20 Replenishment Parameters

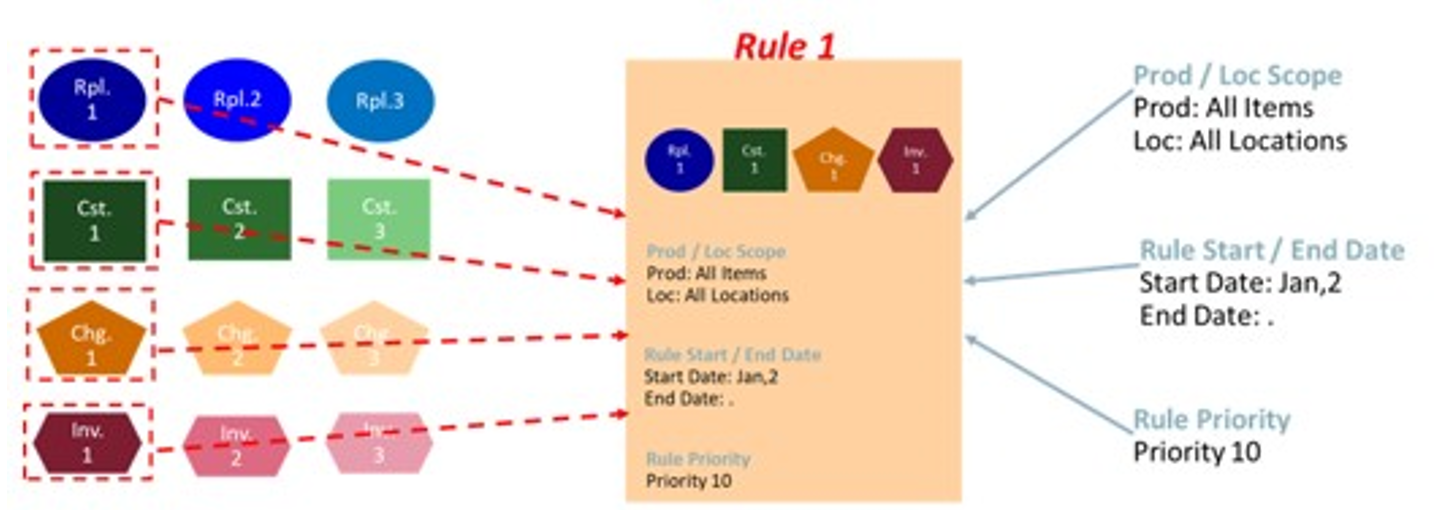

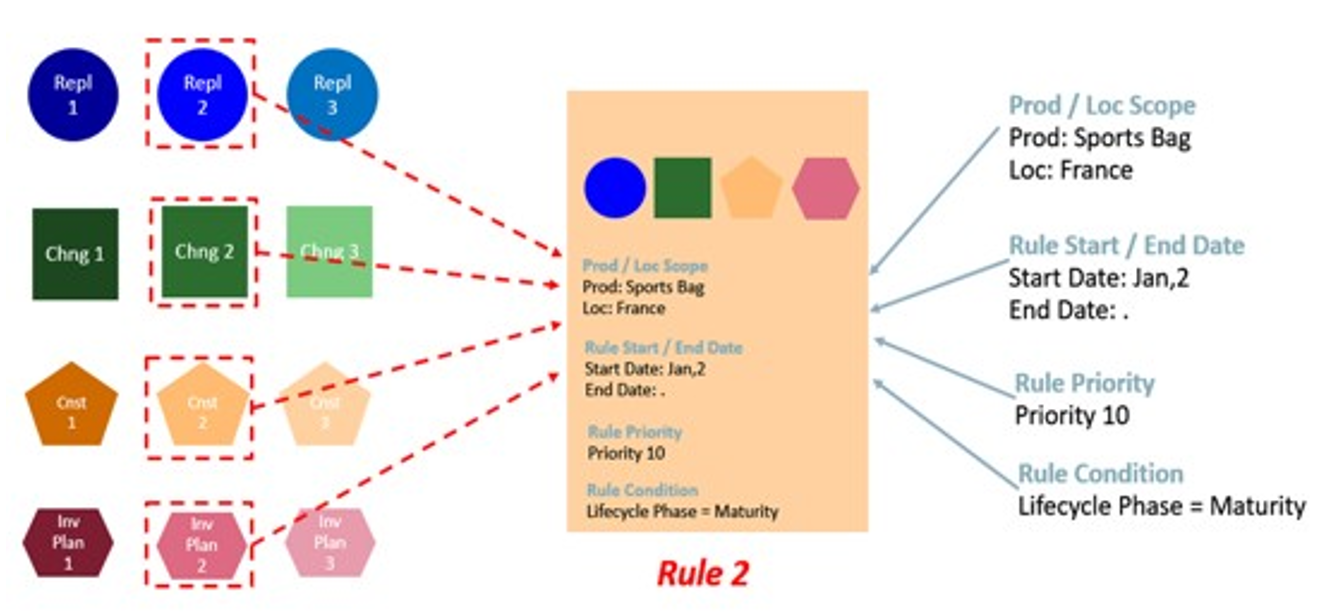

This chapter describes the functionality that allows you to set up and review the replenishment and inventory parameters that are used within the Allocation & Replenishment calculations. The Replenishment Parameters Workspace is where you can set up the replenishment parameters, change parameters, constraint parameters and inventory planning parameters. Once they are defined you can configure rules and conditions to specify where they should be applied. In a similar way to the Supply Chain Network workspace, the rule engine does the heavy work for you and calculates the right parameters at the product and location level using the available assortment and lifecycle information.

You can further specify the priority and the period where the rule should apply (start and end date if applicable). Based on the set up, the rules engine determines the most appropriate rule and then distributes the parameter to each item and location.

Figure 20-1 Rules Engine Process

Replenishment Parameters Workspace, Steps, and Views

The following table lists the workspaces, steps, and views of the Replenishment Parameters task.

Table 20-1 Replenishment Parameters Workspace, Steps, and Views

| Workspace | Steps | Tab | Views |

|---|---|---|---|

|

Overview |

|||

|

Scope |

|||

|

Replenishment Parameters |

|||

|

Inventory Plan Parameters |

|||

|

Constraint Parameters |

|||

|

Setup |

|||

|

Review |

|||

|

Filter |

Replenishment Parameters Workspace

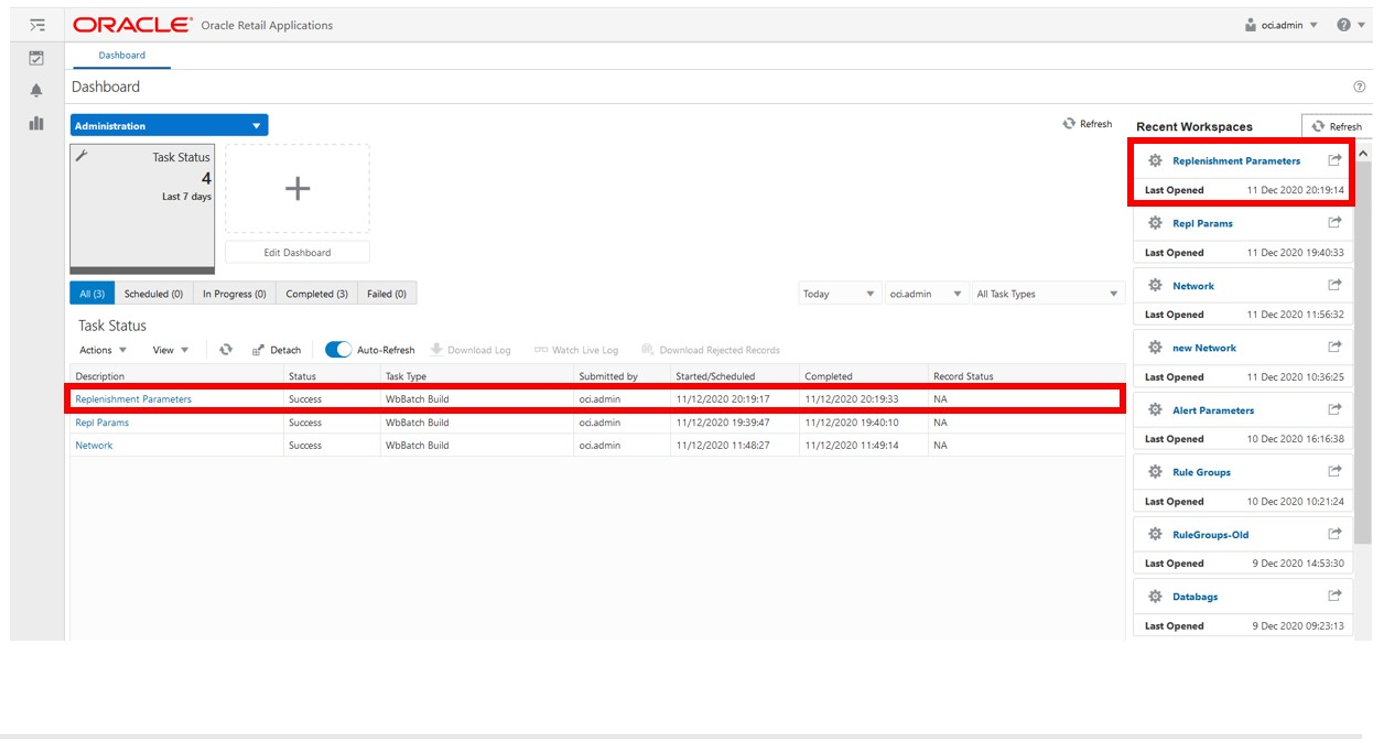

The Replenishment Parameters workspace allows you to access all the views listed in the Replenishment Parameters Workspace, Steps, and Views. To build the Replenishment Parameters workspace, perform these steps:

-

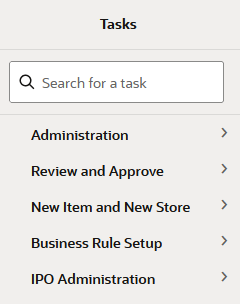

From the left sidebar menu, click the Task Module to view the available tasks.

Figure 20-2 Task Module

-

Click the Business Rule Setup activity to access the available workspaces.

-

Click Replenishment Parameters.

-

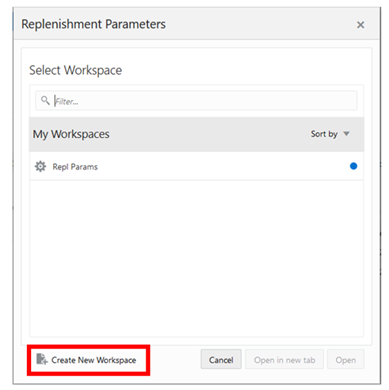

The Replenishment Parameters wizard opens. You can open an existing workspace, but to create a new workspace, click Create New Workspace.

Figure 20-3 Replenishment Parameters Wizard

-

Enter a name for your new workspace in the label text box and click OK.

Figure 20-4 Enter Workspace Label

-

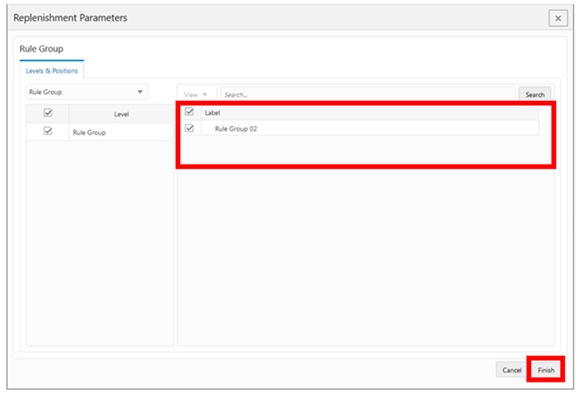

Select the rule groups you want to work with and click Finish.

Figure 20-5 Workspace Wizard: Rule Groups

Note:

Only the rule groups that are from the Replenishment rule group type are available for selection. The rule group type value is managed in the Manage Rule Groups workspace.

-

The wizard notifies you that your workspace is being prepared. Successful workspaces are available from the Dashboard.

Figure 20-6 Successful Workspace Build

Note:

The workspace is built using the selected rule group scope. The products, locations, source locations and attributes available in the workspace are the ones in the rule group scope that is managed in the Manage Rule Groups workspace.

Overview Step

This step contains these views:

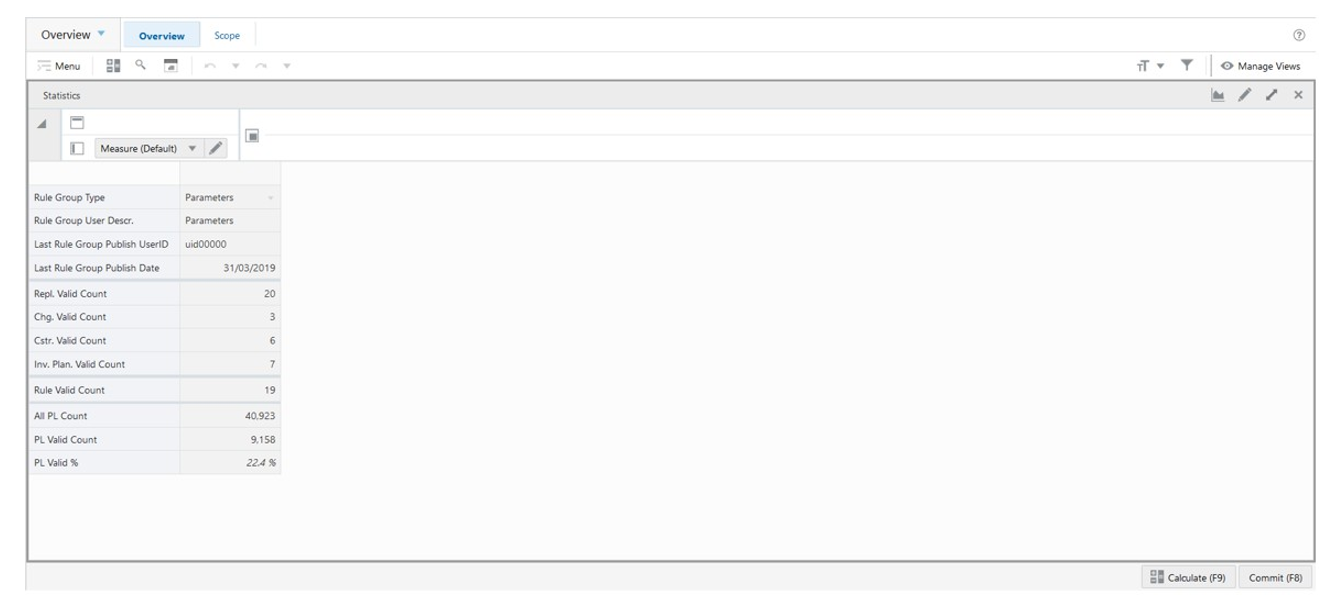

Statistics View

The Statistics View, under the Overview tab, allows you to review the statistics of the Replenishment Parameters. The view has statistical information regarding the number of valid counts for each set up (for example, Replenishment Parameters, Change Parameters) and rules. It also provides the number of product and location combinations within the workspace.

Figure 20-7 Statistics View

Statistics View - Default Profile Measures

The Statistics view contains the following measures.

Rule Group Type

Rule Group Type is a loaded read-only measure used to display the rule group type that was set up for the rule group in the Manage Rule Group workspace.

Rule Group User Description

Rule Group User Description is a loaded read-only measure used to display the user-description that was set up for the rule group in the Manage Rule Group workspace.

Last Rule Group Publish User ID

Last Rule Group Publish User ID is a loaded read-only measure used to display the user-identifier that performed the last rule group’s change in the Manage Rule Group workspace.

Last Rule Group Publish Date

Last Rule Group Publish Date is a loaded read-only measure used to display the date and time when the last rule group’s change was performed in the Manage Rule Group workspace.

Replenishment Valid Count

Replenishment Valid Count is a calculated measure used to display the total number of valid replenishment parameters that are set up for the rule group.

Change Valid Count

Change Valid Count is a calculated measure used to display the total number of valid change parameters that are set up for the rule group.

Constraint Valid Count

Constraint Valid Count is a calculated measure used to display the total number of valid constraint parameters that are set up for the rule group.

Inventory Plan Valid Count

Inventory Plan Valid Count is a calculated measure used to display the total number of valid inventory plan parameters that are set up for the rule group.

Rule Valid Count

Rule Valid Count is a calculated measure used to display the total number of valid rules that are set up for the rule group.

All Product Location Count

All Product and Location Count is a calculated measure used to display the total number of product and location combinations that have a lifecycle phase value.

Product Location Valid Count

Product and Location Valid Count is a calculated measure used to display the total number of product and location combinations that have a valid rule assigned.

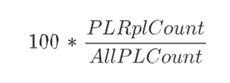

Product Location Valid %

Product and Location Valid Percentage is a calculated measure used to indicate, in percentage, how much the product and location combinations with a valid rule assigned represent in the total of product and location combinations with a lifecycle phase value. The measure is calculated as:

Figure 20-8 Calculation

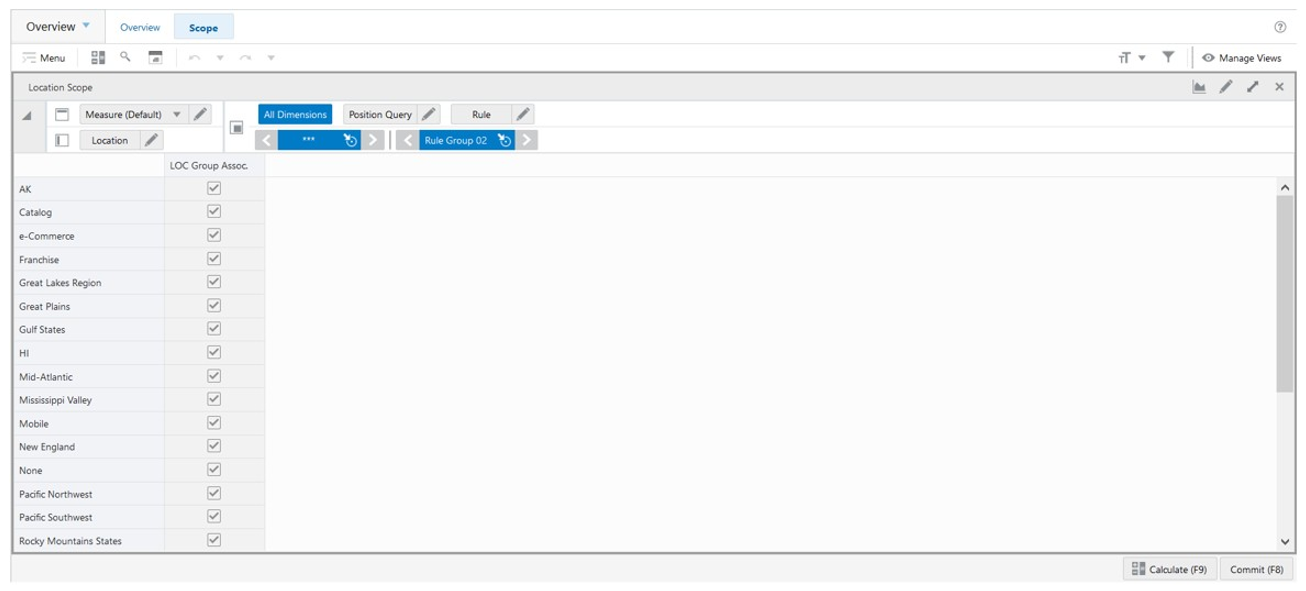

Location Scope View

The Location Scope View, under the Scope tab, allows you to review what specific locations are in the scope of a rule group and loaded into the workspace.

Figure 20-9 Location Scope View

Location Scope View - Default Profile Measures

The Location Scope view contains the following measure.

Location Group Association

Location Group Associated is a loaded read-only measure used to indicate the location groups that are associated with the rule group. This measure is managed in the Manage Rule Groups workspace.

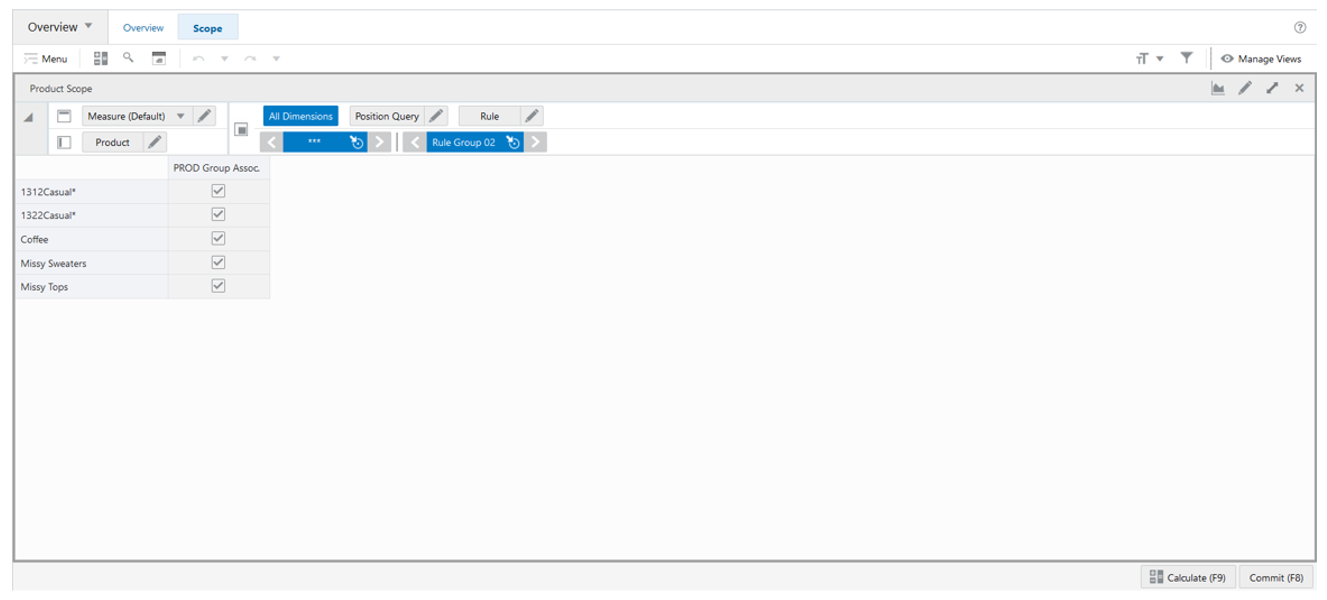

Product Scope View

The Product Scope View, under the Scope tab, allows you to review what specific products are in the scope of a rule group and loaded into the workspace.

Figure 20-10 Product Scope View

Product Scope View - Default Profile Measures

The Product Scope view contains the following measure.

Product Group Association

Product Group Associated is a loaded read-only measure used to indicate the products groups that are associated with the rule group. This measure is managed in the Manage Rule Groups workspace.

Replenishment Parameters Step

This step contains these views:

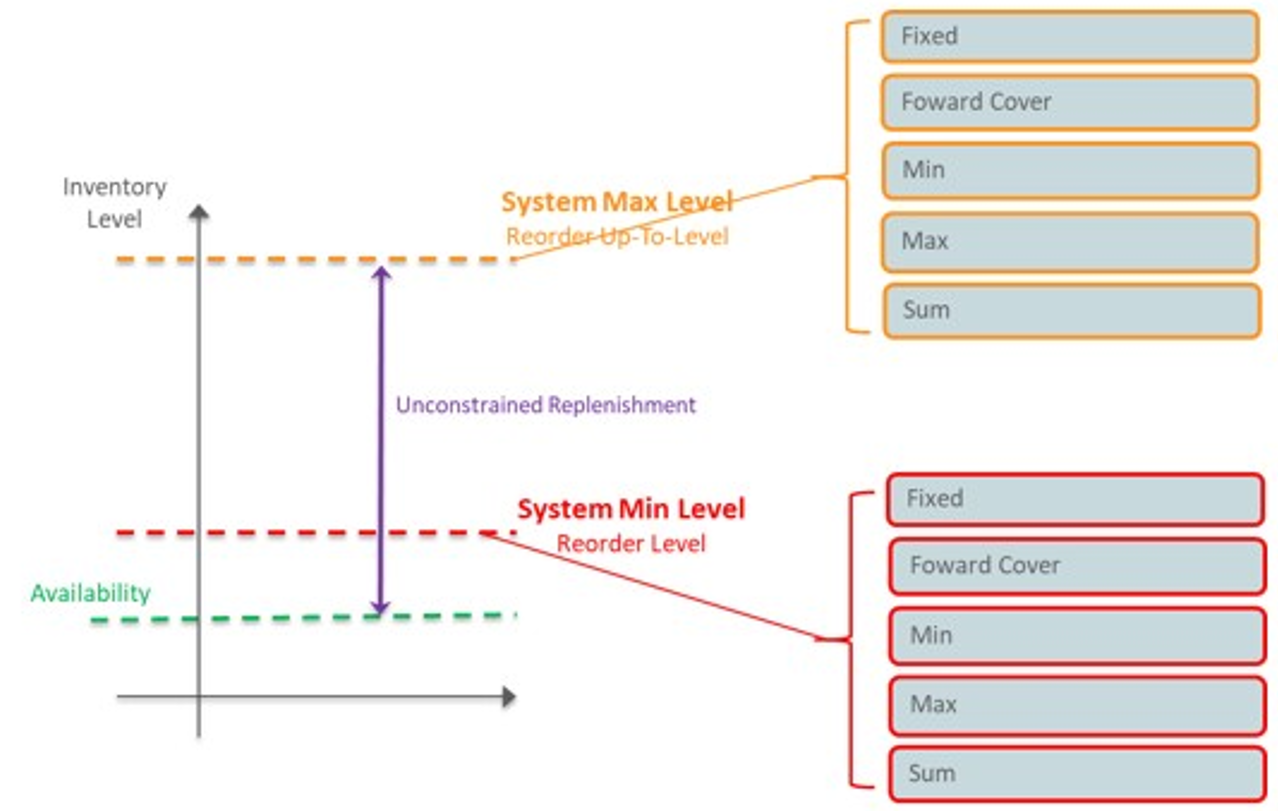

Replenishment Key Concepts

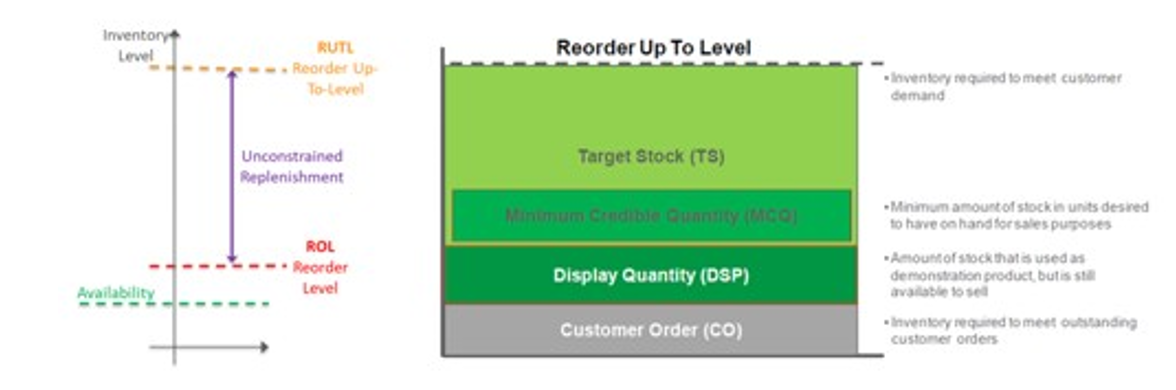

Replenishment parameters are used to specify the Reorder Level (ROL) and the Reorder Up to Level (RUTL) methods along with the associated parameters that is used in generating point in time planned orders.

Reorder Level (ROL) is the inventory level that determines whether an order for replenishment should be placed at the time of review or not. At the time of review, if the stock levels are less than the ROL, then an order for replenishment is placed, otherwise it is ignored until the next cycle.

Reorder Up to Level (RUTL) is level that must be maintained to meet expected service levels for demand fulfilment.

Figure 20-11 Reorder Level (ROL) and Reorder Up to Level (RUTL)

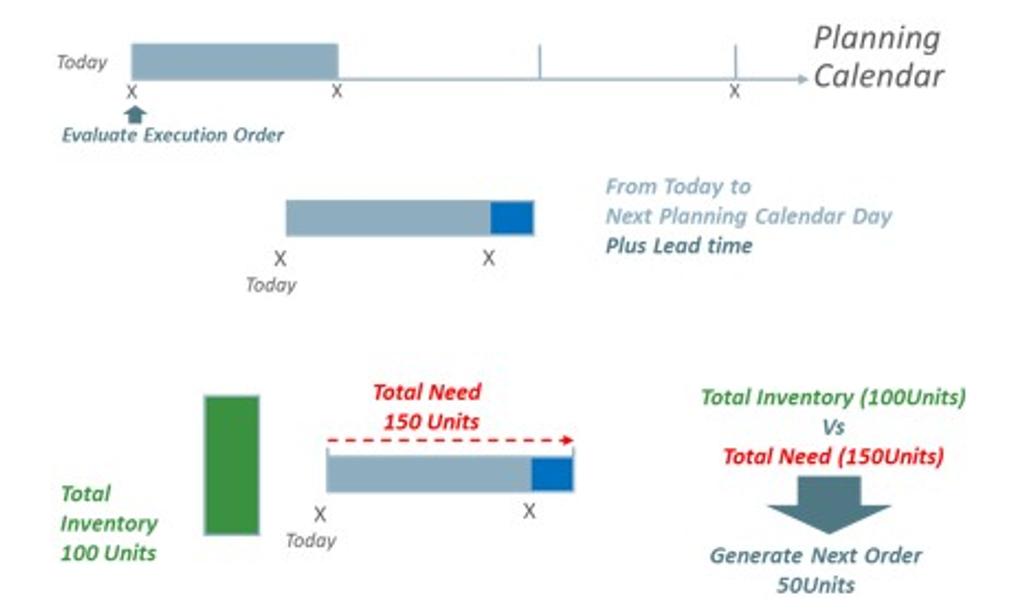

The replenishment is a point in time replenishment. In another words, it calculates the replenishment units, for a particular product and location combination, to fulfil the demand from the system date until the next planning day in the Planning Calendar plus the lead time.

Figure 20-12 Point in Time Replenishment

Point in Time Replenishment Methods

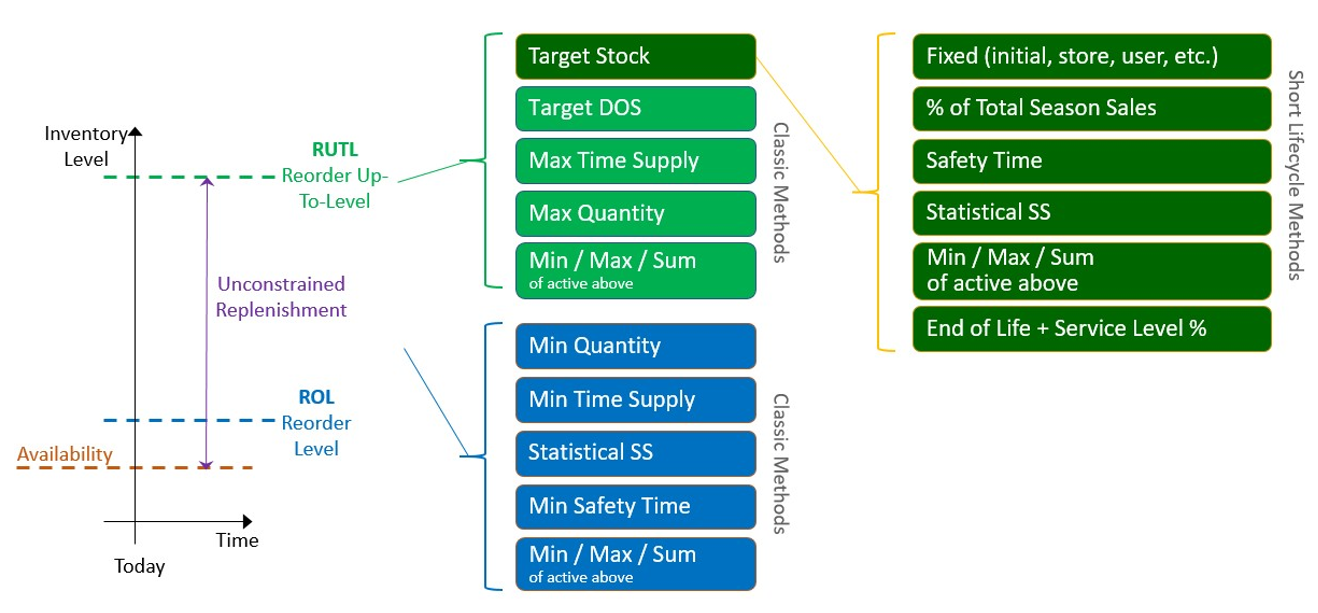

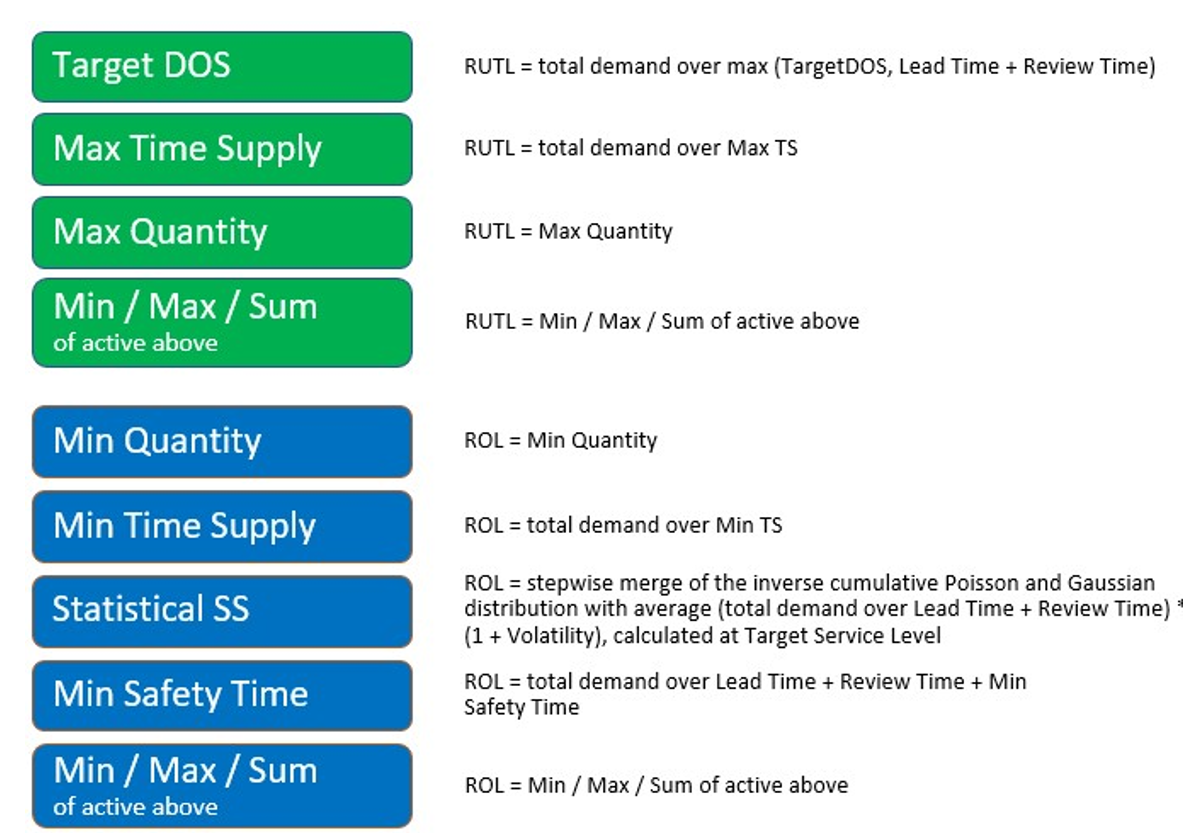

Lifecycle Inventory Planning has the following replenishment methods for the ROL and RUTL calculations.

ROL Methods

-

Statistical Safety Stock: This replenishment method calculates the ROL taking into account the cumulated demand forecast from current date up to the number of days set as Lead Time plus Next Review Time. It considers the Target Service Level (Target SL %) and Volatility (Volatility %) in the calculation too

-

Minimum Time Supply: This replenishment method calculates the ROL taking into account the cumulated demand forecast from current date up to the number of days defined as minimum time to supply (in days).

-

Minimum Quantity: This replenishment method calculates the ROL taking into account the value defined as the minimum quantity units.

-

Minimum Safety Time: This replenishment method calculates the ROL to the cumulated demand forecast from the first forecast date up to the number of days set to Lead Time plus Next Review Time plus the number of days to shift set in Minimum Safety Time (days).

-

Minimum: This replenishment method calculates the ROL to the minimum of the active ROL methods.

-

Maximum: This replenishment method calculates the ROL to the maximum of the active ROL methods.

-

Sum: This replenishment method calculates the ROL to the sum of the active ROL methods.

RUTL Methods

-

Maximum Quantity: This replenishment method calculates the RUTL taking into account the value defined as the maximum quantity units.

-

Maximum Time Supply: This replenishment method calculates the RUTL taking into account the cumulated demand forecast from current date up to the number of days defined as maximum time to supply (in days).

-

Target Days Of Supply:This replenishment method calculates the RUTL taking into account the cumulated demand forecast from current date up to the number of days defined as days of supply or up to the number of days of Lead Time plus Next Review Time. The application picks the highest number of days between the two options.

-

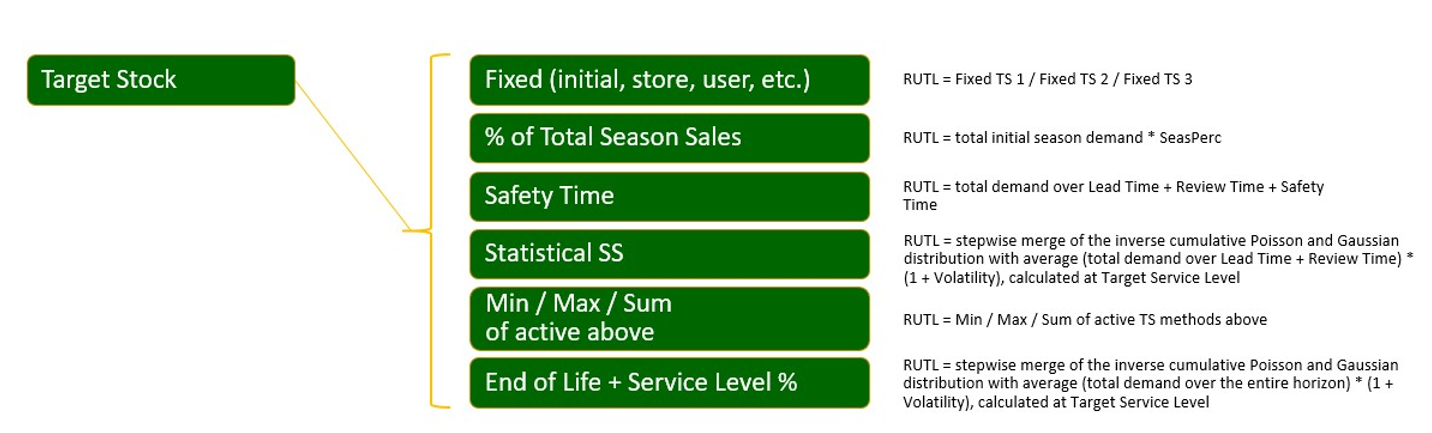

Target Stock: This replenishment method more suitable to the short lifecycle products. The replenishment engine calculates the RUTL based on a target stock quantity. The target stock quantity can be calculated using the following options.

-

Fixed 1: This method sets the target stock to the initial allocation quantity (loaded from external sources).

-

Fixed 2: This method sets the target stock to an user-entered allocation quantity (managed within IPOCS-Lifecycle Allocation and Replenishment).

-

Fixed 3: This method sets the target stock to any other potential source for the initial allocation (this is a placeholder than can be used by customers).

-

Season Sales Percentage: This method sets the target stock a percentage of the total season sales. Used to define percentage to calculate the value from the total initial forecast for the season.

-

Stock Safety Time: This method sets the target stock to the cumulated demand forecast from the first forecast date in the future up to the number of days set to Lead Time plus Next Review Time plus the number of days to shift.

-

Statistical Safety Stock: This method sets the target stock to the cumulated demand forecast from current date up to the number of days set as Lead Time plus Next Review Time. It considers the Target Service Level (Target SL %) and Volatility (Volatility %) in the calculation too.

-

End of Life: This method sets the target stock to the cumulated demand forecast from current date up to the end of life date. It considers the Target Service Level (Target SL %) and Volatility (Volatility %) in the calculation too.

-

-

Minimum: This method sets the target stock to the minimum of the active Target Stock methods (excluding End of Life).

-

Maximum: This method sets the target stock to the maximum of the active Target Stock methods (excluding End of Life).

-

Sum: This method sets the target stock to the sum of the active Target Stock methods (excluding End of Life).

-

Minimum: This replenishment method calculates the RUTL to the minimum of the active RUTL methods.

-

Maximum: This replenishment method calculates the RUTL to the maximum of the active RUTL methods.

-

Sum: This replenishment method calculates the RUTL to the sum of the active RUTL methods.

Figure 20-13 Point in Time Replenishment Methods

Figure 20-14 Reorder Level (ROL) and Reorder Up to Level (RUTL) Method Details

Figure 20-15 Reorder Level (ROL) and Reorder Up to Level (RUTL) Method: Target Stock Details

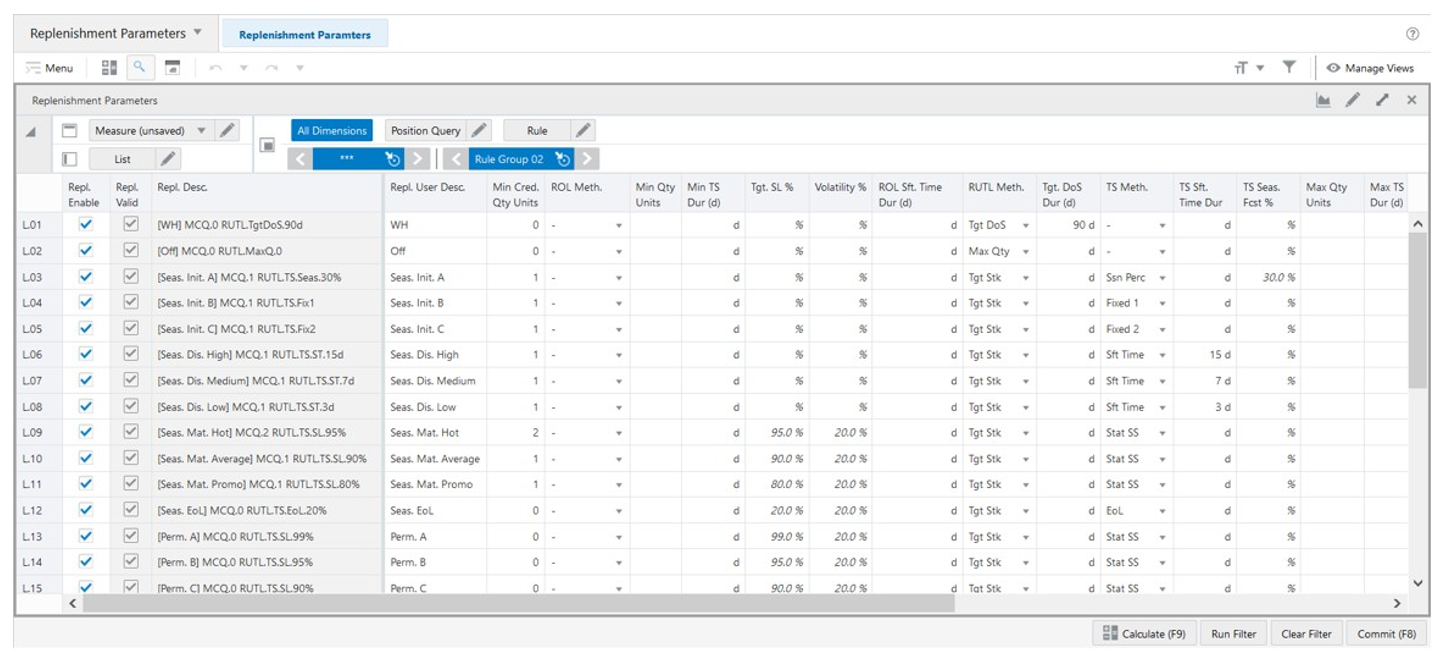

Replenishment Parameters View

The Replenishment Parameters View, under the Replenishment Parameters tab, allows you to set up of all possible Replenishment Parameters that can be used by the replenishment parameters rules to be applied on products and locations for the Replenishment (Point-In-Time) calculation. Each list (row) in the view represents a different replenishment parameter set up.

Figure 20-16 Replenishment Parameters View

Replenishment Parameters View - Default Profile Measures

The Replenishment Parameters view contains the following measures.

Replenishment Enable

Replenishment Enable is an editable measure used to enable or disable a replenishment parameter. Each row (or list) represents a different replenishment parameter.

Replenishment Valid

Replenishment Valid is a calculated measure used to indicate if the set up of the replenishment parameter is valid or not. For example, if the Reorder Level (ROL) and Reorder Up to Level (RUTL) methods are missing then the replenishment parameter is not valid for the rule engine.

Replenishment Description

Replenishment Description is a calculated measure used to indicate the replenishment parameter description. The description is calculated based on the replenishment parameter user-defined description and the replenishment parameter set up selected by you.

Replenishment User Description

Replenishment User Description is an editable measure used to enter a user-defined replenishment parameter description. The final replenishment parameter description takes the user-defined description into consideration. The entered value must not contain a colon punctuation mark (:).

Minimum Credible Quantity Units

Minimum Credit Quantity Units is an editable measure used to define the minimum amount of stock desired to have on hand for sales purposes.

Reorder Level (ROL) Method

Reorder Level Method is an editable measure to select the method to be used by the replenishment engine to calculate the ROL. Valid values are:

-

-

Option to clear the ROL Method.

-

Minimum Quantity

Option to set up the ROL Method as the Minimum Quantity method. When selected the ROL is calculated to the value set in the measure Minimum Quantity Units.

-

Minimum Target Stock

Option to set up the ROL Method as the Minimum Time Supply method. When selected the ROL is calculated value of the cumulated demand forecast from current date up to the number of days set in the measure Minimum Target Stock Duration (day).

-

Stat Safety Stock

Option to set up the ROL Method as the Statistical Safety Stock method. When selected the ROL calculation uses the lead time, the next review time in the Planning Calendar, the service level set in the measure Target Service Level % and the volatility set in the measure Volatility %.

Note:

When the RUTL method is set to Target Stock the RUTL and ROL will have the same value. No need to select the ROL method in this case.

Minimum Quantity Units

Minimum Quantity Units is an editable measure used to fix the minimum amount of stock desired when the ROL method is set to Minimum Quantity.

Minimum Target Stock Duration (day)

Minimum Time Supply Duration (day) is an editable measure used to fix the number of days to use to calculate the ROL value from the cumulative demand forecast. This measure is used when the ROL method is set to Minimum Target Stock.

Target Service Level %

Target Service Level Percentage is an editable measure used to define the service level. This value is used in the ROL and RUTL calculation when the statistical safety stock method is used.

Volatility %

Volatility Percentage is an editable measure used to define the volatility. This value is used in the ROL and RUTL calculation when the statistical safety stock method is used.

ROL Stock Safety Time Duration (day) Reorder Up to Level (RUTL) Method

Reorder Level Stock Safety Time Duration (day) Reorder Up to Level Method is an editable measure to select the method to be used by the replenishment engine to calculate the RUTL. The valid values are:

-

-

Option to clear the RUTL Method.

-

Maximum Quantity

Option to set up the RUTL Method as the Maximum Quantity method. When selected the RUTL is calculated to the value set in the measure Maximum Quantity Units.

-

Maximum Target Stock

Option to set up the RUTL Method as the Maximum Time Supply method. When selected the RUTL is calculated to the value of the cumulated demand forecast from current date up to the number of days set in the measure Maximum Target Stock Duration (day).

-

Target Days of Supply

Option to set up the RUTL Method as the Target Days of Supply method. When selected the RUTL is calculated to the value of the cumulated demand forecast from current date up to the highest number of days from the following options.

-

Number of days fixed in the measure Target Days of Supply Duration (day)

-

Number of days of lead time plus number of days to the next review time

-

-

Target Stock

Option to set up the RUTL Method as the Target Stock method. When selected the RUTL is calculated using the method selected in the measure Target Stock Method

Note:

When the RUTL method is set to Target Stock the RUTL and ROL will have the same value. No need to select the ROL method in this case.

Target Days of Supply Duration (day)

Target Days of Supply Duration (day) is an editable measure used to fix the number of days to use to calculate the RUTL value from the cumulative demand forecast. This measure is used when the RUTL method is set to Target Days of Supply.

Target Stock Method

Target Stock Method is an editable measure to select the target stock method to be used by the replenishment engine when the RUTL method is Target Stock. The valid values are:

-

-

Option to clear the target stock Method.

-

Fixed 1

When selected the target stock is calculated to the value set in the measure Target Stock Fixed 1 (initial allocation).

-

Fixed 2

When selected the target stock is calculated to the value set in the measure Target Stock Fixed 2 (manual allocation).

-

Fixed 3

When selected the target stock is calculated to the value set in the measure Target Stock Fixed 3 (placeholder for other source of allocation).

-

Stock Seasonal Percentage

When selected the target stock is calculated as a percentage of the total forecast sales for the season. The percentage used in the calculation is the one set in the measure Target Stock Seasonal Forecast %.

-

Stock Safety Time

When selected the target stock is calculated to the value of the cumulated demand forecast from current date up to the number of days of the lead time plus the number of days to the next review time plus the number of days for the Target Stock Safety Time Duration (measure Target Stock Stock Safety Time Duration (day)).

-

Statistical Safety Stock

When selected the target stock is calculated to the value of the cumulated demand forecast plus the safety stock from current date up to the number of days of the Lead Time plus the number of days for the next review time plus the number of days for the Target Stock Safety Time Duration (measure Target Stock Stock Safety Time Duration (day)). It also considers the service level set in the measure Target Service Level % and the volatility set in the measure Volatility % when calculating the target stock.

-

End of Life

When selected the target stock is calculated to the value of the cumulated demand forecast plus the safety stock from current date up to the number of days to reach the end-of-life date. It also considers the service level set in the measure Target Service Level % and the volatility set in the measure Volatility % when calculating the target stock.

-

Minimum

When selected the target stock is the minimum value from the methods of Fixed, % of Total Season Sales, Safety Time and Statistical SS.

-

Maximum

When selected the target stock is the maximum value from the methods of Fixed, % of Total Season Sales, Safety Time and Statistical SS.

Target Stock Stock Safety Time Duration (day)

Target Stock Stock Safety Time Duration (day) is an editable measure used to set the number of days for the stock safety. This value is used in the target stock calculations when the RUTL method (RUTL Method) is set to Target Stock and the target stock method (Target Stock Method) is set either to Stock Safety Time or to Statistical Safety Stock.

Target Stock Seasonal Forecast %

Target Stock Seasonal Forecast Percentage is an editable measure used to set the percentage of the Seasonal Forecast that should be used to calculate the target stock. This value is used when the RUTL method (RUTL Method) is set to Target Stock and the target stock method (Target Stock Method) is set Season Sales Percentage.

Maximum Quantity Units

Maximum Quantity Units is an editable measure used to fix the maximum amount of stock desired when the RUTL method is set to Maximum Quantity.

Maximum Target Stock Duration (day)

Maximum Target Stock Duration (day) is an editable measure used to fix the number of days to use to calculate the RUTL value from the cumulative demand forecast. This measure is used when the RUTL method is set to Maximum Target Stock.

Order Round

Order Round is an editable measure used to set the percentage on when to round up the orders if the pack size is greater than 1.

Rule Replenishment Count

Rule Replenishment Count is a calculated measure used to display the total number of rules that are using the replenishment parameter.

Product Location Replenishment Count

Product and Location Replenishment Count is a calculated measure used to display the total number of product and location combinations that associated with the replenishment parameter.

Product Location Replenishment %

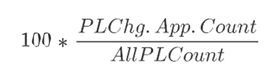

Product and Location Replenishment Percentage is a calculated measure used to indicate, in percentage, how much the product and location combinations associated with the replenishment parameter represents in the total of product and location combinations with a lifecycle phase value. The measure is calculated as:

Figure 20-17 Calculation

Replenishment User Filter

Replenishment User Filter is an editable measure used to select the replenishment parameter to filter the views by the selected replenishment parameter. This measure is used by the Run Filter action button responsible to calculate the filters applied to the views within the Replenishment Parameters workspace.

Replenishment Change Parameters Concept

Replenishment change parameters allows you to set up parameters to override the system calculated Re-Order Level (ROL) and the Re-Order Up to Level (RUTL) values (calculated from the replenishment parameters set up).

The change replenishment parameters provide the following capabilities. You can:

-

Define a percentage to increase or decrease the system calculated ROL and RUTL.

-

Override the replenishment parameters status. When a replenishment parameter status is enabled, the change parameter can force the replenishment parameter status to disable and the other way around.

As an example, the replenishment change parameters can be leveraged to prepare for an upcoming event by incising the RUTL providing the adequate stock to cover the upcoming demand.

Following are some examples of a set up for the change parameters:

-

ON – Overrides replenishment parameters status to Enable OFF – Overrides replenishment parameters status to Disable

-

RUTL +10% – Overrides the system calculated receipt up to level to increase it by 10%

-

RUTL +25 % – Overrides the system calculated receipt up to level to increase it by 25%

-

RUTL -10 % – Overrides the system calculated receipt up to level to decrease it by 10%

-

RUTL -25 % – Overrides the system calculated receipt up to level to decrease it by 25%

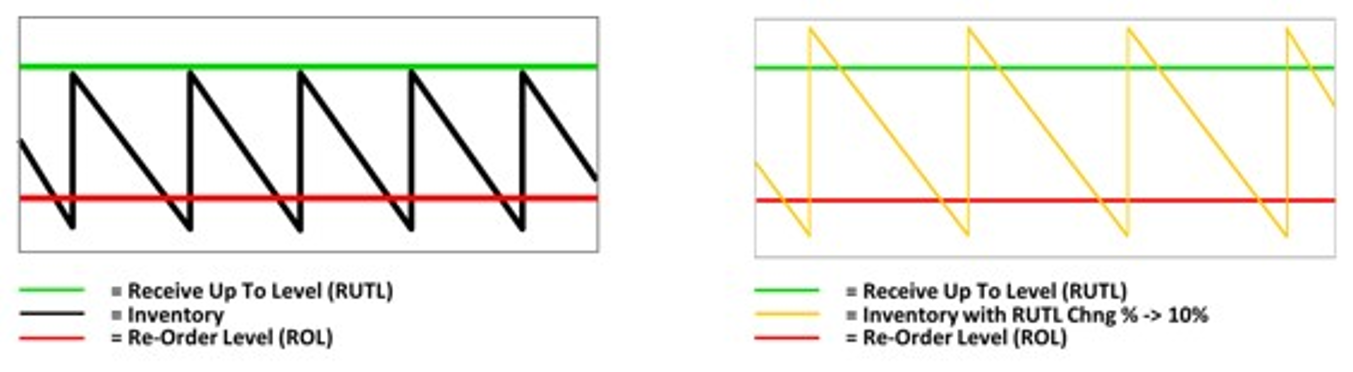

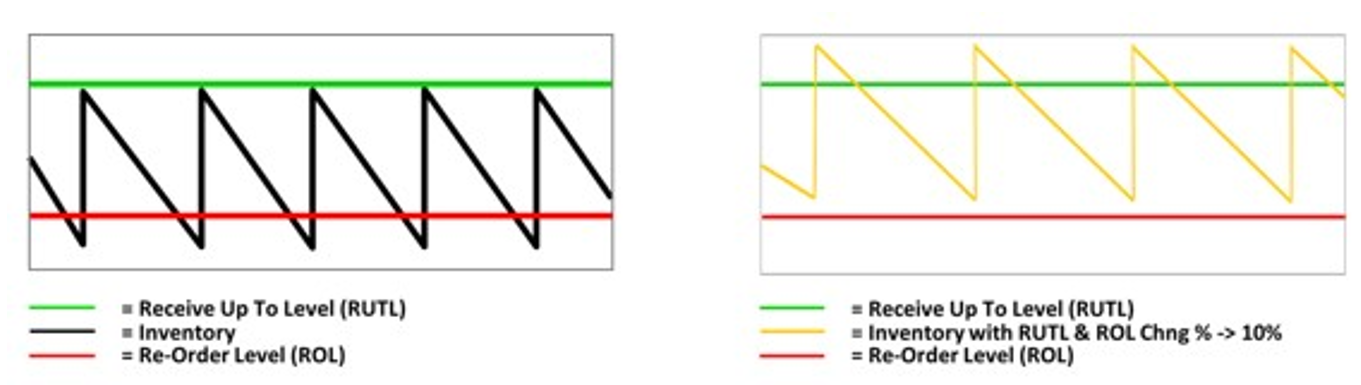

Figure 20-18 Replenishment Change Parameters RUTL +10%

Figure 20-19 Replenishment Change Parameters RUTL +10% & ROL +10%

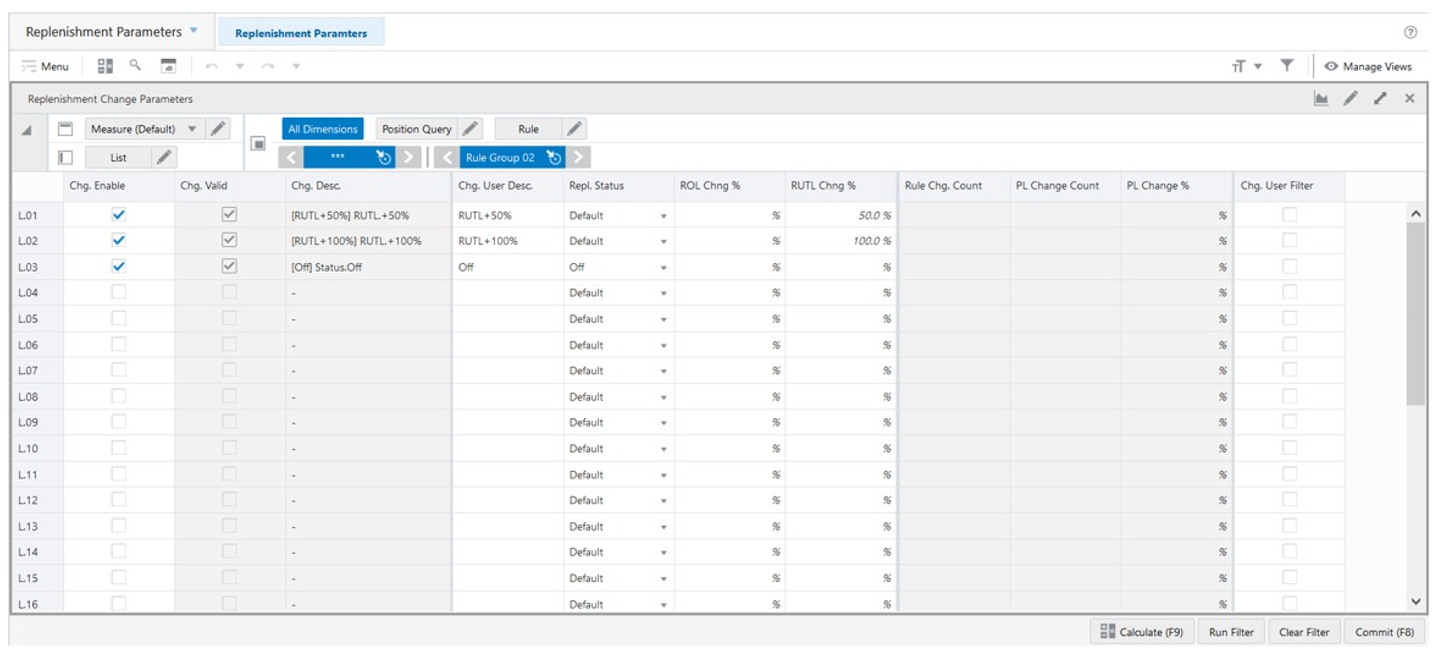

Replenishment Change Parameters View

The Replenishment Change Parameters View, under the Replenishment Parameters tab, allows you to set up changes to the existing replenishment set up. The change parameters allows you to increase or decrease the calculated Reorder Up to Level (RUTL) and Reorder Level (ROL) values and also allows you to override the replenishment status by enabling or disabling it.

Figure 20-20 Replenishment Change Parameters View

Replenishment Change Parameters View - Default Profile Measures

The Replenishment Change Parameters view contains the following measures.

Change Enable

Change Enable is an editable measure used to enable or disable a replenishment change parameter. Each row (or list) represents a different replenishment change parameter.

Change Valid

Change Valid is a calculated measure used to indicate if the set up of the replenishment change parameter is valid or not. For example, if the replenishment status is kept as default and no ROL and/or RUTL change percentage are indicated then the replenishment change parameter is not valid for the engine.

Change Description

Change Description is a calculated measure used to indicate the replenishment change parameter description. The description is calculated based on the replenishment change parameter user-defined description and the replenishment change parameter set up selected by you.

Change User Description

Change User Description is an editable measure used to enter a user-defined replenishment change parameter description. The final replenishment change parameter description takes the user-defined description into consideration. The entered value must not contain a colon punctuation mark (:).

Replenishment Status

Replenishment Status is an editable measure that allows you to override the replenishment status. The valid values are: Default : Option to not change the replenishment status and keep the system generated replenishment status.

-

On — Option to force the replenishment to turn on the replenishment

-

Off— Option to force the replenishment to turn off the replenishment

Reorder Level Change %

Reorder Level Change Percentage is an editable measure used that allows you to increase or decrease the system generated ROL value by the percentage value set in this measure. When the ROL should be increase then enter a positive value. When the ROL should be decreased then enter a negative value.

Reorder Up to Level Change %

Reorder Up to Level Change Percentage is an editable measure used that allows you to increase or decrease the system generated RUTL value by the percentage value set in this measure. When the RUTL should be increase then enter a positive value. When the RUTL should be decreased then enter a negative value.

Rule Change Count

Rule Change Count is a calculated measure used to display the total number of rules that are using the replenishment change parameter.

Product Location Change Count

Product and Location Change Count is a calculated measure used to display the total number of product and location combinations that associated with the replenishment change parameter.

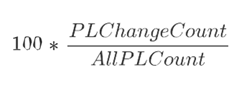

Product Location Change %

Product and Location Change Percentage is a calculated measure used to indicate, in percentage, how much the product and location combinations associated with the replenishment change parameter represents in the total of product and location combinations with a lifecycle phase value. The measure is calculated as:

Figure 20-21 Calculation

Change User Filter

Change User Filter is an editable measure used to select the replenishment change parameter to filter the views by the selected replenishment change parameter. This measure is used by the Run Filter action button responsible to calculate the filters applied to the views within the Replenishment Parameters Rules workspace.

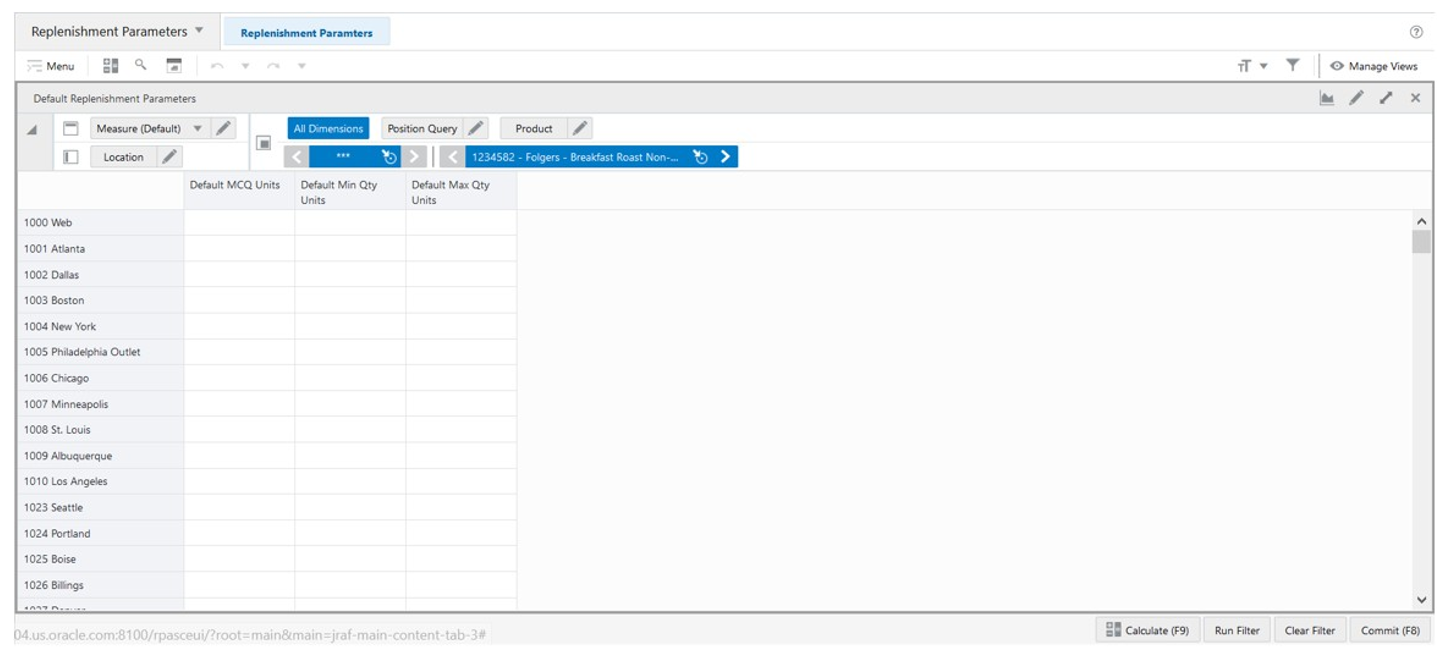

Default Replenishment Parameters View

The Default Replenishment Parameters view allows you to set up the default replenishment strategies.

Figure 20-22 Default Replenishment Parameters View

Default Replenishment Parameters View - Default Profile Measures

The Default Replenishment Parameters view contains the following measures.

Default Minimum Credible Quantity Units

Default Minimum Credible Quantity Units an editable measure used to define the default Minimum Credible Quantity for the product and location combination.

Default Minimum Quantity Units

Default Minimum Quantity Units is an editable measure used to define the default the minimum amount of stock desired when the ROL method is set to Minimum Quantity.

Default Maximum Quantity Units

Default Maximum Quantity Units is an editable measure used to define the default maximum amount of stock desired when the RUTL method is set to Maximum Quantity.

Inventory Plan Parameters Step

This step contains this view, Inventory Plan Parameters View.

Inventory Planning Parameters Key Concept

Use Inventory planning parameters to generate the time-phased inventory planning. Inventory parameters specify the System Minimum (which is the reorder level) and the System Maximum (which is the reorder up to level) methods along with the associated parameters is used in generating the time phased plans.

-

System Minimum (ROL) is the inventory level that determines whether an order for replenishment should be placed at point of receipting week. At the point of receipting week, if the stock levels are less than the System Minimum, then an order for replenishment is placed, otherwise it is ignored until the next cycle.

-

System Maximum (RUTL) is the target inventory level. While the replenishment point in time generates the orders at the system date. The time-phased inventory planning provides you with a weekly view on the inventory and the orders to be placed (the inventory plan is a projection based on current point in time network and product lifecycle status).

Time-Phased Replenishment Methods

IPOCS-Lifecycle Allocation and Replenishment has the following replenishment methods for the System Minimum (ROL) and System Maximum (RUTL) calculations.

System Minimum (ROL)

-

Fixed

This method uses the point-in-time replenishment values and does not calculate at every receipt opportunity. Either the ROL or RUTL values can be chosen from the point in time replenishment.

-

Forward Cover

This method calculates the value to cover the demand for the minimum number of days that should set by you in this method.

-

Minimum

This method uses the calculated value from the Fixed and Forward Cover methods and results is the lowest value between the two.

-

Maximum

This method uses the calculated value from the Fixed and Forward Cover methods and the result is the highest value between the two.

-

Sum

This method uses the calculated value from the Fixed and Forward Cover methods and the result is the sum both values.

System Maximum (RUTL)

-

Fixed

This method sets the value to a fixed user-defined value.

-

Forward Cover

This method calculates the value to cover the demand for the maximum number of days that should set by you in this method.

-

Minimum

This method uses the calculated value from the Fixed and Forward Cover methods and results is the lowest value between the two.

-

Maximum

This method uses the calculated value from the Fixed and Forward Cover methods and the result is the highest value between the two.

-

Sum

This method uses the calculated value from the Fixed and Forward Cover methods and the result is the sum both values.

Figure 20-23 Time-Phased Replenishment Methods

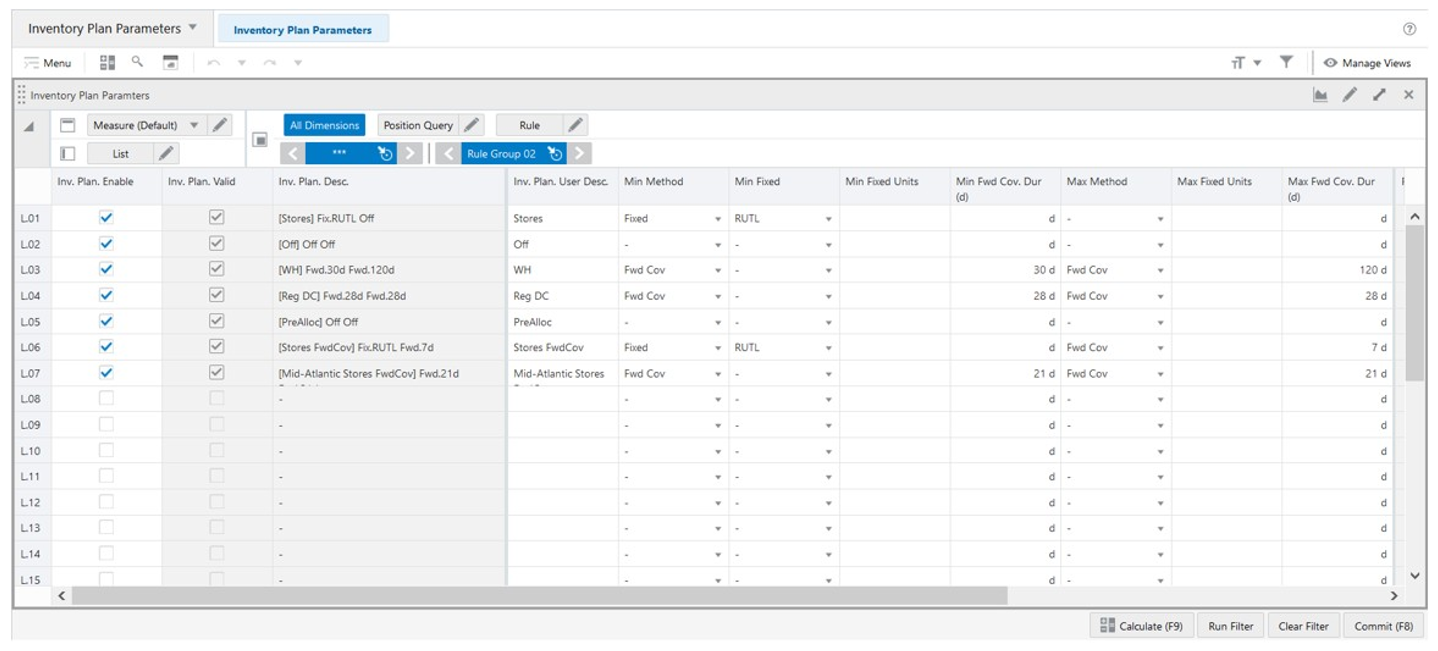

Inventory Plan Parameters View

The Inventory Plan Parameters View, under the Inventory Plan Parameters tab, allows you to set up all the possible Minimum and Maximum Level Methods for the Inventory Plan that can be used to set up the replenishment rules that will then be used by the engine to generate the time-phased replenishment.

Figure 20-24 Inventory Plan Parameters View

Inventory Plan Parameters View - Default Profile Measures

The Inventory Plan Parameters view contains the following measures.

Inventory Plan Enable

Inventory Planning Enable is an editable measure used to enable or disable an inventory planning parameter. Each row (or list) represents a different inventory planning parameter.

Inventory Plan Valid

Inventory Planning Valid is a calculated measure used to indicate if the set up of the inventory planning parameter is valid or not. An inventory planning parameter is considered valid if it is enabled.

Inventory Plan Description

Inventory Planning Description is a calculated measure used to indicate the inventory planning parameter description. The description is calculated based on the inventory planning parameter user-defined description and the inventory planning parameter set up selected by you.

Inventory Plan User Description

Inventory Planning User Description is an editable measure used to enter a user-defined inventory planning parameter description. The final inventory planning parameter description takes the user-defined description into consideration. The entered value must not contain a colon punctuation mark (:).

Minimum Method

Minimum Method is an editable measure used to select the method to calculate the System Minimum (which is the reorder level) value. The valid values are:

-

Fixed

When this option is selected, then the point-in-time replenishment is used for the calculation and in the measure Minimum Fixed.

-

Forward Cover

When this option is selected, then the calculation calculates the demand to cover the amount of stock required for the number of days indicated in the measure Minimum Forward Cover Duration (day).

-

Minimum

When this option is selected, then the calculation sets the value to the minimum value resulted from the Fixed and Forward Cover methods.

-

Maximum

When this option is selected, then the calculation sets the value to the maximum value resulted from the Fixed and Forward Cover methods.

-

Sum

When this option is selected, then the calculation sets the value to the sum of the values resulted from the Fixed and Forward Cover methods.

Minimum Fixed

Minimum Fixed is an editable measure used to select how the Fixed method calculates the System Minimum (which is the reorder level) value. The valid values are:

-

-

When this option is selected the result is set to the value in the measure Minimum Fixed Units.

-

ROL

When this option is selected the result is set to the ROL value from the point-in-time replenishment.

-

RUTL

When this option is selected the result is set to the RUTL value from the point-in-time replenishment.

Minimum Fixed Units

Minimum Fixed Units is an editable measure used to define the minimum fixed quantity to be used when the Minimum Method is Fixed and the Minimum Fixed is -.

Minimum Forward Cover Duration (day)

Minimum Forward Cover Duration (day) is an editable measure used to define the minimum number of days of cover to be used when the Minimum Method is Forward Cover.

Maximum Method

Maximum Method is an editable measure used to select the method to calculate the System Maximum (which is the reorder up-to level) value. The valid values are:

-

Fixed

When this option is selected the calculation sets it to the value in the measure Maximum Fixed Units.

-

Forward Cover

When this option is selected, then the calculation calculates the demand to cover the amount of stock required for the number of days indicated in the measure Maximum Forward Cover Duration (day).

-

Minimum

When this option is selected, then the calculation sets the value to the minimum value resulted from the Fixed and Forward Cover methods.

-

Maximum

When this option is selected, then the calculation sets the value to the maximum value resulted from the Fixed and Forward Cover methods.

-

Sum

When this option is selected, then the calculation sets the value to the sum of the values resulted from the Fixed and Forward Cover methods.

Maximum Fixed Units

Maximum Fixed Units is an editable measure used to define the maximum fixed quantity to be used when the Maximum Method is Fixed.

Maximum Forward Cover Duration (day)

Maximum Forward Cover Duration (day) is an editable measure used to define the maximum number of days of cover to be used when the Maximum Method is Forward Cover.

Rule Inventory Planning Count

Rule Inventory Planning Count is a calculated measure used to display the total number of rules that are using the inventory planning parameter.

Product Location Inventory Planning Count

Product and Location Inventory Planning Count is a calculated measure used to display the total number of product and location combinations that associated with the inventory planning parameter.

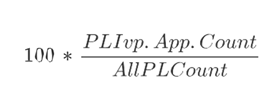

Product Location Inventory Planning %

Product and Location Inventory Planning Percentage is a calculated measure used to indicate, in percentage, how much the product and location combinations associated with the inventory planning parameter represents in the total of product and location combinations with a lifecycle phase value. The measure is calculated as:

Figure 20-25 Calculation

Inventory Planning User Filter

Inventory Planning User Filter is an editable measure used to select the inventory planning parameter to filter the views by the selected inventory planning parameter. This measure is used by the Run Filteraction button responsible to calculate the filters applied to the views within the Replenishment Parameters workspace.

Constraint Parameters Step

This step contains these views:

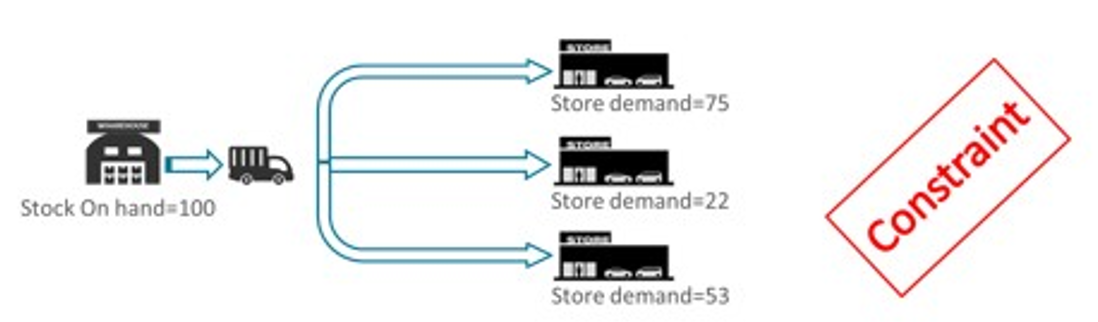

Replenishment Constraint Parameters Concept

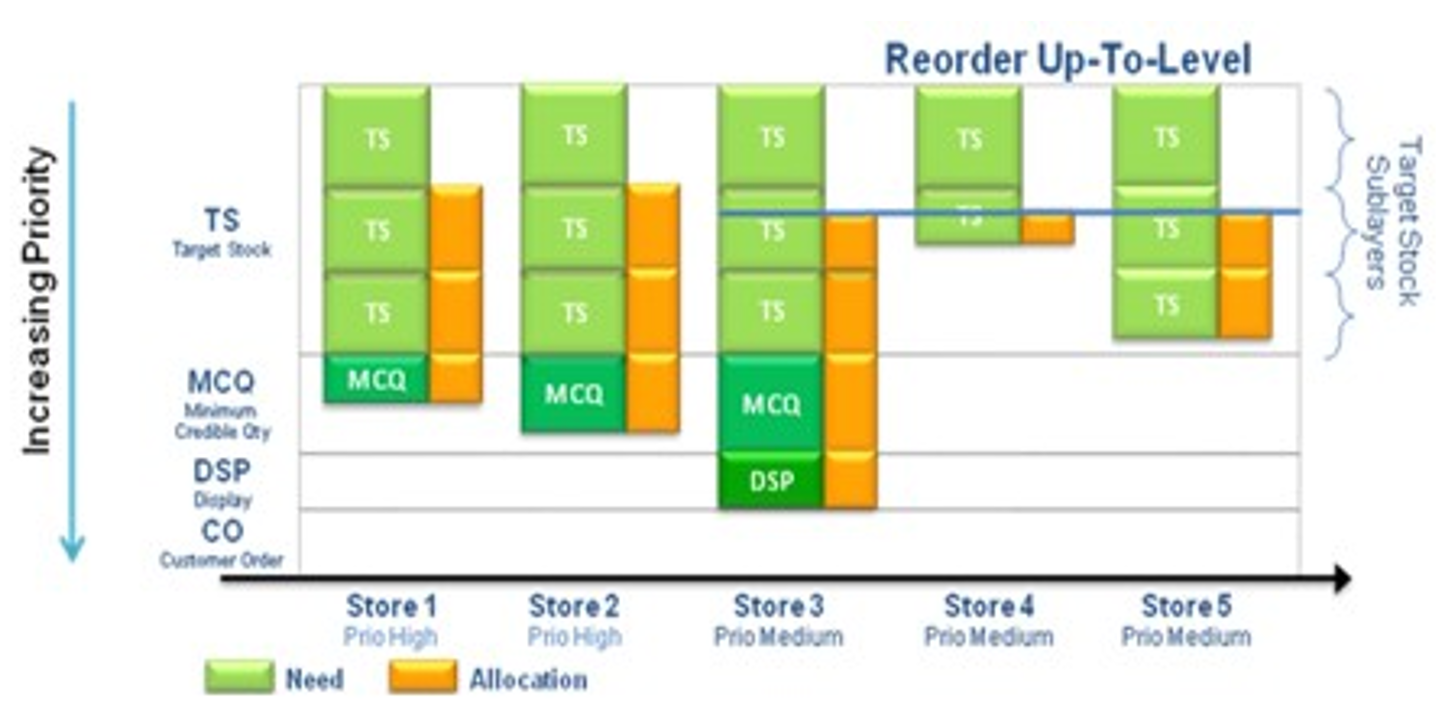

Replenishment Constraint Parameters allows you to set up parameters to indicate to the replenishment engine how to ration the stock when there is a stock constraint (for example, shortage). When facing stock shortages, the engine needs to adapt and fulfil the remaining stock to the stores in a way that ensures that the highest probability of sales is covered.

Figure 20-26 Example of a Replenishment Constraint

Rationing constrained stock is not solely based on store priority; allocating to the biggest (most important) stores can create missed sales. The replenishment engine approaches rationing based on the concept of layers. It tries to fulfill the most important on all stores requiring stock (using the store priority) before moving to the next layer. In this manner, the replenishment engine maximizes both service levels and the ability to sell.

The following available layers within IPOCS-Lifecycle Allocation and Replenishment are listed from the highest priority to the lowest priority:

-

Customer Orders

-

Display Quantity

-

Minimum Credible Quantity

-

Target Stock - Reorder Level (ROL)

-

Target Stock - Reorder Up-To Level (RUTL)

-

Target Stock - Pack

-

Target Stock - Push

Figure 20-27 Example of Rationing based on Layers

As illustrated in the previous image the engine prioritizes the Store 3 despite the fact it is not the store with the higher priority. However, the Store 3 is where the layer with the higher priority needs to be fulfilled first. Once that layer is fulfilled, the engine moves to the stores the next layer with more priority needs to be fulfilled and so on until the available stock is distributed. Note that if there are two stores for the same layer priority to be fulfilled then the store priority is used.

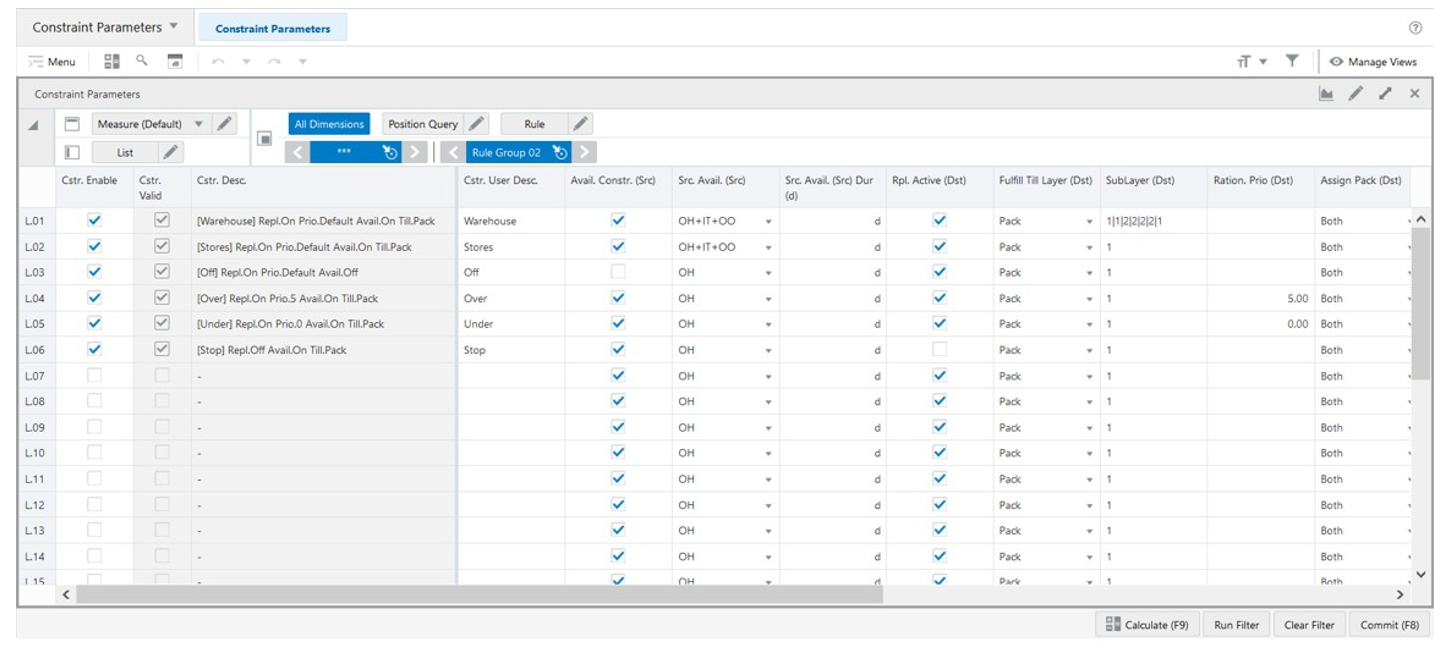

Constraint Parameter View

The replenishment engine utilizes constraint parameters to define the allocation of stock by changing the priorities of the destination location and/or changing the layer of allocation to fulfill. You may also set the destination location to active or not and the source location to constrained or unconstrained.

Figure 20-28 Constraint Parameters View

Constraint Parameters View - Default Profile Measures

The Constraint Parameters view contains the following measures.

Constraint Enable

Constraint Enable is an editable measure used to enable or disable a replenishment constraint parameter. Each row (or list) represents a different replenishment constraint parameter.

Constraint Valid

Constraint Valid is a calculated measure used to indicate if the set up of the replenishment constraint parameter is valid or not. A replenishment constraint parameter is considered valid if it is enabled.

Constraint Description

Constraint Description is a calculated measure used to indicate the replenishment constraint parameter description. The description is calculated based on the replenishment constraint parameter user-defined description and the replenishment constraint parameter set up selected by you.

Constraint User Description

Constraint User Description is an editable measure used to enter a user-defined replenishment constraint parameter description. The final replenishment constraint parameter description takes the user-defined description into consideration. The entered value must not contain a colon punctuation mark (:).

Available Constraint (Source)

Available Constraint (Source) is an editable measure used to enable or disable the constraint for the source location.

Source Available (Source)

Source Available (Source) is an editable measure to select which stock units are used from the source locations. The valid values are:

-

OH

Option to use stock on hand as the available stock.

-

OH+IT

Option to use stock on hand plus the stock in transit as the available stock.

-

OH+IT+OO

Option to use stock on hand plus the stock in transit plus the stock on-order as the available stock.

Source Available Order

This measure allows the ability to decide from which bucket to choose the units while allocating purchase orders. The options are:

-

OH followed by OO

The on-hand units are used first, then the on-order.

-

OO followed by OH

The on-order units are used first, then the on-hand.

Source Available (Source) Duration (day)

Source Available (Source) Duration (day) is an editable measure used to define the number of days to get the in-transit and on-order stock. This number of days is used to calculate the available stock at the source location, measure Source Available (Source), when the in-transit and/or on-order option is selected.

Replenishment Active (Destination)

Replenishment Active (Distribute) is an editable measure used to enable or disable the replenishment for the destination location.

Fulfill Till Layer (Destination)

Fulfill Till Layer (Distribute) is an editable measure used to select the layer until which the engine should fulfill the demand at the destination location. You should select one of the following options:

-

1st layer = Customer Order

-

2nd layer = Display Quantity

-

3rd layer = Minimum Credible Quantity

-

4th layer = Reorder Level

-

5th layer = Reorder Up to Level

-

6th layer = Pack

-

7th layer = Push

SubLayer (Destination)

SubLayer (Distribute) is an editable measure used to define the sublayer at the destination location for each of the layers until the selected layer in the measure FulFill Till Layer (Destination). Use the | character to separate the number of sublayers between layers. For example, if the layer selected in the measure FulFill Till Layer (Destination) is the 5th layer = Reorder Up-To Level and the sublayers are as follows:

-

Customer Order has one layer

-

Display Quantity has two layers

-

Minimum Credible Quantity has two layers

-

Reorder Level (ROL) has two layers

-

Reorder Up to Level (RUTL) has two layers

Then the value for this measure is: 1|2|2|2|2

Ration Priority (Destination)

Ration Priority (Distribute) is an editable measure used to define a rationing priority for the destination locations.

Assign Pack (Destination)

Assign Pack (Distribute) is an editable measure to define pack types assigned for the destination locations. The valid values are:

-

Complex

Option to select pack which type is complex

-

Simple

Option to select pack which type is complex

-

Both

Option to select all pack types – simple and complex

Rule Constraint Count

Rule Constraint Count is a calculated measure used to display the total number of rules that are using the replenishment constraint parameter.

Minimum Pack Fill Rate 1 (Dst) %

Minimum Pack Fill Rate 1 (Distribute) Percentage is an editable measure used to define the minimum pack fill rate percentage for first round of complex pack assignment.

Minimum Pack Fill Rate 2 (Dst) %

Minimum Pack Fill Rate 2 (Distribute) Percentage is an editable measure used to define the minimum pack fill rate percentage for second round of complex pack assignment.

Note:

The fill rate is defined as: Fill rate = sum of the need of all components of the pack / sum of

components of the pack

LAR sorts the pack configuration from the largest to smallest, then pick the best pack with fill rate greater than or equal to Min Pack Fill Rate 1. If it does not satisfy this condition then it looks for the next pack configuration and compare it to Min Pack Fill Rate 2. If there is no pack that has minimum pack fill rate of 1 and 2 then it switches to allocating by eaches.

The lower the percentage the higher the chance to allocate more than the need.

For instance, if the Minimum Pack Fill Rate is set to 100%, LAR will fit as many packs as possible without overallocating, and the remaining need is allocated with eaches. If the Minimum Pack Fill Rate is set to 0%, LAR will allocate only packs, very likely overallocating. It will allocate eaches only if the pack inventory is exhausted.

Product Location Constraint Count

Product and Location Constraint Count is a calculated measure used to display the total number of product and location combinations that associated with the replenishment constraint parameter.

Product Location Constraint %

Product and Location Constraint Percentage is a calculated measure used to indicate, in percentage, how much the product and location combinations associated with the replenishment constraint parameter represents in the total of product and location combinations with a lifecycle phase value. The measure is calculated as:

Figure 20-29 Calculation

Constraint User Filter

Constraint User Filter is an editable measure used to select the replenishment constraint parameter to filter the views by the selected replenishment constraint parameter. This measure is used by the Run Filter action button responsible to calculate the filters applied to the views within the Replenishment Parameters workspace.

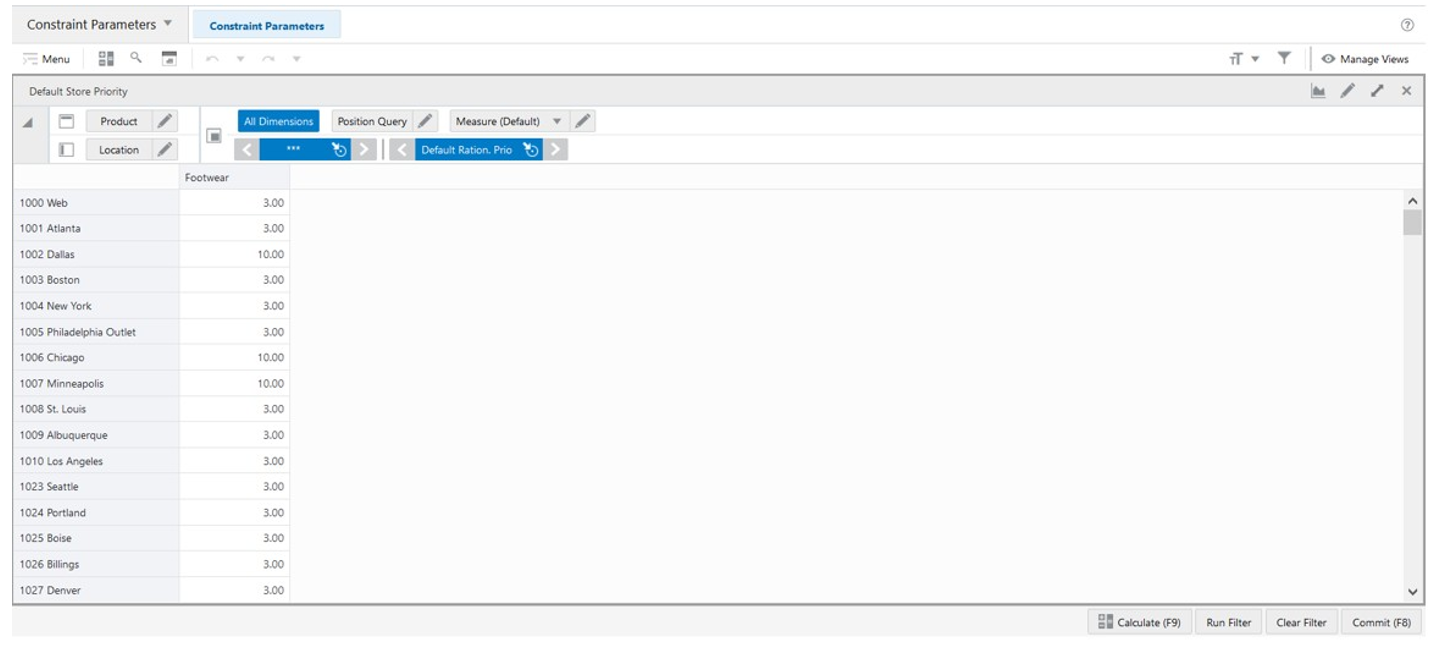

Default Store Priority View

The Default Store Priority View, under the Constraint Parameters tab, allows you to set up the locations priority by product partition to be used by the rationing process.

Figure 20-30 Default Store Priority View

Default Store Priority View - Default Profile Measures

The Default Store Priority view contains the following measure.

Default Ration Priority

Default Rationing Priority is an editable measure used to define the location’s priority, for the selected product partition, to be used by the engine for the rationing.

Rules Step

This step contains these views:

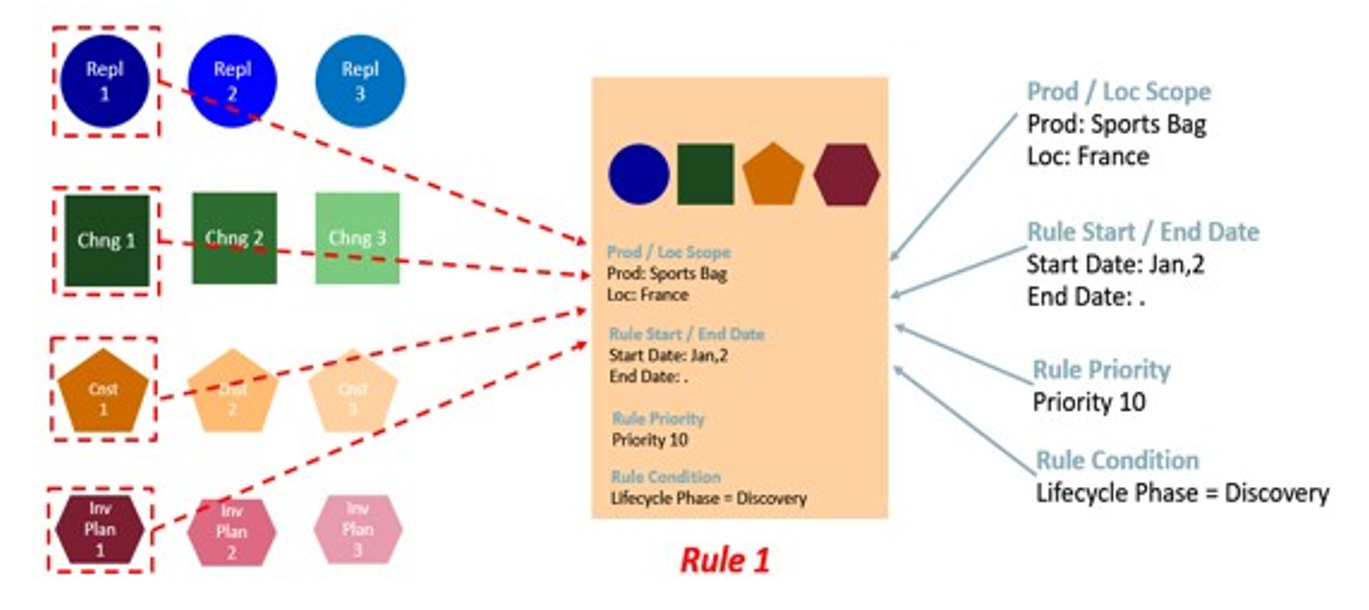

Rules Concept for the Replenishment Parameters Task

In a similar way to the Supply Chain Network workspace, IPOCS-Lifecycle Allocation and Replenishment provides a powerful engine that enables you to create a set of rules to apply all the set up completed, within the Replenishment Parameters Task (replenishment parameters, replenishment change parameters, replenishment constraint parameters and inventory planning parameters), down to the item and location levels. You can define multiple rules at higher-levels using product, location, and product-location combinations. The rule engine determines the correct set to apply a the lowest level of product and location combinations.

Rules allow you to specify the time frame for the rule (if applicable) and the rule priority. The rule priority allows the rule engine to choose the correct rule to be applied if a product and location combination fits in more than one replenishment parameter rule (higher the number, higher the priority). The rule start and end date are used by the engine to know if the rule should be considered or discarded. If the system date falls in the start date and end date (or rule dates are empty) then it is considered. Otherwise, it is discarded.

Following are two examples and illustrations of rules for the Replenishment Parameters task.

-

Rule 1

Should be configured to apply the Replenishment Param 1, Change Param 1, Constraint Param 1, and Inventory Plan Param 1.

-

The scope of the rule group where it is being configured (for example, Sport Bag products and the country France).

-

The condition where the rule applies is for all locations and products in the scope where the product-location lifecycle phase attribute is Discovery.

-

-

Rule 2

Should be configured to apply the Replenishment Param 2, Change Param 2, Constraint Param 2, and Inventory Plan Param 2.

-

The scope of the rule group where it is being configured (for example, Sport Bag products and the country France).

-

The condition where the rule applies is for all locations and products in the scope where the product-location lifecycle phase attribute is Maturity.

-

Note:

The condition is used by the rule engine to apply the set up to the product and location combinations that match the condition within the rule scope. The rule scope is defined by the Product Groups and Location Groups associated with the rule’s rule group.

Figure 20-31 Illustration for a Rule 1

Figure 20-32 Illustration for a Rule 2

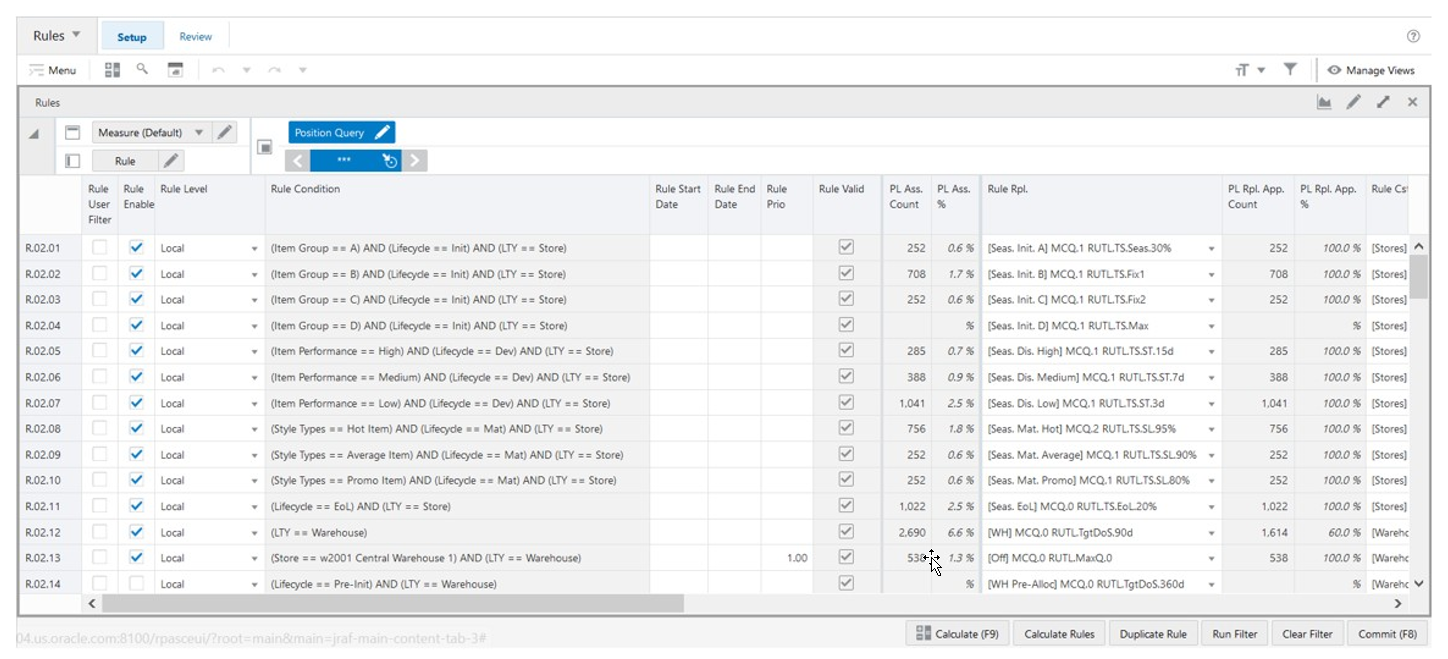

Rules View

The Rules View, under the Setup tab, allows you to configure the rules by enabling them and defining the rule start date, end date and priority for each one. Once configured you can set up the rule by selecting the replenishment parameters, replenishment change parameters, replenishment constraint parameters and inventory planning parameters that the rule uses. The product and locations that applies the rule set up is based on the scope of the rule’s rule group (Product Scope and Location Scope views) and the rule’s condition that is set up and managed in the Conditions view.

Figure 20-33 Rules View

Rules View - Measure Profiles

The Rules View contains the following profiles to change the measures that are visible in the view:

-

Default

This profile is used as default by the view. All the available or visible measures are listed and described in the section Measure: Default Profile.

-

Change

This profile displays a subset of measures from the default profile. It focuses on the rule and in the replenishment change parameters measures only. All other parameter related measures are left out of the visible measures.

-

Constraint

This profile displays a subset of measures from the default profile. It focuses on the rule and in the replenishment constraint parameters measures only. All other parameter related measures are left out of the visible measures.

-

Inventory Plan

This profile displays a subset of measures from the default profile. It focuses on the rule and in the inventory planning parameters measures only. All other parameter related measures are left out of the visible measures.

-

Replenishment

This profile displays a subset of measures from the default profile. It focuses on the rule and in the replenishment parameters measures only. All other parameter related measures are left out of the visible measures.

Rules View - Default Profile Measures

The Rules View contains the following measures.

Rule User Filter

Rule User Filter is an editable measure used to select the rule to filter the views by the selected rule. This measure is used by the Run Filter action button responsible to calculate the filters applied to the views within the Replenishment Parameters workspace.

Rule Enable

Rule Enable is an editable measure used to enable or disable a rule. Each row (or list) represents a different rule.

Rule Level

Rule Level an editable measure used to select the level at what the engine will run the rule. The valid options are:

-

Global

In this option the rule engine will fully override the rule group scope that was set up in the Manage Rule Groups workspace and applies the rule to all valid product and location combinations.

-

All Product

In this option the rule engine will partially override the rule group scope that was set up in the Manage Rule Groups workspace. The rule engine applies the rule to all valid product but for the locations in the rule group location’s scope only.

-

All Location

In this option, the rule engine will fully override the rule group scope that was set up in the Manage Rule Groups workspace. The rule engine applies the rule only to the products in the rule group product’s scope and all valid locations.

-

Local

In this option the rule engine applies the rule to products and locations in the rule group scope defined in the Manage Rule Groups workspace.

Rule Condition

Rule Condition is a calculated measure used to indicate the condition for which the rule is valid. The condition is the result of the set up completed in the Conditions view.

Rule Start Date

Rule Start Date is an editable measure used to define a start date for the rule (when the rule should become active). When the rule is valid, and the start date is empty then the rule engine applies it. When the rule is valid, and the start date is populated the rule engine will start to apply it only when the start date is reached.

Rule End Date

Rule End Date is an editable measure used to define an end date for the rule (when the rule should become inactive). When empty, the rule engine assumes that the rule has no end date and if it is valid, then the rule engine applies it. When the rule is valid, and the end date is populated, the rule engine stops applying it starting from the defined date.

Rule Priority

Rule Priority is an editable measure used to define the rule’s priority. The higher the number the higher the priority of the rule is. This rule priority is important to the rule engine as it is used when rules overlap each other. The rule engine uses the rule priority to select which one to apply.

Rule Valid

Rule Valid is a calculated measure used to indicate if the set up of the rule is valid or not. For example, if all replenishment parameters are missing then the rule is not valid for the rule engine. The engine needs at least one of them to be assigned for the rule to be considered as valid.

Product Location Associated Count

Product and Location Associated Count is a calculated measure used to display the total number of product and location combinations that are associated with the rule based on the rule’s condition.

Product Location Associated %

Product and Location Associated Percentage is a calculated measure used to indicate, in percentage, how much the product and location combinations, where the rule is applicable, represent in the total of product and location combinations within the rule group scope. The measure is calculated as:

Figure 20-34 Calculation

Rule Replenishment

Rule Replenishment is an editable measure for the you to select the replenishment parameter to be applied by the rule. This measure is a list populated with all valid replenishment parameters that were set up in the Replenishment Parameters view.

Product Location Replenishment Applied Count

Product and Location Replenishment Applied Count is a calculated measure used to display the total number of product and location combinations that applies this rule’s replenishment parameter. The calculation takes into account all the valid rules where the product and location combinations fall into and based on the priority calculates the count of product and location that applies the selected replenishment parameter.

Product Location Replenishment Applied %

Product and Location Replenishment Applied Percentage is a calculated measure used to indicate, in percentage, how much the product and location combinations, where the rule’s replenishment parameter is applicable, represent in the total of product and location combinations within the rule group scope. The measure is calculated as:

Figure 20-35 Calculation

Rule Constraint

Rule Constraint is an editable measure used to select the replenishment constraint parameter to be applied by the rule. This measure is a list populated with all valid replenishment constraint parameters that were set up in the Constraint Parameters view.

Product Location Constraint Applied Count

Product and Location Constraint Applied Count is a calculated measure used to display the total number of product and location combinations that applies this rule’s replenishment constraint parameter. The calculation takes into account all the valid rules where the product and location combinations fall into and based on the priority calculates the count of product and location that applies the selected replenishment constraint parameter.

Product Location Constraint Applied %

Product and Location Constraint Applied Percentage is a calculated measure used to indicate, in percentage, how much the product and location combinations, where the rule’s replenishment constraint parameter is applicable, represent in the total of product and location combinations within the rule group scope. The measure is calculated as:

Figure 20-36 Calculation

Rule Change

Rule Change is an editable measure used to select the replenishment change parameter to be applied by the rule. This measure is a list populated with all valid replenishment change parameters that were set up in the Replenishment Change Parameters.

Product Location Change Applied Count

Product and Location Change Applied Count is a calculated measure used to display the total number of product and location combinations that applies this rule’s replenishment change parameter. The calculation takes into account all the valid rules where the product and location combinations fall into and based on the priority calculates the count of product and location that applies the selected replenishment change parameter.

Product Location Change Applied %

Product and Location Change Applied Percentage is a calculated measure used to indicate, in percentage, how much the product and location combinations, where the rule’s replenishment change parameter is applicable, represent in the total of product and location combinations within the rule group scope. The measure is calculated as:

Figure 20-37 Calculation

Rule Inventory Planning

Rule Inventory Planning is an editable measure used to select the inventory planning parameter to be applied by the rule. This measure is a list populated with all valid inventory planning parameters that were set up in the Inventory Plan Parameters view.

Product Location Inventory Planning Applied Count

Product and Location Inventory Planning Applied Count is a calculated measure used to display the total number of product and location combinations that applies this rule’s inventory planning parameter. The calculation takes into account all the valid rules where the product and location combinations fall into and based on the priority calculates the count of product and location that applies the selected inventory planning parameter.

Product Location Inventory Planning Applied %

Product and Location Inventory Planning Applied Percentage is a calculated measure used to indicate, in percentage, how much the product and location combinations, where the rule’s inventory planning parameter is applicable, represent in the total of product and location combinations within the rule group scope. The measure is calculated as:

Figure 20-38 Calculation

Copy & Paste

Copy and Paste is an editable measure to select whether the rule is the source or destination for the copy paste rules functionality (Copy-Paste Rules). Valid values are:

-

Copy

Option to select in the rule to be used as the source of the copy.

-

Paste

Option to select in the rule to be used as destination of the copy.

-

-

Option selected to clear the measure.

Note:

Only one rule should be selected as a source, Copy but multiple rules can be selected as a destination, Paste.

Conditions View

This view allows you to define the conditions for the rules based in product, location, and product-location attributes. A rule condition is what allows the engine to find the product and location combinations where the rule is applicable.

Figure 20-39 Conditions View

Conditions View - Default Profile Measures

The Conditions view contains the following measures.

Condition Attribute

The Condition Attribute measure allows you to select the attribute for the condition, The attributes for the rules are assigned in the Attribute Review workspace.

Within Condition Operator

The Within Condition Operator measure allows you to specify the operator to be used inside the condition.

Table 20-2 Within Condition Operator Measure Available Operators

| Possible Operators | Descriptions | Example |

|---|---|---|

|

== |

Checks if the attribute value is equal with the Condition Value |

brand == Private Label |

|

!= |

Checks if the attribute value is different from the Condition Value |

average sales != 0 |

|

> |

Checks if the attribute value is larger than the Condition Value |

Average sales >5 |

|

>= |

Checks if the attribute value is larger or equal to the Condition Value |

|

|

< |

Checks if the attribute value is less than the Condition Value |

Standard deviation of sales <6 |

|

<= |

Checks if the attribute value is less or equal to the Condition Value |

|

|

contain |

||

|

not contain |

||

|

match |

||

|

not match |

Condition Value

The Condition Value measure is used when the type of the attribute is numeric. Example: average sales > 10

Condition Value String

The Condition Value String measure is used when the type of the attribute is a string. Example: brand == Private Label

Condition Value Measure

The value of the Condition Value measure is a measure name, which is populated by an expression that let’s you refine the condition value. For instance private label versus non-private label.

This measure is used when you want to refine the condition value.

For instance, for the coffee items, except Private Label, you want to assign items to the rule that sell more than 50 per week. For Private Label items you may want the value to be 100. You need to populate your Condition measure with a value of 100 for all Private Label items, and the rest of the coffee items with 50.

Condition Value Date

The Condition Value Date measure is used when the type of the attribute is a date. Example: today >= 02/30/2024"

Between Condition Operator

Within a rule there can be multiple conditions and also multiple condition groups. This is specified in the Condition Group measure. Conditions with the same Condition Group value belong to the same group.

For example, if a rule has 4 conditions, Conditions 1 and 2 can belong to condition group 1, and conditions 3 and 4 can belong to the condition group 2. Also, the Condition Order measure gives the ranking of the conditions inside the group.

The following table is an assumed use case:

Table 20-3 Between Condition Operator Assumed Use Case

| Condition | Between Condition Operator | Condition Order | Condition Group |

|---|---|---|---|

|

Condition 1 |

AND |

1 |

1 |

|

Condition 2 |

OR |

2 |

1 |

|

Condition 3 |

OR |

3 |

2 |

|

Condition 4 |

4 |

2 |

The value for the Between Condition Operator can be the logical operators AND or OR.

The conditions are evaluated first inside a condition group and then between groups. In the previous case, the resulting condition is:

(Condition 1 AND Condition 2) OR (Condition 3 OR Condition 4)

Here is an example where all conditions belong to the same condition group:

Table 20-4 Example: All Conditions Belong to the Same Condition Group

| Condition | Between Condition Operator | Condition Order | Condition Group |

|---|---|---|---|

|

Condition 1 |

AND |

1 |

1 |

|

Condition 2 |

OR |

2 |

1 |

|

Condition 3 |

OR |

3 |

1 |

|

Condition 4 |

4 |

1 |

The resulting condition for the rule is given by:

Condition 1 AND Condition 2 OR Condition 3 OR Condition 4

Note that the conditions are evaluated in the order given by the values in the Condition Order measure.

Condition Order

The Condition Order measure displays the order in which conditions are evaluated, wither independently or inside a condition group.

Condition Group

The Condition Group measure allows you to group conditions. This is useful when you want to evaluate conditions in a two-step process. First, the conditions are evaluated inside groups. In the second step, the group results are evaluated .

Validation Result

The Validation Result measure displays the condition expressions that are validated.

Invalid Flag

The Invalid Flag measure indicates if a condition is invalid.

Valid Flag

The Valid Flag measure indicates if a condition is valid.

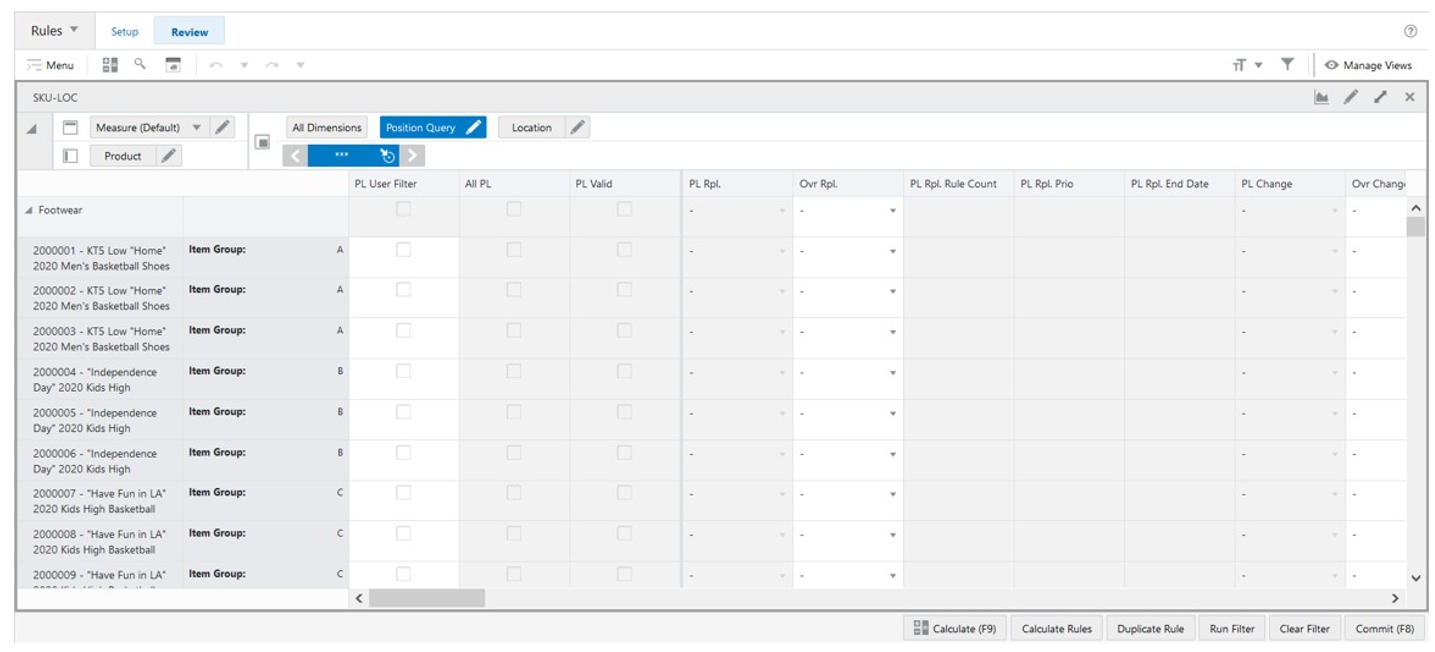

Item-Location View

The Item-Location View, under the Review tab, allows you to review the results of running the rule engine calculation based on the rules set up in the workspace. In this view you can review to the results at the lowest level, item and location levels, and can also create exceptions, at the item-location level, to overwrite the replenishment set up calculated by the rule engine (for example, a particular item and location that should apply a different replenishment parameter from all the other item locations in the same rule).

Figure 20-40 Item-Location View

Item-Location View - Measure Profiles

The Item-Location View contains the following profiles to change the measures that are visible in the view:

-

Default

This profile is used as default by the view. All the available/visible measures are listed and described in the section Measure: Default Profile.

-

Change

This profile displays a subset of measures from the default profile. It focuses on the replenishment change parameters measures only. All other parameter related measures are left out of the visible measures.

-

Constraint

This profile displays a subset of measures from the default profile. It focuses on the replenishment constraint parameters measures only. All other parameter related measures are left out of the visible measures.

-

Inventory Plan

This profile displays a subset of measures from the default profile. It focuses on the inventory planning parameters measures only. All other parameter related measures are left out of the visible measures. Replenishment: This profile displays a subset of measures from the default profile. It focuses on the replenishment parameters measures only. All other parameter related measures are left out of the visible measures.

Item-Location View - Default Profile Measures

The Item-Location View contains the following measures.

Product Location User Filter

Product and Location User Filter is an editable measure used to select the product and location combinations to filter the views by the selected the product and location combinations. This measure is used by the Run Filter action button is responsible to calculate the filters applied to the views within the Supply Chain Network workspace.

All Product Location

All Product and Location is a calculated measure used to indicate if a product and location combination is valid or not. If the combination is valid for a lifecycle phase, it displays as selected.

Product Location Valid

Product and Location Valid is a calculated measure used to indicate if a product and location combination has a valid rule from where the rule engine calculates the replenishment parameters. If the product-location combination is valid, it displays as selected.

Product Location Replenishment

Product and Location Replenishment is a calculated measure used to indicate the replenishment parameter applied to the product and location combination. The replenishment parameter displayed is the one calculated by the rule engine using the replenishment rules set up.

Over Replenishment

Over Replenishment is an editable measure that allows you to create exceptions at the item-location level. You can select the replenishment parameter to override the assigned replenishment parameter (measure Product Location Replenishment). This measure is a list populated with all valid replenishment parameter that were set up in the Replenishment Parameters view.

Product Location Replenishment Rule Count

Product and Location Replenishment Rule Count is a calculated measure used to indicate the total number of replenishment parameters that are assigned to the product and location combination based on the Rules set up. Note that a product and location combination can only have one replenishment parameter active. The one that is active is the one from the rule with the highest priority or the user-exception override.

Product Location Replenishment Priority

Product and Location Replenishment Priority is a calculated measure used to indicate the priority of the rule from where the replenishment parameter was calculated for the product and location combination.

Product Location Replenishment End Date

Product and Location Replenishment End Date is a calculated measure used to indicate the end date of the rule from where the replenishment parameter was calculated for the product and location combination.

Product Location Change

Product and Location Change is a calculated measure used to indicate the replenishment change parameter applied to the product and location combination. The replenishment change parameter displayed is the one calculated by the rule engine using the replenishment rules set up.

Over Change

Over Change is an editable measure used that allows you to create exceptions at the item-location level. You can select the replenishment change parameter to override the assigned replenishment change parameter (measure Product Location Change). This measure is a list populated with all valid replenishment change parameters that were set up in the Replenishment Change Parameters view.

Product Location Change Rule Count

Product and Location Change Rule Count is a calculated measure used to indicate the total number of Replenishment change parameters that are assigned to the product and location combination based on the Rules set up. Note that a product and location combination can only have one replenishment change parameter active. The active Replenishment change parameter is either the one from the rule with the highest priority or the user-exception override.

Product Location Change Priority

Product and Location Change Priority is a calculated measure used to indicate the priority of the rule from where the replenishment change parameter was calculated for the product and location combination.

Product Location Change End Date

Product and Location Change End Date is a calculated measure used to indicate the end date of the rule from where the replenishment change parameter was calculated for the product and location combination.

Product Location Constraint

Product and Location Constraint is a calculated measure used to indicate the replenishment constraint parameter applied to the product and location combination. The replenishment change parameter displayed is the one calculated by the rule engine using the replenishment rules set up.

Over Constraint

Over Constraint is an editable measure used that allows you to create exceptions at the item-location level. You can select the replenishment constraint parameter to override the assigned replenishment constraint parameter (measure Product Location Constraint). This measure is a list populated with all valid replenishment constraint parameters that were set up in the Constraint Parameters view.

Product Location Constraint Rule Count

Product and Location Constraint Rule Count is a calculated measure used to indicate the total number of replenishment constraint parameters that are assigned to the product and location combination based on the Rules set up. Note that a product and location combination can only have one replenishment constraint parameter active. The active Replenishment constraint parameter is either the one from the rule with the highest priority or the user-exception override.

Product Location Constraint Priority

Product and Location Constraint Priority is a calculated measure used to indicate the priority of the rule from where the replenishment constraint parameter was calculated for the product and location combination.

Product Location Constraint End Date

Product and Location Constraint End Date is a calculated measure used to indicate the end date of the rule from where the replenishment constraint parameter was calculated for the product and location combination.

Product Location Inventory Planning

Product and Location Inventory Planning is a calculated measure used to indicate the inventory planning parameter applied to the product and location combination. The inventory planning parameter displayed is the one calculated by the rule engine using the replenishment rules set up.

Over Inventory Planning

Over Inventory Planning is an editable measure used that allows you to create exceptions at the item-location level. You can select the inventory planning parameter to override the assigned inventory planning parameter (measure Product Location Inventory Planning). This measure is a list populated with all valid inventory planning parameters that were set up in the Inventory Plan Parameters view.

Product Location Inventory Planning Rule Count

Product and Location Inventory Planning Rule Count is a calculated measure used to indicate the total number of inventory planning parameters that are assigned to the product and location combination based on the Rules set up. Note that a product and location combination can only have one inventory planning parameter active. The active inventory planning parameter is either the one from the rule with the highest priority or the user-exception override.

Product Location Inventory Planning Priority

Product and Location Inventory Planning Priority is a calculated measure used to indicate the priority of the rule from where the inventory planning parameter was calculated for the product and location combination.

Product Location Inventory Planning End Date

Product and Location Inventory Planning End Date is a calculated measure used to indicate the end date of the rule from where the inventory planning parameter was calculated for the product and location combination.

Default MCQ Units

Default Minimum Credible Quantity Units is an editable measure used to define the default Minimum Credible Quantity for the product and location combination.

Minimum Credible Quantity @ Today Units