Examples of Using a Constrained Supply Plan as a Supply Schedule in a Multiechelon Replenishment Plan

This topic provides a simple example and a detailed example of the use of a constrained supply plan as a supply schedule in a multiechelon replenishment plan.

Simple Example

Consider a manufacturing organization named MFG that's being planned in a constrained supply plan and a distribution center named DC that's being planned in a multiechelon replenishment plan with a planning horizon of 13 days, as depicted by the following table:

| Day 1 | Day 2 | Day 3 | Day 4 | Day 5 | Day 6 | Day 7 | Day 8 | Day 9 | Day 10 | Day 11 | Day 12 | Day 13 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Supply at MFG | 15 | – | – | – | – | 20 | – | – | – | 25 | – | – | – |

| Transfer orders (MFG to DC) | – | 10 | – | – | – | – | – | – | – | – | – | – | – |

| Unconstrained planned orders (MFG to DC) | – | – | – | – | 25 | – | – | 20 | – | – | – | 30 | – |

| Constrained planned orders (MFG to DC) | – | – | – | – | – | 25 | – | – | – | 20 | – | – | – |

Note the following points:

- MFG has three supplies, one of 15 units on Day 1, one of 20 units on Day 6, and

one of 25 units on Day 10.

This information will be read by the replenishment plan after it's run with the Consider supply schedule checkbox selected on the Parameters tab in the Run Plan dialog box.

- DC has one transfer order and three unconstrained planned orders to be sourced

from MFG.

The transfer order has a ship date of Day 2 and is for 10 units.

The units and ship dates for the unconstrained planned orders are 25 units on Day 5, 20 units on Day 8, and 30 units on Day 12.

- When the replenishment plan is run with the Consider supply

schedule checkbox selected, orders are created as follows:

- The supply on Day 1 is used for fulfilling the transfer order on Day

2.

The supply is reduced to five units after the transfer order is fulfilled.

- A constrained planned order of 25 units is created on Day 6 for

fulfilling the unconstrained planned order of 25 units of Day 5.

The remaining supply of five units on Day 1 is used along with the supply of 20 units on Day 6 for fulfilling the unconstrained planned order of 25 units.

Two constrained planned orders of 5 and 20 units weren't created, and the constrained planned order of 25 units was created only when there was enough supply at MFG.

The supply at MFG is now zero.

- A constrained planned order of 20 units is created on Day 10 for

fulfilling the unconstrained planned order of 20 units on Day 8.

The constrained planned order couldn't be created earlier because a supply of 25 units was received by MFG on only Day 10. The supply at MFG is now reduced to five units.

- The supply on Day 1 is used for fulfilling the transfer order on Day

2.

- For the unconstrained planned order of 30 units on Day 12, no constrained planned order is created because there isn't enough supply at MFG in the planning horizon.

Detailed Example

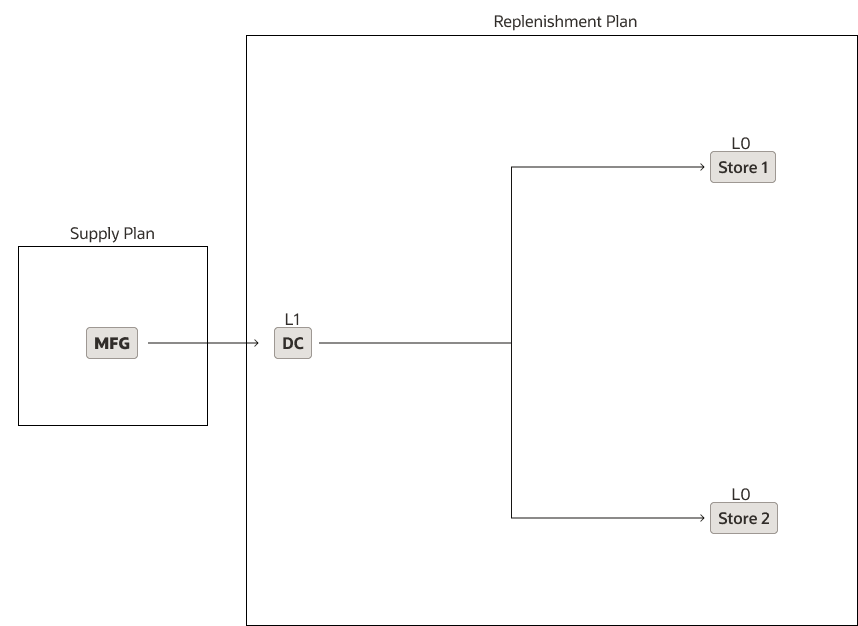

Consider a multiechelon replenishment plan for a distribution center named DC and two stores named Store 1 and Store 2 at the lower echelons. The low-level code for DC is 1, while the low-level code for Store 1 and Store 2 is zero. DC gets its supplies from a manufacturing center named MFG that's covered in a constrained supply plan. The following figure depicts this detailed example:

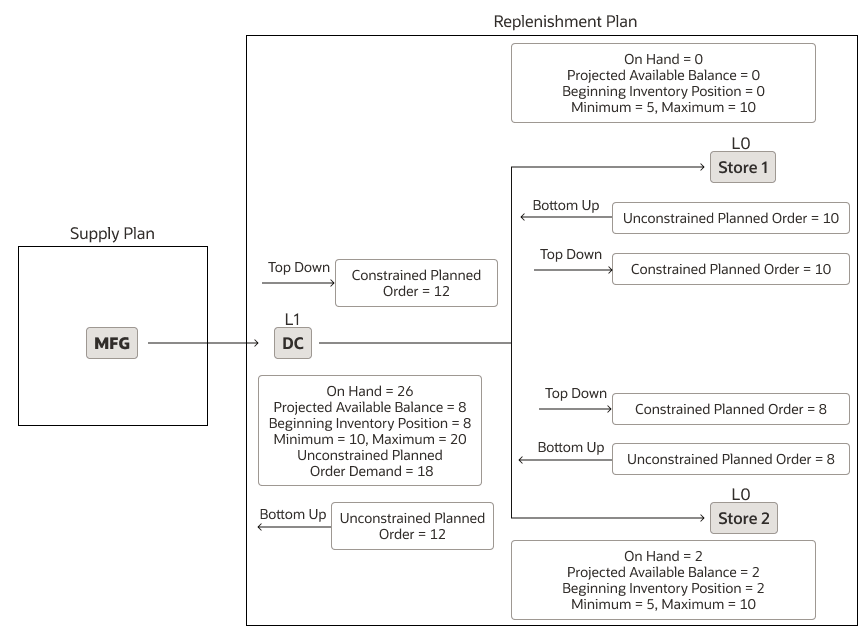

When the multiechelon replenishment plan is run for the first time with the Refresh with current data option selected and the Consider supply schedule checkbox not selected on the Parameters tab in the Run Plan dialog box, the result is as depicted in the following figure:

- For Store 1, the On Hand, Projected Available Balance, and Beginning Inventory Position measures are zero. The policy type is min-max planning, the minimum units are five, and the maximum units are 10.

- For Store 2, the On Hand measure, Projected Available Balance, and Beginning Inventory Position measures are 2. The policy type is min-max planning, the minimum units are five, and the maximum units are 10.

- After the bottom-up pass, an unconstrained planned order of 10 units is created

for Store 1. This quantity is required to bring the inventory up to the maximum

quantity.

Similarly, an unconstrained planned order of 8 units is created for Store 2. This quantity is required to bring the inventory up to the maximum quantity.

- For DC, the On Hand measure is 26. After the bottom-up pass, the demand for

unconstrained planned orders propagated from Store 1 and Store 2 is 18 units.

When this demand is met, the Projected Available Balance and Beginning Inventory

Position measures become 8.

The policy type is min-max planning, the minimum units are 10, and the maximum units are 20.

- After the bottom-up pass, an unconstrained planned order of 12 units is created for DC. This quantity is required to bring the inventory up to the maximum quantity.

- During the top-down pass, a constrained planned order of 12 units is created at

DC.

A constrained planned order of 10 units is created at Store 1, and a constrained planned order of 8 units is created at Store 2.

Only the lead times are considered when the constrained planned orders are created.

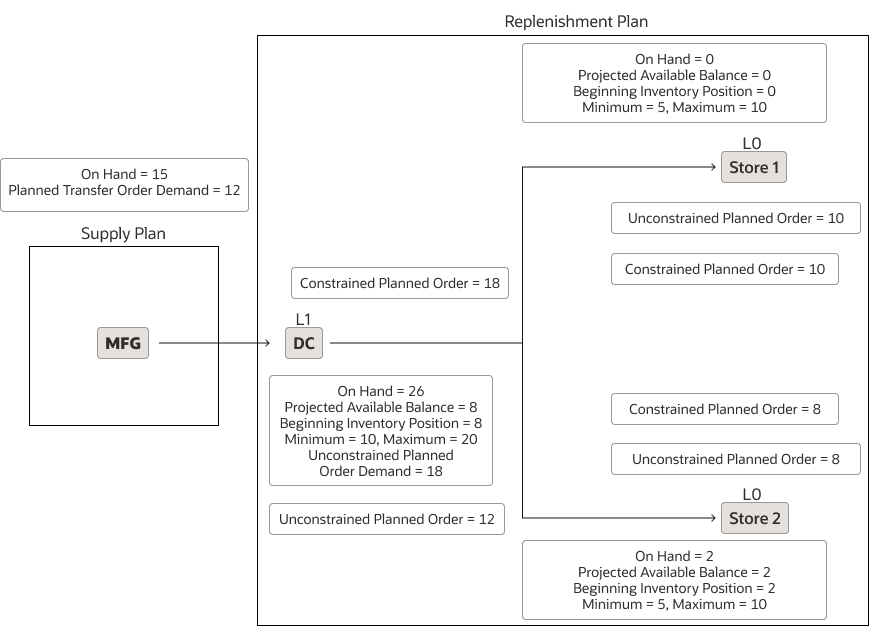

The constrained supply plan is run with the multiechelon replenishment plan selected as a demand schedule on the Organizations and Schedules subtab on the Supply tab on the Plan Options page. The result is as depicted in the following figure:

Note these points:

- For MFG, the On Hand measure is 15.

- The unconstrained planned order demand from the multiechelon replenishment plan is shown as 12 units for the Planned Transfer Order Demand measure for the constrained supply plan. The supplies that are pegged to the Planned Transfer Order Demand measure will be read by the multiechelon replenishment plan when it's run again.

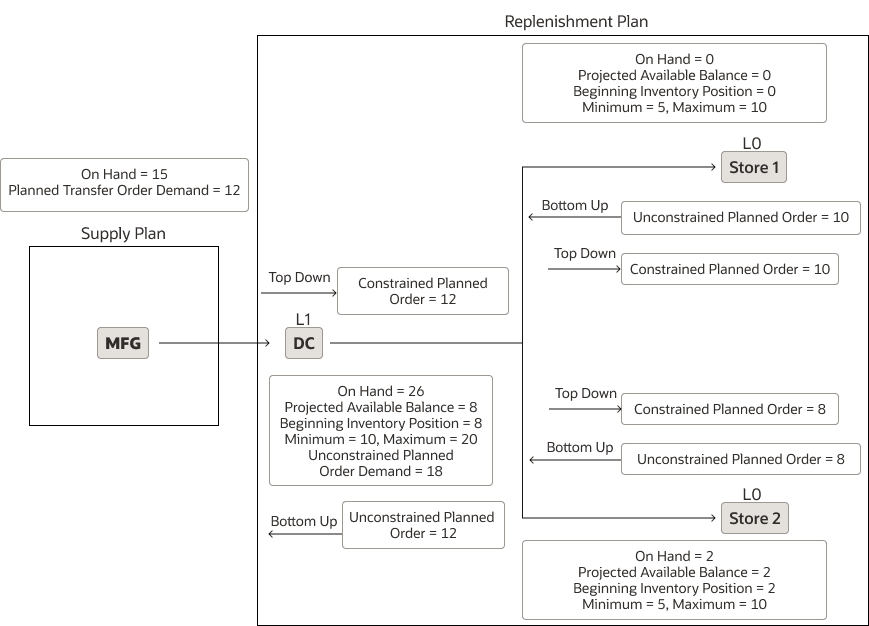

When the multiechelon replenishment plan is run for the second time with both the Refresh with current data option and the Consider supply schedule checkbox selected on the Parameters tab in the Run Plan dialog box, the result is as depicted in the following figure:

Note these points:

- The supplies that are pegged to the Planned Transfer Order Demand measure in the constrained supply plan are read by the multiechelon replenishment plan.

- After the bottom-up pass, the unconstrained planned orders at DC, Store 1, and Store 2 are 12, 10, and 8 respectively.

- After the top-down pass, the constrained planned orders at DC, Store 1, and Store 2 are 12, 10, and 8 respectively.

When the supplies and demands for the multiechelon replenishment plan change, the process must be repeated.