T1) supply. The process then applies the fourth netting sequence step of the attribute-based netting rule to identify a common supply that it can peg to the remaining 5 units of (P2, P2T2) demand. The common supply is allocated to P2 project demand since it belongs to project group PG1. This project group is allowed to net common supply as per sequence number 4 netting sequence step of the attribute-based netting rule. The process then pegs 5 units of common supply to 5 units of (P2, P2T2) demand. This pegging completely consumes the common supply. |

|

Day 4 |

The process identifies an additional common supply of 10 units. The process applies the first, second, and third netting sequence steps of the attribute-based netting rule but doesn't find any matching or excess supplies. The process then applies the fourth netting sequence step of the attribute-based netting rule to identify a common supply that it can peg to 10 units of (P3, P3T1) demand. Because P3 belongs to project group PG2, and as per the fourth netting sequence step of the attribute-based netting rule, only project demands of project group PG1 can net common supply. For this 10 units of unmet demand, the process recommends a planned order. Because the fixed order quantity defined for the item is 20, the process creates a planned order of 20 units. |

|

Day 5 |

The process pegs 10 units of common supply to 10 units of common demand. This pegging completely consumes the common supply. |

|

Day 6 |

The process applies the first, second, third, and fourth netting sequence steps of the attribute-based netting rule but doesn't find any available supplies. For the 10 units of unmet (P1, P1T1) demand, the process recommends a planned order of 20 units after considering the fixed order quantity defined for the item. |

|

Day 7 |

The planning process aggregates unmet demands at the project group level to recommend planned orders. Because P1 and P2 belong to the same project group PG1, the process aggregates the unmet (P1, P1T1) demand and (P2, P2T2) demand. The process recommends a planned order of 20 units after considering the fixed order quantity defined for the item based on the attributes selected in Attributes for Planned Orders of the attribute-based netting rules. The process then assigns the project and task attribute to the planned order based on the attribute of the first demand, which is project P1 and task P1T1. |