1 Feature Summary

Oracle Retail Store Inventory Operations Cloud Services includes the following applications:

-

Oracle Retail Enterprise Inventory Cloud Service (EICS)

-

Oracle Retail Store Operations Cloud Service (SOCS)

This chapter describes the feature enhancements in this release.

Note:

Defect fixes from prior monthly Hot Fixes are also included in this 26.1.101.0 update.

Noteworthy Enhancements

This guide outlines the information you need to know about new or improved functionality in the Oracle Retail Store Inventory Operations Cloud Services update and describes any tasks you might need to perform for the update. Each section includes a brief description of the feature, the steps you need to take to enable or begin using the feature, any tips or considerations that you should keep in mind, and the resources available to help you.

Column Definitions

-

Feature: Provides a description of the feature being delivered.

-

Module Impacted: Identifies the module impacted associated with the feature, if any.

-

Scale: Identifies the size of the feature. Options are:

-

Small: These UI or process-based features are typically comprised of minor field, validation, or program changes. Therefore, the potential impact to users is minimal.

-

Medium: These UI or process-based features are typically comprised of field, validation, or program changes. Therefore, the potential impact to users is moderate.

-

Large: These UI or process-based features have more complex designs. Therefore, the potential impact to users is higher.

-

-

Delivered: Identifies whether the feature is Enabled or Disabled upon initial delivery.

- Customer Action Required: You must take action before these features can be used. These features are delivered disabled and you choose if and when to enable them.

Table 1-1 Noteworthy Enhancements

| Feature | Module Impacted | Scale | Delivered | Customer Action Required? |

|---|---|---|---|---|

| RFID Bluetooth and External Device Support |

SOCS |

Small |

Yes |

Set the store configuration correctly. |

| RFID Location and Locator | SOCS | Small | Yes | Assign permissions and configuration. |

| Extended Attribute Setup and Configuration | SOCS | Small | Yes | Assign permission. |

| Quality of Life Changes | SOCS | Small | Yes | No |

| REST Services | EICS | Medium | Yes | No |

| Database, Retail Data Store (RDS), and Golden-Gate DAS Updates | RDS/DAS | NA | NA | NA |

Note:

MAF was deprecated at the end of 2025. This release does not include any MAF workflows, nor will a prior MAF version work with this release. Jet Mobile is the UI for SOCS going forward.

All MAF workflows have been removed from the documentation. In addition, system and store configuration options and permissions have been removed if they only applied to MAF.

New Feature Descriptions

This section describes the new features.

RFID Bluetooth and External Device Support

As part of adding RFID external Bluetooth support, the external Bluetooth device support has also slightly changed. A new store option is added to ensure that people who are not using this feature do not have this screen clutter up their workflows.

A new screen is added to the external scanner configuration area to allow configuring the RFID scanners.

The user preferences have also been updated to allow the user to quickly change the scan strength of the RFID scanner as well as see the remaining battery strength.

Store Parameters

Enable External Barcode Scanning (New)

- Values: Yes/No

- Default: No

- Topic: Admin

- Editable: Yes

- Yes: This indicates an external Barcode scanning device is connected and supported by the system. If this is enabled, the system allows the user to connect the external scanners using the external Scanner Configuration screen. The Barcode tab on the screen is enabled only if this parameter is set to Yes.

- No: This indicates the system will not connect to the external Barcode scanners and the Barcode tab is not visible on the External Scanner screen.

Enable External RFID Scanning (New)

- Values: Yes/No

- Default: No

- Topic: Admin

- Editable: Yes

- Yes: This indicates the external RFID scanning device is connected and supported by the system. If this is enabled, the system allows the user to connect the external scanners using the External Scanner Configuration screen. The Barcode tab on the screen is enabled only if this parameter is Yes.

- No: This indicates the system will not connect to the external RFID scanners and the RFID tab is not visible on the External Scanner screen.

External Scanner Configuration

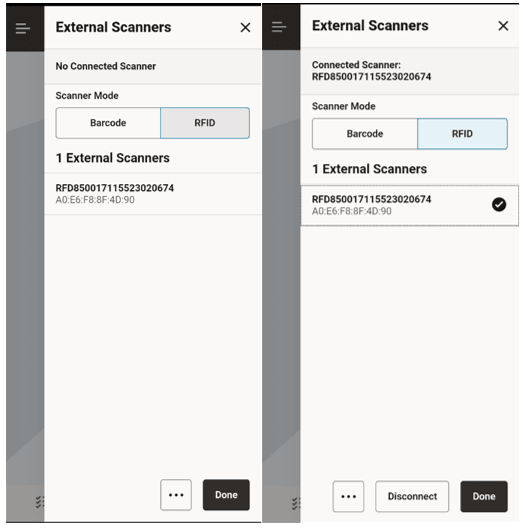

External Scanners Screen

- This screen on the mobile application is used to configure the external scanners.

- This screen is displayed by selecting the External Scanners menu option within Configurations from the drawer/menu.

-

The system lists the devices available based on the scanner mode type you selected.

Scanner Mode:

- Barcode:

- Displayed only if the Enable External Barcode Scanning store parameter is set to Yes.

- All the scanners that are of BT type are listed here.

- RFID:

- Displayed only if the Enable External RFID Scanning store parameter is set to Yes.

- All external RFID scanners are listed under this tab.

- Barcode:

- The connected scanner is displayed at the header section and a check mark appears at the detail level.

- The user can select the device to connect. Once connected, the system allows the user to disconnect using the Disconnect button.

-

The following functions can be accessed from the footer menu (…):

- Locate: This locates the scanner and produces a beep sound on the device.

- Config: This option is visible if there is currently a connected RFID scanner. This takes the user to the External Scanner Configuration dialog.

- Refresh: Upon selecting this button, the system refreshes the list of devices and shows the currently Bluetooth paired/USB connected scanners.

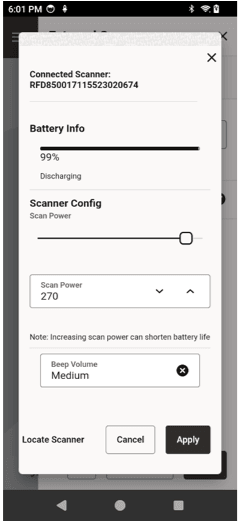

Scanner Detail Screen

This screen is accessed on the mobile application by selecting the Configure option from the External Scanners screen after an external scanner has been connected. The system displays the following configurations details and allows the user to configure the scanner:

- Scanner Name: <Scanner Name> - the name of the connected scanners whose settings are displayed on the screen.

- Battery Info Bar: Visual progress bar showing the amount of battery remaining in the scanner:

- Battery %: Shows the amount of battery life remaining as a numeric value (0 to 100%).

- Battery State: Displays either Charging or Discharging depending on if the battery is charging or discharging.

- Scan Power Slider Bar: Displays the amount of power each scan takes on a slider bar. The slider bar can be dragged to a new value. The values are between 0 and 300 dBM.

- Scan Power Input Field: Displays the amount of power each scan takes as a numeric value. A user can enter a new numeric value in this field. Any value less than zero will be set to zero, and any value greater than 300 is set to 300. This value updates if the slider bar value is changed.

- Scan Volume: Displays the current beep volume during a scan and presents values in a drop down to change. Values are: Quiet, Low, Medium, and High.

Buttons

- Apply: Applies the settings to the connected external scanner.

- Locate Scanner: Upon selecting this button, the system makes the scanner you are connected to beep to help identify which one is used.

Note:

This button is displayed only in IOS.User Preferences Screen

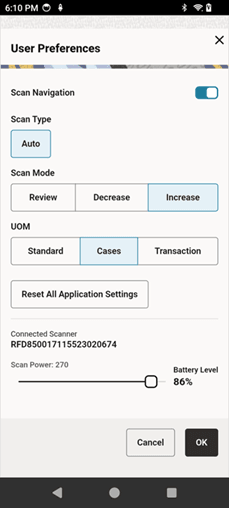

The Preferences dialog is accessed by selecting Preferences from the Quick Actions menu or by selecting Preferences from the Additional Options (…) menu in the upper right-hand corner. Preferences are for the user on the mobile application. Preferences include: displaying images, scan navigation preference, Scan Type, Scan Mode, UOM, and configure the scan power of the connected scanner if any.

The Scan Power Slider Bar displays the amount of power each scan takes on a slider bar. The slider bar can be dragged to a new value. The values are between 0 and 300 dBM. The Battery Level%: <Battery %> - shows the amount of battery life remaining as a numeric value (0 to 100%).

The Display Images preference is available if the Display Images system setting is set to Yes.

RFID Location and Locator

When integrating from the third-party system RFID tags, a location can be defined. SIOCS uses this information in two ways:

- RFID location is a dialog in Item Lookup that displays the location from the RFID tag if this information is integrated.

- RFID Locator is a dialog that allows a user to find an item based on the RFID tag scanning strength. In other words, a user identifies an item and the RFID tags that have been integrated are displayed with their signal strength. The user can then select the one with the strongest RF strength and start walking to it to find that exact item faster.

Store Parameters

RFID Locations Enabled (New)

- Values: Yes/No

- Default: No

- Topic: Admin

- Editable: Yes

- Yes: This indicates RFID support is enabled for the store and the RFID data is populated in the system using a third-party solution. If this is enabled, the user can view the RFID Locations on the Item Lookup dialog for the item for which data is available.

- No: RFID Locations is disabled. This means no RFID location data is populated from the third-party system.

Security Permissions

| Permission | Topic | Usage |

|---|---|---|

| Access RFID Locator | Admin |

Without this permission, the user cannot access the dialog. |

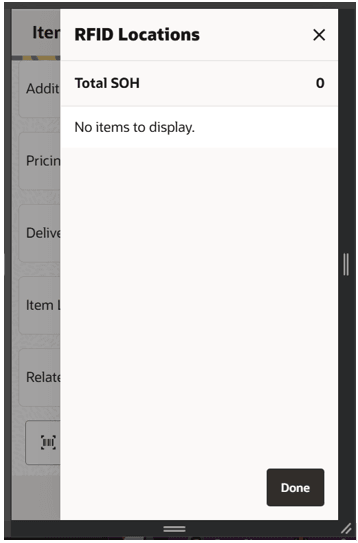

RFID Locations Screen

Selecting RFID Locations from Item Detail displays the RFID location inventory. This screen is available only if the store parameter RFID Locations Enabled is set to Yes and the item is an RFID item. RFID locations are defined in the RFID solution and uploaded into the system.

RFID locations are shown with their stock on hand. The inventory positions shown here are the accumulated numbers of the tags present in the location represented in standard unit of measure.

RFID Locator Screen

The RFID Locator functionality provides the user with the ability to locate the RFID tags in the store. This helps the store users to locate the items quickly by navigating the mobile device based on the signal strength.

The RFID Locator dialog can be accessed from the Lookup menu.

The search field on the scan bar is item. The user can scan or enter the item barcodes.

This screen is used for locating the RFID Tags in the store. The purpose of the RFID Locator functionality is to enable the user to find the specific unit where it is placed in the store using RFID scanning.

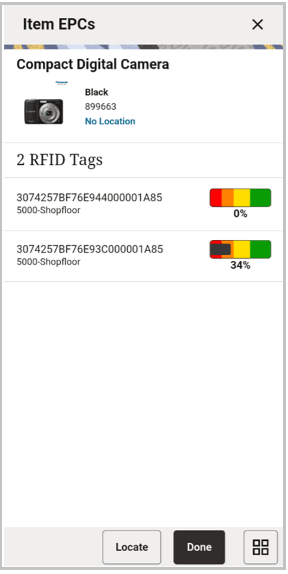

If the user has scanned/entered an EPC and if the corresponding item of the scanned EPC contains more than one EPCs/Tags in the system, the system takes the user to the Item EPCs for the user to select the appropriate tag to find it.

If the user has scanned/entered an EPC and if the corresponding item of the scanned EPC contains only one EPC that is the scanned EPC, the system takes the user to the RFID Tag Finder showing the signal strength.

Item EPCs Screen

On this screen, the system displays the list of found active RFID tags based on the provided item.

From the list, the user can select a specific tag to start locating the tag or select the Locate option to start searching the listed tags using the radar and display the strength of the signal.

On the list, the system displays the Tag id and the description of the item along with the item information on the header.

This screen lists all the RFID Tags that are flagged as present in the system for the given item number.

From this screen, the user can try to locate all tags flagged as present to determine the approximate distance or select one tag and find.

RFID Tag Finder Screen

The user reaches this screen using the RFID Locator screen if the Tag id was scanned or entered. Alternatively, selecting the RFID Tag from the Item EPCs screen brings the user here as well. The user can use the Locate option to start locating the tag. The system displays the signal strength to indicate how close the tag is while the user moves around the search area holding the trigger on the scanner. On the header, the system displays the item information.

Extended Attribute Setup and Configuration

To support capturing and managing lot, batch, and extended attributes better, several new fields and flags have been added to the extended attributes setup and configuration screens. At this point, several of these new fields are yet not active, but have been added for future use.

In addition, all appropriate REST services have been updated to support inbound and outbound integration of extended attributes.

The following integration points have been updated:

- Inventory Adjustments

- Transfer Receiving

- Transfer Shipment

- DSD Receiving

- Return to Vendor

- Customer Order Deliveries

- Stock Counts

For inbound REST Calls, the integration message requires the use of the GS1 standard Application Identifier (AI).

For outbound REST, the publish indicator needs to be set. The published value is optional and added to allow easier mapping with external systems. In addition to the publish value (if configured), the AI number and its captured value are also published.

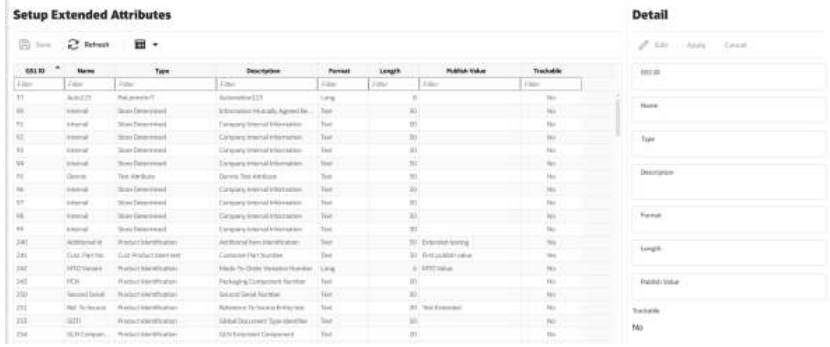

Setup Extended Attributes Screen

The Setup Extended Attributes screen is pre-populated with all the current GS1 Application Identifiers and enables the user to view and edit Name, Type, and Description of the extended attributes, depending on the business needs for the entire system. The format and length are view only. The Publish value is a code or value published for the extended attribute on the transaction (if extended attributes are published). Lastly, the trackable indicator is a Yes or No value to determine whether or not this extended attribute can be tracked. At this time, it is defaulted to No and is not editable. The trackable indicator is intended for future functionality.

The user must have the appropriate permission to access the screen and edit extended attributes.

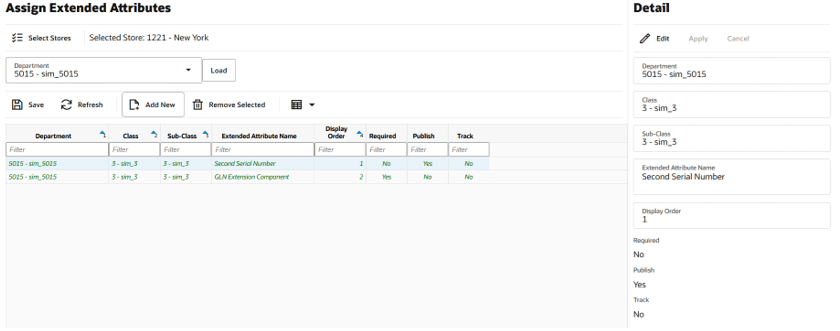

Assign Extended Attributes Screen

This screen lists the assignments made for the various sub-classes and their display order in the transactions. Assignments are made in the Assign Extended Attributes popup (see below) and are applied to this screen. Once assigned, they can be edited in the detail block. Only the Display Order, Required, Publish, and Track fields can be edited.

The assignment made here is applicable to the stores selected in the select store list. All extended attributes for the current store will replace those of the selected stores.

The user must have the appropriate permissions to access the screen.

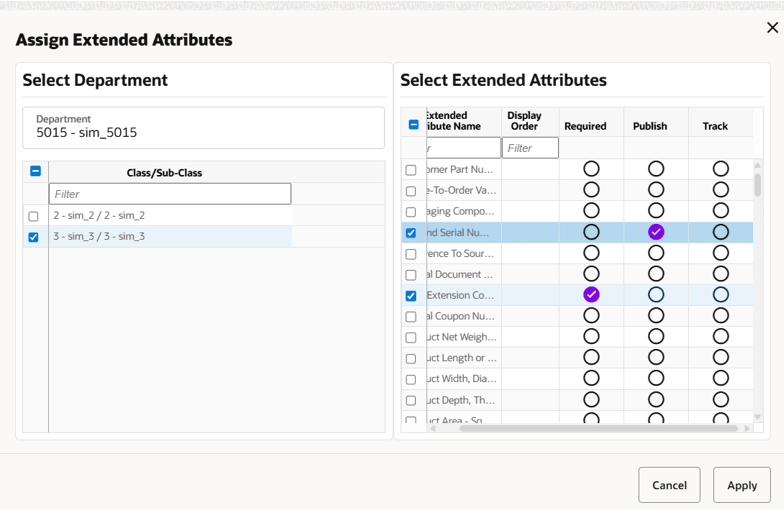

Assign Extended Attributes Popup

The Assign Extended Attributes popup enables the user to assign the extended attributes to a department/class/sub‑class hierarchy and identify the order in which they will be displayed in the data entry screens in the transactions. Additionally, other indicators can be flagged for the attribute. The Required indicator determines if the attribute should be required to be captured on the transaction. The Publish indicator determines if the extended attribute will be published on the transaction. Lastly, the track indicator indicates if the attribute is tracked on the transaction. The track indicator is only editable if the extended attribute was flagged as trackable on the Setup Extended Attribute screen.

Note:

The required and track indicators are intended for future functionality.Quality of Life Changes

As with every release, a small quantity of changes are added to the application. The following small changes have been introduced to make operations and find data easier:

- Stock Count ID is added to the Item Detail screen and Child Count Info screen.

- Display of the External container ID on:

- Direct Delivery Containers (DSD)

- Transfer receiving container items

- The Snapshot button is added to the Child Count list screen for Unit and Amount counts.

- Display of stock on hand (SOH) is added on the Auto Print Item screen.

- Transaction History is renamed to Completed Transaction History.

- The mode selection in DSDs is disabled if the user does not have the permission to allow receiving damaged quantities.

REST Services

Similar to prior releases, SIOCS added or updated some services. In this release, the following services have been updated:

- Store order service: The submit and cancel submit APIs have been added.

- Manifest Service: Container ID has been added.

Note:

These services are not meant for initial data load. Data seeding integration jobs exist for the initial data load. Some of these services can be used instead of their equivalent RIB messages.Technical Changes

This section describes the technical changes in this release.

General Updates

As with all updates for SIOCS, there are several technical changes that have been made:

- The Purge-Completed-UIN batch process has been enhanced for performance improvements:

- Chunked Commits: The batch now commits transactions in chunks, reducing the overall processing time and minimizing the risk of long-running transactions.

- Dynamic Purge Limit: The batch now utilizes the Purge Maximum Query Limit system configuration to determine the maximum number of records to delete in a single execution. This ensures that the batch process is adapted to the system's configuration and avoids running for extended periods.

-

The Cleanup Price History batch has been optimized to improve performance.

Additionally, a new system configuration, Retain Recent Price History Records, has been introduced, allowing retailers to specify whether to retain recent price history records. This configuration value determines the behavior of the batch process when deleting price history records that meet the deletion criteria. When set to true (default), the batch process will delete all eligible records except for the two most recent records (across all price types), which will be retained. Conversely, when set to false, the batch process will delete all eligible records without exception.