5 Maintenance

This chapter explains Acme Packet 3900 hardware maintenance procedures.

Although several user-replaceable components of the Acme Packet 3900 are hot-swappable, some limited Acme Packet 3900 maintenance procedures require that you shut down the system.

- Removing the unit from the equipment rack for any reason

- Removing the cover from the chassis

- Replacing transcoder DSP modules

- Replacing the T1/E1 TDM card.

- Always observe correct ESD procedures.

- Before you start any maintenance procedure which includes parts replacement, make sure you have the correct part on-hand. Any user-replaceable components may be ordered in advance from Oracle.

- Oracle recommends stocking replacement parts for:

- Air filters

- Fans

- Power supplies

- Optical transceivers

- DSP modules

System Shutdown

Before you shut down or restart the Acme Packet 3900, ensure that there are no active calls in progress. The command to show active calls is “show sessions.”

ACMEPACKET# show sessionsProcedures to reroute call and network traffic around the Acme Packet 3900 are outside the scope of this guide.

You can set the Acme Packet 3900 to reject all incoming calls from your system with the set-system-state command. When set to offline, this command lets calls in progress continue uninterrupted, but no new calls are admitted.

After all call processing has stopped, you can power off your Acme Packet 3900. Shutting down the system is appropriate when you are replacing a power supply or are removing the Acme Packet 3900 from the equipment rack.

Rebooting, Resetting, and Power Cycling

Reboot

Rebooting the Acme Packet 3900 shuts down the system in an orderly fashion and then automatically restarts it. The operating system gracefully shuts down as processes are terminated and the file system is stopped. While the system and its processes are stopped, all call processing is immediately halted. You may therefore wish to perform tasks that call for a reboot during off-peak maintenance hours.

Rebooting the Acme Packet 3900 is required every time you upgrade with a new version of the software.

Save your configurations before rebooting. Refer to the Maintenance and Troubleshooting Guide for a full explanation of this procedure. The save-config command is used to save the configuration in the example below.

To reboot:System Reset

Resetting the Acme Packet 3900 via the reset pushbutton on the rear of the chassis performs a cold reboot. This action is the equivalent of disconnecting the power from the system and then reconnecting it. There is no orderly termination of tasks, and the system shuts down abruptly. You should only reset the Acme Packet 3900 when it becomes unstable and no other means of gaining administrative control is possible.

During a system reset, certain files are not closed properly, and they may become corrupted. If an unclean shutdown is detected, filesystem recovery/repair will be run to ensure the system returns to a stable state. Filesystem verification also runs every 30 boots as a precautionary measure.

Note:

Always try to reboot first from the ACLI before performing a cold reset. Only reset the system as a last resort.Power Cycling

Power cycling the Acme Packet 3900 is the process of turning the chassis off and then on again. When power cycling, it is imperative that you wait at least 10 seconds between power down and power up to ensure that all components are completely powered down before restarting the system.

Standby State for HA Nodes

When performing hardware maintenance on the Acme Packet 3900, it is best to minimize any risk of interrupting network traffic or losing data. If the Acme Packet 3900s are configured as an HA node, you should only work on the node that is in standby state.

- If you are in the same physical location as the Acme Packet 3900 you can view the HA LEDS on the front bottom right. A standby unit lights the STBY LED, while an active unit lights the ACT LED.

- If you are not in the same physical location as the Acme Packet 39004, you can use the ACLI show health command. The output of this command indicates the current HA state of the Acme Packet 3900.

Once you have determined that the Acme Packet 3900 due for maintenance is in standby state, you can continue with the appropriate procedures to replace a part.

If you need to perform maintenance on the active Acme Packet 3900 you need to manually force the two Acme Packet 3900s to switch HA states. Forcing a switchover renders the currently active Acme Packet 3900 in Standby state, and the current standby Acme Packet 3900 will assume all traffic processing and forwarding as the active system.

Note:

This procedure is only applicable to an HA deployment.Maintenance With Power

Some maintenance tasks may be performed without powering down the system.

- Clean air inlets in the front left bezel

- Replace air filters

- Clean fan modules

- Replace fans

- Replace power supplies

- Replace optical transceivers

Maintaining the Cooling Components

- Replace the fan filter every three months

- Clean the air inlets once a week.

Cooling maintenance encompasses cleaning the fan module and cleaning the air inlets on the front of the Acme Packet 3900 chassis. Cleaning the fan module requires that you remove the module itself. If you are not shutting down the Acme Packet 3900, this procedure must be performed quickly or else the system may overheat and cause packet processing to stop.

This maintenance should be performed alongside other preventive maintenance to take place within a planned maintenance or downtime window, during off-peak hours.

Fan and Air Filter Maintenance

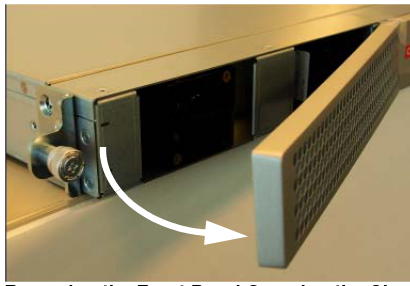

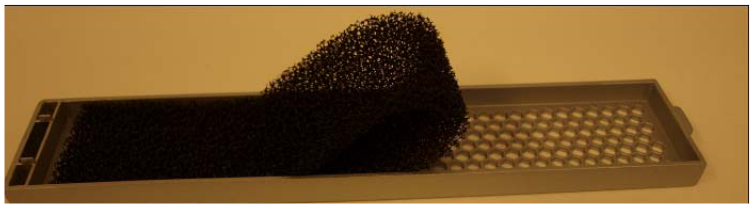

This section explains how to remove a fan and replace the air filter on your Acme Packet 3900.

Note:

You can perform routine maintenance on the Acme Packet 3900 front panel fans and air filter with the unit normally installed in the equipment rack. Also, you do not need to remove the the power from the chassis.Power Supply Removal and Replacement

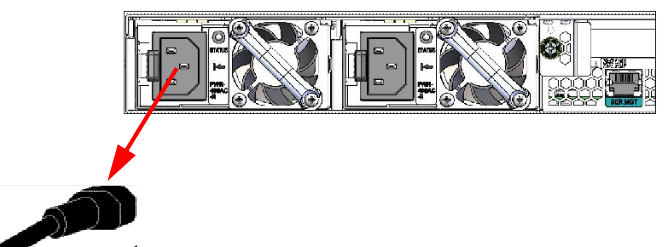

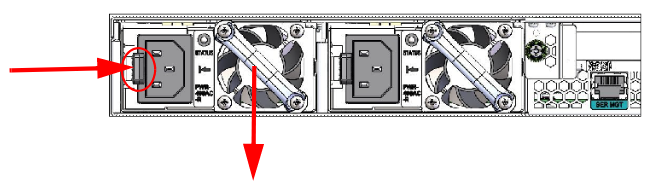

You can replace malfunctioning power supplies yourself.

Note:

Ground yourself first using appropriate ESD grounding equipment such as a wrist strap.

Note:

Power supplies can be removed from the chassis while it is still installed in the rack and while the second power supply is providing system power; this is called a warm swap.Note:

After unplugging a power supply, disconnect it from the power source before you remove or install it in the chassis.Optical Transceiver Removal and Replacement

- Converts electrical signals into optical signals used to communicate with other optical networking equipment.

- Serves as the receptacle for the LC duplex fiber optic connectors.

Optical transceivers are hot swappable and may be replaced while the Acme Packet 3900 is powered on.

To obtain a replacement optical transceiver, contact customer support.

Note:

To prevent damage to the optical lens, Acme Packet recommends that the protective dust cover stay on the optical transceiver port when the physical interface card is not cabled.Removing an Optical Transceiver

- Unplug all fiber optic cables from the optical transceiver to be replaced.

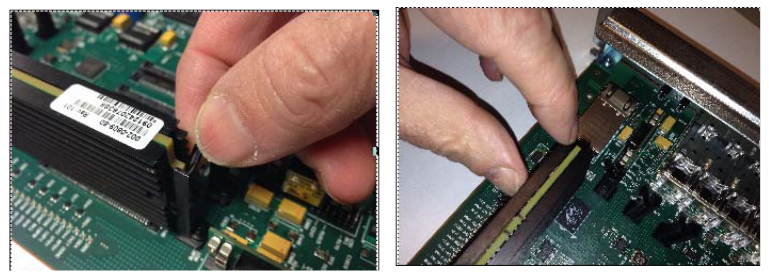

- Pull the bale clasp latch out and down. It will pivot downwards on its hinge.

- Holding the extended bale clasp latch, pull the optical transceiver fully out

of its socket of the physical interface card.

Install an Optical Transceiver

- Slide the replacement optical transceiver into the socket on the rear

panel.

- Press on the face of the optical transceiver to seat it in the socket.

- Flip the bale clasp latch back into the rest position.

- Reconnect the optical cables to their corresponding ports.

Maintenance Without Power

Some maintenance tasks must be performed after powering down the system.

- Remove the chassis cover

- Remove the chassis from an equipment rack

- Remove and replace transcoder DSP modules

- Remove and replace T1/E1 TDM modules

Remove the Chassis Cover

Caution:

Always gracefully power down the Acme Packet 3900 and then disconnect the power supplies from the power source when removing the chassis cover.- Ensure there is enough slack in the unit cabling to allow the chassis to slide forward.

- Remove the power from the Acme Packet 3900.

- Loosen the two thumbscrews on the rear panel.

- Loosen the two thumbscrews on the front panel.

- Pull the Acme Packet 3900 to the front of the rack until the chassis assembly stops.

- Push the chassis cover backwards about ½ inch.

- Lift the cover up until it is free of the chassis.

Replacing Transcoder DSP Modules

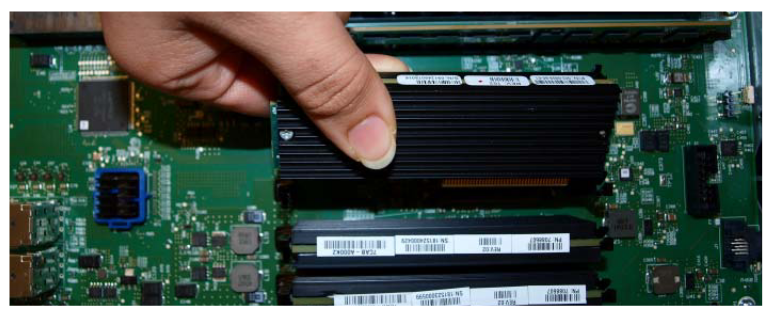

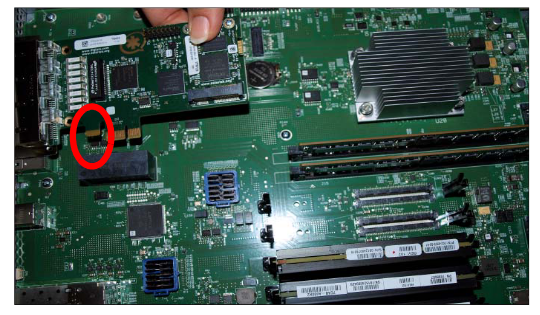

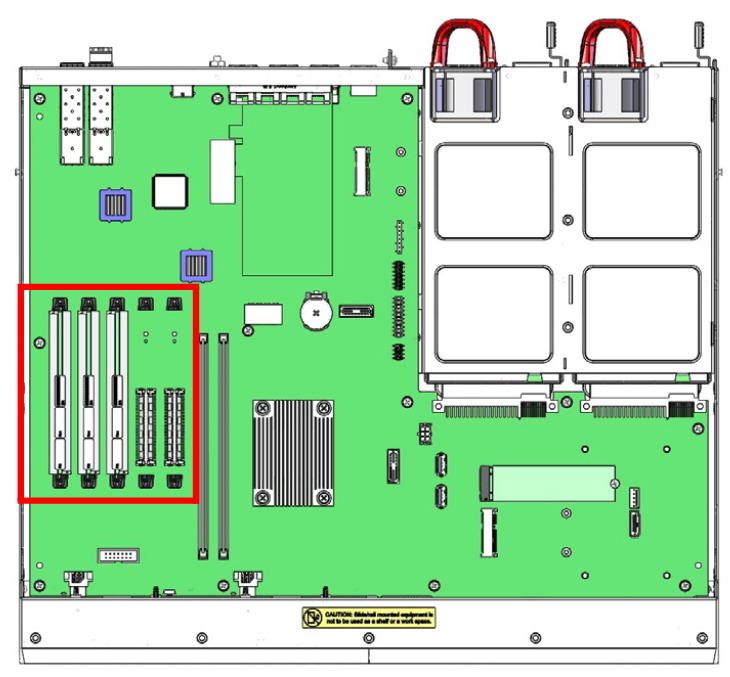

Up to 5 transcoder DSP modules may be installed on the Acme Packet 3900 printed circuit board (PCB).

There are slots for installing the transcoder DSP modules in one location on the Acme Packet 3900 PCB. The slots are numbered 0-4. Slot 0 is the closest slot to the edge of the unit when looking at it from the front of the chassis. Transcoder DSP modules should be installed consecutively in numerical order, starting with slot 0.

Guidelines

- The transcoder DSP module can be installed only in the designated location.

- Ground yourself and follow proper ESD grounding procedures.

- Remove the transcoder DSP module from the shipped packaging.

- The installation of these modules should be performed during low-traffic periods or during times of scheduled maintenance.

- Follow industry-standard procedures to ensure ESD protection.

- When installing or removing a DSP module, move the card to an ESD-safe location.

Note:

Before handling any components, follow the proper ESD grounding procedures. Failure to do so could damage the card and its components.Required Parts

- ESD wrist strap

- ESD-safe location

- Transcoder DSP module

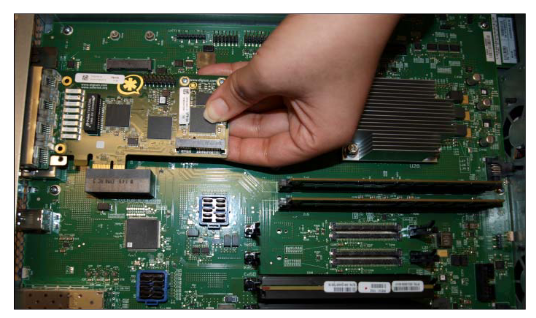

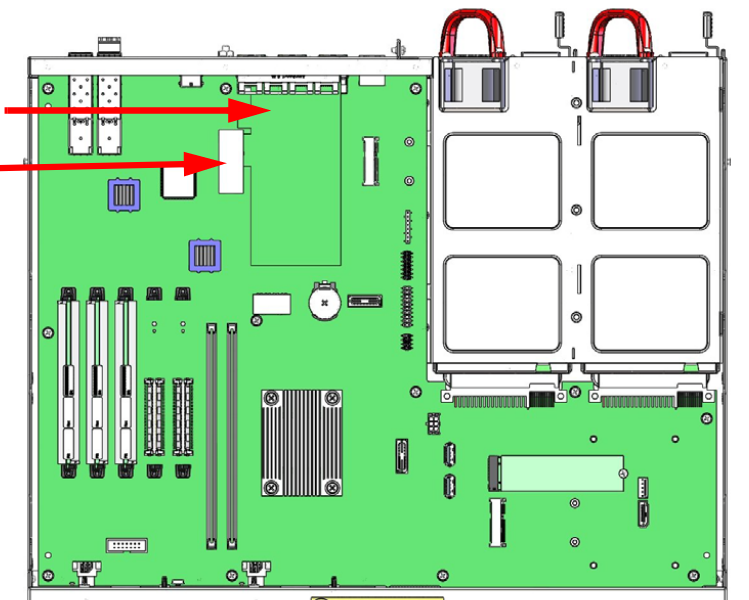

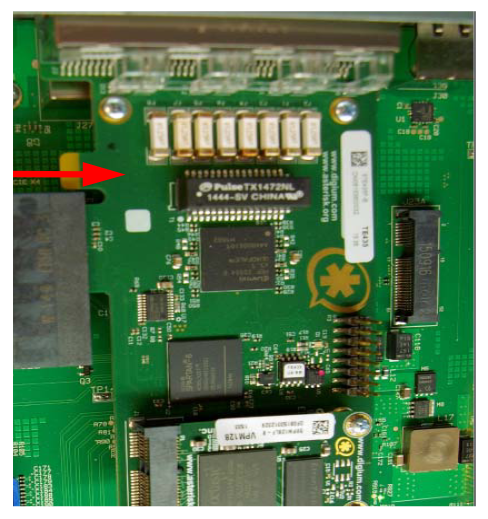

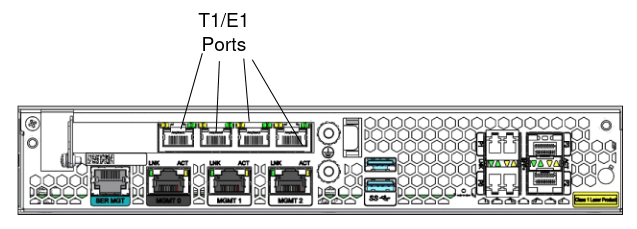

Removing and Replacing the T1/E1 TDM Module

The TDM module is located near the rear of the board.

Guidelines

- Ground yourself and follow proper ESD grounding procedures.

- Remove the transcoder TDM module from the shipped packaging.

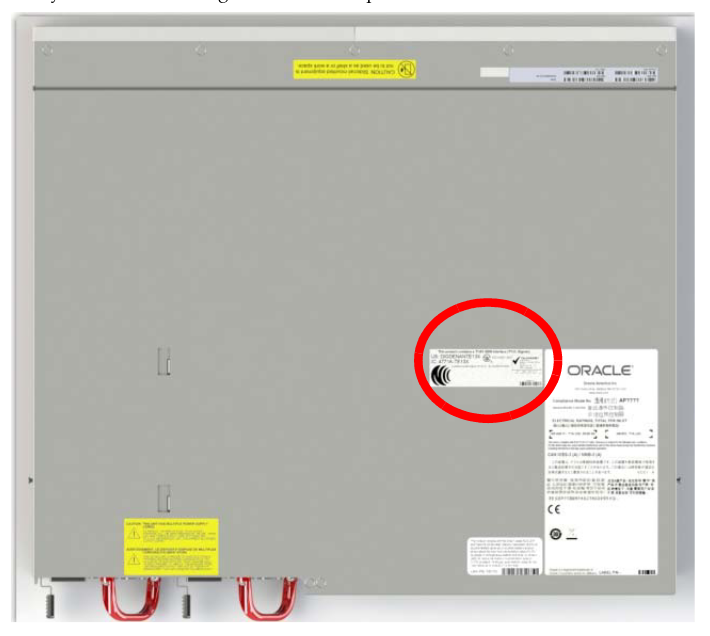

Note:

In the box with the new T1/E1 TDM modules, there will be aTelecom label in a plastic envelope. Attach the Telecom label to the chassis cover as described below.Note:

The installation of these modules should be performed during low-traffic periods or during times of scheduled maintenance.Caution:

Before handling any components, follow the proper ESD grounding procedures. Failure to do so could damage the card and its components.Required Parts

- ESD wrist strap

- ESD-safe location

- New or replacement TDM module

- Telecom label to attach to the chassis cover