Transportation Split Creation

Transportation split allows you to load a single order detail to multiple loads. This trigger may come from OTM based on their loading capacity.

You can perform transportation split via Planned Load Interface.

To perform the transportation split for an order detail, do the following:

- Open the Planned OB Load Interface .xml file.

- Enter the Order details to split.

Based on the planned_qty, the system splits the order detail. If you skip the planned_qty entry, the system plans the load for the complete order detail quantity. Also, you can enter multiple order details to assign the load.

Note: If multiple details are added, the system identifies and filters the order details in the following sequence to uniquely identify an order detail (to be interfaced in the Planned OB Load interface file).- order_nbr + order_seq_nbr

- erp_fulfillment_line_ref

- 4 part key

- ship_request_line

- Enter a Load Number (External Planned load) to assign for the order detail.

- Enter the “CREATE” action code at the load level.

- Save the file.

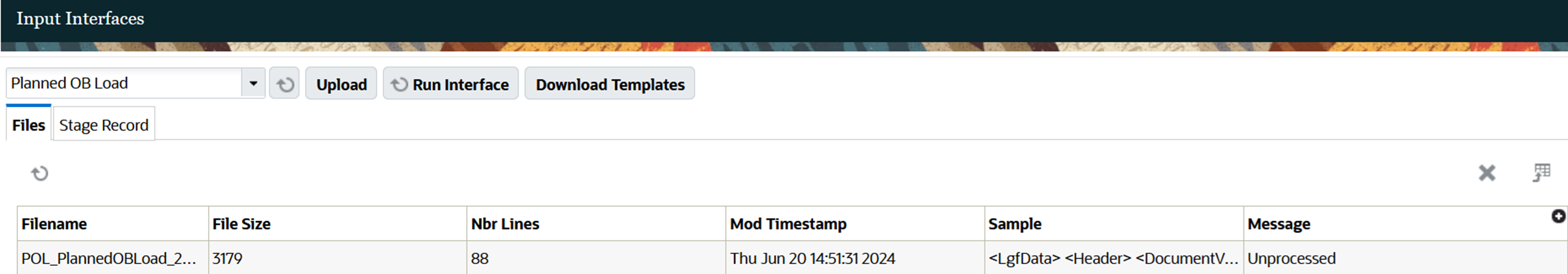

- Navigate to the Input Interfaces UI.

- Select Planned OB Load from the drop-down list.

- Click Upload and choose the saved Planned OB Load Interface .xml file.

- Click Upload.

You can observe the uploaded file under the Files tab.

- Click Run Interface to run the Planned OB Load interface file.

The system displays a pop-up message “Interface completed”. If any execution fails, the system displays an error message.

You can check the processed records under the Stage Record tab.

Points for Consideration:

- The system displays an error message in the following conditions:

- If the Planned Load Quantity > Order Detail Quantity.

- If the Planned Load Quantity > (Order Detail Quantity - Shipped Quantity).

- If Order Detail does not exist.

- If the Planned Quantity is 0.

- If the Order Detail has any allocated Quantity. No pending allocations should be present for the Order Detail.

- If you leave “qty_uom_code” as blank, by default, the system considers the Item Primary UOM as UOM Code.

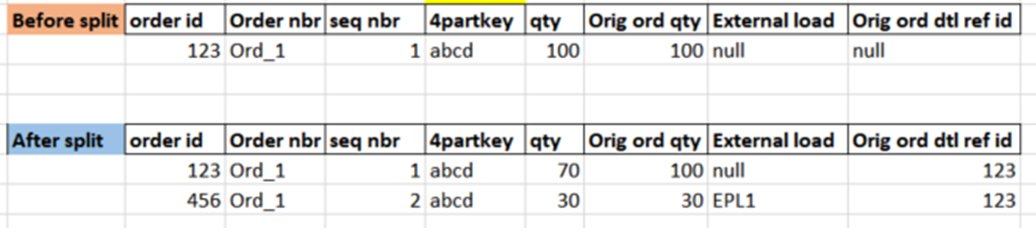

- As you are splitting the Order Detail, every time the system creates a new sequence number. So, the unique identifier here is the 4-part key (erp_source_hdr_ref + erp_source_line_ref + erp_source_shipment_ref + erp_fulfillment_line_ref).

For example, consider an order ORD-01 requires 100 quantities of SKU-1.

Order Before Planning:

| Order Number | SKU | Ordered Quantity | External Planned Load Number |

| ORD-01 | SKU-1 | 100 |

If you plan LOAD-1 and LOAD-2 with 50 and 20 quantities respectively via Planned OB Load Interface, the system splits the 100 quantities of ORD-01 order detail and updates the order details as follows.

| Order Number | SKU | Ordered Quantity | External Planned Load Number |

| ORD-01 | SKU-1 | 30 | |

| ORD-01 | SKU-1 | 50 | LOAD-1 |

| ORD-01 | SKU-1 | 20 | LOAD-2 |