Example of Supply Creation

The planning process aggregates unmet demands based on the attributes selected for Demand Grouping in Attributes for Planned Orders of the attribute-based netting rules. Let's understand this with an example.

Let's assume that the attribute-based netting rule and the item associated with the plan have these configurations:

-

Reservation Level: Project group

-

Item Hard Pegging Level: Project and Task

-

Item Fixed Order Quantity: 40

| Attributes for Planned Orders | |

| Demand Grouping | Striping |

| Project Group | Project Group |

| Project | |

| Task | |

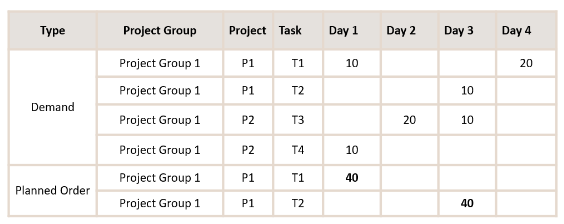

Here's the supply recommendation for unmet demands:

In this example, the planning process identifies an aggregated unmet demand of 20 units at the project group level on Day 1 and Day 3.

The process considers the fixed order quantity and creates a planned order of 40 units for Day 1 and Day 3. The planned orders acquire the project and task attributes of the first project demand.

The process allocates the remaining 20 units from Day 1 to the demand on Day 2 and 20 units from Day 3 to the demand on Day 4.