6Extra Configuration

Sequence Counters

System counters keep track of record numbers (for example, ASN Numbers) that are automatically generated by the system. Additionally, sequence counters allow you to configure the record number generated for each label/document/output file, such as Inbound Shipment numbers, BOL numbers, and Outbound Load files.

You can only create new sequence counters by copying from existing ones. To do this, from the Sequence Counter screen, select the sequence counter that will be created, and click “Copy” ().

Description of Fields

- Sub_code: This field is used in conjunction with Company Parameter “OBLPN_COUNTER_SUB_CODE_FIELD”. See description of this parameter for details.

- Counter Description: The sequence counter description.

- Recycle_flg: When the max number (“End Number”) is reached in the current sequence counter, this flag determines whether or not the system automatically restarts the counter back to the “Start Number”.

- If CHECKED, WMS automatically resets the counter when the max number is reached.

- If UNCHECKED, WMS does not reset the counter when the “End Number” is reached. When this happens, you will not be able to create the new record until its sequence counter is reset.

If the current number is at 1,000 and the “Max Number” is 1,000, the system returns an error message when attempting to generate a new number.

- Prefix: Defines the prefix value that displays for the current record. For example, if the prefix is “BOL”, the system generates the number as “BOLXXXX”.

- Start/End Number: Defines the start and max number for the given sequence counter. When the End Number is reached, you must either reset the counter by checking the ‘recycle_flg’ or increase the “End Number” value manually.

- Nbr_suffix: Hardcodes a suffix to every sequence in that counter.

- Current Number: Denotes the current number that the sequence counter is on.

- Sequence Length: Denotes the string length of the sequence counter. Note that the prefix is NOT included in this count.

- Append Facility Code to Prefix: Flag that automatically appends the facility code to the sequence counter.

- Increment: The increment value in which the sequence counter increases.

- Check Digit Method: The method that calculates the last digit of the LPN number. Supported methods are SSCC, BOL, and EAN13.

- Destination Company/Facility: You can also make sequence counters exclusive to a Company and Facility. NOTE: Since this may lead to duplicate sequence counters, it is highly recommended to use a unique prefix for every Company/Facility sequence counter combination.

Barcode Types

You can also configure the company to have a fixed barcode format depending on the barcode type. The configurable barcode types are:

- Asset

- Seal

- Batch

- Cart

- Inbound LPN

- Inbound Shipment

- Item

- Location

- Outbound LPN

- Pallet

Description of Fields

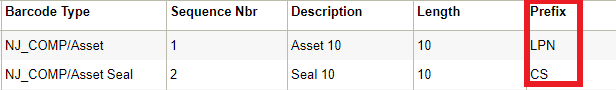

- Barcode Type: Denotes the barcode type that is being edited/created.

- Sequence Nbr: Used as a number identifier for a group of Barcode Types.

- Description: Displays the barcode type’s description.

- Length: Denotes the string length required for the barcode type. Note that the Prefix is included in this count. For example, if the Prefix = “LPN” and Length = 10, the system accepts the value “LPN0000001” (10 digits total). NOTE: If you want to disable to the barcode type validation in the system, the length must be set to “-1”. This will override any other configuration existing for that barcode type.

- Prefix: Denotes the prefix used for the barcode type.

- Remove Prefix: If this flag is checked, the barcode type ignores the “Prefix” field.

- Numeric_flg: Forces the barcode type to only accept numeric values.

Custom_barcode: Calls custom scanning logic for scanning inbound LPNs into the system.

Configuring Barcode Types

Barcode Types are used for situations where the company requires a fixed barcode prefix/length for a given label.

The configuration would be as follows:

With the configuration above, the system only accepts Inbound Containers that have the barcode of prefix LPN and CS. For example: “LPN0000001” & “CS00000001”. Scanning a barcode that is different from either one of these formats produces the following error message in the RF:

"Invalid Barcode for type IBLPN"

Printers

Types of Printers

Oracle WMS Cloud supports four types of printers/printing options:

- Label Printers: Oracle WMS supports the Zebra Printing Language, ZPL. Printers manufactured by Zebra as well as many other companies that support the ZPL printing language should work. The client is required to test it and verify that label printing works as expected. Some typical models in use by current clients are Zebra / ZM400, Zebra 105SL, INTERMEC /PD42. This application prints to label printers at client locations via network access that must be configured as described in the network configuration section below. These printers must be configured in the Oracle WMS application.

- Laser printers for reports:Report documents are typically generated as a PDF by the Oracle WMS application desktop web interface and can be printed to a local printer by the user. As such these printers typically do not need to be configured in the Oracle WMS application. If the ability to print certain PDF documents from the handheld RF interface is used, then laser printers also need to be setup in the application and accessed by the Oracle WMS application over the network similar to label printers.

- GDD Printers:These are dot matrix or line matrix printers that use the ESCP printing language. We have a GDD.txt that serves as a template and we generate the actual file to be printed based on this, (somewhat like the .lbl template) and then printed from the server via lp, just like for label printers. GDD printers also have to be defined on the server. These must be setup as network accessible printers similar to laser printers. Some sample models used by current clients are PRINTRONIX/P7220, EPSON / DFX 9000, EPSON / FX890, OKI/Pacemark 4410.

- Print to Email Address: You have the option to print to an email address. To set this up, configure the printer in the Printer screen with protocol (mailto) , domain / IP (John.doe@mail.xyz). Then in the User Config screen, in the Default Printer section (email: John.doe@mail.xyz). Next, log out and login and you should be able to print labels as emails.

Configuring Printers in the Printer UI

To configure Printers from the Printer UI, complete the following steps:

- From the Printer UI, click Create.

- Select the printer type (DOCUMENT, ZEB, ESCP.)

- Add the printer name.

- Add the description name.

- Choose the printer protocol (lpd, socket.)

- Add the domain_or_ip with printers IP.

- Add the port field.

- Add the printer_queue_name field, same as printer name.

- Click Save.

You need to configure Primary and Secondary IPs for your instance (PRODUCTION, PREPRODUCTION, UAT). These are provided by the Oracle WMS Cloud team.

The IP Addresses for the Oracle WMS Cloud Print Servers can be found in your welcome letter. If you do not have these you can log a SR with Oracle Support and request these. When you print a label from Oracle WMS Cloud, the print job leaves our cloud servers from these IP addresses to reach customer printers in a warehouse. Customer networks and more specifically firewalls need to make sure they can accept traffic from above two Oracle Cloud-WMS IPs.

Make sure you are allowing traffic within your firewall from these two IPs on a specific port. Those ports are customer defined. Default ports used are 9100 or 515 but they are controlled by the customer printer or print server configuration.

Additional Notes

- In case the Oracle WMS Cloud Print screen shows that the label printer status is ok but nothing gets printed, make sure that Oracle Cloud WMS Printer screen has the same protocol selected for the affected printer as configured on the customer print/print-server. If it does not match, you will see the behavior that nothing gets printed. If your physical printer/print-server is configured as LPD in the Oracle WMS Cloud Print screen, select the affected printer and make sure that the protocol is selected as LPD. The other protocol that is supported is Socket/Raw. Please make sure both ends match the protocol to avoid printing issues.

- Print Servers: We recommend that you use a print server to manage printers that the Oracle WMS application needs to access. Printers connected to an external dedicated print server (typically a Windows Server or a Linux Server) are more robust and can handle larger volumes of labels. Printers that use a built in print server (network card or dongle) may have trouble with higher volumes and may have issues with lost labels or repeated labels etc. Based on the expected volume and type of use the right choice must be made. For example, if you are going to routinely print dozens or hundreds of label at a time from the wave, they should have a dedicated print server to avoid problems. In addition, print servers avoid the need to have multiple public IP addresses for printers.

- Take into consideration that the print service is not encrypted.

Print Custom Reports from UI

If you have designed custom reports using Web Reports, you can trigger some of these custom reports directly from relevant UI screens instead of manually launching and printing them from Web Reports.

In order to achieve this, you need to configure these reports in the “Company Report Type” UI with a sub report type of “WebReport”.

Configure and Generate Custom WebReport for OBLPN Packing Slip

For example, if a custom OBLPN Packing Slip has been designed using Web Reports and if you need this custom report to be printed by clicking “Packing List” button on OBLPN UI, the following configuration needs to be in place.

- From the Web Report UI:

- Create a web report for category : “AllocationToContainer”.

- User can also add other categories with AllocationToContainer_ID

- From the Company Report Type UI select the following:

- Report type: OBLPN_PACKING

- “Report Sub Type” = WebReport

- “web report path” = folder_name\web_report_name ,OR folder_name/web_report_name

- “Web report format”: select your preference

- From the OBLPN Inquiry

- When you select single/multiple records and click on 'Packing List' button, the system generates the custom OBLPN packing slip for the selected record(s)

- o PDF format will be displayed in a Dashboard

- o CSV and XLS format will get auto-downloaded

- From RF Print Ship Label (Module: rf.outbound.cwrfprintshiplbl)

- When the screen parameter “print-packing-slip” is set as “OBLPN”, the system generates the custom OBLPN packing slip for scanned OBLPN in the “Output interface file UI.”

- When screen parm “print-packing-slip” is set as “Both” system generates the custom OBLPN packing slip for scanned OBLPN in “Output interface file UI”.

- Along with the OBLPN packing slip, system generates ORDER Packing Slip w.r.t the configuration mentioned below.

- When the screen parameter “print-packing-slip” is set as “OBLPN”, the system generates the custom OBLPN packing slip for scanned OBLPN in the “Output interface file UI.”

- From RF Print Packing Slip (Module: rf.outbound.cwrfprintlpnpackingslip)

- When the screen parameter “packing-slip-type” is set as “OB LPN packing”, the system generates the custom OBLPN packing slip for the scanned OBLPN in “Output interface file UI.”

- When the screen parameter “packing-slip-type” is set as “Both”, the system generates the custom OBLPN packing slip for the scanned OBLPN in the “Output interface file UI”.

- Along with the OBLPN packing slip, the system generates the ORDER Packing Slip with respect to the configuration mentioned below.

Configure and Generate Custom WebReport for ORDER Packing Slip

- From the Web Report UI:

- Create a web report for category: “Order”.

- You can also add other categories with Order_HDR ID

- From the Company Report Type UI:

- Report type: ORDER_PACKING

- “Report Sub Type” = WebReport

- "web report path" = folder_name\web_report_name ,OR folder_name/web_report_name

- "Web report format" : select as preference

- From theOrder Header View UI:

- When you select single/multiple records and click on the 'Packing Slip' button, the system generates the custom ORDER packing slip for the selected record(s)

- PDF format will be displayed in a Dashboard

- CSV and XLS format will get auto-downloaded

- From RF Print Ship Label (Module: rf.outbound.cwrfprintshiplbl)

- When the screen parameter “print-packing-slip” is set as “Order” system generates the custom ORDER packing slip for the Order associated with the scanned OBLPN in the “Output interface file UI”

- When the screen parameter “print-packing-slip” is set as “Both”, the system generates the custom ORDER packing slip for the Order associated with the scanned OBLPN in the “Output interface file UI”.

- Along with the ORDER packing slip, the system generates the OBLPN Packing Slip with respect to the configuration mentioned above

- From RF Print Packing Slip (Module: rf.outbound.cwrfprintlpnpackingslip)

- When the screen parameter “packing-slip-type” is set as “Order LPN packing”, the system generates the custom ORDER packing slip for the Order associated with the scanned OBLPN in “Output interface file UI”.

- When the screen parameter “packing-slip-type” is set as “Both”, the system generates the custom OBLPN packing slip for the Order associated with the scanned OBLPN in the “Output interface file UI”.

- Along with the ORDER packing slip, the system generates the OBLPN Packing Slip with respect to the configuration mentioned above.

Note: The generation of custom OBLPN/Order packing slip might fail:

- If the web report category is not valid

- If the web report category has a filter, which doesn’t match the RF scanned/UI selected record(s).

Reports Supported

“Company Report Type” UI supports sub report type “WebReports” for the following reports:

- OBLPN Packing Slip – Generated by clicking “Packing List” on the OBLPN UI. “OBLPN_PACKING” in “Company Report Type” needs to be configured with the sub report type “WebReports”.

- Order Packing Slip - Generated by clicking “Packing Slip” button on the Order Header UI. “ORDER_PACKING” in “Company Report Type” needs to be configured with sub report type “WebReports”

- Task Report – Generated by clicking “Task Reports” on the Wave Inquiry UI. “TASK” in “Company Report Type” needs to be configured with the sub report type “WebReports”.

- Inbound Receipt Report - Generated by clicking “Inbound Receipt” on the IB Shipment UI. “INBOUND_RECEIPT_REPORT” in “Company Report Type” needs to be configured with the sub report type “WebReports”.

- Pallet Packing List - Generated by clicking “Pallet Packing List” on the Pallet View UI. “PALLET_PACKING” in “Company Report Type” needs to be configured with the sub report type “WebReports”.

- Pick Travel Report - Generated by clicking “Pick Travel Report” on the Wave Inquiry UI. “PICK_TRAVEL” in “Company Report Type” needs to be configured with sub report type “WebReports”.

- Receiving Variance Report - Generated by clicking “Receiving Variance Report” button on the Appointment UI. “RCV” in “Company Report Type” needs to be configured with sub report type “WebReports”

- BOL - Generated by clicking “Bill of Lading” button on the OB Load UI. “BOL” in “Company Report Type” needs to be configured with sub report type “WebReports”

- Commercial Invoice - Generated by clicking “Commercial Invoice” on the OB Load UI. “COMM INV” in “Company Report Type” needs to be configured with sub report type “WebReports”.

- Export Shipment Packing List - Generated by clicking “Export Shipment Packing List” on the OB Load UI. “EXPL” in “Company Report Type” needs to be configured with the sub report type “WebReports”.

- Shipper’s Export Declaration - Generated by clicking “Shipper’s Export Declaration” on the OB Load UI. “SED” in “Company Report Type” needs to be configured with sub report type “WebReports”