Workflow of Replenishment with Picking Wave

When replenishment is run with a picking wave, the system first identifies the order need. After the order need is determined, the system checks if the locations have the inventory. If the selected SKUs are available to satisfy the order need, then the system does not proceed with the replenishment process. However, once the need for replenishment is determined, the system looks for the source location by giving priority to the permanent locations. If the permanent location’s capacity is fulfilled, then the system finds a dynamic location to replenish.

- You need to configure the Replenishment Type on the item facility and a

search sequence by Replenishment type to Replenishment Zone configuration.

This provides flexibility to set similar items together while assigning them to

dynamic locations.

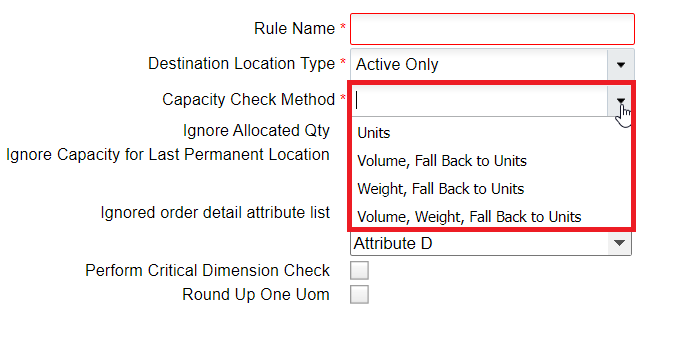

- Define capacity checks to assess how much can be replenished.

- On assessing the capacity, the system performs the capacity check based on

the configuration you select. You can choose to perform capacity check based

on any of the following methods:

- Upon assessing the capacity for reserve locations to perform replenishment, the system performs max volume and weight check, max units, and max LPN's check.

- The Replenishment Rule associated to a wave template indicates the system to search for any replenishment opportunities.

- On running the wave via a Wave Template, the system creates the replenishment allocation first based on the replenishment rule and then proceeds with the allocation phase.

- Typically, replenishment with a picking wave will always replenish to locations defined in allocation mode sequences for the wave template. Therefore, its crucial to configure the Allocation Mode in the Wave and define the picking locations. This provides flexibility for users to replenish locations where the picking takes place.

- After completing the Order selection phase, the system determines the total need required for each distinct SKU based on the Wave Search criteria in the Wave template. Then system calculates the required quantity needed to be replenished after considering the available inventory for each SKU in the locations. The system calculates the available inventory for the location as (In-transit + Current – Allocated).

- If there is a need to replenish, the system first searches for permanent active locations for the SKU. The source locations of the SKU are fetched based on the replenishment rule and the destination permanent locations will be picked from the allocation mode sequence.

- If Permanent Active Locations are full, then the system will search for Dynamic Active Locations for the SKU with inventory. Based on the location pick sequence, the available locations will be identified

- After replenishing SKUs to permanent location is complete and if there are no further outstanding needs, the replenishment for dynamic active locations will be invoked. Replenishment of dynamic active locations will be done until the order need is satisfied.

- On completing the replenishment phase, as part of the allocation phase, the system will provide the facility to allocate SKUs from In-Transit Inventory to the location. This allocated quantity is from the source location and apart from current quantity.

- As part of the task creation phase, the system will create replenishment tasks, along with the picking tasks. There will be a single task creation rule for the wave template.