Input Interface

Now with UOM support in Input Interfaces. Vendors will have the ability to send different entities with different UOM’s to the Warehouse Management. WMS converts the UOM sent by the vendor to the respective UOM tracked in the WMS. This change helps the floor users to track the WMS entities in their respective UOM.

New fields have been introduced for different entities to track the quantity/weight/volume/dimension

- uom_code ( This field will be used to specify the UOM sent for quantity)

- weight_uom_code

- volume_uom_code

- dimension_uom_code

- The uom sent in the quantity fields should be within the same uom class as the item’s primary uom. In case of multiple details, then you can send different UOMs provided it matches with primary UOM class of respective items.

Decimal Handling in Input Interface

- If Item & Item's Primary UOM class both are enabled for decimal handling, then system allows you to send & store the quantity value in decimal.

- If Item is not enabled for decimal handling & Items Primary UOM class is enabled for decimal handling, then system will not allow you to store decimal quantity.

- You can interface Quantity value in decimal, even though respective item's primary

UOM class is not tracking in decimal. Reason, the converted value may be in integer

based on the items primary UOM.Note: The system stores the quantity value based on decimal precision defined at the company level.

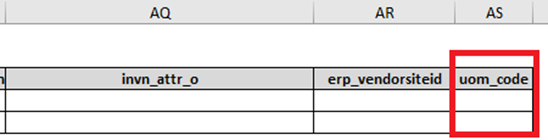

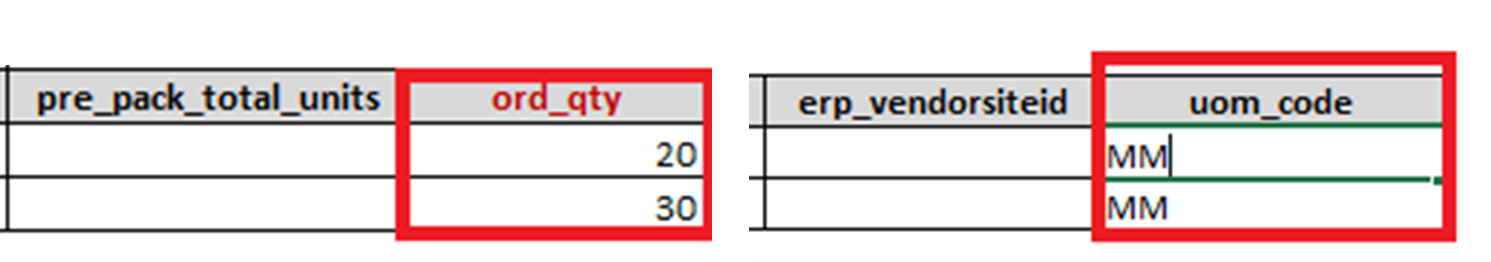

Defining UOM in the Interface File

- For example, in the Purchase Order Detail interface file, enter the ord_qty

value and define the uom_code in the respective columns.

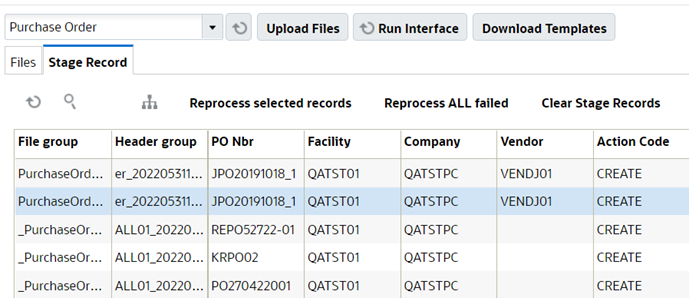

- Upload the interface file and Run Interface.Note: You can download the latest templates of the interface files from the Download Template folder.

- For pre-existing uom field, the supported UOM's are CASES, PACKS & UNITS which are limited to system class UOM and supports XML, XLS, PSV formats.

The newly supported UOM Fields are applicable for following input interface files:

- Purchase Order

- Inbound Shipment

- Order

- Item Prepack

- Work Order

- Location

- Outbound load

- Planned OB load

How Quantity Value and UOM is Captured

Let’s say you’re interfacing a Purchase Order and UOM Class is enabled for decimal tracking in below example:

| Item | Item Decimal Handling | PO Detail Qty | PO Detail UOM | Item Facility UOM | Converted Qty Value | Allow PO Detail Creation |

|---|---|---|---|---|---|---|

| ITM1 | Yes | 2.5 | KG | Grams | 2500 | Yes |

| ITM2 | Yes | 0.5 | Dozen | Each | 6 | Yes |

| ITM3 | No | 2.2 | Liters | Milliliters | 2200 | Yes |

| ITM4 | No | 0.8 | Milliliters | Milliliters | 0.8 | No |

| ITM5 | No | 500 | Milliliters | Liters | 0.5 | No |

- The PO is interfaced with 2.5 kilograms for ITM1 with decimal handling set to Yes.

- Based on the item facility UOM, the system converts 2.5 KG into decimal value of 2500 grams.

- Based on the converted value, the system creates the PO details.

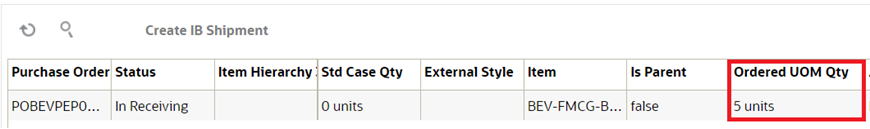

During Purchase Order interface, order quantity value is captured in the new column ordered_uom_qty and its respective UOM value (units, cases, packs) is captured in the column ordered_uom for the respective PO detail.

UOM Conversion during PO Interface for Quantity UOM (ord_qty)

Conversion, when UOM for the Item is defined with system UOM class (Units):

If you send Quantity UOM as Units during PO interface, then UOM conversion is not required. As Primary UOM for Item/Item facility for system class supports only Units as UOM.

Existing Behavior, where UOM as Packs & Cases:

When you send quantity UOM as Packs/Cases, then system converts the quantity value based on items Std Pack quantity/ Std Case quantity and store the value in terms of Item's facility Primary UOM.

Example:

If you want to continue with existing Package UOM of Packs & Cases.

- For "ITEM1" Primary UOM on the Item is Grams, Std Pack Quantity is 10 with Pack UOM defined as Packs. During PO interface, if Qty value is 5 Packs for ITEM1, then value should be saved as 5x10= 50 Grams.

- For "ITEM1" Primary UOM on the Item is Grams, Std Case Quantity is 30 with Case UOM defined as Case. During PO interface, if Qty value is 10 Cases for ITEM1, then value should be saved as 10x30= 300 Grams.

Standard conversion, When UOM for the Item is user defined UOM

- Item facility primary UOM is not defined on the item:

If Quantity UOM value is different from respective item's Primary UOM, then system converts the value to respective item's primary UOM.

- Item facility primary UOM is defined on the item:

If Quantity UOM value is different from item facility Primary UOM, then system converts the value to respective item facility specific primary UOM.

Example,

- Consider a company C1, operating in Facility F1 having item

"ITEM1" whose Primary UOM on the Item is defined as Grams. Whereas, the

facility primary UOM for ITEM1 is not defined with any value.

During PO interface for Company/Facility C1/F1, if Qty sent is 5 with quantity UOM of KG for ITEM1, then value should be saved as 5000 Grams (As per primary UOM defined on the Item).

- Consider a company C1, operating in Facility F5 having item

"ITEM2" whose Primary UOM on the Item is defined as Grams. Whereas, the

facility primary UOM for ITEM1 is defined as Pounds.

During PO interface for Company/Facility C1/F5, if Qty sent is 2 with quantity UOM of KG for ITEM1, then value should be saved as 4.41 Pounds (As per primary UOM defined on the Item Facility).

Pack UOM

When Quantity UOM on the PO detail is matching with the Pack UOM of respective item, then system considers Std Pack Quantity value for conversion. Convert the value into Items primary UOM then convert into item's facility primary UOM.

Example:

- During PO interface for Company/Facility C1/F5, if Qty sent is 5 with quantity UOM of Box for ITEMP1, then value should be saved as 5*15 = 75 Bottles.

Case UOM

Example:

Consider a company C1, operating in Facility F1 having item "ITEMP5" whose Primary UOM on the Item liters & Item facility primary UOM is defined as Gallon. Whereas, Case UOM for ITEMP5 is defined as Jar and standard case quantity is defined as 12.

UOM Conversion when UOM value is not defined during PO interface:

Without Item Barcode: Item Barcode , uom & uom_code values are not sent in the PO detail.

If Vendor Barcode (item_barcode) is not defined, then ord_qty value is considered w.r.t Item's Primary UOM.

Example :

Consider a company C1, operating in Facility F1 having item "ITEMB1" whose Primary UOM on the Item is defined as KM. Whereas the facility primary UOM for ITEM1 is defined as Pounds.

- During PO interface for Company/Facility C1/F1, if Qty sent is 5 without any quantity UOM for ITEMB1, then given value is considered as 5 LBs.

With Item Barcode: Item Barcode value is sent but uom & uom_code values are not sent in the PO detail.

If Vendor Barcode (item_barcode) is defined then:

In this case, the system allows you to send quantity not as per standard Case/ Pack quantity. When an item is fulfilled by different vendors there are chances that from vendor-to-vendor packaging capacity varies and customers can use item barcode to get the exact value of quantity).

- System considers conversion factor from Quantity per UOM defined on the respective Item Barcode.

Example is w.r.t System Class: Item Barcode (ITEMABC) is defined with UOM of Packs & Quantity per UOM = 15.

If PO detail is sent with "ord_qty"= 5, then order quantity for respective detail is 5x15 =75. Prior to UOM, all the conversions with respect to item barcode were considered in terms of units. Hence during PO interface, if the item barcode is sent and the respective items primary UOM is not Units, then we need to have an error condition "Item Barcode %Item Barcode% is not supported for items primary UOM other than Units "

UOM Conversion during Shipment creation during PO Interface (Comp Param "CREATE_ASN_FOR_EACH_PO")

When system creates Shipment during PO interface, then shipped quantity for the shipment detail is equal to order quantity for respective item associated with the PO detail. During Shipment creation, shipment detail quantity is saved w.r.t Item Facility/ Item Primary UOM:

For example, ITEM1 with Facility Primary UOM as KG,

During PO interface, If ITEM1 is defined with order quantity as 100 grams, then system should store value as 0.1Kg for PO detail. For the Shipment created w.r.t ITEM1 system should store shipped quantity as 0.1 Kg and same value should be displayed in the shipment UI.

Validations During the Interface

| Validation | Error Messages |

|---|---|

| If given Quantity UOM value is not present in the UOM configuration, then system display error message |

"%UOM code not found" |

| If given Quantity UOM value is other than (Units/ Cases/Packs) for system UOM class, then system display error message |

"%UOM code not supported" |

| If the Quantity UOMs class is not matching with the Item's Primary UOM class, then system displays error message |

"Primary UOM Class is not matching with UOM class of %Item" |

| If the Item is not enabled for decimal tracking, but the converted quantity value (Based on the Item Facility/ Item Primary UOM) is in decimals then system displays error message |

"Item does not allow decimal quantities" |

Handling UOM for Weight, Volume, and Dimension

IB Shipment interface

You can send UOM for Weight/Volume/Length/ Width/ Height for the LPN's present on the shipment. When Weight/Volume of LPN's is known, receiving activity can be optimized by selecting proper equipment's based on capacity handling of equipment's.

You can define UOM for Weight/Volume/ Dimension fields for LPN's associated with the IB shipment interface by:

- Three new UOM fields on the IB Shipment Interface at IB shipment detail for

(XML/PSV/XLS) formats:

- Weight UOM (weight_uom_code)

- Volume UOM (volume_uom_code)

- Dimension UOM (dimension_uom_code)

- You can send UOM for following fields present on the IB shipment interface:

IB Shipment Interface

Interface Fields Associated UOM Class lpn_weight Weight UOM lpn_volume Volume UOM lpn_length Dimension UOM lpn_width Dimension UOM lpn_height Dimension UOM

Item Prepack

You can define UOM for Child Units, Weight/Volume/ Dimension fields for Item Prepack interface where that helps the floor users to see the converted value for child items based on respective facility UOM during Prepack processing during Work Order.

| Interface Fields | Associated UOM Class |

|---|---|

| child_units | UOM (Quantity UOM) |

| pre_pack_weight | Weight UOM |

| pre_pack_volume | Volume UOM |

| pre_pack_length | Dimension UOM |

| pre_pack_width | Dimension UOM |

| pre_pack_height | Dimension UOM |

Location

| Interface Field | Associated Interface Field |

|---|---|

| weight_uom_code | min_weight, max_weight |

| volume_uom_code | min_volume, max_volume |

| dimension_uom_code | length, width, height |

Cycle Count Threshold UOM code in Location interface

You can send the UOM code in the "cc_threshold_uom_code" field in XLS, XML format along with cc threshold value for calculating location threshold as a part of opportunistic cycle count.

- GET support for the location entity API fetches the newly introduced field (cc_threshold_uom_code).

- During location interface(XLS, PSV), user should be able to send UOM of LPNs/UNITS in cc_threshold_uom_code field along with cc_threshold_value for active/reserve locations.

Outbound Load and Planned OB Load

You can send any user defined UOM for weight/volume related fields in planned OB loads interface, and therefore the system converts weight/volume related UOM fields to respective company weight/volume UOM and process the value

| Interface Fields | Associated UOM Class |

|---|---|

| total_weight, stop_weight | Weight UOM |

| total_volume, stop_volume | Volume UOM |