View Calendar Details Example: Work Order

This example describes a work order that has been rescheduled in, meaning the Suggested Due Date is earlier than the old due date.

Collected work orders are scheduled differently from the other order types. If planning didn't reschedule the work order, then the suggested dates seen in the Calendar Details window are the ones that were collected from the source system.

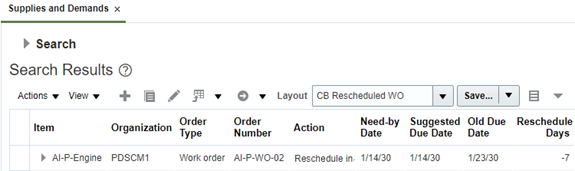

Looking at the order in the Supplies and Demands page, we can see the old dates (before rescheduling) as well as the new suggested dates. The Reschedule Days column displays the number of working days on the Organization Manufacturing Calendar that the work order was scheduled in or out. When the work order is rescheduled in, meaning the Suggested Due Date is earlier than the old due date, Reschedule Days will be a negative number. In this example, the work order has been rescheduled in by 7 working days on the Organization Manufacturing Calendar.

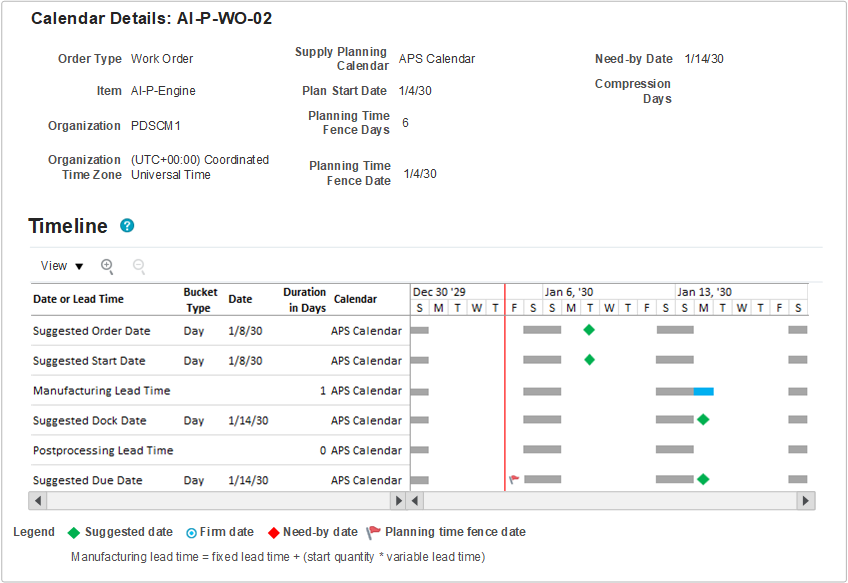

When looking at the Gantt chart of a work order, the Transit Lead Time and Suggested Ship Date rows aren't displayed. Make orders aren’t shipped or received, so these dates don’t factor into the scheduling of a make order (planned or otherwise). Because this an existing work order collected from the source system, Preprocessing Lead Time is not applied, so this row is also hidden.

The Organization Manufacturing Calendar is used in calculating all suggested dates and lead times of a work order.

The red vertical line in the Gantt chart represents the plan start date, which is also shown in the header field. This line is only visible when the plan start date is within the visible portion of the Gantt window.

When rescheduling a work order, planning doesn’t recalculate suggested dates by subtracting lead times. Instead, planning will adjust the suggested dates by subtracting the Reschedule Days from the collected dates, as described in the following table.

| Date or Lead Time Row | Value | Explanation |

| Suggested Due Date | January 14 |

In this example, planning has rescheduled the work order in by 7 days to meet the Need-by Date. So the Suggested Due Date is the same as the Need-by Date, which is January 14. When milestone dates overlap, the suggested date is always displayed on top in the Gantt chart. If you hover over the Suggested Due Date milestone, you can see that both the Need-by Date and Suggested Due Date are on January 14. The Need-by Date is also displayed in the header section for quick reference without having to hover. The calendar used in calculating the Suggested Due Date, as well as all other suggested dates, is the Organization Manufacturing Calendar. In this example, the calendar used is APS Calendar, which has Saturdays and Sundays as nonworking days, represented by gray bars in the Gantt chart. The planning bucket type for this date and all other dates is day. This lets you know that the Suggested Due Date didn’t get moved to the last working day of the planning bucket, which is what happens when planning in aggregate planning buckets. |

| Postprocessing Lead Time | 0 days |

The Postprocessing Lead Time’s duration in days value comes from the Items page and includes any simulation set overrides. In this case there’s no Postprocessing Lead Time defined, so there’s no bar in the Gantt chart that represents Postprocessing Lead Time. |

| Suggested Dock Date | January 14 | Instead of calculating a Suggested Dock Date using the item’s Postprocessing Lead Time, planning calculates a Suggested Dock Date by adjusting the old (also known as collected) dock date to be 7 working days earlier on the Organization Manufacturing Calendar. |

| Manufacturing Lead Time | 1 day |

The Manufacturing Lead Time’s duration in days value is calculated using the item’s fixed and variable lead time and includes any simulation set overrides, where Manufacturing Lead Time = Fixed Lead Time + (Start Quantity * Variable Lead Time). The Manufacturing Lead Time end date is set to the Suggested Dock Date. The start date of the Manufacturing Lead Time is calculated by subtracting the Manufacturing Lead Time from the end date of the Manufacturing Lead Time, counting only the working days. In this example, the Manufacturing Lead Time starts at the beginning of the day on Monday, January 14, and goes through to the end of that same day. |

| Suggested Start Date | January 8 |

The start date is Tuesday, January 8, which appears to be earlier than needed, given the Manufacturing Lead Time shown in the Calendar Details window. Instead of calculating a Suggested Start Date using the item's Manufacturing Lead Time, planning calculates a Suggested Start Date by adjusting the old (also known as collected) start date to be 7 working days earlier on the Organization Manufacturing Calendar. The work order start date established by the manufacturing execution source system considers various constraints, which unconstrained planning doesn't. So unconstrained planning tries to honor those constraints, as best as it can, by keeping the same number of working days between the supply dates. |

| Suggested Order Date | January 8 |

Because Preprocessing Lead Time isn’t applied to work orders, the Suggested Order Date is set to the Suggested Start Date. |