Putaway Priorities

Putaway Priorities determine the order in which Putaway Types are triggered for putaway.

- Go to the “Putaway Priorities” screen and click “Create”.

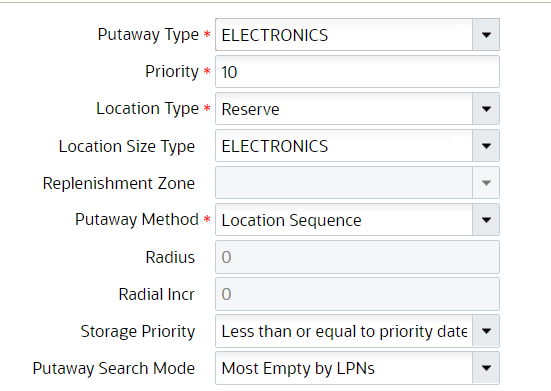

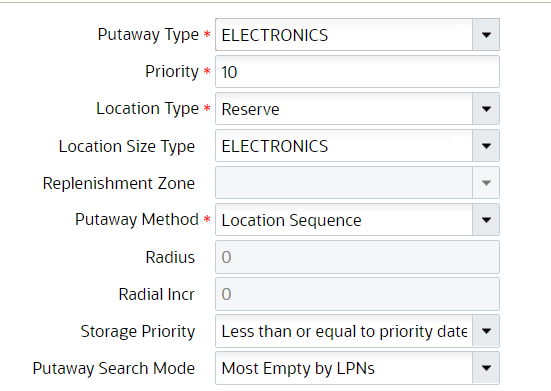

- Fill out the following information to create a new Putaway Priority.

- Putaway Type: The putaway type that will be used for the priority.

- Priority: Determines the order of the putaway priority.

- Location Type: The Location Type that is used in the logic – Reserve/Active.

- Location Size Type: The Location Size Type that will pair with the previously selected Putaway Type.

- Replenishment Zone: Only applies to active locations. This field defines the active location’s replenishment zone.

- Putaway Method: The putaway method used: by Location Sequence or Radial.

- Radius: If “Radial” is selected for the Putaway Method, this field is required. It defines the radius of locations that will be used during the putaway logic process.

- Radial Incr: If “Radial” is selected for the Putaway Method, this field is required. It defines the increment radius value in which WMS will look for locations during putaway.

- Storage Priority (Consider FEFO flag): You can putaway inventory to a location that has a higher priority date than the incoming inventory so that the inventories with lesser priority dates stay in front of the inventories with higher priority dates during picking.

- Putaway Search Mode: This defines how WM will determine a location for

putaway.

-

Sample Putaway Priority configuration

The above configuration translates to the following:

When an IBLPN of Putaway Type “ELECTRONICS” is scanned for putaway, WMS will look for all locations that have Location Size Type “ELECTRONICS” to putaway to. Out of these eligible locations, WMS will look for the location with the least amount of LPNs (“Most Empty by LPNs”). At the same time, these locations will ordered based on its “putaway sequence” value. If the locations have a max weight greater than zero, the system will validate the location weight with the IBLPN weight .

-

- Click “Save” .

Search for Locations with the Same Item

Search Location with matching SKU flag in the Putaway Priority View UI, once enabled on Putaway method priority, the system directs you to the location that already has a matching SKU required to be putaway. This helps you to optimize the location with identical SKU’s instead of having the same SKU spread across the different locations. This also helps to achieve a smooth picking transaction and thereby reduces accessing any further location.

Let's say, you have an IBLPN with a single SKU or pallets having IBLPN single SKU during directed putaway, all the eligible locations (satisfying capacity check), and putaway method priority. The system further narrows down and prompts the location that already has the SKU (Physical Inventory not In-transit) similar to the SKU targeted for putaway.

- Go to PutawayPriorityViewUI.

- Click Create to create new priority. Or, select the listed Putaway Type > Click edit icon to edit the existing priority.

- Fill in the mandatory details.

- Check or un-check the Search Location with matching SKU checkbox to enable or disable the functionality.

- Click Save.

- By default, this new flag is disabled on the Putaway Method Priority UI. You need to check the flag explicitly to enable.

- This function is applicable to both Active & Reserve Locations.

- Search Location with matching SKU flag honors during Split Putaway to Active Location and Putaway Method Location Sequence/ Radial.

- On scanning an LPN, if there are multiple locations that have matching SKUs, then the system applies putaway search mode to the eligible location (that is, locations that have matching SKUs).

FEFO FLAG IN PUTAWAY

When a putaway priority record is configured with the Storage Priority (previous, Consider FEFO flag), you can putaway inventory to a location that has a higher priority date than the incoming inventory so that the inventories with lesser priority dates stay in front of the inventories with higher priority dates during picking.

For example:

Let’s say, you receive a shipment of milk with a priority date of 7/30/21. You have two locations where you store milk. In the first location, you have inventory with a priority date of 7/15/21, and in the second location, you have inventory with a priority date of 8/30/21. If you had the Consider FEFO flag enabled, the system would direct incoming inventory to the second location. This method was most suitable for push-back racks as the incoming inventory will be prioritized ahead of the older inventory.

FEFO Flag in Putaway

Putaway Priority supports FEFO operation for gravity feed mechanisms and also where the picking happens from the opposite direction of putaway. As a result, you can putaway inventory to a location that has a lesser priority date than the incoming inventory so that the inventories with lesser priority dates stay in front of the inventories with a higher priority date during picking.

By default, the Storage Priority drop-down is blank (which indicates that FEFO operation is not enabled for the putaway priority record).

The Storage priority drop-down has the following options for you to choose from;

- Blank: The priority dates will not be considered for the putaway priority record.

- Less than or equal to priority date (default option when Consider FEFO flag

is turned on): You can putaway inventories with a lesser expiry date than the

location inventory expiry date. Note: This mode is suitable for Push back Racks.

- Greater than or equal to the priority date: You can putaway inventories with

a higher expiry date than the location inventory expiry date. Note: This mode is suitable for Gravity feed Racks.

Configure Weight Check During Putaway

You can evaluate container (inventory) weight with location weight during Putaway and Replenishment. The system directs you to available location to hold the incoming inventory within the defined weigh. You can search Locations by most empty (by weight) and least empty (by weight) during directed putaway.

Putaway - Weight Based Capacity Check

Direct Putaway for LPN/Pallet

You can perform capacity weight check during directed putaway for LPN/Pallet. That is, when performing directed putaway, the system directs you to location that can hold an incoming pallet into the respective location.

You can search the modes with either “most empty by weight” or “least empty by weight” in the Putaway Search Mode

To setup max weight and min weight:

- Go to the Location UI.

- Configure the Max Weight" and "Min Weight" columns to maximum and minimum weight

on location that helps you in perform capacity check during putaway and

replenishment.Note: You can also process the location interface file with max_weight and min_weight fields. The system supports Excel and XML (Input interface and Init stage interface) file formats.