3WFM Configuration

WFM Configuration

The following topics provide more details about configuring different parts of WFM:

User

In the past, in order to interface any data from WMS successfully into WFM, it was necessary to ensure that users that are created in WMS are also created in WFM (or interfaced into WFM). However with the merge of WMS WFM DB, there is single user view which is common to both WMS and WFM. Any user created in a WMS application is applicable to WFM as well.

For user creation, roles and permissions, refer to the WMS Online Help.

Team

A group of users performing same activities are categorized under a team. Teams are mainly created for VAS activities. Although users can clock individually or a as team to perform VAS activities, the measure of VAS activity performed is captured only at a team level using the Daily VAS Track view.

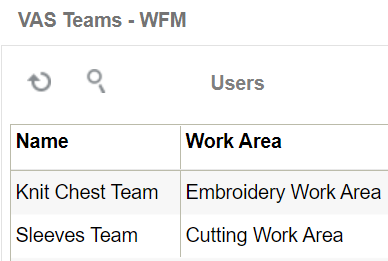

Teams View

Teams are created using the Teams view and each team is assigned to a Work Area which corresponds to a VAS activity. The same team could be assigned to multiple Work Areas. Also, multiple teams could be assigned to a Work Area.

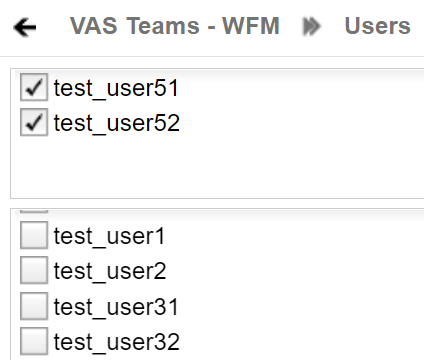

Assigning Users to a Team

To assign users to a Team, select the Team, example “Sleeves Team” and hit the Users button. This takes you to the next view with two frames that displays a list of all users configured in the application in the lower frame.

Select the users that need to be assigned to this Team. Checking the box moves the selected Team to the frame above. Hit save button.

SKU Line and SKU Line Group

Items in a warehouse are assigned to SKU Lines. Multiple SKU Lines are further grouped into SKU Line Groups. The groups could be determined based on the physical characteristics of the items and the effort required to handle the items. Placing items in different groups helps set the appropriate goal for each SKU Line Group.

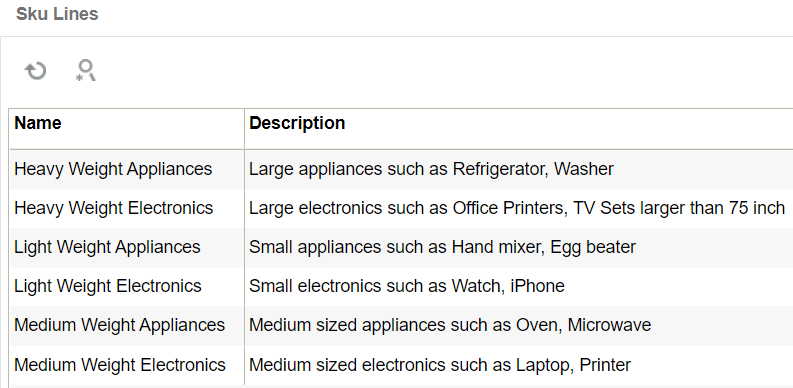

For example, appliances and electronic items in a warehouse could be categorized into SKU Lines and SKU Line Groups as shown below:

| Item | SKU Line | SKU Line Group |

|---|---|---|

| Watch | Light Weight Electronics | Light Weight Products |

| iPhone | ||

| Hand Mixer | Light Weight Appliances | |

| Egg Beater | ||

| Laptop | Medium Weight Electronics | Medium Weight Products |

| Microwave | ||

| Scanner | ||

| Printer | ||

| TV | ||

| Stove | Medium Weight Appliances | |

| Oven | ||

| Microwave | ||

| 84" Inch TV | Heavy Weight Electronics | Heavy Weight Products |

| Office Printer | ||

| Refrigerator | Heavy Weight Appliances | |

| Washer | ||

| Dryer |

In the above example, different goals can be set for each SKU Line Group. For example, it’s possible to handle 100 units of Light Weight Products in an hour. However it would probably take about 1 hour to move just 1 unit of a Heavy Weight Product.

SKU Line

SKU Lines are assigned to the items in WMS in the items view. In WMS items view, the Item Line field contains the SKU Line of an item. The same SKU Lines need to be defined in WFM using the SKU Line view.

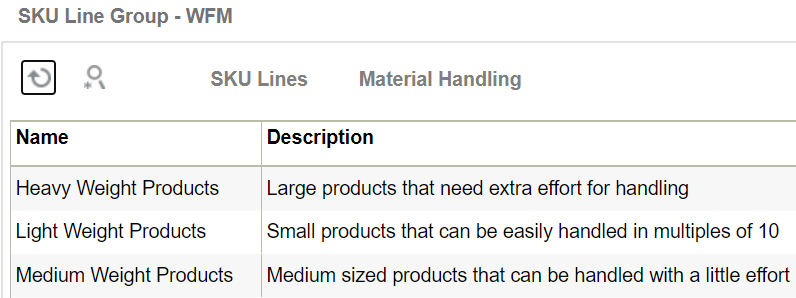

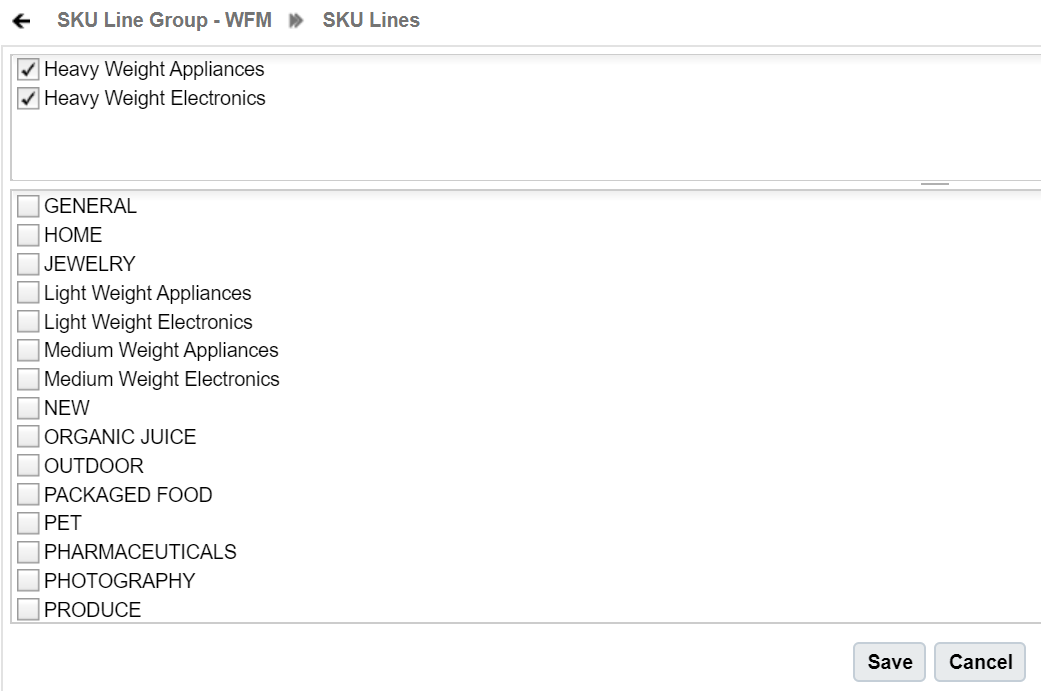

SKU Line Group

Each SKU Line is assigned to a SKU Line Group using the SKU Line Group view.

To assign SKU Lines to a SKU Line group, select the SKU Line group, example “Heavy Weight Products” and hit the SKU Line button. This takes you to the next view with two frames that displays a list of all SKU Lines configured in WFM in the lower frame.

Select the SKU Lines that need to be assigned to this SKU Line group. Checking the box moves the selected SKU Line to the frame above. Click Save.

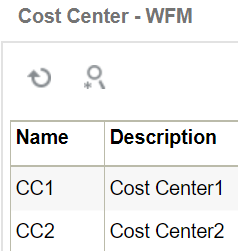

Cost Center

A single cost center or multiple cost centers can be created in a facility using the Cost Center view.

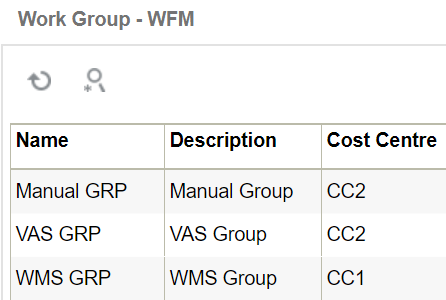

Work Group

A single work group or multiple work groups can be created within a cost center using the Work Group view.

Work Area

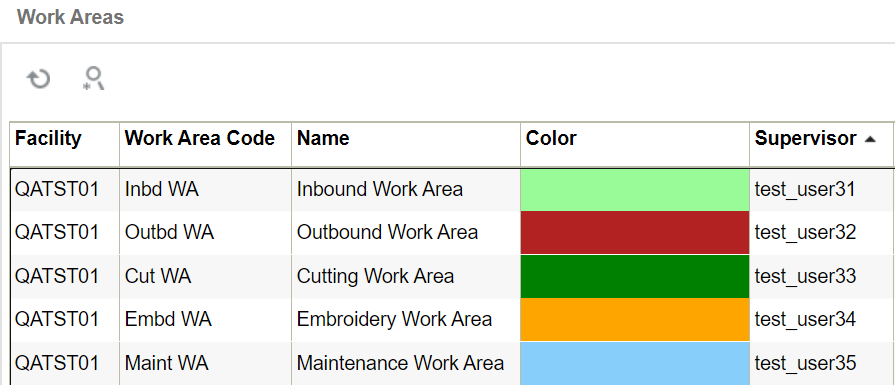

A single work area or multiple work areas can be created within a work group using the Work Area view. A supervisor could also be assigned to each Work Area.

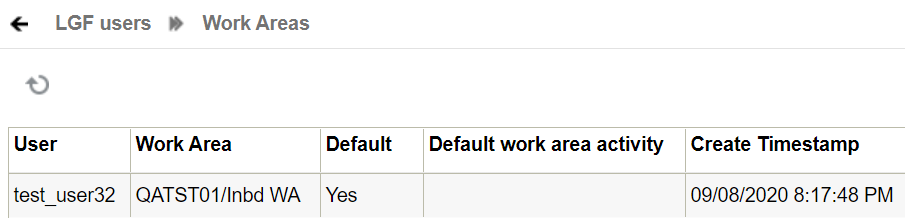

Every user that performs activities on the warehouse floor needs to be assigned to a Work Area. A user can be assigned to multiple Work Areas. Personnel that clock other users using WFM RF option should be assigned to at least one Work Area that is marked as a default. The Work Area button on Users view is used to assign a user to Work Areas.

To mark the Work Area as a default for the user, enable the Default checkbox in the create pane.

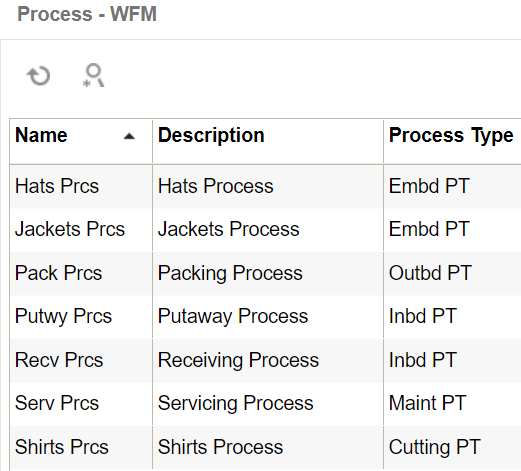

Process and Process Type

A set of related activities are grouped under a Process and multiple Processes are grouped into a Process Type. For example, the RF receiving options in WMS could be grouped under one Process. All Inbound activities such as Receiving and Putaway could be grouped under one Process Type.

Group Activity

Group Activities are associated with the activities in a Work Area.

Work Area Activities

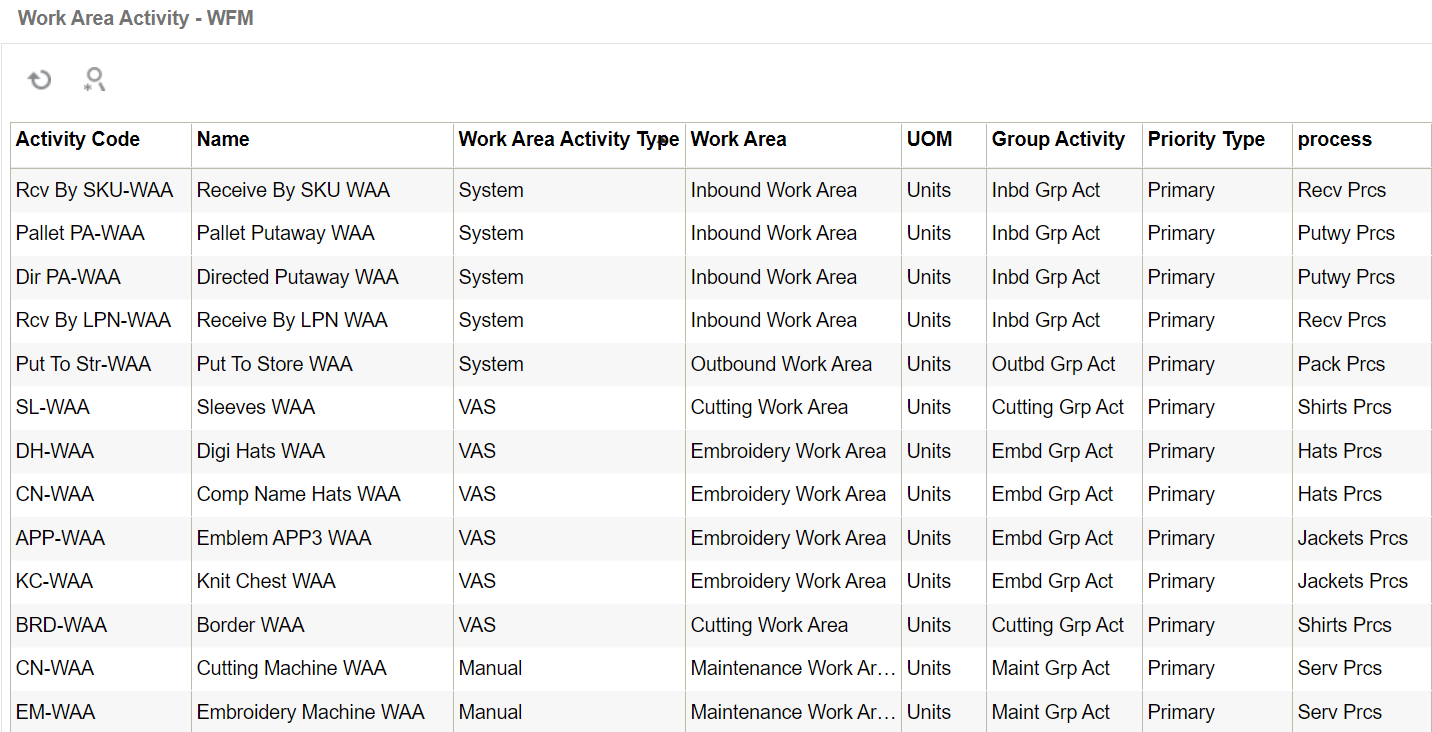

The three different activities that users could perform in a Work Area are System Activities, VAS Activities and Manual Activities. These are configured in WFM using the Work Area Activity view.

WMS Transaction

Since activities performed using WMS RF screens are considered as system activities, all such RF screens need to be associated with the System Work Area Activity in WFM. This association is made in the WMS Transaction view in WFM.

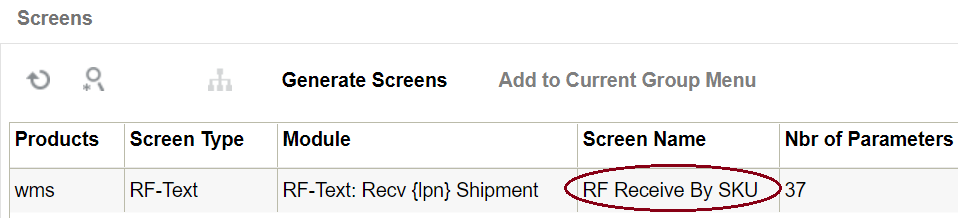

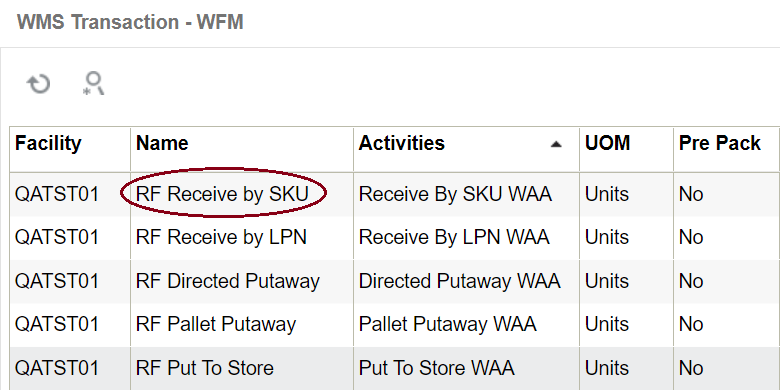

For example, assume that user needs to perform receiving by SKU. In WMS screens view, an RF screen “RF Receive by SKU” is configured.

In WFM, this screen is associated with a Work Area Activity using the WMS Transaction view. The name field in WMS Transaction view should exactly match with the screen name in WMS. If not, when data for such screens is extracted by WMS WFM Interface, it fails with the error “Unknown Transaction”

Goals

Since System and VAS Activities are productive, goals must be defined for each System and VAS Activity.

Goals for System Activities

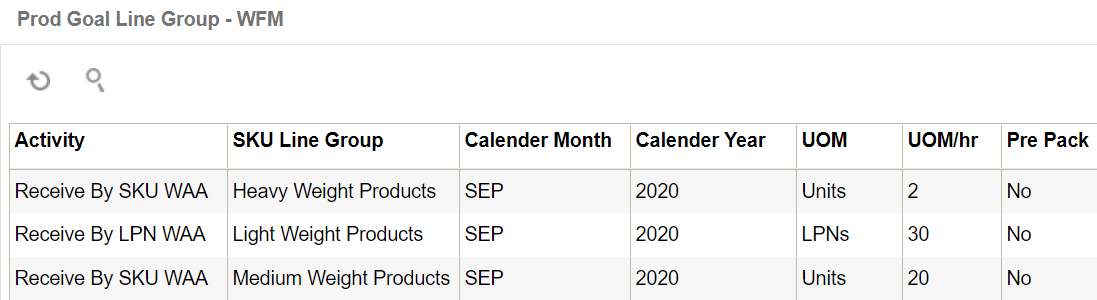

Goals for system activities are configured using the Prod Goal Line Group view.

Every system activity needs to have atleast one goal defined for each month of a year. The same activity could have different goals defined based on the SKU Line Group. For example, a user could receive 10 units of light weight products such as microwave or laptop in an hour. However, it could take about 1 hour for the user to receive just 1 unit of a heavy weight item such as a refrigerator. Therefore goals for each activity needs to be defined based on the SKU Line Group.

Goals for VAS Activities

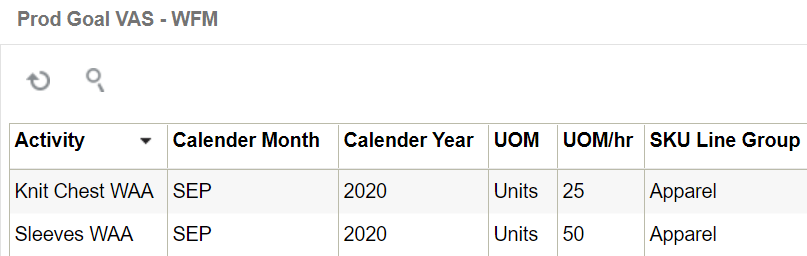

Goals for VAS activities are configured using the Prod Goal Line Group view.

Similar to system activity, every VAS activity needs to have atleast one goal defined for each month of a year. The same activity could have different goals defined based on the SKU Line Group.

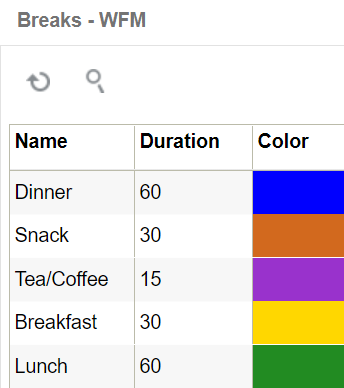

Breaks

Predetermined breaks are configured in WFM using the breaks view. A certain duration (in minutes) is allocated for each break. Users need to clock into the relevant break when they take time off from their activities for a break. This helps WFM calculate the actual time taken for a break versus the time allotted for the break.