8 Working with JD Edwards EnterpriseOne Product Data Management for Apparel Management

This chapter contains the following topics:

-

Section 8.1, "Understanding JD Edwards EnterpriseOne Product Data Management for Apparel Management"

-

Section 8.3, "Creating Routing Instructions for Style Items"

-

Section 8.4, "Setting Up Outsource Operations for Style Items"

8.1 Understanding JD Edwards EnterpriseOne Product Data Management for Apparel Management

The JD Edwards EnterpriseOne Product Data Management system enables you to integrate all of the aspects of product data. This system provides basic data for other manufacturing systems. Bills of material (BOM), routings, and work center information are used throughout an organization.

The bill of material is the primary method for defining and communicating the structure of the product. A BOM identifies the manufacture of finished products (end items), subassemblies, and components. When you can create a bill of material, you define components, quantities, reference information, and additional information as necessary. The system uses a bill of material as a master list when generating the parts lists for work orders, cost roll-ups, lead-time roll-ups, and production scheduling.

After you have defined a style item's components using a bill of material, you must specify where each operation occurs and the sequence of operations that is necessary to manufacture the item. Work centers consist of people and machines in which routing operations occur. Routing instructions define the operations that are required to produce a style item and the lead time for a style item at each routing instruction step.

For an operation that is to be performed on a style item by an external supplier, you can define an outside routing operation. An external supplier may perform such outside operations as cutting, dyeing, or sewing. For an outside operation, a purchase order is required. The JD Edwards EnterpriseOne Procurement Management system enables you to automatically generate purchase orders for outsourced operations on the routing instructions. You can generate the purchase order when you run the Work Order Processing for Style Items program (R31F410). You can also enter a purchase order interactively after you have attached the routing to the work order.

After you set up the style item root level 0 and child style items in the JD Edwards EnterpriseOne Apparel Management system, you can use the JD Edwards EnterpriseOne Product Data Management system to set up bills of material, create routings, and set up outsource operations for the manufacture of style items.

8.1.1 Prerequisites

Before you complete the tasks in this chapter:

-

Verify the following user-defined codes (UDCs) setup:

-

Verify item branch/plant information setup for style items.

See Working with JD Edwards EnterpriseOne Inventory Management for Apparel Management.

8.2 Setting Up Bills of Material for Style Items

This section provides an overview of bills of material for style items, lists prerequisites, and discusses how to:

-

Enter bills of material for style item root level 0.

-

Enter bill of material associations.

-

Enter bill of material usage.

-

Define bill of material exceptions.

-

Generate bills of material for child style items on demand.

-

Generate bills of material for child style items by batch.

-

Copy bills of material for style items.

8.2.1 Understanding Bills of Material for Style Items

A bill of material defines all the components that are included in the manufacture of a style item. For style items, you define the bill of material for the style item root level 0. The bill of material for the style item root level 0 cascades down to the lowest-level child style items.

|

Note: Style items use discrete manufacturing only. |

Style items are multilevel items with complex bills of material, for example, 100 styles with 5 colors, 5 sizes, and 3 fits creates 7500 child style items. Each child style item has a different bill of material because the components are based on attributes, such as size and color. Thus, one style can have 75 different bills of material.

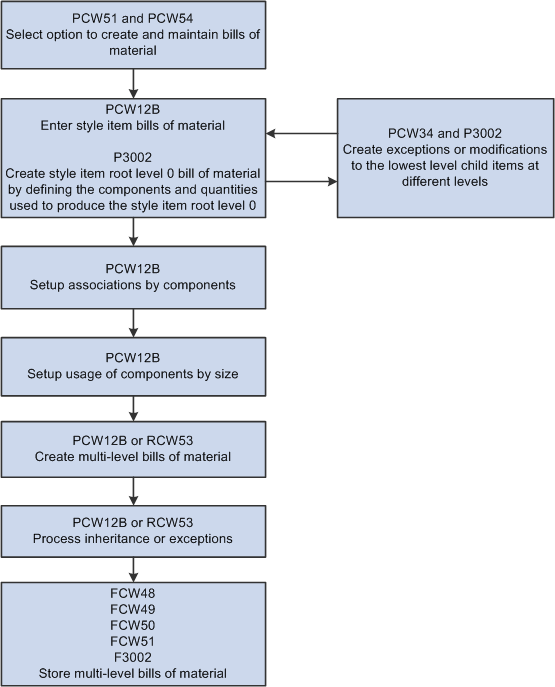

When defining the bill of material for the style item root level 0 for the first time, you must use either the Style Item Master program (PCW51) or the Collection Item Master program (PCW54). The Style Item Master and Collection Item Master programs provide access to the Bill of Material for Style Items program (PCW12B), which in turn calls the Bill of Material Revisions program (P3002) for bill of material entry and update.

The Bill of Material for Style Items program enables:

-

Creation of the style item root level 0 bill of material.

-

Generation of multilevel inheritance and exceptions.

-

Association of components based on attributes.

-

Definition of usage of quantities for the components based on sizes.

-

Copying a bill of material.

You can create bills of material for child style items on demand using the Bill of Material for Style Items program (PCW12B) or by batch using the Create BOM for Child Style Items program (RCW53).

The system provides visual assistance on the Work With Bill of Material for Style Items form (WCW12BA) as color coding in the column headings. The color of the column headings changes according to the following statuses:

-

Blue is status 0.

The color is blue after you create the bill of material for the style item root level 0 or any level of the style item but you have not yet created bills of material for the child style items.

-

Red is status 2.

The color is red after you make changes to the bill of material for the style item root level 0 or any level of the style item without re-creating the bills of material for the child style items.

-

Black is status 9.

The color is black when all updates to the bill of material for the style item root level 0 or any level of the style item have been proliferated to the child style items.

The system stores bill-of-material information for style items in the Bill of Material Association Header (FCW48) and Bill of Material Association Detail (FCW49) tables. The Bill of Material Master File table (F3002) is also populated with the multilevel bills of material.

This diagram illustrates the on-demand bill-of-material creation process for style items:

Figure 8-1 On-demand bill-of-material creation process for style items

Description of "Figure 8-1 On-demand bill-of-material creation process for style items"

When creating the bill of material, you enter the components that you need without accounting for an attribute such as color. An example is a jacket that is made of fabric, a zipper, and a lining.

You then further define the bills of material by creating component associations, which is an automated process to:

-

Associate colors of components with style items.

-

Associate sizes of components with style items.

The system supports 9 levels of associations and up to 30 values. You use the Bill of Material for Style Items program to define associations. The bill of material associations are stored in the Bill of Material Association Matrix table (FCW50).

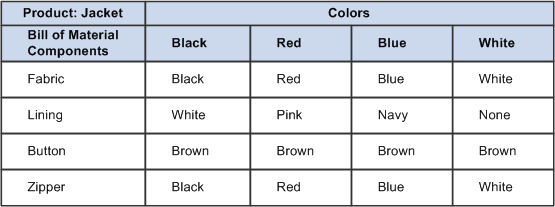

You associate the bill of material with colors, such as black fabric, black lining, and black zipper. This diagram shows an example of color associations for a bill of material:

Figure 8-2 Bill of material associations by color

Description of "Figure 8-2 Bill of material associations by color"

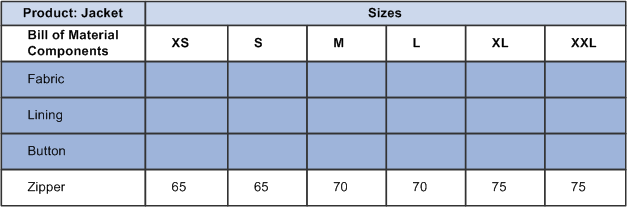

You can also associate the size of components with style items. This diagram shows an example of size associations for a bill of material:

Figure 8-3 Bill of material associations by size

Description of "Figure 8-3 Bill of material associations by size"

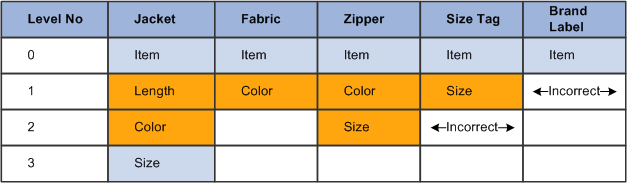

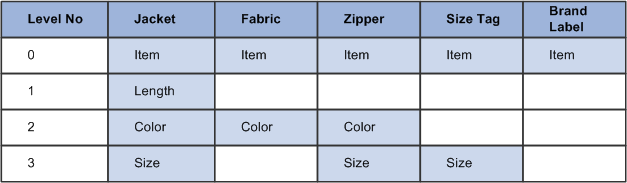

Bill of material associations cannot be made based on level numbers. This diagram illustrates the errors that occur when you attempt to create associations by level number:

Figure 8-4 Incorrect associations by level number

Description of "Figure 8-4 Incorrect associations by level number"

Bill of material associations must be based on column position. This diagram illustrates associations by column position:

Figure 8-5 Associations by column position

Description of "Figure 8-5 Associations by column position"

See Working with JD Edwards EnterpriseOne Inventory Management for Apparel Management.

|

Note: For bill of material associations to work, the column position of a level of a BOM component must match the column position of the related level of the BOM parent. |

When you enter the quantity for components on the bills of material, you enter the quantity that is used for the majority of the bills of material. The bills of material for the lower-level child style items inherit the associations from the style item root level 0. Once you generate bills of material for the lowest-level child style items, you can use the Bill of Material Exception program (PCW34) to define exceptions at the desired level of the style item's bill of material. For example, an exception might be a different quantity of fabric based on size, a blue skirt with a black button, or using a 1/2 cm size button on a size extra small (XS) skirt.

After associations are created, you define usage. In usage, you define the quantity of components based on style item size and not by level in the style item structure. For example, component quantity is associated with sizes such as extra small (XS), small (S), and such. The quantity entered for the style item root level 0 is the default value for usage, but you can override the values. The bill of material usage is stored in the BOM Usage table (FCW51).

The style item root level 0 is always passed from the entry points of the Style Item Master (PCW51) and Collection Item Master (PCW54) programs to the Bill of Material for Style Items program, regardless of the level from which it was called. You use the Bill of Material Exception program to select the level of the style item to modify. The system also supports the use of substitute items.

You can run the Create BOM for Child Style Items program (RCW53) in batch to create the BOMs for the lowest-level child style items.

The creation of BOMs for child style items is different than the item creation process for style items. When you create BOMs for style items, the system creates BOM records for the lowest-level child style items only. The system does not create a BOM for items at an intermediate level because BOMs are not needed for intermediate-level style items. You can use the Bill of Material Exception program to create a BOM for an intermediate-level style item. The system uses the BOM of an intermediate-level style item to track exceptions to apply to lower-level style items.

In the manufacture of some style items, not all components are on the bill of material. For example, in the apparel industry, thread is generally not part of the bill of material. Thread is considered as a base foundation item and is purchased in bulk.

The bill of material is used to derive the cost of the style items. The JD Edwards EnterpriseOne Apparel Management system uses the base manufacturing cost functionality in Oracle's JD Edwards EnterpriseOne Product Costing and Manufacturing Accounting systems in the JD Edwards EnterpriseOne Manufacturing and Supply Chain Management suite from Oracle.

To maintain bills of material for style items, Oracle recommends that you perform maintenance through the Style Item Master and Collection Item Master programs to enable inheritance and maintain links between parent and child style items

When you copy a bill of material that already has multilevel bill-of-material definitions, the system copies the definitions for levels other than level 0. When you copy a style item with a different item structure, the system automatically disables the Copy associations and usages option and copies only the FCW48 and F3002 records.

When you delete a bill of material at the parent level, the Bill of Material for Style Items program deletes all records for the style item root level 0 and child style items from the FCW48, FCW49, FCW51, and F3002 tables. You use the Create BOM for Child Style Items program for both the deletion and creation of bills of material. When deleting bills of material, you define a version of the Create BOM for Child Style Items program in the processing options of the Style Item Master program. The version of the Create BOM for Child Style Items program defined in the Style Item Master program must have a specific data selection set.

8.2.2 Prerequisites

Before you complete the tasks in this section:

-

Set the Bill of Material Revisions (P3002) processing option on the Version tab of the Style Item Master program (PCW51) to specify the version of the Bill of Material Revisions program for the Bill of Material for Style Items (PCW12B) program to use.

-

Set the Bill of Material Revisions (P3002) processing option on the Version tab of the Collection Item Master program (PCW54) to specify the version of the Bill of Material Revisions program for the Bill of Material for Style Items (PCW12B) program to use.

-

Set the Bill of Material Creation processing option on the Bill of Material tab of the Style Item Master program (PCW51) to specify whether the system creates bills of material on demand or by batch.

-

Set the Create BOM for Child Style Items (RCW53) processing option on the Version tab of the Style Item Master program if the Bill of Material Creation processing option on the Bill of Material tab of the Style Item Master program is set to 1.

8.2.3 Forms Used to Set Up Bills of Material for Style Items

| Form Name | FormID | Navigation | Usage |

|---|---|---|---|

| Work With Bill of Material for Style Items | WCW12BA | Style Item Management (G41F11), Work with Style Items

Search for a style item and select a row on the Work With Style Item Master Browse form (WCW51E); then select Bill of Material from the Row menu. Style Item Management (G41F11), Work with Style Items by Collection Search for a collection and select a row on the Work With Collection Style Item Master Browse form (WCW54A); then select Bill of Material from the Row menu. Style Item Management (G41F11), Work with Style Items On the Work With Style Routing form, select a row and then select Bill of Material from the Form menu. |

Work with bills of material for style items.

Generate bills of material for child style items on demand. Note: The Bill of Material for Style Items program (PCW12B) is accessible only from another application. |

| Enter Bill of Material Information | W3002A | On the Work With Bill of Material for Style Items form, click Add.

On the Work With Bill of Material for Style Items form, select a record and click Select. |

Enter bills of material for style items.

Review and update bills of material for style items. Note: When you click Add, the system preloads the style item root level 0 into the Parent Item field on the form. |

| Define Bill of Material Association by {Variable Name} | WCW12BC | On the Work With Bill of Material for Style Items form, select a record and then select Association from the Row menu.

On the Work With Bill of Material for Style Items form, select a record and then select Usage from the Row menu. |

Enter bill of material associations.

Enter bill of material usage. |

| Work With Bill of Material Exception | WCW34A | On the Work With Bill of Material for Style Items form, select a record and then select Exception from the Row menu. | Define bill of material exceptions.

Note: The Bill of Material Exception program (PCW34) is accessible only from another application. |

| View Bill of Material Information | W3002A | On the Work With Bill of Material Exception form, select a record and then select View BOM from the Row menu. | Review bills of material.

Note: You can review the bill of material for the lowest-level child style item without saving any changes. |

| Copy Bill of Material for Style Items | WCW12BD | On the Work With Bill of Material for Style Items form, select a record and then click Copy. | Copy bills of material. |

8.2.4 Entering Bills of Material for Style Item Root Level 0

Access the Enter Bill of Material Information form.

To enter bills of material for style item root level 0:

-

Enter a value in each of the following fields in the header, if applicable:

-

Branch/Plant

-

Parent Item

-

Batch Quantity

-

Type of Bill

-

-

Define the components, quantities, and additional information required to manufacture the style item.

-

Click OK to create the bill of material for the style item root level 0.

|

Important: The system generates the bill of material for the style item root level 0 only. You create bills of material for the lowest-level child style items on demand or by batch. |

8.2.5 Entering Bill of Material Associations

Access the Define Bill of Material Association by {Variable Name} form.

Figure 8-6 Define Bill of Material Association by Colors form

Description of "Figure 8-6 Define Bill of Material Association by Colors form"

|

Note: The Define Bill of Material Association by {Variable Name} form enables associating values of each style item root level 0 with components possessing similar levels. If the value that you entered does not match with the system default values, then you can enter another value for the corresponding level. You can enter any value you want even if the values match.Depending upon the style item definition, you may have to define several associations for a style item. The association forms succeed each other when you click Next or select Next on the Form menu. The system stores any changes made on the current form before moving to the next Define Bill of Material Association by {Variable Name} form. The system supports up to 9 attributes of the Define Bill of Material Association by {Variable Name} form. The system suggests associations for the first level on the Define Bill of Material Association by {Variable Name} form. The Define Bill of Material Association by {Variable Name} form displays the variable as columns for the style item root level 0 bill of material and grid with the specific values for each component. |

To enter bill of material associations:

-

Enter values for variables.

-

Click the Next button or select Next on the Form menu to navigate to the next form.

The system suggests associations for the second level on the Define Bill of Material Association by {Variable Name} form.

-

Click the Next button or select Next on the Form menu to navigate to the next form.

The system supports up to 9 attributes of the Define Bill of Material Association by {Variable Name} form.

When you initially create the associations for the style item root level 0, the system launches the Define Bill of Material Association By Usage form. The system returns to the Work with Bill of Material for Style Items form after completing the BOM usage.

When you complete all associations for the lowest-level child style items using the Association option from the Row menu, the system returns you to the Work With Bill of Material for Style Items form.

If any specification is omitted, then the component is not used for the variable under consideration. For example, if the lining variable for white fabric is blank, then the system creates a BOM for the white skirt without the lining component.

8.2.6 Entering Bill of Material Usage

Access the Define Bill of Material Association by Usage form.

Figure 8-7 Define Bill of Material Association by Usage form

Description of "Figure 8-7 Define Bill of Material Association by Usage form"

|

Important: You maintain the required quantities for each component in the BOM for a style item using only the Define Bill of Material Association by Usage form in the Bill of Material for Style Items program (PCW12B). |

To enter bill of material usage:

-

Enter the quantity required for each component based on size.

-

Click the Next button or select Next on the Form menu to navigate to the next form.

8.2.7 Defining Bill of Material Exceptions

Access the Work With Bill of Material Exception form.

You define exceptions at the desired level of style items. You can apply exceptions to associations, usages, BOMs, or all three.

To define bill of material exceptions:

-

Select the style item level in the tree for which to apply an exception.

-

Click Select.

-

On the Work With Bill of Material for Style Items form, select the same record that you selected on the exceptions tree and click Select.

-

Enter bill of material exceptions on the Enter Bill of Material Information form.

-

Click OK to save the changes.

The bill of material record is red.

-

Select a record on the Work With Bill of Material for Style Items form and select Create from the Row menu.

The bill of material record is black.

-

Click Close to return to the Work With Style Item Master Browse form.

8.2.8 Generating Bills of Material for Child Style Items on Demand

Access the Work With Bill of Material for Style Items form.

You set the Bill of Material Creation processing option on the Bill of Material tab of the Style Item Master program (PCW51) to blank to specify that the system creates bills of material on demand.

To generate bills of material for child style items on demand:

-

Select a style item root level 0.

-

Select Create from the Row menu.

The system validates and generates the bills of material for all lowest-level child style items. After bill-of-material creation, you can view the bills of material for the lowest-level child style items. Also, once the system creates bills of material for child style items, the color of the row of the parent style item changes from blue to black.

You can set data selection and data sequencing for the program.

8.2.9 Generating Bills of Material for Child Style Items by Batch

Select Product Data Management (G41F24), Create BOM for Child Style Items.

You can set data selection and data sequencing for the Create BOM for Child Style Items program.

8.2.10 Copying Bills of Material for Style Items

Access the Copy Bill of Material for Style Items form.

Figure 8-8 Copy Bill of Material for Style Items form

Description of "Figure 8-8 Copy Bill of Material for Style Items form"

To copy bills of material for style items, complete the following fields and select the option as applicable:

-

Item Number

-

Branch/Plant

-

Type of Bill

-

Batch Quantity

-

Copy associations and usages

8.3 Creating Routing Instructions for Style Items

This section provides an overview of routing instruction creation for style items, lists prerequisites, and discusses how to:

-

Enter routing instructions for style item root level 0.

-

Generate routings for child style items.

-

Define routing instruction exceptions.

8.3.1 Understanding Routing Instruction Creation for Style Items

Routing instructions are the sequence of operations carried out in the process of manufacturing a style item. You use the Work With Style Routing Master program (PCW35) and Enter/Change Routing (P3003) to define the routing for the style item root level 0. The style item root level 0 is always passed into the Work With Style Routing Master program regardless of the level from which it is called in the Style Item Master (PCW51) or Style Items by Collection (PCW54) program.

The routings for the lowest-level child style items are copied from the style item root level 0. In the JD Edwards EnterpriseOne Apparel Management system, the routing typically remains the same for the style item root level 0 as well as the child style items.

Routing instructions do not depend on attributes such as color or size. For example, the process for the production of a blue jacket is no different from that for a green jacket. The process also remains the same in regard to size because the process does not change for a jacket size of small (S) versus medium (M). Thus, child style items inherit the routing of the style item root level 0.

The system enables review and modification of child style item routings. You use the Routing Exception program (PCW36) to override the style item root level 0 routing at the child level through exception processing. The child style item has the same routing as the style item root level 0 except when:

-

One material is not used for a color or a size.

For example, a skirt lining is not used for the black color.

-

Manufacturing times differ for bigger versus smaller sizes.

For example, the number of hours required for the stitching operations.

The system provides visual assistance on the Work With Style Routing form as color coding in the column headings. The color of the column headings changes according to the following statuses:

-

Blue is status 0

The color is blue after you create the routing for the style item root level 0 or any level of the style item but you have not yet created routings for the child style items.

-

Red is status 2

The color is red after you change the routing for the style item root level 0 or any level of the style item without re-creating the routings for the child style items.

-

Black is status 9

The color is black when all updates to the style item root level 0 or any level of the style item routing have been proliferated to the child style items.

The system stores routing information in the Style Routing Master File (FCW52) and Routing Master File (F3003) tables.

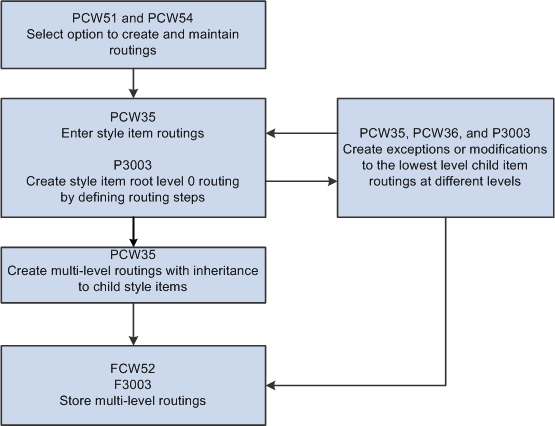

This diagram illustrates the routing creation process for style items:

Figure 8-9 Routing creation process for style items

Description of "Figure 8-9 Routing creation process for style items"

Once the routing is created, the system uses standard JD Edwards EnterpriseOne functionality.

If you use the Work With Style Routing Master program to delete a routing, then the system deletes the routings for the style item root level 0 or any level of the style item. The system deletes the routing records from the FCW52 and F3003 tables.

The system enables the use of outside operations for which a particular operation is outsourced to a vendor. For example, manufacturers in the apparel industry might outsource such manufacturing tasks as dyeing, cutting, and sewing. A specific operation sequence in the routing instructions is identified as an outside operation. After defining the routing steps, the system creates the required documents, such as a purchase order, for the outside operations.

8.3.2 Prerequisites

Before you complete the tasks in this section:

-

Set the Work With Routing Master (P3003) processing option on the Version tab of the Style Item Master program (PCW51) to specify the version of the Enter/Change Routing program for the Work With Style Routing Master program to call.

-

Set the Work With Routing Master (P3003) processing option on the Versions tab of the Collection Item Master program (PCW54) to specify the version of the Enter/Change Routing program for the Work With Style Routing Master program to call.

8.3.3 Forms Used to Create Routing Instructions for Style Items

| Form Name | FormID | Navigation | Usage |

|---|---|---|---|

| Work With Style Routing | WCW35B | Style Item Management (G41F11), Work with Style Items

Select a row on the Work With Style Item Master Browse form (WCW51E), and then select Routing from the Row menu. Style Item Management (G41F11), Work with Style Items by Collection Select a row on the Work With Collection Style Item Master Browse form (WCW54A), and then select Routing from the Row menu. On the Work With Bill of Material for Style Items form, select Routing from the Form menu. |

Work with routings for style items.

Note: The Work With Style Routing Master program (PCW35) is accessible only from another application. |

| Enter Routing Information | W3003B | On the Work With Style Routing form, click Add.

On the Work With Style Routing form, select a record and then click Copy. On the Work With Style Routing form, select a record and click Select. |

Enter routing instructions for style items.

Copy routings for style items. Review and update routings for style items. Note: For style items, you must use the Work With Style Routing Master program (PCW35) to access the Enter/Change Routing program (P3003). |

| Work With Routing Exception | WCW36A | On the Work With Style Routing form, select a row and then select Exception from the Row menu. | Define routing instruction exceptions.

Note: The Routing Exception program (PCW36) is accessible only from another application. |

| View Routing Information | W3003B | On the Work With Routing Exception form, select a record and select View Routing from the Row menu. | Review routings for style items.

Note: You do not apply changes on the View Routing Information form. |

8.3.4 Entering Routing Instructions for Style Item Root Level 0

Access the Enter Routing Information form.

To enter routing instructions for style item root level 0:

-

Define the operations, work centers, hours, and other applicable information required to manufacture the style item root level 0.

-

Click OK.

Important:

The system generates the routing for the style item root level 0 only the first time that you create the routing.

8.3.5 Generating Routings for Child Style Items

Access the Work With Style Routing form.

To generate routings for child style items:

-

Select the row for the routing line written in blue.

-

Select Create from the Row menu to generate routings for all child style items.

Note:

The line color changes to black.

8.3.6 Defining Routing Instruction Exceptions

Access the Work with Routing Exceptions form.

To define routing instruction exceptions:

-

Select the style item level in the tree for which to apply an exception.

-

Click Select.

-

Select a record on the Work With Style Routing form and click Select.

-

Enter routing instruction exceptions on the Enter Routing Information form.

-

Click OK to save the changes.

The routing instruction record is red.

-

Select a record on the Work With Style Routing form and select Create from the Row menu.

The routing instruction record is black.

-

Click Close to return to the Work With Style Item Master Browse form.

8.4 Setting Up Outsource Operations for Style Items

This section provides an overview of outsource operations for style items, lists prerequisites, and discusses how to:

-

Set processing options for Exchange Rates for Style Item Outsource Operations (PCW62).

-

Set up exchange rates for style item outsource operations.

-

Set processing options for Copy to Outsource Operation Details for Style Items (RCW93). (Release 9.1 Update)

-

Create outsource operation details for style items.

-

Copy outsource operation details for style items.

8.4.1 Understanding Outsource Operations for Style Items

The JD Edwards EnterpriseOne Apparel Management system enables the use of outside operations in which a particular operation is outsourced to a vendor. The outsource operation is for a service. For example, manufacturers in the apparel industry might outsource such manufacturing tasks as dyeing, cutting, and sewing.

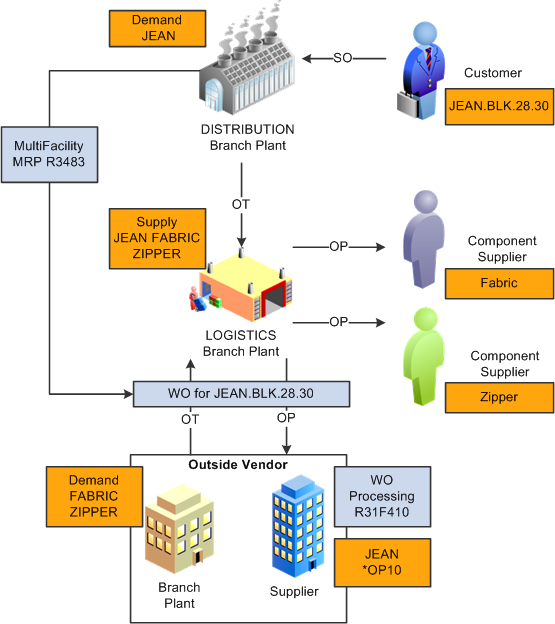

This diagram illustrates the outsource operations process for style items:

Figure 8-10 Outsource operations process for style items

Description of "Figure 8-10 Outsource operations process for style items"

A specific operation sequence in the routing instructions is identified as an outside operation. For example, if routing sequence 10 of style item JEA301 is defined as an outside operation, then the system creates style item JEA301*OP10. Both the stocking type and line type for style item JEA301 are set to X (outside processing).

After defining the routing steps, the system creates the required documents, such as a purchase order, for the outside operations.

Each time a new vendor or style item is set up, you must complete setup activities such as creating all style items, bills of material, routings, prices, cost records, and branch/plant relationships. To enable outsourcing of style items, the system:

-

Creates and maintains the *OP item.

-

Copies bills of material and routings.

-

Creates Item Branch/Plant records for the style item root level 0, all child style items, and all components.

-

Updates the item supplier and country of origin.

You use the Exchange Rates for Style Item Outsource Operations program (PCW62) to define exchange rates between currencies for style items. The value in the From Currency Code field on the Exchange Rates for Style Item Outsource Operations Detail form is the default value from the Currency Code From processing option.

You use the Create Outsource Operation Details for Style Items program (PCW93) to create the outside operations for style items by copying from a source branch/plant to a target branch/plant. The Source Branch/Plant field represents the logistics branch/plant. The Target Branch/Plant field represents the outside vendor to perform the outside operations.

The Create Outsource Operation Details for Style Items program copies and creates a *OP outside operation for the target branch/plant only if an outside operation is in the source branch/plant. If the Job Type field on the routing instruction for the outside operation is blank, then no routing is created. Also, the code in the Outsource Operation Code field on the Style Item Outsource Operation Details form and the code in the Job Type field in the routing instruction must match. If the codes do not match, then the system does not create the *OP items. The system does not display an error message.

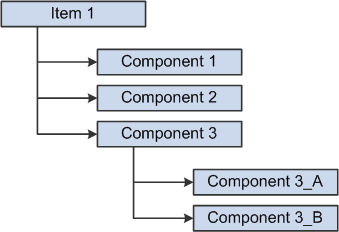

If you leave the Multi Level BOM processing option on the Process tab of the Create Outsource Operation Details for Style Items program blank, then the system copies the multilevel bill of material for the style item. However, the system does not copy the bills of material for the components of the style item that was copied. For example, a style item has the following bill of material:

Figure 8-11 Style item bill of material example

Description of "Figure 8-11 Style item bill of material example"

Item 1 has a bill of material consisting of Component 1, Component 2, and Component 3. Component 3 has a bill of material consisting of Component 3_A and Component 3_B. Item 1 and Component 3 are style items with lower-level child style items.

On the Process tab of the Create Outsource Operation Details for Style Items processing options, the Bill of Material processing option is left blank to process bills of material and the Multi Level BOM processing option is left blank to process multilevel bills of material.

When the Create Outsource Operation Details for Style Items program processes Item 1, the system copies the bill of material of Item 1 from the source branch/plant to the target branch/plant. It also copies the child style item records of Item 1 from the source branch/plant to the target branch/plant. The system copies only Component 1, Component 2, and Component 3 in the bill of material.

The system does not copy the bill-of-material records for the child items of Component 3 to the target branch/plant. If you want the bill of material records for Component 3, then you must run the Create Outsource Operation Details for Style Items program to copy the Component 3 records to the target branch/plant.

The Copy to Outsource Operation Details for Style Items program (RCW93) enables you to create outside operation items (*OP items) for style items along with item cost, item price, and item location. The Copy to Outsource Operation Details for Style Items report prints the No Data Selected message on the report if no records exist in the FCW93 table corresponding to the data selection.

The Work Order Processing for Style Items program (R31F410) creates outside operation (*OP) purchase orders if the system is setup to automatically create the purchase orders.

The manufacturer sends the work to the outside vendor and the vendor completes the work and sends it back to the manufacturer. The outsource work is applied to internal work orders.

|

Important: Use the outsource operation programs only if you have outside operations. |

8.4.2 Prerequisites

Before you complete the tasks in this section:

-

Set up the following user-defined codes:

-

Set the Inventory Cost Level field in the Item Master program (P4101) to a value of 1 or 2 for style items.

-

Enter a value for the style item root level 0 in the Item Cost File table (F4105) in the Item Branch program (P41026).

-

Set processing options for the Create Outsource Operation Details for Style Items program (PCW93).

-

Set processing options for the Copy to Outsource Operation Details for Style Items program (RCW93).

8.4.3 Forms Used to Set Up Outsource Operations for Style Items

| Form Name | FormID | Navigation | Usage |

|---|---|---|---|

| Work With Exchange Rates for Style Item Outsource Operations | WCW62A | Product Data Management Setup (G41F48), Exchange Rates for Style Item Outsource Operations

On the Work with Outsource Operations for Style Items form, select Transaction Rate from the Form menu. |

Work with exchange rates for style item outsource operations. |

| Exchange Rates for Style Item Outsource Operations Detail | WCW62B | On the Work With Exchange Rates for Style Item Outsource Operations form, click Add. | Set up exchange rates for style item outsource operations. |

| Work with Outsource Operations for Style Items | WCW93A | Product Data Management (G41F24), Create Outsource Operation Details | Work with outsource operations for style items. |

| Style Item Outsource Operation Details | WCW93B | On the Work with Outsource Operations for Style Items form, click Add. | Create outsource operation details for style items. |

8.4.4 Setting Processing Options for Exchange Rates for Style Item Outsource Operations (PCW62)

Processing options enable you to specify the default processing for programs and reports.

8.4.4.1 Default

- Currency Code From

-

Specify a code for the currency of a transaction.

8.4.5 Setting Up Exchange Rates for Style Item Outsource Operations

Access the Exchange Rates for Style Item Outsource Operations Detail form.

Figure 8-12 Exchange Rates for Style Item Outsource Operations Detail form

Description of "Figure 8-12 Exchange Rates for Style Item Outsource Operations Detail form"

The value in the From Currency Code field on the Exchange Rates for Style Item Outsource Operations Detail form is the default value from the Currency Code From processing option.

To set up exchange rates for style item outsource operations:

-

Enter a currency code in the To Currency Code field.

-

Enter a date in the Effective Date field.

-

Enter an exchange rate in the Exchange Rate field.

-

Enter additional effective dates and exchange rates as needed.

-

Click OK.

8.4.6 Setting Processing Options for Copy to Outsource Operation Details for Style Items (RCW93) (Release 9.1 Update)

Processing options enable you to specify the default processing for programs and reports.

8.4.6.1 Source

- 1. Target Branch/Plant (Required)

-

Specify the branch/plant that the system copies records to for style item outsource operations.

- 2. Type Bill of Material (Required)

-

Specify a user-defined code (40/TB) that designates the type of bill of material. You can define different types of bills of material for different uses. For example:

M: Standard manufacturing bill

RWK: Rework bill

SPR: Spare parts bill

The system enters bill type M in the work order header when you create a work order, unless you specify another bill type. The system reads the bill type code on the work order header to know which bill of material to use to create the work order parts list. Material requirements planning (MRP) uses the bill type code to identify the bill of material to use when it attaches MRP messages. Batch bills of material must be type M for shop floor management, product costing, and MRP processing.

- 3. Type of Routing (Required)

-

Specify a user-defined code (40/TR) that indicates the type of routing. You can define different types of routing instructions for different uses. For example:

M: Standard Manufacturing Routing

RWK: Rework Routing

RSH: Rush Routing

You define the routing type on the work order header. The system then uses the specific type of routing that you define in the work order routing.

Product Costing and Capacity Planning systems use only M type routings.

- 4. Update Supplier (Source Item Branch/Plant)

-

Specify how the system updates the supplier field in the Item Branch File table (F4102) for the source item branch/plant. The system determines the value in the supplier field based on the address number of the branch/plant in the Inventory Constants table (F41001). This processing option works in conjunction with the Create item branch processing option on the Process tab. Values are:

Blank: Do not update the supplier field in the source item branch record.

1: Update the supplier field in the source item branch record with the address number from the target/subcontractor branch/plant record in the F41001 table.

2: Update the supplier field in the source item branch record with the address number from the component branch/plant record in the F41001 table.

3: Update the supplier field in the source item branch record with the value entered in the Supplier Number field in the Routing section of the Style Item Outsource Operation Details form (WCW93B).

- 5. Update Country of Origin (Source Item Branch/Plant)

-

Specify whether the system updates the country of origin field when the supplier field is updated in the source item branch. This processing option works in conjunction with the Create item branch processing option on the Process tab and the Update Supplier processing option on the Source tab. Values are:

Blank: Update the country of origin field when the supplier field is updated in the source item branch record.

1: Do not update the country of origin field when the supplier field is updated in the source item branch record.

- 6. Base Currency Code (Exchange Rates)

-

Specify a code that identifies the currency of a transaction.

8.4.6.2 Process

- 1. Bill of Material

-

Specify whether the system includes the bill of material (BOM) when copying the product data. Values are:

Blank: Include the bill of material when copying the product data.

1: Do not include the bill of material when copying the product data.

- 2. Routing

-

Specify whether the system includes the routing details when copying the product data. Values are:

Blank: Include the routing details when copying the product data.

1: Do not include the routing details when copying the product data.

- 3. Create item branch

-

Specify whether the system creates the item branch record in the Item Branch File table (F4102) for the target/subcontractor branch/plant. Values are:

Blank: Create the item branch record in the F4102 table for the target/subcontractor branch/plant.

1: Do not create the item branch record in the F4102 table for the target/subcontractor branch/plant.

- 4. Cost method to copy

-

Specify whether the system copies the cost method in the Item Cost File table (F4105) from the source branch/plant to the target/subcontractor branch/plant. This processing option is used in conjunction with the following processing options:

-

Create item branch on the Process tab: If this processing option is set to blank, then the system copies the cost information from the source branch/plant to the target/subcontractor branch/plant for the specified cost method.

-

Bill of Material on the Process tab: If this processing option is set to blank, then the system copies the cost information from the source branch/plant to the target/subcontractor branch/plant for the components of the BOM.

Values are:

Blank: Do not copy the cost method for the target/subcontractor branch/plant.

Value from UDC 40/CM: Copy the specified cost method for the target/subcontractor branch/plant.

-

- 5. Create item *OP

-

Specify whether the system copies the cost details in the Item Cost File table (F4105) and purchase price details in the Supplier Price/Catalog File table (F41061) from the source branch/plant to the target/subcontractor branch/plant for a *OP item. This processing option applies only when an outside operation (*OP) item exists in one of the routing steps for the style item.

This processing option is used in conjunction with the Cost method to copy for item *OP and Update buying Price *OP processing options on the Process tab. Values are:

Blank: Copy the cost details from the F4105 table and the purchase price details from the F41061 table from the source branch/plant to the target/subcontractor branch/plant for a *OP item.

1: Do not copy the cost details from the F4105 table and purchase price details from the F41061 table for a *OP item.

- 6. Cost method to copy for item *OP

-

Specify whether the system copies the cost details from the Item Cost File table (F4105) from the source branch/plant to the target/subcontractor branch/plant for the *OP item. This processing option is used in conjunction with the Create item *OP processing option on the Process tab. Values are:

Blank: Do not copy the cost details for the *OP item.

Value from UDC 40/CM: Copy the specified cost details for the *OP item from the source branch/plant to the target/subcontractor branch/plant.

- 7. Update buying Price *OP

-

Specify whether the system copies the buying price details from the Supplier Price/Catalog File table (F41061) from the source branch/plant to the target/subcontractor branch/plant for the *OP item. The system uses the supplier and operation price entered in the Create Outsource Operation Details for Style Items program (PCW93). This processing option is used in conjunction with the Create item *OP processing option on the Process tab. Values are:

Blank: Copy the buying price details from the source branch/plant to the target/subcontractor branch/plant for the *OP item.

1: Do not copy the buying price details for the *OP item.

- 8. Multi Level BOM

-

Specify whether the system copies the multilevel bill of material for the style item from the source branch/plant to the target branch/plant. The system does not copy the bills of material for the components of the style item that was copied. This processing option is used in conjunction with the Bill of Material processing option on the Process tab. Values are:

Blank: Copy the multilevel bill of material for the style item from the source branch/plant to the target branch/plant.

1: Do not copy the multilevel bill of material for the style item.

8.4.6.3 Target

- 1. Type of bill of material to create

-

Specify a user-defined code (40/TB) that designates the type of bill of material. You can define different types of bills of material for different uses. For example:

M: Standard manufacturing bill

RWK: Rework bill

SPR: Spare parts bill

The system enters bill type M in the work order header when you create a work order, unless you specify another bill type. The system reads the bill type code on the work order header to know which bill of material to use to create the work order parts list. MRP uses the bill type code to identify the bill of material to use when it attaches MRP messages. Batch bills of material must be type M for shop floor management, product costing, and MRP processing.

- 2. Type of routing to create

-

Specify a user-defined code (40/TR) that indicates the type of routing. You can define different types of routing instructions for different uses. For example:

M: Standard Manufacturing Routing

RWK: Rework Routing

RSH: Rush Routing

You define the routing type on the work order header. The system then uses the specific type of routing that you define in the work order routing.

Product Costing and Capacity Planning systems use only M type routings.

8.4.6.4 Component Branch/Plant to Exclude

- 1. Branch/Plant for Component 1 through 10. Branch/Plant for Component 10

-

Specify the component branch/plant that the system excludes when copying the bill of material. Values are:

Blank: Do not exclude any component branch/plant when copying the bill of material.

Values from Business Unit Search form: Exclude the specified component branch/plant when copying the bill of material.

8.4.7 Creating Outsource Operation Details for Style Items

Access the Style Item Outsource Operation Details form.

Figure 8-13 Style Item Outsource Operation Details form

Description of "Figure 8-13 Style Item Outsource Operation Details form"

To create outsource operation details for style items:

-

Enter a branch/plant in the Target Branch/Plant field.

-

Enter a code in the Outsource Operation Code field.

-

Enter a value in the Style Item Root Level 0 field.

-

To create bills of material for outsource operations, complete the following fields:

-

Component Branch/Plant

-

Issue Type Code

-

-

To create routings for outsource operations, complete the following fields:

-

Supplier Number

-

Work Center

-

Queue Hours

-

-

To create price and cost for outsource operations, complete the following fields:

-

Operation Price

-

Currency Code

-

Effective Date

-

Expiration Date

-

-

Click OK.

- Target Branch/Plant

-

An alphanumeric code that identifies a separate entity within a business for which you want to track costs. For example, a business unit might be a warehouse location, job, project, work center, branch, or plant. You can assign a business unit to a document, entity, or person for purposes of responsibility reporting. For example, the system provides reports of open accounts payable and accounts receivable by business unit to track equipment by responsible department. Business unit security might prevent you from viewing information about business units for which you have no authority.

- Outsource Operation Code

-

A user-defined code (06/G) that identifies the jobs within your organization. You can associate pay and benefit information with a job type and apply that information to the employees who are linked to that job type.

For JD Edwards EnterpriseOne Apparel Management, the system compares the code in the Outsource Operation Code field to the code in the Job Type field of the outside operation routing step for the source branch/plant. The system verifies that the job type codes in the Outsource Operation Code and Job Type fields match during the outsource operation process.

- Component Branch/Plant

-

A secondary or lower-level business unit. The system uses the value that you enter to indicate that a branch or plant contains several subordinate departments or jobs. For example, assume that the component branch is named MMCU. The structure of MMCU might be:

Branch/Plant - (MMCU)

Dept A - (MCU)

Dept B - (MCU)

Job 123 - (MCU)

- Issue Type Code

-

A code that indicates how the system issues each component in the bill of material from stock. In JD Edwards EnterpriseOne Shop Floor Management, it indicates how the system issues a part to a work order. Values are:

I: Manual issue

F: Floor stock (no part is issued)

B: Backflush (when the part is reported as complete)

P: Preflush (when the parts list is generated)

U: Super backflush (at the pay-point operation)

S: Sub-contract item (send to supplier)

Blank: Shippable end item

You can issue a component in more than one way within a specific branch/plant by using different codes on the bill of material and the work order parts list. The bill of material code overrides the branch/plant value.

- Supplier Number

-

The address book number of the preferred provider of this item.

- Work Center

-

A code that represents a high-level business unit. Use this code to refer to a branch or plant that might have departments or jobs that represent lower-level business units subordinate to it. For example:

Branch/Plant (MMCU)

Dept A (MCU)

Dept B (MCU)

Job 123 (MCU)

Business unit security is based on the higher-level business unit.

- Queue Hours

-

The total hours that an order is expected to be in queue at work centers and moving between work centers. The system stores this value in the Item Branch table (F4102). You can calculate this value using the Leadtime Rollup program or you can enter it manually. When you run the Leadtime Rollup program, the system overrides manual entries and populates the table with calculated values.

- Operation Price

-

The unit cost of one item, as purchased from the supplier, excluding freight, taxes, discounts, and other factors that might modify the actual unit cost that you record when you receive the item.