System Directed Putaway

The RF – Transaction “Directed Putaway” is used to putaway cases/pallets to a storage/picking location. The system directs you to a specific putaway location.

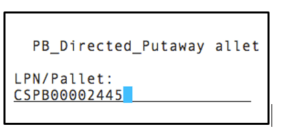

To initiate Directed Putaway:

- Go to the RF transaction “Directed Putaway”.

- Scan the LPN on the label of the pallet or case that needs to be putaway.

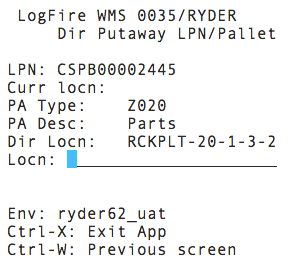

The RF screen directs you to a putaway location.

- To complete the putaway, go to the directed location prompted and scan the location barcode.

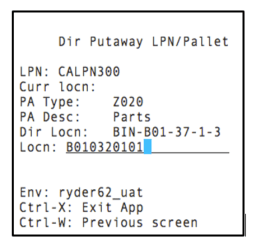

You can override the putaway location by choosing another available location in the same zone.

To override the putaway location, do the following:

- In RF ‘Directed Putaway’, scan another available location (Locn field) in the same

zone.

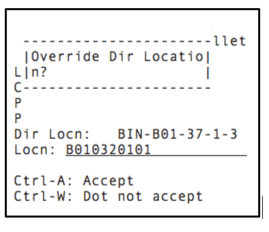

The system displays a pop-up message “Override Dir Location?”

- To accept the overriding of the location prompted, press Ctrl-A.Note:

- If you override with a location that is full or insufficient to putaway the LPN, the system displays an error message “Insufficient Capacity”.

- You can also get a list of alternate locations by entering CTRL-K. Once you enter CTRL-K, the system will show the next location based on putaway method priority.

Direct Putaway Improvements to Matching SKU Logic for Multi-SKU LPNs

Directed Putaway process supports logic for Multi-SKU License Plate Numbers (LPNs).

When you enable the "Search Location with Matching SKU" option in the Putaway Priority UI, following flow is set on priority, where:

- The system first searches for locations with a matching SKU for the item with the largest quantity on the LPN.

-

- If multiple matching locations are found, then the system uses the location putaway sequence to prioritize.

- If no matching SKU is found, then the system moves to the next most-represented SKU on the LPN.

- If no locations match any SKU from the LPN, then the system searches for available locations without a matching SKU.

Note: Radial Putaway logic requires a permanent location and does not use matching SKU

functionality.