Optimize Putaway Operations with Enhanced Cart Support, Task Criteria, and Location Flexibility

You can optimize your Putaway process using PUTAWAY cart support, task criteria, and location flexibility. Cart numbers and their positions are displayed directly in the Container View, enabling easy tracking and effective task allocation.

If a Putaway task is interrupted, it can be resumed without interruption with all critical details preserved, minimizing errors.

Cart management is optimized with capacity alerts that notify when a cart is full, preventing overloading. Outdated cart data is automatically cleared after task completion, maintaining a clean and organized workflow. Built-in validation checks prevent duplicate or incorrect moves, ensuring accurate inventory allocations.

For handling failed LPNs during Putaway, the system displays the following error messages:

- For partial failures, “Remove LPN Scan” screen while keeping the successful ones in the cart.

- For single failures, the system automatically removes the failed LPN after scanning the drop location.

- For complete failures, all failed LPNs are removed by scanning the drop location. After removal, cart details are updated, successful items remain allocated, and activity logs ensure traceability.

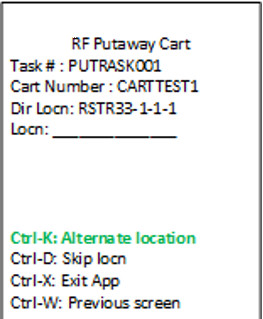

When a designated storage location is unavailable, the system quickly identifies alternate locations, ensuring uninterrupted workflows and efficient item handling.

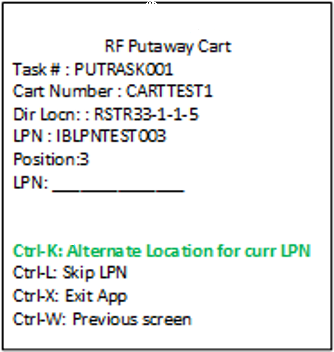

The "Ctrl-K: Alternate Location" option appears in the Location prompt, while the "Ctrl-K: Alternate Location for current LPN" option is available in the LPN/Position prompt.

The latter is specifically used to update the location only for the prompted LPN when it cannot fit within the designated space. Upon pressing Ctrl-K, the system will perform a Reason Code Selection Check as outlined.