2 Getting Started

Initial System Configuration

Initial System Configuration is a one-time activity performed in Merchandising environments which involves defining a group of system critical settings, required at a minimum to initiate a given environment. This particular set of system options are required before the system becomes available for use, because they drive how other options are defaulted and how some seed data is loaded into the solution.

Initial system configuration needs to be performed and activated for each distinct environment; therefore, careful attention must be paid to ensure your various environments are configured with the same setting selections. Differences in setting values could lead to issues during data migration activities.

Once initial system configuration is complete, there will be additional configuration settings to review and adjust, such as System Options and Report Options for further alignment with your technical and business needs. Prior to initial system configuration, access to everything besides the Initial System Configuration screen is restricted.

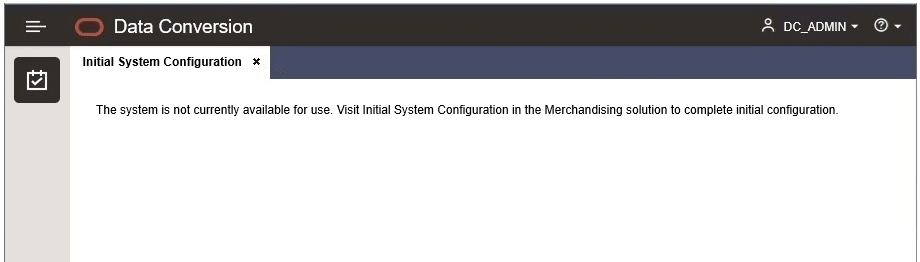

When initial system configuration has not yet been performed in Merchandising, various solutions and services within the ecosystem will display a default message requesting you to navigate to the Merchandising solution to complete, or check the status of, initial system configuration.

Pre-Initial Configuration Use of REST Services, Integrations, BDI and Batches

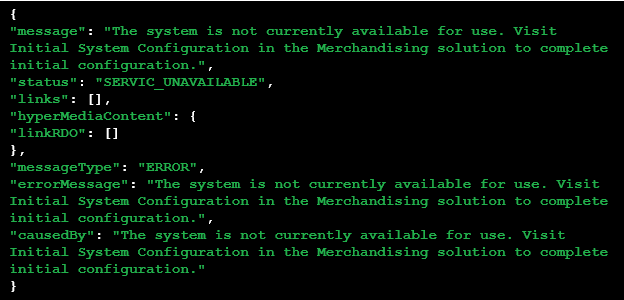

All REST services, integrations, BDI, batches invoked through Process Orchestration and Monitoring (POM) will throw an error message indicating that access is not allowed until the initial system configuration process is complete.

When a REST service is accessed prior to initial system configuration, it will respond with an error message indicating the status of initial system configuration. The response should inform the client that initial system configuration must be complete before further actions can proceed. A similar error will also be presented when SOAP web services are invoked. Here's how such a response would be structured in JSON format:

Performing Initial System Configuration

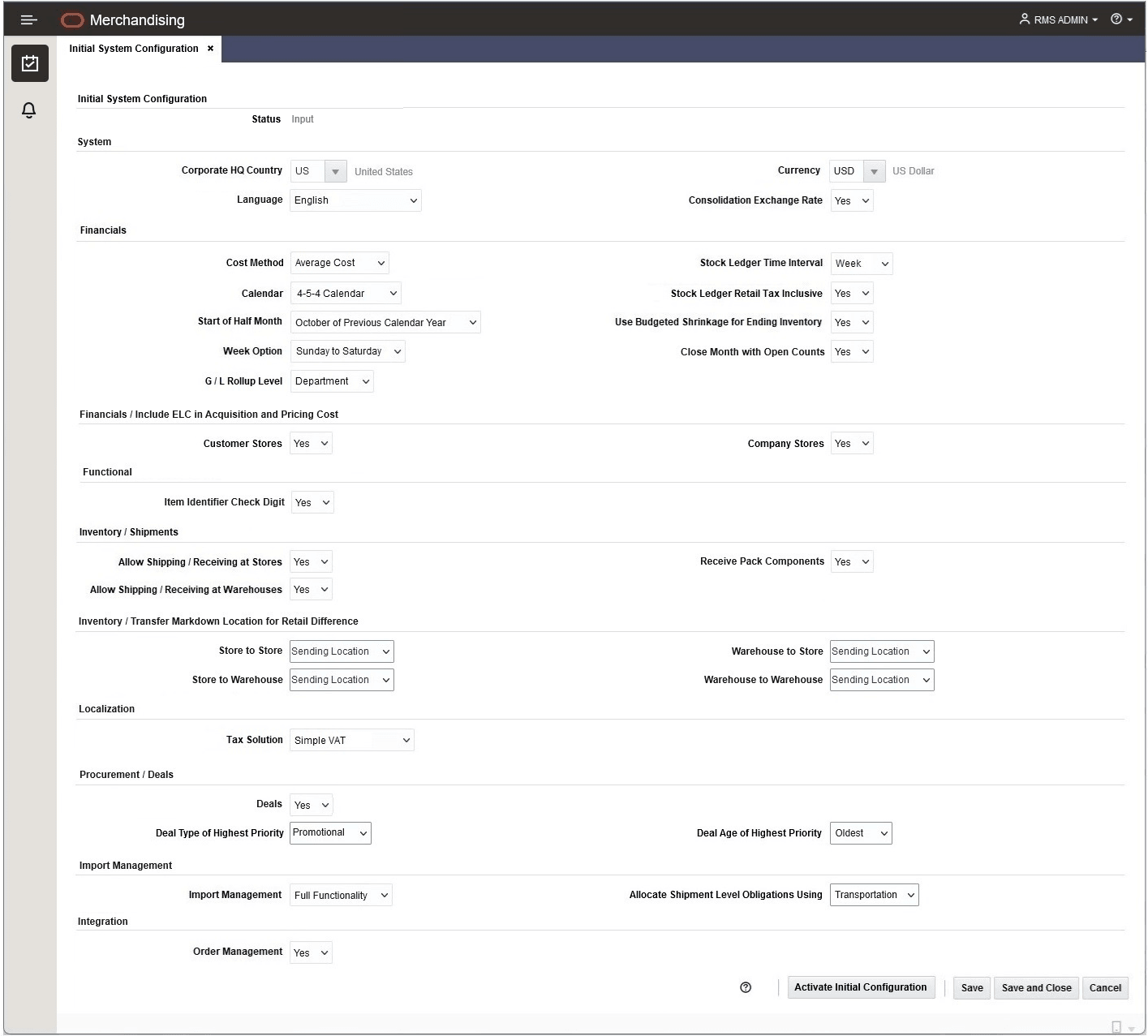

Upon provisioning a new Merchandising environment, the Initial System Configuration screen will be displayed by default upon entering the Merchandising solution.

The sections below outline the system optionsFoot 1 or configurations that must be provided at the beginning of your Merchandising implementation through the Initial System Configuration screen. Even if you are not planning to use certain features right away, you may want to consider some of the items now as they are not easily changed later. It should also be noted that some of these attributes are not able to be updated using the Merchandising screens. If you need to update some of these attributes in a production environmentFoot 2, an SR will need to be logged to have the Oracle Cloud Operations team assist in making these updates in a cloud services implementation.

Initial Virtual Date

Merchandising uses a virtual date (sometimes referred to as vdate) in much of its processing. This is usually the same as the actual date, but in some cases, such as when processing end of day batches, the vdate may lag behind the actual date while the end of day processing completes. The initial virtual date will be set upon provisioning in the format DD-MON-YYYY. The end of the nightly batch run will advance the virtual date to the next day.

Company

The provisioning process will initialize the organizational and merchandising hierarchies with the single required company record. This record will be set up with a dummy name and address information. This dummy information can be updated later, if desired, by using the Company spreadsheet template which is listed under the Foundation template type.

System Options Required During Initial System Configuration

The options listed below are those that you will be asked to provide during initial system configuration of your Merchandising environments upon provisioning, as they drive how other options are defaulted and how some seed data is loaded into the solution. It is important to review these options and make sure they are well understood as many cannot be changed after initial implementation. The initial system configuration system options must be provided in order to gain full access to the system, you can enter one or more values and click Save or Save and Close to save your progress until you have had a chance to review and enter a value for all of the options. When ready, you can click the Activate Initial Configuration button to complete initial system configuration of the system. The system options required during initial system configuration are described below, in the groupings in which they are presented in the screen.

System

| System Option | Optional? | Re-configuration Restricted? | Default Value | Description |

|---|---|---|---|---|

|

Corporate HQ Country |

No |

No |

Contains the base country code used in Merchandising assumed to be the primary country of import. It is mostly used as a default for various functions in Merchandising. |

|

|

Language |

No |

Yes |

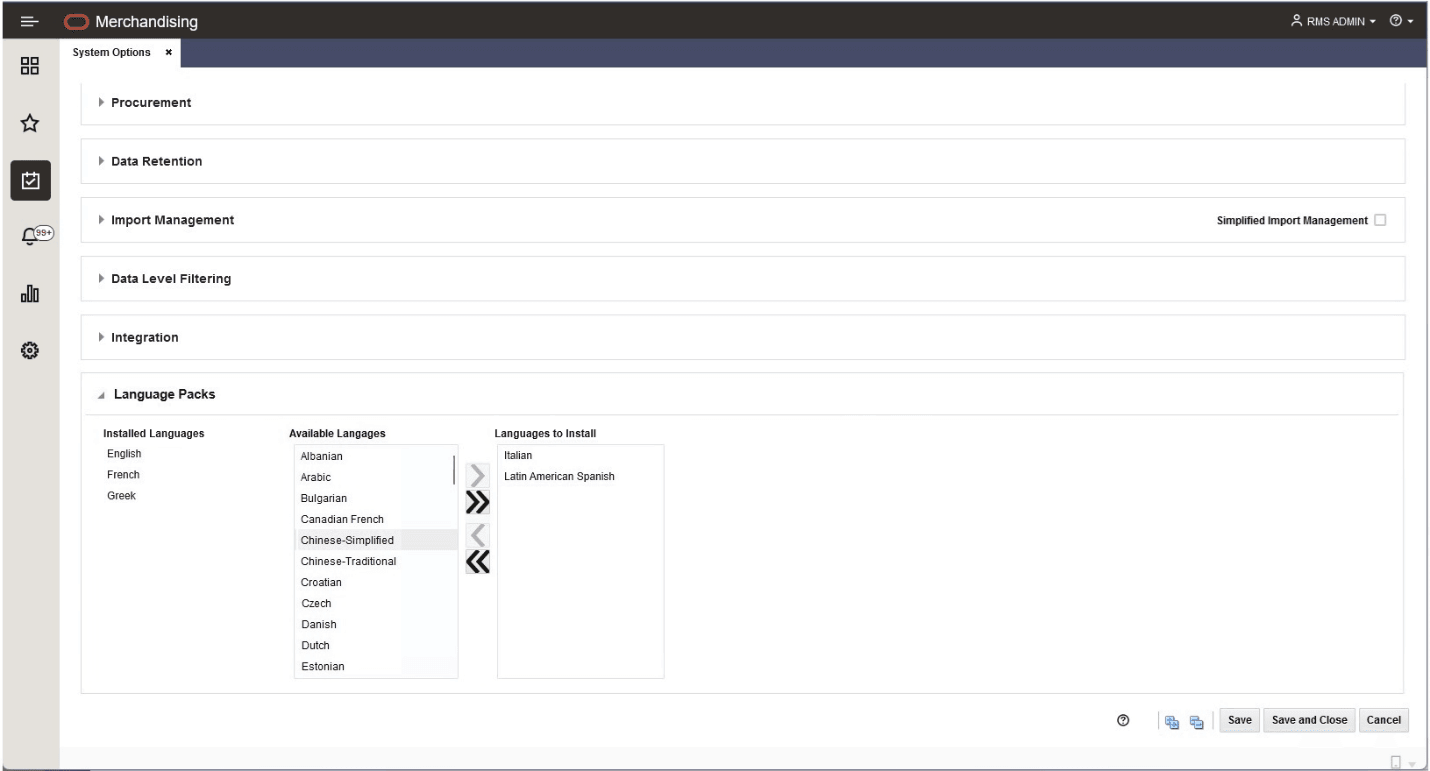

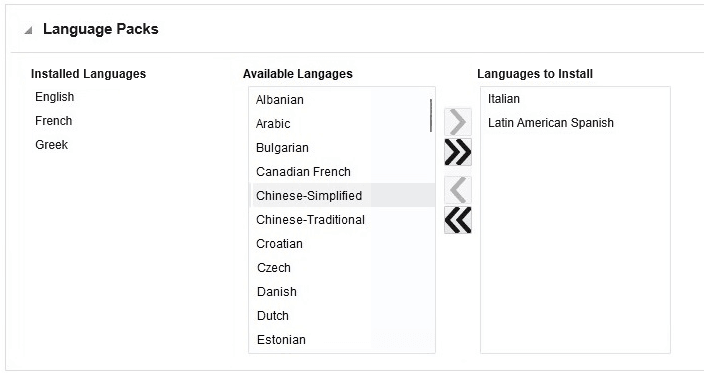

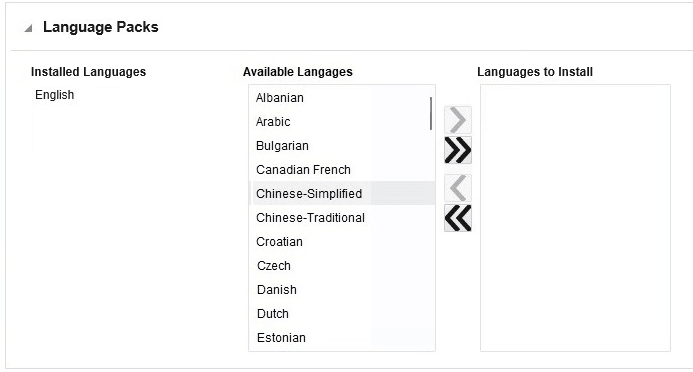

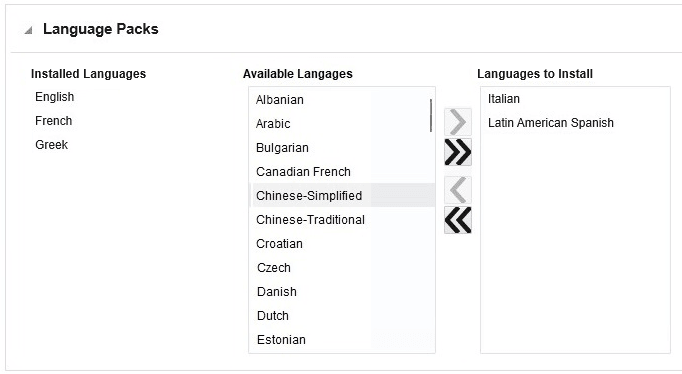

Contains the "base" or "primary" language used in Merchandising. This is the language that it is assumed all data entities will be created in and controls the language used for integration to other solutions. Upon provisioning, the English language pack will be installed by default. If a language other than English is selected as the “base” language during initial system configuration, the corresponding language pack for the selected language will be installed during the processing of the initial system configuration. After Initial System Configuration is complete, additional language packs can be installed through the System Options screen as desired. |

|

|

Currency |

No |

Yes |

Contains the code representing the base or primary currency used in Merchandising solutions. |

|

|

Consolidation Exchange Rate |

No |

Yes |

Indicates whether Oracle Retail will support the addition, maintenance, and viewing for the consolidation exchange rate. If Yes, then the consolidation exchange rate is used as the default for currency conversion within the Merchandising solutions. If No, the operational exchange rate is used as the default. Valid values are Yes (Y) or No (N). |

|

|

Table Owner |

No |

Yes |

RMS01 |

Indicates the owner of the database tables. This system option is populated upon provisioning and is neither displayed nor editable during Initial System Configuration. |

Financials

| System Option | Optional? | Re-configuration Restricted? | Default Value | Description |

|---|---|---|---|---|

|

Cost Method |

No |

Yes |

Indicates whether standard cost or weighted average cost (WAC) will be used for inventory and gross profit calculations. This parameter must be set even if using the retail method. Valid values are: Weighted Average Cost (A) or Standard Cost (S). |

|

|

Calendar |

No |

Yes |

Indicates whether the Gregorian or the 4-5-4 calendar is going to be used in Merchandising. Valid values are Gregorian (C) or 454 (4). |

|

|

Start of Half Month |

No |

Yes |

This is the month number of the first month of the first half of any year. The month number must be from -12 to 12, excluding 0 and -1. A negative number indicates that the first half of the year starts in the previous calendar year with -2 = February, -3 = March, and so on. A positive number corresponds to the normal calendar month number. For example: If your fiscal year starts in February of the same calendar year, then you would set this value to 2 If your fiscal year start in November of the previous calendar year, then you would set this value to -11 Note: Updates to this option require the entire calendar to be rebuilt. This should not be changed after you have started creating inventory related transactions in Merchandising. |

|

|

Week Option |

No |

Yes |

This will determine which day your week begins. This is an option needed for Initial System Configuration, but it is not a retained option that is displayed in the System Options screen, it is used during calendar setup and then discarded. Valid values are: Saturday – Friday (1) Sunday – Saturday (2) Monday – Sunday (3) |

|

|

G/L Rollup Level |

No |

Yes |

Denotes the level at which information will be sent to the General Ledger from the Merchandising stock ledger. Valid values are Department (D), Class (C), or Subclass (S). |

|

|

Stock Ledger Time Interval |

No |

Yes |

Determines the lowest time interval for the stock ledger, either month (M) or week (W). Week can be selected only if you are running a 454 calendar. |

|

|

Stock Ledger Retail Tax Inclusive |

No |

Yes |

This field indicates whether retail value in stock ledger is tax inclusive or not. When the Tax Solution is set to Simple VAT (SVAT) or Global Tax (GTS), this value is often set to Yes (Y). |

|

|

Budgeted Shrinkage Usage Level |

No |

Yes |

This field indicates whether budgeted shrinkage will be used in the calculation of period ending inventory value in the stock ledger and the level at which the budgeted shrinkage percentage will be defined - department, class or subclass. If this option is set to Department (D), then shrinkage will be calculated as a percentage of sales when the month is closed in the stock ledger using the budgeted shrinkage percent defined at the department level. If this option is set to Class (C), then shrinkage will be calculated as a percentage of sales when the month is closed in the stock ledger using the budgeted shrinkage percent defined at the class level. If this option is set to Subclass (S), then shrinkage will be calculated as a percentage of sales when the month is closed in the stock ledger using the budgeted shrinkage percent defined at the subclass level. Lastly, if this value is set to No Budgeted Shrinkage (N), then actual shrinkage is used when the month is closed in the stock ledger. |

|

|

Close Month with Open Counts |

No |

Yes |

Determines whether a fiscal month can be closed if an open Unit & Value type stock count exists. Valid values are Yes (Y) or No (N). If this system option is set to No, the length of time required for confirming stock count results should be considered when scheduling counts so as not to hold up the close of a month. When set to Yes, a Unit & Value count can remain open after the close of only one month. If it is still not completed by the end of the second month close, it will delay the month closing. |

|

|

Include ELC in Acquisition and Pricing Cost - Customer Stores |

No |

Yes |

Y |

Used to indicate if the pricing and acquisition cost should be inclusive or exclusive of estimated landed cost (ELC) for customer stores (e.g. franchise stores). Valid values are Yes (Y) or No (N). |

|

Include ELC in Acquisition and Pricing Cost - Company Stores |

No |

Yes |

Y |

Used to indicate if the pricing cost should be inclusive or exclusive of estimated landed cost (ELC) for company-owned stores. Valid values are Yes (Y) or No (N). |

Functional

| System Option | Optional? | Re-configuration Restricted? | Default Value | Description |

|---|---|---|---|---|

|

Item Identifier Check Digit |

No |

Yes |

This field indicates whether or not check digits will be used when the Oracle Retail Item Number type is generated. This option is often set to Yes (Y). Note: other item types, such as UPC-A and EAN8 also use check digits, but those are not controlled by this parameter and are always validated. |

Inventory

| System Option | Optional? | Re-configuration Restricted? | Default Value | Description |

|---|---|---|---|---|

|

Allow Shipping / Receiving at Stores |

No |

Yes |

Indicates whether or not Merchandising should allow the receipt of shipments at stores within Merchandising screens, or if receipts will always be done in an external system, such as Store Inventory Operations (SIOCS). This may be set to Yes even in cases where a store inventory management system exists in order to support exception handling at corporate. Valid values are Yes (Y) or No (N). |

|

|

Allow Shipping / Receiving at Warehouses |

No |

Yes |

Indicates whether or not Merchandising should allow receipt of shipments at warehouses within Merchandising screens, or if receipts will always be done in an external system, such as a warehouse management system. This may be set to Yes even in cases where a warehouse management system exists in order to support exception handling at corporate. Valid values are Yes (Y) or No (N). |

|

|

Receive Pack Component |

No |

Yes |

Y |

Indicates if stores will receive at the component or pack level. Valid values are Yes (Y), indicating that receiving will be at the component level, or No (N), indicating receiving will occur at the pack level. This flag is used in conjunction with the tampered carton functionality. |

|

Transfer Markdown Location for Retail Difference - Store to Store |

No |

Yes |

For store to store transfers, if there is a retail difference between the two locations, a markdown will be recorded for one of the locations. This option identifies which location is impacted. Valid values are Sending Location (S) or Receiving Location (R). |

|

|

Transfer Markdown Location for Retail Difference - Store to Warehouse |

No |

Yes |

For store to warehouse transfers, if there is a retail difference between the two locations, a markdown will be recorded for one of the locations. This option identifies which location is impacted. Valid values are Sending Location (S) or Receiving Location (R). |

|

|

Transfer Markdown Location for Retail Difference - Warehouse to Store |

No |

Yes |

For warehouse to store transfers, if there is a retail difference between the two locations, a markdown will be recorded for one of the locations. This option identifies which location is impacted. Valid values are Sending Location (S) or Receiving Location (R). |

|

|

Transfer Markdown Location for Retail Difference - Warehouse to Warehouse |

No |

Yes |

For warehouse to warehouse transfers, if there is a retail difference between the two locations, a markdown will be recorded for one of the locations. This option identifies which location is impacted. Valid values are Sending Location (S) or Receiving Location (R). |

Localization

| System Option | Optional? | Re-configuration Restricted? | Default Value | Description |

|---|---|---|---|---|

|

Tax Solution |

No |

Yes |

Determines what type of taxation is being used in Merchandising. Valid values are: Simple VAT (SVAT), Sales and Use Tax (SALES) or Global Tax Solution (GTS). Since this option cannot be changed post implementation, it is recommended that those with stores and warehouses only present in countries that do not use Value Added Tax (VAT), such as the US, should still use Simple VAT or Global Tax and then set up a VAT Region that is tax exempt for their US stores and warehouses. This will allow for future expansion into other regions. If the Tax Solution is set to Simple VAT (SVAT), during initial system configuration, the system will create VAT Region 1000, and will set the Default VAT Region system option to 1000. After initial system configuration is complete, you can create one or more additional VAT Regions and update the Default VAT Region system option to another region of your choosing. |

Procurement

| System Option | Optional? | Re-configuration Restricted? | Default Value | Description |

|---|---|---|---|---|

|

Deals |

No |

No |

Indicates whether or not deals functionality is used within Merchandising. If this is Yes, then additional deals options will be displayed in the Initial System Configuration screen. When Deals functionality is enabled by setting this option to Yes (Y), users with the applicable privileges will have access to the Deals workflows and functionality. If No, then Deals capabilities will be hidden for all users. Valid values are Yes (Y) or No (N). In order to utilize Allowance Deals functionality, Estimated Landed Cost functionality must also be enabled. |

|

|

Deal Type of Highest Priority |

No |

Yes |

Indicates if annual deals or promotional deals have a higher priority when calculating deal income. Valid values are Promotional (P) or Annual (A). If the Deals system option is set to No (N), since the Deal Type of Highest Priority is a required column in the database, it will be defaulted to Promotional (P) during initial system configuration, but will be hidden from the System Options screen and will not drive any processing. |

|

|

Deal Age of Highest Priority |

No |

Yes |

Indicates if older or newer deals have a higher priority when calculating deal income, and also indicates the order of application of allowance deals based on the deal’s approval date. Valid values are Oldest (O) or Newest (N). If this option is set to Oldest (O), older deals will have a higher priority when calculating deal income, and the allowance deal with the oldest/earliest approval date will be applied to a given purchase order first. Conversely, if this option is set to Newest (N), newer deals will have a higher priority when calculating deal income, and the allowance deal with the most recent/latest approval date will be applied to a given purchase order first. If multiple allowance deals have the same approval date, the deal identifier (DEAL_ID) will be used as the basis, such that, if this option is set to Oldest (O), the allowance deal with the oldest/minimum identifier value will be applied first, when set to Newest (N), the allowance deal with the most recent/maximum identifier value will be applied first. Deal Age of Highest Priority is only utilized if deals functionality is enabled in the system. If the Deals system option is set to No (N), since the Deal Age of Highest Priority is a required column in the database, it will be defaulted to Oldest (O) during initial system configuration, but will be hidden from the System Options screen and will not drive any processing. |

Import Management

| System Option | Optional? | Re-configuration Restricted? | Default Value | Description |

|---|---|---|---|---|

|

Import Management |

No |

Yes |

Indicates whether Import Management functionality is being used in your implementation, and if the full functionality will be available or simplified functionality. Valid values are Full Functionality (F), Simplified Functionality (S) or No Import Functionality (N). If you think you may utilize any of the Import Management functionality in the future it is recommended to select Full Functionality during Initial System Configuration. Access to import related workflows and screens can be hidden by not assigning any users the security privileges to access those workflows, so the functionality can be hidden even if you select Full Functionality during Initial System Configuration. |

|

|

Allocate Shipment Level Obligations Using |

No |

Yes |

Indicates which quantities will be used during the allocation of a transportation-level obligation to order/item/location actual landed cost (ALC). Valid values include Advanced Shipping Notice (ASN) or Transportation (TRNSPRT). When the method is set to ASN, the allocation process will use quantities from the ASN records and you will need to manually associate transportation records with ASNs. Additionally, all obligations, when allocated, result in the creation of actual landed cost (ALC) records for each order/item/obligation/ASN or order/item/vessel/voyage/ETD/ASN combination, with the receipt quantity driving the allocation process. In this case, it will not be possible to accurately allocate obligations at the Container or BOL/AWB (air waybill) level since these identifiers are not present on the ASN. Finalization will be performed for each order/ASN shipment combination. When the method is set to Transportation, the allocation process will use quantities from the transportation records and will result in the creation of ALC records for each order/item/obligation or order/item/vessel/voyage/ETD/obligation combination. Finalization will be performed for each order. This value can only be defined when Import Management is set to Full Functionality during Initial System Configuration, this setting is not applicable when using Simplified Import Management. |

System Options

The sections below outline the system optionsFoot 3 or configurations that should be reviewed at the beginning of your Merchandising implementation. Even if you are not planning to use certain features right away, you may want to consider some of the items now as they are not easily changed later. It should also be noted that some of these attributes are not able to be updated using the Merchandising screens. If you need to update some of these attributes in a production environmentFoot 4, an SR should be logged to have the Oracle Cloud Operations team assist in making these updates in a cloud services implementation. If implementing on premise, you will need to update the values in the database directly.

System

The options in this section are used throughout Merchandising and even in the other Merchandising suite of solutions to drive processing. Many of the options in this section are also part of the installer options described above, which means changing them after initial implementation is difficult if not prohibited. Care should be taken before changing any of these options in order to prevent data integrity errors in the solution.

| System Option | Optional? | Re-configuration Restricted? | Default Value | Description |

|---|---|---|---|---|

|

Corporate HQ Country |

See System Options Required During Initial System Configuration. |

|||

|

Table Owner |

||||

|

Language |

||||

|

Calendar |

||||

|

Primary Currency |

||||

|

Consolidated Exchange Rate |

||||

|

Allow Data Access Schema (DAS) Replication |

Yes |

Re-configuration is restricted once the option is set to Yes (checked). |

N |

Indicates whether or not DAS replication is allowed for the Merchandising solutions. Valid values are Yes (Y) or No (N). This field will default to No (N). Setting this option to Yes (Y) / checked indicates that tables may be enabled for replication. Once this value has been set to Yes (Y) and saved, it cannot be set back to No (N). When the Allow Data Access Schema (DAS) Replication is set to Yes (Y), users with the appropriate security privileges can access the Data Access Schema Administration screen. |

|

Image Path |

Yes |

No |

http://www.oracle.com/ |

Holds the default path for where image URLs are stored. This will default onto items when image relationships are created, but can be updated as needed. |

|

Default Item Image |

Yes |

No |

Holds the default image file name for item image that will be displayed in reports in Merchandising when an item image is not found, if you want to configure a specific image to be displayed. If no value is given, then the default Merchandising image will be shown. This value is assumed to be found at the default image path location. |

|

|

Historical Exchange Rates to Display |

No |

No |

5 |

Used to control how many historical exchange rates are presented to users while selecting an exchange rate. The currently active exchange rates and future effective rates are included in the list of values by default. This option controls how many historical rates should also be included. |

|

Quantity/Percentage Decimal Precision - Maximum |

No |

No |

4 |

Holds the maximum decimal digits for quantity or percentage precision displayed in Merchandising. The value should be between 0 and 4. |

|

Quantity/Percentage Decimal Precision - Minimum |

No |

No |

0 |

Holds the minimum decimal digits for quantity or percentage precision displayed in Merchandising. The value should be between 0 and 4. |

|

Use Translated UOM Codes for Spreadsheet Templates |

No |

No |

N |

Indicates whether or not translated unit of measure (UOM) codes will be displayed and entered in spreadsheet templates. When this option is set to Yes (Y), each column in spreadsheet templates that contains a UOM code will have a dropdown displayed for user selection. This dropdown will display UOM codes in the user’s language if translations exist. UOM code translations for spreadsheet templates are maintained via the Codes and Descriptions spreadsheet template, under a series of code types depending on which UOMs are valid in a particular instance. Prior to checking this option it is important to review the related code types via the Codes and Descriptions spreadsheet template to ensure your units of measure are represented and to hide those that are not applicable for your business by setting the Used flag to No. The related code types are: All Units of Measure Except Pack and Miscellaneous Classes (UEPM), All Units of Measure Except Pack, Miscellaneous, and Quantity Classes with Eaches (UPMQ), Cases, Pallets and All Units of Measure Except Pack and Miscellaneous Classes (UCPU), Units of Measure in the Dimension Class (UDIM), Units of Measure in the Mass Class (UMSS), Units of Measure in the Liquid Volume Class (ULVL), Units of Measure in the Miscellaneous Class (UMSC), and All Units of Measure (UOMS). See the Configure Seeded Data – Units of Measure (UOMs) section below for more details. Once the system option is checked, the next time one of the spreadsheets is downloaded, the desired dropdown should appear in the UOM column(s) and a secondary language user should be able to see the translated codes and also select the desired code from the dropdown. If this option is checked, all users will need to download a new version of any spreadsheet template that contains a unit of measure column. |

Financials

Financials system options are used to determine how the financial portion of inventory transactions are recorded in Merchandising, as well as they are rolled up into the stock ledger and posted to the General Ledger. Like the options in the System section, many of these are set up at initial install and cannot be modified after due to their impact on inventory valuation.

| System Option | Optional? | Re-configuration Restricted? | Default Value | Description |

|---|---|---|---|---|

|

Apply Prefix / Suffix to Document External Reference |

No |

No |

N |

Indicates whether or not the system should append a prefix or suffix to the external reference populated on the financial document generated by Merchandising (MFCS) and sent to Invoice Matching (REIMCS). Valid values are Yes (Y) or No (N). Note, when this flag is set to No (N) a suffix may still be appended for non-merchandise invoices generated from obligations or customs entries to ensure the external reference is unique for each location. This suffix will be a dash followed by the count of the location. For example, if there are three locations on a purchase order against which an obligation or customs entry is created, non-merchandise invoices will be generated for each location. The external reference on the non-merchandise invoice for the first location will have a suffix of "-1", the external reference on the non-merchandise invoice for the second location will have a suffix of "-2", and for the third location, a suffix of "-3". Changes to this option will only impact processing from that point forward. |

|

Record Zero Tax Lines in Transaction Data |

No |

No |

N |

Indicates whether or not records with transaction code 87 (VAT IN Cost for purchase transactions) or 88 (VAT OUT Retail for sales transactions), should be posted to Transaction Data when the total calculated tax amount is zero, or rounds to zero. This option is only applicable when the Tax Solution system option is set to Simple VAT (SVAT) or Global Tax Solution (GTS). If this flag is changed from Yes to No, or No to Yes, will only impact transaction data postings from that point forward. Valid values are Yes (Y) or No (N). This option is initially defaulted to No (N). |

|

Close Month After Days |

No |

No |

5 |

Determines how many days after the end of a fiscal month that the month will be closed in the stock ledger. If set to zero, then the stock ledger will close the month on the last day of the fiscal period. If set to a value greater than zero, then that many days will be added to the end of the fiscal period to determine when the month will be closed. |

|

Close Month with Open Counts |

See System Options Required During Initial System Configuration. |

|||

|

Cost Method |

See System Options Required During Initial System Configuration. |

|||

|

G/L Rollup Level |

See System Options Required During Initial System Configuration. |

|||

|

Margin History Impact Records to Display |

Yes |

No |

Indicates how many historical future cost records will be displayed for an item-supplier-country-location on the Margin Impact screen. |

|

|

Minimum Cumulative Mark-on |

Conditional |

No |

Indicates the minimum value that will be used when comparing the calculated cumulative mark-on percentage for a subclass/location/month. If the calculated value falls below this minimum then the Markup % of Retail for the department will be used. This is only required if you are using retail accounting in some departments. |

|

|

Maximum Cumulative Mark-on |

Conditional |

No |

Indicates the maximum value that will be used when comparing the calculated cumulative mark-on percentage for a subclass/location/month. If the calculated value is above this maximum then the Markup % of Retail for the department will be used. This is only required if you are using retail accounting in some departments. |

|

|

Merchandise Cost Mapping Code |

No |

No |

9999999 |

Contains the value that will be used to create transaction data records for purchases, and to map merchandising cost to a General Ledger account. Care should be taken to ensure the value does not overlap with any non-merchandise codes used in Merchandising. It also needs to be a different value than is defined for the Unmapped Cost Components Mapping Code system option. |

|

Post Positive Debits and Credits |

No |

No |

N |

Allows you to specify whether the financial postings should always post only positive debits and credits. If yes (Y), only positive values will be posted to the General Ledger. If no (N), the posting negative amounts will be allowed, when applicable. This parameter can be edited; this will result in the changes being reflected in GL posting batch runs subsequent to the change. |

|

Start of Half Month |

See System Options Required During Initial System Configuration. |

|||

|

Start of Half Month |

See System Options Required During Initial System Configuration. |

|||

|

Stock Ledger Retail Tax Inclusive |

See System Options Required During Initial System Configuration. |

|||

|

Stock Ledger Time Interval |

See System Options Required During Initial System Configuration. |

|||

|

Unmapped Cost Components Mapping Code |

Conditional |

No |

8888888 |

Contains the value that will be used as a catch-all to sum up any cost components which are not mapped to a specific non-merchandise code under this value. Care should be taken to ensure the value does not overlap with any other non-merchandise codes used in Merchandising. It also needs to be a different value than what is defined for the Merchandise Cost Mapping Code system option. Only required if using estimated landed cost (ELC) in Merchandising. |

|

Budgeted Shrinkage Usage Level |

Can be used to indicate the hierarchy level (department, class, or subclass) for which the shrinkage percentage should be used in Half Data calculations. It is an implementation time setting and new users can define the desired level at which the value needs to be managed only at that point. The following are the valid values for this field – Blank (NULL), Department, Class, Subclass. For more details, see System Options Required During Initial System Configuration. |

|||

|

Include ELC in Acquisition and Pricing Cost - Company Stores |

See System Options Required During Initial System Configuration. |

|||

|

Include ELC in Acquisition and Pricing Cost - Customer Stores |

See System Options Required During Initial System Configuration. |

|||

| Use Dynamic Segments | No | No | N | Used to indicate whether dynamic segment functionality will be used in Merchandising. The dynamic segment functionality allows for a subset of fields that make up the key during definition of GL cross references (Dept/ Class/ Subclass/ Location/ GL Ref. No.) to have individual mappings defined, independent of the cross-reference definition. Internal process will combine these individual mappings together with information on the cross-reference records to dynamically create the complete cross references. |

| External Account Validation | No | No | N |

Indicates whether Account Combinations introduced through the Cross Reference processes should be validated against an external financial system. If selected, a webservice call will be invoked to validated account combinations that are not found locally (FIF_GL_ACCT). If unselected, account validation will be limited to validating against the account combinations available locally (FIF_GL_ACCT). |

Foundation

This section contains system options that are targeted at configurations and defaults for merchandise hierarchy and supplier setup, items, cost changes, and rounding rules for case packs.

| System Option | Optional? | Re-configuration Restricted? | Default Value | Description |

|---|---|---|---|---|

|

Department/Class/Subclass |

||||

|

Automatically Generate IDs |

No |

No |

N |

Identifies whether the department, class and subclass ID's will be automatically generated or whether users will key in the ID values. Valid values are Yes (Y) or No (N). |

|

Supplier |

||||

|

Automatically Generate IDs |

No |

No |

N |

Identifies whether supplier and partner identifiers will be automatically generated by Merchandising. Valid values are Yes (Y) or No (N). It is recommended that if you are integrating suppliers and partners into Merchandising from a financial system that you set this to No, as this integration will initially load both suppliers and partners into the supplier table in Merchandising and you will need to re-create the partners manually using the same ID in order to facilitate transactional integration.. |

|

Bracket Costing |

No |

No |

N |

Indicates whether or not bracket costing is enabled in Merchandising. If any of your suppliers support bracket costing this should be set to Yes and then the flags and brackets can be defined for suppliers and items. Valid values are Yes (Y) or No (N). |

| External Supplier Management | No | No | N | Indicates whether suppliers will be managed externally or within Merchandising. If opted for, supplier creation within Merchandising will be restricted and supplier enrichment capabilities through the REST service will be available. Valid values are Yes (Y) or No (N). |

| Filter Inactive Suppliers | No | No | N | Indicate whether Inactive Suppliers should be subscribed to. This configuration will only impact Suppliers/Partner creation through the Supplier and Partner Upload service If checked, Inactive Suppliers will not be subscribed to on a Create payload. Valid values are Yes (Y) or No (N). |

| Use Purchase Pay Sites | No | No | N | Indicates whether Purchase and Pay side flags on the Supplier and Partner Upload service payload should govern creation of the Purchasing Address (04) and Remittance Address (06) if the Address Type is not explicitly specified . Valid values are Yes (Y) or No (N). |

| Use Site Defaults | No | No | N |

Indicates whether Supplier Site information should be used to build missing supplier details for a subset of the fields in the input payload of the Supplier and Partner Upload Service. If set to No, it will be expected that all supplier details will be sent explicitly through the integration. Valid values are Yes (Y) or No (N). |

|

Item |

||||

|

Auto Approve Child Items |

No |

No |

Y |

Determines whether children of approved parents will be created in approved status. If Yes, children of approved parents will be created in approved status. If set to No, child items will be created in a worksheet status and must be separately approved before they can be used for transactions. If all critical item information for transaction level items can be inherited from the parent, Yes is the recommended setting. But, if transaction level items are unique such as having different costs or supplier from the parent, then it is suggested this be set to No. Valid values are Yes (Y) or No (N). |

|

Auto Range Child Items |

No |

No |

Y |

Determines whether locations ranged to the parent will automatically be inherited by the child during child item creation. Valid values are Yes (Y) and No (N). |

|

Default Packing Method |

No |

No |

HANG |

Used to indicate the default packing method for items when they are created. Valid values are Flat (F) or Hanging (H), and are managed under the code type PKMT. If desired, additional values can be specified or the names of the current values could be updated as part of your implementation. |

|

EAN / UCC-13 Prefix |

Yes |

No |

123456 |

If EAN/UCC-13 or EAN/UCC-13 with Supplement item numbers are auto generated, this option determines the prefix for the generated item number. This field must be either NULL or contain a 6-digit long prefix. |

|

Grocery Items |

No |

No |

Y |

Indicates whether the Grocery Attributes container will be displayed in the Items screen, which is used to specify item attributes related to perishability, wastage, and packaging. It also will control whether or not catch weight will be selectable when creating new items. |

|

UCC-12 Prefix |

No |

No |

If UCC-12 or UCC-12 with Supplement item numbers are auto generated, this option determines the prefix for the generated item number. This field must be either NULL or contain a 6-digit long prefix. If no prefix is provided here, when the system generates a UCC-12 or UCC-12 with Supplement item number, a 5-digit prefix of '40000' will be concatenated with a 6-digit sequence number followed by a check digit. The supplement will be appended if the number type is UCC-12 with Supplement. If a prefix is provided here the 6-digit prefix will be used with a 5-digit sequence number instead. |

|

|

Location Traits Default |

||||

|

Returnable |

No |

No |

Y |

Used as a default for items when item/location traits do not exist for an item or item/location. It will also be a default for when item/location traits are added to item/locations. Valid values are Yes (Y) or No (N). |

|

Refundable |

No |

No |

Y |

Used as a default for items when item/location traits do not exist for an item or item/location. It will also be a default for when item/location traits are added to item/locations. Valid values are Yes (Y) or No (N). |

|

Back Orderable |

No |

No |

Y |

Used as a default for items when item/location traits do not exist for an item or item/location. It will also be a default for when item/location traits are added to item/locations. Valid values are Yes (Y) or No (N). |

|

Item Location |

||||

| Capture Selling Phase Start Date | No | No | N | Indicates whether the selling phase start date needs to be captured at the item location level. The associated date field will contain the latest/most recent date upon which a receipt of significance occurred at the location. It may be reset over time based on type and quantity of receipt that can be configured at the item location level. Customers can choose if receipts resulting from direct to store orders, store to store transfers, warehouse to store transfers/allocations or a combination of these along with minimum units on the transaction will trigger an update. |

| Update Selling Phase Start Date on Clearance Reset | No | No | N | Indicates whether the Selling Phase Start Date should be updated or not when a clearance reset is executed for the associated item location combination. |

|

Use Defaulted From for Profile Mass Updates |

No |

No |

A |

This value will be used when setting up mass rate updates of an expense for an expense profile. This system option specifies whether the system will always determine which expenses to update based on from where the expense initially defaulted; never determine which expenses to update based on where the expense initially defaulted from; or allow this decision to be specified for each expense profile mass rate update. Valid values are found under code type EUDF - Always (A), Never (V), Default Yes (Y), Default No (N). |

|

First Port Used for Base Zone Expense |

No |

No |

CZ |

Specifies which discharge port should be used first when attempting to systematically mark zone level item expenses as the Base Expense. Valid values are Base Cost Zone’s Discharge Port (CZ) or Supplier Import Attributes Discharge Port (S), found under code type FDPB. When a supplier is associated with an item and expense profiles default, the system will attempt to systematically mark a set of zone level item expenses as the Base Expense. If more than one set of expenses default, the system will look for a matching record for the item’s base cost zone and the base cost zone’s primary discharge port or the supplier import attributes discharge port depending on the value of this system option. This option provides a way for you to specify which check should be done first; you should choose the one that is most likely to contain the desired discharge port to mark as base. Changes to this option will only impact processing from that point forward. |

|

Rounding |

||||

|

Case |

No |

No |

50 |

Holds the value for case rounding threshold that is used as a default when creating items, if a default has not been defined for the supplier. During rounding, this value is used to determine whether to round partial case quantities up or down. If the case-fraction in question is less than the threshold proportion, it is rounded down; if not, it is rounded up. For instance, with a case size of 10 and a Threshold of 80%, Case quantities such as 18, 29 and 8 would be rounded up to 20, 40 and 10 respectively, while quantities of 12, 27 and 35 would be rounded down to 10, 20 and 30 respectively. Quantities are never rounded down to zero; a quantity of 7, in the example above, would be rounded up to 10. |

|

Inner |

No |

No |

50 |

Holds the value for inner rounding threshold that is used as a default when creating items, if a default has not been defined for the supplier. During rounding, this value is used to determine whether to round partial inner quantities up or down. If the inner-fraction in question is less than the threshold proportion, it is rounded down; if not, it is rounded up. Quantities are never rounded down to zero. See the case rounding attribute for examples of how the threshold is used. Inner rounding is used for transfers and allocations, not purchase orders. |

|

Layer |

No |

No |

50 |

Holds the value for layer rounding threshold that is used as a default when creating items, if a default has not been defined for the supplier. A layer is defined as the case size x ti size. During rounding, this value is used to determine whether to round partial layer quantities up or down. If the layer-fraction in question is less than the threshold proportion, it is rounded down; if not, it is rounded up. Quantities are never rounded down to zero. See the case rounding attribute for examples of how the threshold is used. |

|

Order Rounding Level |

No |

No |

C |

Holds the default value for rounding level that is used as a default when creating items, if a default has not been defined for a supplier. This is value, along with the case, layer, and/or pallet rounding thresholds will be used to determine how to round order quantities for an item/location/supplier/country. Valid values are defined on the codes table with a code type of ORL: Case (C), Layer (L), Pallet (P), Case/Layer (CL), Layer/Pallet (LP), Case/Layer/Pallet (CLP). Case, Layer, and Pallet use their respective rounding thresholds, while Case/Layer, Layer/Pallet, and Case/Layer/Pallet round from the highest rounding level down by threshold. |

|

Pallet |

No |

No |

50 |

Holds the value for pallet rounding threshold that is used as a default when creating items, if a default has not been defined for the supplier. A pallet is defined as the case size x ti quantity x hi quantity. During rounding, this value is used to determine whether to round partial pallet quantities up or down. If the pallet-fraction in question is less than the threshold proportion, it is rounded down; if not, it is rounded up. Quantities are never rounded down to zero. See the case rounding attribute for examples of how the threshold is used. |

Functional

The attributes in this section are used to configure a few different areas. One set is used to indicate which functions in Merchandising are being used by your implementation, another is used to define default units of measure, and the last is used to define how certain item numbers will be generated by the solution.

| System Option | Optional? | Re-configuration Restricted? | Default Value | Description |

|---|---|---|---|---|

|

Functionality Used in the Application |

||||

|

Contracts |

No |

No |

Y |

Indicates whether or not contract functionality is used within Merchandising. If this is Yes, then the contracting options will be displayed in the task list to users with the applicable privileges. If No, then they will be hidden for all users. Valid values are Yes (Y) or No (N). |

|

Import Management |

No |

Yes |

Indicates whether Import Management functionality is being used in your implementation. Valid values are Yes (Y) or No (N). Note: This is set during Initial System Configuration along with the Import Management Simplified indicator. |

|

|

Estimated Landed Cost |

No |

No |

Y |

Determines whether estimated landed cost will be used within the system. When used, this will also enable cost zones, cost components, and cost profiles to be used. Changing the value from Yes to No after items have been created is not advised and will require a mini-conversion of item data to ensure a cost zone group is associated with each item. Valid values are Yes (Y) or No (N). Estimated Landed Cost must be enabled in order to utilize Allowance Deals functionality. |

|

Retain Customer Information |

No |

No |

N |

Indicates whether or not customer details will be stored with a customer order while it is retained in Merchandising. If set to Yes (Y), when a customer fulfillment order is imported into Merchandising, the customer details will be retained. If set to No (N), when a customer fulfillment order is imported into Merchandising, the customer details will not be retained and the fulfilling solutions (warehouse, store, supplier) will need to use a lookup to get the details from an order management solution based on order number or customer ID. If the value is changed, only customer fulfillment orders imported into Merchandising after that point will follow the updated value. Valid values are Yes (Y) or No (N). |

|

Concession/ Consignment |

No |

No |

Y |

Determines if you have enabled functionality for using consignment and/or concession items. Valid values are Y or N. |

|

Inventory Layers |

No |

No |

N |

Indicates whether inventory layer tracking will be available in Merchandising. Valid Values are Yes (Y) or No (N). When this option is checked for the first time or changed from unchecked to checked (No to Yes), the ITEM_LOC_SOH_LEDGER table will be initialized. The current total SOH will be created as an initial layer record without any identifier, if applicable for each item location. Additionally, the Inventory Identifier fields at the department and class level will be set to Null and enabled on respective UI screens. When this option is changed from checked to unchecked (Yes to No), all records from the ITEM_LOC_SOH_LEDGER table will be cleared and the Inventory Identifier fields at the department and class level will be set to Null and disabled on the respective UI screens. |

|

Franchise |

No |

No |

Y |

Indicates whether or not franchise functionality will be enabled in Merchandising. If enabled, then stores of type Franchise can be created, and franchise orders and returns will be able to be created. Valid values are Yes (Y) or No (N). |

|

Open to Buy |

No |

No |

N |

Determines whether open to buy budgets will be validated when approving purchase orders. It also will be used to control recalculation of OTB during reclassification. Valid values are Yes (Y) or No (N). |

|

Replenishment |

No |

No |

Y |

Indicates whether or not replenishment functionality is used within Merchandising. If this is Yes, then the replenishment options will be displayed in the task list, as well as other menu options where replenishment attributes can be viewed and maintained by users with applicable privileges. If No, then they will be hidden for all users. Valid values are Yes (Y) or No (N). |

|

Deals |

See System Options Required During Initial System Configuration. |

|||

|

Default Values for Units of Measure |

||||

|

Dimension UOM |

No |

No |

IN |

Contains the default dimension unit of measure. All dimension UOM fields will default to this value, but can be updated as needed in most cases. Valid values are any UOM in the UOM Class of Dimension. |

|

Standard UOM |

No |

No |

EA |

Contains the default standard UOM will be used during item setup. However, this can be changed on an item by item basis as needed. Standard unit of measure indicates how inventory will be tracked for the item. Usually this will be set to EA. However, if most items are inventoried by weight or length, you may want to change this to a different value. |

|

Unit of Purchase |

No |

No |

S |

Contains the default unit of purchase used when creating purchase order. This will determine how quantity is entered on an order in terms of eaches, cases (or the case equivalent) or pallets. Eaches will be defined as the standard unit of measure for an item. Valid values are: S (standard unit of measure), C (case or case equivalent), P (pallet). |

|

Volume UOM |

No |

No |

IN3 |

Contains the default volume unit of measure. All volume UOM fields will default to this value, but can be updated as needed in most cases. Valid values are any UOM in the UOM Class of Volume. |

|

Weight UOM |

No |

No |

LBS |

Contains the default weight unit of measure. All weight UOM fields will default to this value, but can be updated as needed in most cases. Valid values are any UOM in the UOM Class of Mass. |

|

Item Identifier Generation Rule |

||||

|

Check Digit |

See System Options Required During Initial System Configuration. |

|||

|

Modulus # |

No |

No |

11 |

The modulus number for check digit calculations used within Oracle Retail. |

|

Weight 1 |

No |

No |

2 |

The value to be used as a weight for the check digit calculation in the rightmost position. Valid values 1-999 |

|

Weight 2 |

No |

No |

4 |

The value to be used as a weight for the check digit calculation in the 2nd digit position from the right. Valid values 1-999 |

|

Weight 3 |

No |

No |

8 |

The value to be used as a weight for the check digit calculation in the 3rd digit position from the right. Valid values 1-999 |

|

Weight 4 |

No |

No |

16 |

The value to be used as a weight for the check digit calculation in the 4th digit position from the right. Valid values 1-999 |

|

Weight 5 |

No |

No |

32 |

The value to be used as a weight for the check digit calculation in the 5th digit position from the right. Valid values 1-999 |

|

Weight 6 |

No |

No |

64 |

The value to be used as a weight for the check digit calculation in the 6th digit position from the right. Valid values 1-999 |

|

Weight 7 |

No |

No |

128 |

The value to be used as a weight for the check digit calculation in the 7th digit position from the right. Valid values 1-999 |

|

Weight 8 |

No |

No |

256 |

The value to be used as a weight for the check digit calculation in the 8th digit position from the right. Valid values 1-999 |

Inventory

There is a large set of options that are used to configure the various inventory functions in Merchandising. Because of that the sections below have been broken into functional areas where the system options best align: Replenishment, Shipment, Transfers and RTVs, Allocation, Sales and Returns, and Stock Counts.

Replenishment

| System Option | Optional? | Re-configuration Restricted? | Default Value | Description |

|---|---|---|---|---|

|

Default Size Profile |

No |

No |

N |

Defines if the size profile should be defaulted when defining item/location level replenishment attributes. When set to Yes the Apply Size Profile checkbox on replenishment attributes screen is checked by default. Valid values are Yes (Y) or No (N). |

|

Distribution Rule |

No |

No |

PRORAT |

Indicates which distribution rule to use when it is necessary to spread inventory between virtual warehouses. This usually occurs when Merchandising receives an updated quantity for a physical warehouse for a transaction or which the impacted virtual warehouse is not known - usually a stock count. The valid values for this option are Proration (PRORAT), Minimum to Maximum (MN2MX), or Maximum to Minimum (MX2MN). |

|

Maximum Weeks of Supply |

Yes |

No |

26 |

Contains the default maximum weeks of supply to use in the investment buy opportunity calculation. The investment buy opportunity calculation will not recommend an order quantity that would stock the associated warehouse beyond this number of weeks. While most retailers set maximum weeks of supply at the system level only, Merchandising does offer the ability to override this parameter at the warehouse or warehouse/department level. This value is currently used by the investment buy functionality only. |

|

Maximum Scaling Iterations |

Yes |

No |

Determines the maximum number of iterations the constraint scaling process should perform when attempting to find a valid solution for an order before the process should stop. This is meant to prevent lengthy or run-away scaling processes. For orders consisting of dynamic or time supply replenishment methods, this value represents the maximum number of days of supply added to the order before stopping. For non-forecasted items, this value represents the maximum number of cases that will be added to an item/location due to scaling. If the maximum scaling iterations variable is reached during the scaling process, scaling will consider this an invalid solution and notify the user that a valid solution could not be reached due to the maximum scaling iterations value. Maximum scaling values can also be set at the item/location level. Item/location maximums will prevent an item/location from being scaled further, but allow other item/locations to continue the scaling process. In all cases, if the maximum scaling iterations value is set to zero, scaling will view it as no limit and will process until a solution is reached. If using scaling it is recommended to set this to a value greater than zero. |

|

|

Order Not After Days |

Yes |

No |

3 |

Contains the number of days after the replenishment date plus the maximum lead time of the item/locations on the order that the not after date should fall for orders created by the replenishment process. The not before date is calculated by the replenishment date plus the minimum lead time of the item/locations on the order (i.e. not before date = replenishment date + minimum lead time) |

|

Reject Store Orders |

Yes |

No |

N |

This indicator is no longer used by Merchandising. It was replaced with a similar indicator at the item/location level. |

|

Allow Optimize Option for Min/Max Method |

No |

No |

Y |

When the Allow Optimize Option for Min/Max Method system option is set to Yes (Y), the ability to optimize Item/locations via an integration with Inventory Optimization (IO) is supported for forecastable items. This includes showing the Optimize and Service Level fields when the Min/Max Method of the Replenishment is used in the Replenishment Attributes screen. |

|

Replenish Clearance Item from Warehouse Stock |

Yes |

No |

N |

This indicates if items that are on clearance need to be replenished for the case where the replenishment stock category is 'Warehouse Stocked'. If this option is set to Yes (Y), items on clearance would be considered as eligible for replenishment. If this is set to No (N), items on clearance will be excluded from the replenishment process. Any changes to this option will impact the replenishment processing from that point onwards. Valid values are Yes (Y) or No (N). |

|

Use Activity Schedules for Delivery Dates |

No |

No |

Y |

Indicates if location activity schedules are used when calculating the not before date and not after date on replenishment generated orders. Valid values are Yes (Y) or No (N). |

|

Use Delivery Schedules for Delivery Dates |

No |

No |

Y |

Indicates if location delivery schedules are used when calculating the not before date and not after date on replenishment generated orders. Valid values are Yes (Y) or No (N). |

|

Use Delivery Schedule for Pickup Date |

No |

No |

N |

Indicates if location delivery schedules are used when calculating the pickup date on replenishment generated purchase orders. Valid values are Yes (Y) or No (N). |

|

Use Size Profile on Presentation Stock |

No |

No |

N |

Determines whether the size profile concept is applied to presentation stock. If Yes, then when the replenishment attributes that are defined for a parent item/diff are spread to the transaction item level, presentation stock is included in this computation. Valid values are Yes (Y) or No (N). |

|

WH / Cross Link Stock Category |

No |

No |

Y |

Determines if the WH/Cross Link stock category will be used in replenishment. This stock category attempts to fulfill store need with warehouse inventory first and then creates linked purchase orders to fulfill the balance of a store's need. |

|

Worksheet Order Cleanup Delay Days |

No |

No |

1 |

Contains the delay, in days, in closing manually created orders that were never approved and are in Worksheet or Submitted status. The number of days is based on the written date for the purchase order. |

|

Warehouse Store Assignment Type |

Yes |

No |

A |

Determines which item/location records are updated by the Warehouse/Store Assignment Process. Valid values are Warehouse Stocked (W), Cross-docked (C), WH/Cross Link (L), and All (A). If set to All, the source warehouse for all types are updated. Otherwise, only those item/locations with the indicated stock category are updated. If not using the Warehouse Store Assignment functionality in Merchandising, or it is not desired to use it to update the source warehouse for replenishment, then this can be left as NULL. |

|

Investment Buy |

||||

|

Annual Cost of Money |

Conditional |

No |

6.5 |

Contains the cost of money, defined as the annualized percentage cost to borrow capital for investing. This value represents your cost of tying up money in inventory rather than using it for other purposes. This parameter is one of several system parameters used to determine carrying costs in the investment buy calculation and can be set at the system level with the option to override at the warehouse or warehouse/department level. It is currently used by the investment buy functionality only. |

|

Look Ahead Days |

Conditional |

No |

30 |

Contains the number of days before a cost event (deal end or cost increase) that the investment buy opportunity calculation will begin considering the event. The parameter is set at system level and cannot be overridden. For investment buy eligible items, the system monitors deal expirations and cost changes occurring within this time frame set by the retailer, and includes these opportunities in the investment buy calculation. This value is currently used by the investment buy functionality only. For item/locations on replenishment, supplier reviewing time will override the look ahead days parameter when the number of days is greater. This ensures the investment buy opportunities are evaluated in the same cycle as the replenishment review, which allows users to combine investment buy and replenishment quantities on supplier orders. |

|

Storage Type |

Conditional |

No |

W |

Indicates which type of storage costs should be used as the default storage cost when calculating investment buy opportunities. Valid values are Warehouse (W) and Outside (O). This parameter can be set at the system level with the option to override at the warehouse or warehouse/department level, and is currently used by the investment buy functionality only. |

|

Target ROI |

Conditional |

No |

20 |

Dictates the percent return on the investment buy purchase that must be met or exceeded for the calculation to recommend an order quantity. The investment buy algorithm will solve for the target date, which is the maximum number of days in advance the investment buy can be purchased while remaining within the target ROI. The target ROI parameter can be set at the system level with the option to override at the warehouse or warehouse / department level. This value is currently used by the investment buy functionality only. |

|

Outside Storage |

||||

|

Cost Measure |

Conditional |

No |

E |

Contains the type of the outside storage cost. Valid values include: Mass, Volume, Pallet, Case, Each, Stat Case. This parameter can be overridden at the warehouse and/or warehouse/department level. |

|

Cost UOM |

Conditional |

No |

Contains the unit of measure for which the default cost of outside storage is applicable, used when the Outside Storage - Cost Measure is Mass or Volume. This parameter can be set at the system level with the option to override at the warehouse or warehouse/department level, and is currently used by the investment buy functionality only. |

|

|

Weekly Cost |

Conditional |

No |

Contains the default cost of outside storage, expressed as the weekly cost per the unit of measure specified in Outside Storage - Cost UOM. This parameter can be set at the system level with the option to override at the warehouse or warehouse/department level. This value is held in the primary currency and currently used by the investment buy functionality only. Cost of outside storage is defined as the weekly fully loaded cost of warehousing products in a non-retailer owned facility, including all applicable expenses related to storing the inventory, including lease, rent or building depreciation, taxes, labor, insurance and estimates of additional pallet handling as a result of investment buy. |

|

|

Warehouse Storage |

||||

|

Cost Measure |

Conditional |

No |

E |

Contains the type of the warehouse storage cost. Valid values include: Mass, Volume, Pallet, Case, Each, Stat Case. This parameter can be overridden at the warehouse and/ or warehouse/ department level. |

|

Cost UOM |

Conditional |

No |

Contains the unit of measure for which the default cost of warehouse storage is applicable, used when the Warehouse Storage - Cost Measure is Mass or Volume. This parameter can be set at the system level with the option to override at the warehouse or warehouse/department level, and is currently used by the investment buy functionality only. |

|

|

Weekly Cost |

Conditional |

No |

Contains the default cost of warehouse storage, expressed as the weekly cost per the unit of measure specified in Warehouse Storage - Cost UOM. This parameter can be set at the system level with the option to override at the warehouse or warehouse/ department level. This value is held in the primary currency and currently used by the investment buy functionality only. Cost of warehouse storage is defined as the weekly fully loaded cost of warehousing products in a company-owned facility, including all applicable expenses related to storing the inventory, including lease, rent or building depreciation, taxes, labor, insurance and estimates of additional pallet handling as a result of investment buy. |

|

Shipment

| System Options | Optional? | Re-configuration Restricted? | Default Value | Description |

|---|---|---|---|---|

|

Allow Auto Receiving at Stores |

Yes |

No |

N |

Indicates whether or not auto receiving of shipments at stores may be allowed in Merchandising. This option is intended to be used as a default value, and works in conjunction with the Auto Receive flag on store definitions. Each store can be set to use this system level default, System Default (D) or each store can be explicitly set to Yes (Y) or No (N) regardless of the system level setting. Valid values for this system option are Yes (Y) or No (N). If you wish to have all stores use the value set at the system level, then the Auto Receive flag on each store definition should be set to System Default (D). |

|

Allow Duplicate Receiving |

No |

No |

N |

Indicates whether or not duplicate receiving is allowed. If set to No, Merchandising will attempt to identify receipts that may have accidentally been processed from a warehouse or a store multiple times and skip processing them a second time. If detected, an error will be raised in processing the receipt. If set to Yes, then duplicate receipts will not be monitored for by Merchandising. Valid values are Yes (Y) or No (N). |

|

Allow Shipping/Receiving at Stores |

See System Options Required During Initial System Configuration. |

|||

|

Allow Shipping/Receiving at Warehouses |

See System Options Required During Initial System Configuration. |

|||

|

Close Open Shipments After Days |

No |

No |

3 |

Indicates the number of days that a shipment will stay open (in Unmatched status) before Merchandising will attempt to close it. |

|

Receive Pack Components |

See System Options Required During Initial System Configuration. |

|||

|

Wrong Store Receipt Exception Handling |

No |

No |

Y |

Indicates whether or not the system will look for wrong store receipts for transfers and allocations and attempt to reconcile based on the occurrence, or handle it as over and under receipts at each location. Valid values are Yes (Y) and No (N). |

|

Reserve Customer Orders on Receipt |

No |

No |

N |

Indicates whether customer orders that have inventory sourced from another location will be reserved automatically upon receipt in the store or wait on a second fulfillment message from OMS. Valid values are Yes (Y) or No (N). |

Transfers and RTVs

| System Options | Optional? | Re-configuration Restricted? | Default Value | Description |

|---|---|---|---|---|

|

Auto Close Transfers to Stores |

No |

No |

N |

This option will auto close any stock orders (transfers or allocations) to stores regardless of source after the first receipt. Only set this to Yes if all stock orders to stores will use the Transfer Receipt Treatment system option for overages and shortages and if only one shipment is expected for store receipts. Valid values are Yes (Y) or No (N). |

|

Auto Close Transfers to Warehouses |

No |

No |

N |

This option will auto close any stock orders to warehouses regardless of source after the first receipt. Only set this to Yes if all stock orders to warehouses will use the Transfer Receipt Treatment system option for overages or shortages and if only one shipment is expected for warehouse receipts. Valid values are Yes (Y) or No (N). |

|

Auto Close Unshipped/ Partially Shipped Transfers |

No |

No |

N |

Setting this flag to Yes will automatically cancel an overdue transfer after so many days, based on either the create date for the transfer (if it has never been shipped), or the latest ship date. The number of days is determined based on the Stock Order Auto Close Days. Note: this option is not used for Allocations |

|

Department Level Transfers |

No |

No |

N |

Indicates whether to enforce a single department on transfers. If Yes, then each transfer must contain only items within a single department. If No, then items from multiple departments can appear on a single transfer. This is also used by replenishment to determine if warehouse to store transfers should be split by department. Valid values are Yes (Y) or No (N). |

|

Allow Transfer Quantity Increase after Approval |

No |

No |

N |

Controls if the transfer quantity can be increased once a transfer has been approved. If Yes, then transfer quantity can be changed if there is outstanding quantity on the transfer (e.g. transfer qty > distributed/selected/shipped qty). When No, a user can only update the transfer to indicate total stock on hand should be shipped instead of a manually entered quantity. Valid values are Yes (Y) or No (N). |

|

Intercompany Transfer Basis |

No |

No |

T |

Determines if intercompany transfers are based on transfer entity or set of books. Valid values are Transfer Entity (T) or Set of Books (B). |

|

RTV Not After Date Lead Time Days |

No |

No |

1 |

Determines the default number of days between the Transfer Not After Date and the RTV Not After Date when RTVs are created as part of the mass-return transfer (MRT) process. |

|

RTV Unit Cost Source |

No |

No |

A |

This parameter determines the value used to set the default unit cost on an RTV (return to vendor). Valid values are Average Cost (A), Standard Cost (S), or Last Receipt Cost (R). Note: if more than one receipt occurs in the same day with different costs, the last receipt cost used will be the higher cost, to favor the retailer. |

|

RTV/RAC Transfer |

No |

No |

A |

Identifies whether RTV and re-allocation transfer types will always be handled as intracompany transfers or not. These two types are used when creating transfers in the mass return transfer (MRT) functionality in Merchandising. Valid values are Intracompany (A) or Intercompany (E). If set to Intra-Company, RTV and reallocation transfers will be processed as intra-company transfers from the stock ledger standpoint regardless of whether the transfer is across entities. |

|

Transfer Price to Exceed From Loc WAC |

No |

No |

Y |

Indicates whether the price for an intercompany transfer should be allowed to exceed the weighted average cost of the item at the from location or not, indicating a profit for the selling entity. Valid values are Yes (Y) or No (N). |

|

Validate Availability for Customer Orders |

No |

No |

Y |

Controls whether or not the Customer Order Fulfillment interface will perform inventory validation. If the value of this parameter is Yes (Y), inventory validation will be performed when customer orders are uploaded into Merchandising. If set to No (N), then inventory validation will be bypassed. Note: for orders fulfilled from store inventory, Merchandising does not validate inventory regardless of the setting. |

|

Validate External Warehouse Availability |

No |

No |

Y |

Controls whether or not the External Transfer interface will perform inventory validation. If the value of this parameter is Yes (Y), inventory validation will be performed when transfers are uploaded into Merchandising. If set to No (N), then inventory validation will be bypassed. |

|

Validate Availability for External Franchise Orders |

No |

No |

Y |

Controls whether or not external franchise orders (created via batch or via web service) will be subject to inventory availability considerations. If the value of this parameter is Yes (Y), inventory validation will be performed when external franchise orders are uploaded into Merchandising. If set to No (N), inventory validation will be bypassed. |

| Wac Update After Receiving | Yes | No | N | Indicates whether the change of inventory ownership to the receiving location occurs when transfers are received. Change of ownership includes posting the required transaction codes and average cost recalculation. Valid values are Yes (Y) or No (N). By default, this is set to No (N). When set to Yes (Y), change of ownership occurs when the transfer is received. When set to No (N), change of ownership occurs when the transfer is shipped. |

|

Markdown Location for Retail Differences |

||||

|

Store to Store |

See System Options Required During Initial System Configuration. |

|||

|

Store to Warehouse |

See System Options Required During Initial System Configuration. |

|||

|

Warehouse to Store |

See System Options Required During Initial System Configuration. |

|||

|

Warehouse to Warehouse |

See System Options Required During Initial System Configuration. |

|||

|

Stock Order Auto Close Days |

||||

|

Store to Store |

Yes |

No |

For transfers, this option works with the Auto Close Unshipped / Partially Shipped Transfer indicator. The option determines how many days that store to store transfers will remain open before Merchandising tries to close them automatically. In addition to cancelling the unshipped portions of the transfer, these options will apply the Transfer Receipt Treatment options for any discrepancies between shipped and received. If left as null, then auto close logic will not be applied and this type of transfer must be manually closed. |

|

|

Store to Warehouse |

Yes |

No |

For transfers, this option works with the Auto Close Unshipped / Partially Shipped Transfer indicator. The option determines how many days that store to warehouse transfers will remain open before Merchandising tries to close them automatically. In addition to cancelling the unshipped portions of the transfer, these options will apply the Transfer Receipt Treatment options for any discrepancies between shipped and received. If left as null, then auto close logic will not be applied and this type of transfer must be manually closed. |

|

|

Warehouse to Store |

Yes |

No |