10 Working with JD Edwards EnterpriseOne Shop Floor Management for Apparel Management

This chapter contains the following topics:

-

Section 10.1, "Understanding JD Edwards EnterpriseOne Shop Floor Management for Apparel Management"

-

Section 10.2, "Working with Master Work Orders for Style Items"

10.1 Understanding JD Edwards EnterpriseOne Shop Floor Management for Apparel Management

After you enter style items and collections, bills of material, and routings, you can use programs in the JD Edwards EnterpriseOne Shop Floor Management system to complete the manufacture of style items. The JD Edwards EnterpriseOne Shop Floor Management system enables you to manage and track manufacturing work orders.

|

Important: The JD Edwards EnterpriseOne Shop Floor Management system supports discrete manufacturing only for style items. |

Creating one work order for each style item is not ideal in many industries. A master work order is a comprehensive work order that corresponds to one or several style item root level 0 items. A master work order is a collection of individual standard manufacturing work orders that correspond to the child style items.

10.2 Working with Master Work Orders for Style Items

This section provides an overview of master work orders for style items, lists prerequisites, and discusses how to:

-

Set processing options for Master Work Order Processing for Style Items (PCW49).

-

Set processing options for Work Order Processing for Style Items (R31F410).

-

Enter master work order headers for style items.

-

Enter master work order details for style items.

-

Review master work orders for style items.

-

Create parts lists for master work orders for style items.

-

Revise parts lists for master work orders for style items.

-

Create routing instructions for master work orders for style items.

-

Process master work orders for style items.

-

Issue inventory to a master work order for style items.

-

Reverse inventory on a master work order for style items.

-

Complete master work orders for style items.

10.2.1 Understanding Master Work Orders for Style Items

A master work order is a comprehensive work order that corresponds to one or several style item root level 0 items. A master work order encompasses a group of related standard manufacturing work orders that correspond to the child style items. A master work order is not a parent work order.

The system calls the Matrix Entry program (PCW10) when you enter a style item root level 0 on the master work order.

(Release 9.1 Update) You can view the availability of selected style items at the parent level (style item root level 0) or child level (intermediate item level) for a branch/plant or all branch/plants on the Matrix Entry form. To view style item availability on the Matrix Entry form, you must embed the Style Item Availability form on the Matrix Entry form, and map the Selected Style Item field of the Matrix Entry form to the Style Item field of the Style Item Availability form.

See "Creating Embedded EnterpriseOne Form Content" in the JD Edwards EnterpriseOne Tools Composite Application Framework User's Guide.

You manage everything at the master work order level. You group your parts lists and enter the exact quantities to use. The system prorates the quantities between the different lines in the master work order to specify the actual amount of material required for each child work order.

The master work order has corresponding child work orders, such as numbers 1, 2, 3, and so on, for the child style items.

The Work Order Detail for Style Items table (FCW66) ties the master work order of the style item root level 0 to the standard work orders for the child style items.

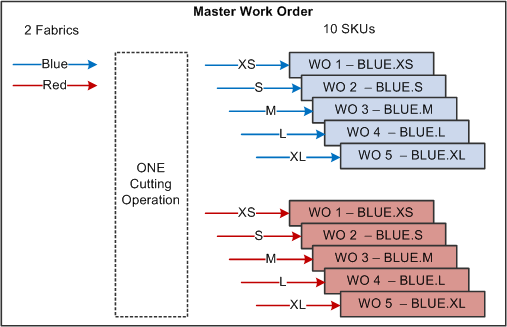

This diagram illustrates a master work order and standard work orders for the associated child style items:

10.2.1.1 Collections

Collections for style items also integrate with master work orders. You can use a collection on the work order, however collection templates do not function with work orders.

You set collection processing options on the Collection tab of the Master Work Order Processing for Style Items program. You enter collection information on the Status Type tab of the Master Work Order for Style Items form during master work order entry.

See Working with Collections Management.

See Working with JD Edwards EnterpriseOne Sales Order Management for Apparel Management.

10.2.1.2 Example: Apparel Industry

An example of a master work order is the apparel-specific process of cutting fabric for one style. In apparel manufacturing, cutting fabrics may be called stack cutting or multiply cutting. Stack cutting consists of cutting 20–50 pieces of the same size at once. The width of the fabric is always assumed to be standard size. In fabric cutting, the sizes and styles are mixed to maximize the use of the fabric with the goal of minimizing waste.

In stack cutting of fabrics, one cutting operation can exist. If two fabrics or style item root level 0 items exist, then two master work orders are needed. From the two master work orders, ten standard work orders are created because the system creates one work order for each child style item.

10.2.1.3 Master Work Order Headers for Style Items

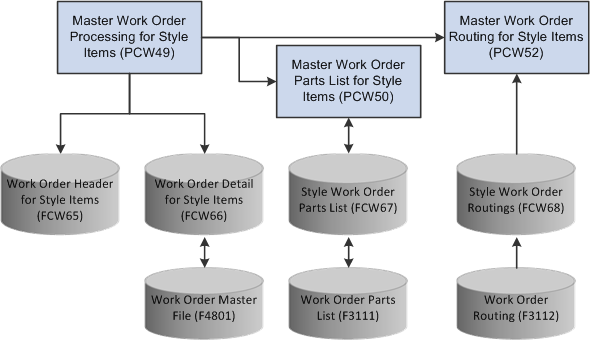

You use the Master Work Order Processing for Style Items program (PCW49) to enter a work order header for the master work order.

For a master work order header, you enter the description, order type, branch/plant, and requested date for the master work order. You can also enter other optional information, such as the revision level for the bill of material and category codes.

|

Note: You need not enter style item numbers in the header for the master work order. |

The system stores the master work order header information in the Work Order Header for Style Items table (FCW65).

10.2.1.4 Master Work Order Details for Style Items

After entering the master work order header, you enter the style item root level 0 items in the master work order detail. The master work order detail supports the generation of each child work order. Each style item root level 0 that you enter on the master work order calls the Matrix Entry form to configure the child style items to include on the master work order.

|

Note: (Release 9.1 Update) If the JD Edwards EnterpriseOne Shop Floor Management system is integrated with the Composite Application Framework, you can view the availability of a style item on the Matrix Entry form. To view the style item availability, select the row for the style item and review the item availability information in the Style Item Availability subform. |

When you save the master work order, the system generates the child level work orders. The system populates the grid with the work order number for each child style item.

The system stores the master work order details in the FCW66 table. The FCW66 table links to the Work Order Header for Style Items (FCW65) and Work Order Master File (F4801) tables.

10.2.1.5 Master Work Order Parts Lists for Style Items

You use the Master Work Order Parts List for Style Items program (PCW50) to create and manage the consolidated parts list at the master work order level. You copy the bill of material for the style item root level 0 to create the parts list for the master work order. The system uses the batch quantity of 0 for the bill of material and routing. You can also run the Work Order Processing for Style Items program (R31F410) to create the parts list. You run the Work Order Processing for Style Items program to protect against performance issues when a master work order contains a significant number of child work orders or deep bills of material.

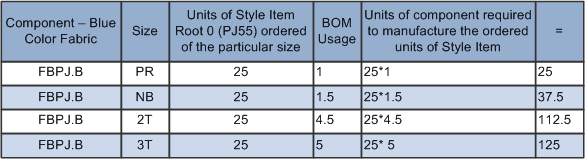

The calculation for the quantity in the Quantity Ordered field on the Master Work Order Parts List Details for Style Items form is (style item root level 0 quantity ordered by attribute) x (bill of material usage for the component) = (quantity of the component required to manufacture the ordered units of the style item).

This diagram shows an example of the quantity-ordered calculation:

Figure 10-2 Quantity ordered calculation example

Description of "Figure 10-2 Quantity ordered calculation example"

Total Quantity of component FBPJ.B = 25 + 37.5 + 112.5 + 125 = 300

You can also use the Master Work Order Parts List for Style Items program to view, modify, and delete parts lists for master work orders. The system stores the parts lists for master work orders in the Style Work Order Parts List table (FCW67). The FCW67 table is a workfile and holds the consolidated view of all the child work order parts lists.

The system also enables the creation of parts lists by means of a batch program. You run the Work Order Processing for Style Items program to create the parts lists by setting data selection over the Work Order Detail for Style Items table (FCW66).

The Master Work Order Parts List for Style Items program generates the standard parts lists for all child style item work orders. Once the child style item work orders are created, transactions and changes to the master work order are pushed down to the parts lists of the individual child style item work orders.

You group the parts lists and enter the exact amount to use. The system prorates the quantities between the different lines to specify the actual amount of material. Changes and additions of components are split over single work orders.

The system enables global changes to the work order parts list of the child style item work orders. You can:

-

Remove a component.

-

Change component quantity.

-

Add a new component.

When entering a new component you should specify a line number of an existing component for the system to base the split off of. Without an existing line number reference, the system cannot append a new component because it does not know how to split the quantity ordered across the single work orders.

|

Note: The components must have records in the Item Structure Definition table (FCW02). |

The system recalculates the parts list every time you use the Parts List option on the Row menu of the Master Work Order Revisions for Style Items form. The system pushes changes at the child style item work order level up to the master work order.

10.2.1.6 Master Work Order Routing Instructions for Style Items

You use the Work Order Routing for Style Items program (PCW52) to create routing instructions for master work orders. You can copy and delete routings at the master work order level using the Work Order Routing for Style Items program. You can also run the Work Order Processing for Style Items program (R31F410) to create the routing instructions. You run the Work Order Processing for Style Items program to protect against performance issues when a master work order contains a significant number of child work orders.

The routing is automatically copied to the master work order when a routing for the ordered quantity, or zero or non-zero batch quantity exists for the Item/Branch Plant/Type of Routing combination. The system automatically creates the routing when you attach a bill of material.

The master work order routing does not have management features similar to master parts lists. For example, after the child style item work orders are created, transactions and changes to the routing on the master work order are not pushed down to individual child style item work orders. You must maintain routing instructions at the child work order level.

The system pushes changes at the child work order level up to the master work order.

The system stores the routing instructions for master work orders in the Style Work Order Routings table (FCW68). The FCW68 table is a workfile and data is present in the table only at the time when the routing is attached.

10.2.1.7 Master Work Order Processing for Style Items

You use the Master Work Order Processing for Style Items program (PCW49) to create, process, and maintain master work orders for style items. After you create the master work order, you run the Work Order Processing for Style Items program (R31F410) to attach the parts lists and routing instructions for each child work order.

The Work Order Processing for Style Items program updates the Work Order Parts List (F3111) and Work Order Routing (F3112) tables.

The source data for the Work Order Processing for Style Items program comes from three tables: Work Order Detail for Style Items (FCW66), Work Order Master File (F4801), and Work Order Master Tag File (F4801T). The FCW66 table stores the cross-reference between the master work order and its child work orders. The cross-reference information enables processing of all child style item work orders based on the master work order number.

Based on the data selection in the Work Order Processing for Style Items program, the system runs the Work Order Processing for Style Items program (R31F410) for each child work order of the master work order. The Work Order Processing for Style Items program calls the Order Processing program (R31410), which processes the work orders to attach parts lists and routing instructions.

If you attach the parts list and routing instructions interactively, you can use the Work Order Processing for Style Items program to generate and print the shop paperwork. The system prints the parts list and routing instructions, shop packet summary, and shortage report based on the processing option settings of the Order Processing program. The system prints all the child work orders together in one output.

After all child work orders are processed, the master work order status is updated if the Master Work Order Detail processing option on the Edits tab is set to a value of 1. The system updates the status of the master work order with the status of the first child work order. Although a child work order is at status 10, the first child work order is at status 45 so the master work order will be at status 45. You use the Manufacturing Work Order Processing program (P48013) to review the child work orders. You can also select a child work order on the Master Work Order Revisions for Style Items form and then select Update Child WO from the Row menu to launch the Manufacturing Work Order Processing program.

The Additional Style Item Information Work File table (FCW63) stores the master work order number derived from a next number bucket.

During master work order processing, the system uses the Work Order Header for Style Items table (FCW65) to enable data selection for outside operations. The system groups the outside operations.

10.2.1.8 Work Order Mass Update for Style Item Work Orders

When you make changes to the master work order, the Master Work Order Processing for Style Items program (PCW49) makes the corresponding updates to the child work orders. This functionality includes the ability to perform a mass update of dates for child work orders associated with a master work order.

You can update the following dates by master work order:

-

Order Date (TRDJ)

-

Start Date (STRT)

-

Request Date (DRQJ)

The work order mass update process enables you to select and modify multiple work orders at one time. You can use the Search for Work Orders (P48022) and Work Order Mass Update (P48714) programs to select work orders to change, and enter the new values to assign to the work order records.

After you select the records to update and specify the new values, you run a batch program to update the work orders in the database. The JD Edwards EnterpriseOne software also provides the Work Order Mass Update Template program (P48710) that enables you to set up templates with default values for the fields to update, and to lock fields to prevent updates to the locked fields.

When you work with manufacturing work order mass updates, you can determine whether to include style items in your search for work orders to update. You set processing options in the Search for Work Orders program to set a default value for a check box to exclude style items, and to lock that filtering check box.

10.2.1.9 Master Work Order Inventory Issues for Style Items

Inventory issues are made at the master work order level. You enter the total consumption of inventory for the master work order. The system splits the inventory issues of the master work order between the individual child work orders.

The system processes a batch inventory issue to record a total of what was used in the manufacturing process. The system does not process the issuing locations as determined based on availability.

The system uses elements of the Work Order Inventory Issues program (P31113) to deduct the quantities that are issued to the shop floor through an issue transaction from inventory. This transaction reports the actual quantities and cost of materials that were used in the production process to the JD Edwards EnterpriseOne Inventory Management and JD Edwards EnterpriseOne Manufacturing Accounting systems. You need to set up the Work Order Inventory Issues program to suggest issue quantities that are based upon the work order quantity.

When you initiate master work order inventory issues for style items from the Master Work Order Processing for Style Items program (PCW49), the system limits the number of visible parts list attributes and input capable fields. The following fields are input capable on the Issues tab of the Master Work Order Parts List Details for Style Items form (WCW50E):

-

Issues (TRQT)

-

Location (LOCN)

-

Lot/Serial Number (LOTN)

You can issue a quantity that is equal to, less than, or greater than the order quantity on the master work order. For a full inventory issue, the split of consumption by work order is based on the quantity on the child work order.

For a partial issue, the system spreads the issue of each component to the child work orders based on the percentage of the child work orders to the total issue. When issuing a partial quantity on the master work order, the system spreads the quantity to all the child work orders without rounding up the quantity. For example, if the order has an issue quantity of 100 buttons and you partial issue 26 buttons, then the master work order shows that 26 buttons have been issued. The system spreads the 26 buttons to the individual child work orders by the percentage that each work order represents. The system does not round up the issue quantity so that only whole numbers of buttons are issued to each child work order.

You can set the Issue Material for processing option on the Display Options tab of the Master Work Order Processing for Style Items program to a value of 1 to have the system automatically suggest issue quantities. If you set the Issue Material for processing option to blank, then you must manually enter a quantity on the Issues tab on the Master Work Order Parts List Details for Style Items form.

When issuing material to the master work order, the system supports splitting to multiple locations. You can perform multiple location issues to a master work order using the Multi Location option on the Row menu of the Master Work Order Parts List Details for Style Items form. When performing a multiple location issue, the system limits the issue to nine locations per component that can be returned to the Issues form.

After you enter quantity and location information on the Issues tab, you click OK on the Master Work Order Parts List Details for Style Items form. The system runs the Work Order Issues for Style Items program (R41F050) to process the inventory issues for the child work orders.

The JD Edwards EnterpriseOne software provides record reservation capability within the Master Work Order Parts List for Style Items program (PCW50) for the master work order and the Work Order Issues for Style Items program for child work orders. Record reservation helps ensure the integrity of the data and prevents data loss. To avoid simultaneous processing of the same records, the system reserves (locks) records for processing by any other manufacturing program. Thus, the system does not enable you to edit a record that has been locked by a different user or application.

The Master Work Order Parts List for Style Items program locks the master work order. When the Work Order Issues for Style Items program runs to process inventory issues for child work orders, the system activates record reservation by work order number so that only the Work Order Issues for Style Items and Master Work Order Parts List for Style Items programs can access the records in the Work Order Header for Style Items (FCW65) and Work Order Master File (F4801) tables. If the Work Order Issues for Style Items and Master Work Order Parts List for Style Items programs encounter a work order that is already locked by another application within the manufacturing system, then the Work Order Issues for Style Items and Master Work Order Parts List for Style Items programs send a message to the Work Center and do not process the work order. You must re-submit the work order for processing.

The Work Order Issues for Style Items program issues inventory to the associated child work orders. After the inventory issues processing is complete, the system removes record reservation on the work orders so that another user or application can access the record to update information in the tables.

If you run the Work Order Issues for Style Items program for the child work orders of a master work order and the Work Order Inventory Issues (P31113), Work Order Completions (P31114), Component Scrap (P31116), Super Backflush (P31123), Hours and Quantities (P311221), or Manufacturing Work Order Processing (P48013) programs try to access the work order, then you receive a message that the file is locked. You must wait until the system releases the records to process them. However, you can view the records.

When a program that uses record reservation is interrupted, orphaned reservation records might remain in the Business Object Reservation table (F00095). This can occur, for example, when technicians are working with a server, or when a workstation shuts down without warning. If an interruption stops one of the programs in the Work Order Issues for Style Items and Master Work Order Parts List for Style Items programs before it releases the reservations that it creates, you cannot update the records until the orphaned reservations are removed.

|

Note: If you click the Cancel button on the Printer Selection form while running the program, then the master work order record remains locked by the system. |

You can use the Remove Business Object Reservation program (P00095) to release unwanted record reservations. This program stores reservation information in the Business Object Reservation table (F00095).

You can also select Issues from the Row menu in the Manufacturing Work Order Processing program (P48013) to issue material to a child style item work order.

If you use serialized components, then you issue the serialized components at the individual child style item work order level.

You can use the Work Order Processing for Style Items program (R31F410) to perform inventory issues at the master work order level when you use preflushing. If you perform preflushing, then you do not perform inventory issues at the child work order level.

You can backflush components by accessing the Work Order Inventory Issues program (P31113) from the Manufacturing Work Order Processing (P48013), Work Order Completions (P31114), and Super Backflush (P31123) programs.

|

Note: The system does not support unplanned issues for master work orders. |

You can reverse issues to a master work order using the Reversal option on the Row menu of the Master Work Order Parts List Details for Style Items form. When reversing a master work order issue, the system spreads the reversal back through all of the child work orders. The system performs reversals for partial issues, completions, and over issues.

If you issued a component across multiple locations and must perform a reverse issue, then the system spreads the entire quantity issued for that location based on the percentage that the quantity represents for each child work order. If the issued lot and location was not blank during the original issue and the quantity is reversed, then the lot and location remains the same in the parts list.

When you issue inventory to a master work order, the Work Order Issues for Style Items program generates a portable document format (PDF) file which specifies whether the batch completed successfully or ended with errors. If inventory issues to the child work orders completed normally, then the PDF indicates that the report completed with success. If inventory issues completed with errors, then the PDF indicates that errors occurred and to check the Work Center for messages. The report completes in error only when hard errors occur during inventory issues processing. Although warning messages may exist in the Work Center, the PDF indicates that the report completed successfully.

10.2.1.10 Master Work Order Completions for Style Items

You use the Work Order Completions Matrix Entry program (PCW46) to complete a master work order using a matrix form. The result is the completion of child work orders as well as completion of the master work order.

You can also review the quantities of child style items on a master work order in a matrix form using the Detail Matrix option on the Row menu of the Work with Master Work Orders for Style Items form (WCW49A).

You perform manual completions at the master work order level only. If you want to perform backflush or super backflush, then you must perform the completion at the child work order level.

10.2.2 Prerequisites

Before you complete the tasks in this section:

-

Set the processing options for the version of the Order Processing program that you specify in the Order Processing (R31410) processing option of the Work Order Processing for Style Items program.

-

Set the Purchase Order Entry (P4310) processing option on the Versions tab of the Order Processing program (R31410) to support outside operations.

-

Set the following processing options for the Purchase Order Entry version that you specify to generate purchase orders for outside operations:

-

Set the Order Type processing option on the Defaults tab to OO for outside operations.

-

Set the Line Type processing option on the Defaults tab to X for outside processing.

-

Set the Business Unit Validation processing option on the Interfaces tab to 1.

-

10.2.3 Forms Used to Work with Master Work Orders for Style Items

| Form Name | FormID | Navigation | Usage |

|---|---|---|---|

| Work with Master Work Orders for Style Items | WCW49A | Shop Floor Management (G41F17), Master Work Order Processing | Work with master work orders for style items. |

| Master Work Order for Style Items | WCW49B | On the Work with Master Work Orders for Style Items form, click Add.

On the Work with Master Work Orders for Style Items form, select a row and select Update Status from the Row menu. |

Enter master work order headers for style items.

Revise master work orders for style items. |

| Master Work Order Parts List Details for Style Items | WCW50E | On the Work with Master Work Orders for Style Items form, select a row and select Parts List from the Row menu.

On the Master Work Order Revisions for Style Items form, select a row and select Parts List from the Form menu. On the Work with Master Work Orders for Style Items form, select a row and select Inventory Issues from the Row menu. |

Create parts lists for master work orders for style items.

Revise parts lists for master work orders for style items. Delete parts lists for master work orders for style items. Issue inventory to a master work order for style items. |

| Work Order Routing for Style Items | WCW52A | On the Work with Master Work Orders for Style Items form, select a row and select Routing from the Row menu. | Create routing instructions for master work orders for style items.

Delete routing instructions for master work orders for style items. |

| Work Order Completions Matrix {variable} | WCW46A | On the Work with Master Work Orders for Style Items form, select a row and select Detail Matrix from the Row menu.

The system displays the Work Order Completions Matrix Inquiry form. On the Work with Master Work Orders for Style Items form, select a row and select Completion from the Row menu. The system displays the Work Order Completions Matrix Entry form. |

Review master work order details in a matrix view.

Complete master work orders for style items. |

| Master Work Order Revisions for Style Items | WCW49D | On the Work with Master Work Orders for Style Items form, find your master work order, select a row, and select Detail from the Row menu. | Enter master work order details for style items

Review master work order details for style items. Revise master work order details for style items. |

| Work With Material Analysis of Style Items | WCW96A | On the Work with Master Work Orders for Style Items, select a row and select Material Analysis from the Row menu. | Review the availability of components for style items.

See Working with Material Planning Operations for Apparel Management. |

10.2.4 Setting Processing Options for Master Work Order Processing for Style Items (PCW49)

Processing options enable you to specify the default processing for programs and reports.

10.2.4.1 Defaults

- 1. Document Type

-

Specify the default document type associated with a work order. Enter a value from user-defined (UDC) table 00/DT (Document Type - All Documents) that identifies the origin and purpose of a document.

- 2. Back Scheduling Unit of Measure

-

Specify the default unit of measure to use for back scheduling the work order. Enter a value from UDC 00/UM (Unit of Measure) that identifies the unit of measure to use in the document.

- 3. Back Scheduling Queue and Move Hours

-

Specify the method that the system uses to back schedule queue hours in the work order routing. Values are:

Blank: Back schedule queue hours as a percentage of the resource units per day.

1: Back schedule queue hours as a percentage of the work hours per day.

- 4. Status Min Display

-

Specify a code from UDC 00/SS that indicates the status of a work order, rate schedule, or engineering change order. Any status change from 90 through 99 triggers the system to automatically update the completion date.

- 5. Work Order Type

-

Specify the default work order type to associate with the work order. Enter a value from UDC 00/TY (Work Order/ECO Type) that identifies the type of work order.

- 6. Work Order Priority

-

Specify the default priority to associate with the work order. Enter a value from UDC 00/PR (Work Order Priority) that identifies the priority of the document.

- 7. Beginning Status

-

Specify the default beginning status code for the work order header. Enter a value from UDC 00/SS (Work Order Status) that identifies the status of the work order to use when a work order is created.

- 8. Charge to Business Unit

-

Specify whether the system uses the project number in the Business Unit Master table (F0006) or the branch/plant on the work order as the Charge to business unit. Values are:

Blank: Branch/plant.

1: Project number.

- 9. Cross Reference Code

-

Specify the default cross-reference code. Enter a value from UDC 41/DT (Cross Reference Type Code) to specify how the system retrieves item replacements for obsolete items.

When you enter an order containing an item that will be obsolete for the work order time frame, the system enables you to specify a replacement item if you set this processing option to R.

- 10. Summary Issued

-

Specify whether to display a summary of the inventory issues. Values are:

Blank: The system does not display the summary of the inventory issues.

1: The system displays the summary of the inventory issues.

10.2.4.2 Category Codes

- 1. Category Code 1, 2. Category Code 2, and 3. Category Code 3

-

Specify the default category codes for the work order. Work order category codes are UDCs 00/W1, 00/ W2, and 00/W3 that identify the category for the work order. Enter the category codes to use as the default values or select them from the Select User Defined Codes form.

- 4. Category Code 1 on the Work Order Header, 5. Category Code 2 on the Work Order Header, and 6. Category Code 3 on the Work Order Header

-

Specify the default item/branch category codes for the work order header. Item/branch category codes are UDCs (32/CC) that identify the item/branch classification codes on the work order header.

10.2.4.3 Edits

- 1. Quantities and Dates

-

Specify whether the system automatically recalculates the parts list and routing instructions when the quantities or the dates on the work order change. Values are:

Blank: Do not recalculate.

1: Recalculate.

- 2. Item Branch/Plant Validation

-

Specify whether the system validates an existing item/branch record when you add or update a work order. Values are:

Blank: Do not validate.

1: Validate.

- 3. Inventory Issues

-

Specify whether to update the master work order status for inventory issues with the status of the work order that was entered first. Values are:

Blank: The system does not update the master work order status.

1: The system updates the master work order status.

- 4. Completion

-

Specify whether to update the master work order status for work order completions with the status of the work order that was entered first. Values are:

Blank: The system does not update the master work order status.

1: The system updates the master work order status.

- 5. Close Master Work Order

-

Specify whether to update the master work order status with the status of the work order that was entered first. Values are:

Blank: The system does not update the master work order status.

1: The system updates the master work order status.

- 6. Parts List

-

Specify whether to update the master work order status for the parts list with the status of the work order that was entered first. Values are:

Blank: The system does not update the master work order status.

1: The system updates the master work order status.

- 7. Master Work Order Detail

-

Specify whether to update the master work order status for master work order detail with the status of the work order that was entered first. Values are:

Blank: The system does not update the master work order status.

1: The system updates the master work order status.

10.2.4.4 Display Options

- 1. Bill of Material Type Field

-

Specify whether the system displays the Bill of Material Type field on the Work Order Details form. Values are:

Blank: Do not display.

1: Display.

- 2. Routing Type Field

-

Specify whether the system displays the Routing Type field on the Work Order Details form. Values are:

Blank: Do not display.

1: Display.

- 3. Issue Material for

-

Specify whether the system enters the recommended issued quantity for all components with a valid issue type code. The system uses the value from the Issue Material For field on the Work With Work Order Inventory Issue form. The system issues only items with an issue quantity. Values are:

Blank: The system does not enter the quantity.

1: The system automatically enters the quantity.

10.2.4.5 Versions

- 1. Bill Availability (P30200)

-

Specify the version for the system to use when you select to access the Bill Availability program (P30200) from the Row menu on the Work With Manufacturing Work Orders form or the Work Order Details form. If you leave this processing option blank, the system uses the ZJDE0001 version of the Bill Availability program.

Versions control how the Bill Availability program displays information. Therefore, you may need to set the processing options to specific versions to meet the business need.

- 2. ECO Work Order Entry (P48020)

-

Specify the version for the system to use when you select to access the ECO Work Order Entry program (P48020) from the Row menu on the Work With Manufacturing Work Orders form or the Work Order Details form. If you leave this processing option blank, the system uses the ZJDE0001 version of the ECO Work Order Entry program.

Versions control how the ECO Work Order Entry program displays information. Therefore, you may need to set the processing options to specific versions to meet the business need.

- 3. Assign Serial Numbers (P3105)

-

Specify the version that the system uses when you select to access the Assign Serial Numbers program (P3105) from the Row menu on the Work With Manufacturing Work Orders form or the Work Order Details form. If you leave this processing option blank, the system uses the ZJDE0001 version of the Assign Serial Numbers program.

Versions control how the Assign Serial Numbers program displays information. Therefore, you may need to set the processing options to specific versions to meet the business need.

- 4. Routings (P3112)

-

Specify the version that the system uses when you select to access the Work Order Routings program (P3112) from the Row menu on the Work With Manufacturing Work Orders form or the Work Order Details form. If you leave this processing option blank, the system uses the ZJDE0001 version of the Routing program.

Versions control how the Routings program displays information. Therefore, you may need to set the processing options to specific versions to meet the business need.

- 5. Parts List (P3111)

-

Specify the version that the system uses when you select to access the Work Order Parts List program (P3111) from the Row menu on the Work With Manufacturing Work Orders form or the Work Order Details form. If you leave this processing option blank, the system uses the ZJDE0001 version of the Parts List program.

Versions control how the Parts List program displays information. Therefore, you may need to enter the processing options to specific versions to meet the business need.

- 6. Material Issues (P31113)

-

Specify the version that the system uses when you access the Work Order Inventory Issues program (P31113) from the Row menu on the Work with Master Work Orders for Style Items form. If you leave this processing option blank, the system uses the ZJDE0001 version of the Work Order Inventory Issues program.

- 7. Enter/Change Order (P48013)

-

Specify which version the system uses when you access the Manufacturing Work Order Processing program (P48013). If you leave this processing option blank, then the system uses ZJDE0001 as the default version.

- 8. Completion (P31114)

-

Specify the version of the Work Order Completions program (P31114) that the system uses when you access the program from the Work Order Details form (W48013A). If you leave this processing option blank, then the system uses ZJDE0001 as the default version.

- 9. Material Analysis (PCW96)

-

Specify the version of the Material Analysis program (PCW96) that the system uses when you access the Work With Material Analysis form (WCW96A). If you leave this processing option blank, then the system uses ZJDE0001 as the default version.

- 10. Matrix Entry (PCW10)

-

Specify the version of the Matrix Entry program (PCW10) that the system uses to retrieve the style item matrix data. If you leave this processing option blank, then the system uses ZJDE0001 as the default version.

This processing option is enabled only if the Use Apparel Management Module system constant (SY41F) is enabled in the EnterpriseOne System Control program (P99410).

10.2.4.6 Interop

- 1. Transaction Type

-

Specify the transaction type that the system uses for export processing. Enter a value from UDC 00/TT (Transaction Type) that identifies the type of transaction for the work order. If you leave this processing option blank, the system does not use export processing.

10.2.4.7 Collection

- 1. Collection

-

Specify a code that represents a coherent assortment of items introduced at the same time mostly for one brand (manufacturer), season, year, and market. You must enter a value from the Collection Header table (FCW06).

- 2. Season Code

-

Specify the season for which the style items are being manufactured. Enter a value from UDC 41F/SE.

- 3. Season Year

-

Specify the year of manufacture of style item. Enter a value from the UDC 41F/SY.

- 4. Check Item Presence in Collection

-

Specify whether the system verifies the style item presence in a collection. Also, if you verify the style item presence, you can specify whether to display a warning message or error message in the absence of the style item. Values are:

Blank: The system does not validate the presence of an item in the collection.

1: The system validates the presence of a style item in the collection and displays a warning message if the item is not present in the collection.

2: The system validates the presence of the style item in the collection and displays an error message if the item is not present in the collection.

- 5. Check Collection on Header

-

Specify whether to validate the collection in the header. Values are:

Blank: The system does not validate the collection in the header.

1: The system validates the collection in the header.

10.2.4.8 Material Analysis

- 1. Work Order Status Code

-

Specify a code from UDC 00/SS that describes the status of a work order, rate schedule, or engineering change order. Any status change from 90 through 99 triggers the system to automatically update the completion date.

10.2.5 Setting Processing Options for Work Order Processing for Style Items (R31F410)

Processing options enable you to specify the default processing for programs and reports.

10.2.5.1 Version

- 1. Order Processing (R31410)

-

Specify the version of the Order Processing program (R31410) that the system uses when generating work orders for style items.

10.2.6 Entering Master Work Order Headers for Style Items

Access the Master Work Order for Style Items form.

To enter master work order headers for style items:

-

Enter a value in the Document Type field, if applicable.

-

Enter a value in the Branch/Plant field.

-

Enter a description of the master work order in the Description field.

-

Enter a value in the Start Date field on the Dates tab.

-

Enter a value in the Requested Date field on the Dates tab.

The requested date is the date when the work order should be completed.

-

Enter additional work order detail information in the fields on the tabs as applicable.

-

Click OK.

The system displays the Master Work Order Revisions for Style Items form.

10.2.7 Entering Master Work Order Details for Style Items

Access the Master Work Order Revisions for Style Items form.

Figure 10-4 Master Work Order Revisions for Style Items form

Description of "Figure 10-4 Master Work Order Revisions for Style Items form"

To enter master work order details for style items:

-

Enter a style item root level 0 in the Item Number field in the first row in the detail form.

-

Click Tab or move off the row.

The system displays the Matrix Entry form.

-

Enter the quantity for each child style item in the Matrix Entry form.

Note:

(Release 9.1 Update) The system displays the Omit Zero Quantities check box on the Matrix Entry form if you set the Availability processing option of the Matrix Entry program (PCW10) as Y.If you select the Omit Zero Quantities check box, the system displays the style items with zero on-hand quantity in gray color font and you cannot enter the quantity for those items. Additionally, if the on-hand quantity of all the style items in a row is zero, the system does not display that row.

If the Splitting Code processing option for the Matrix Entry program is set to automatically split quantities, then the system splits the quantity among the style items with available on-hand quantity.

-

Click OK.

The system displays the Master Work Order Revisions for Style Items form.

-

Review the child style items that appear as lines on the master work order.

Note:

You can continue with another style item root level 0 item, if needed. -

Click OK when all style items are added to the master work order.

The system generates the master work order.

10.2.8 Reviewing Master Work Orders for Style Items

Access the Master Work Order Revisions for Style Items form.

After you enter the master work order header and details, you can view the child style item information that is generated for the master work order.

To review master work orders for style items:

-

Review the following fields for master work order detail information:

-

Item Number

Displays the item number of the child style item.

-

Quantity Ordered

-

Order Number

Displays the child work order that relates to the child style item.

-

Start Date

Displays the start date of the work order.

-

Requested Date

-

-

Click Cancel.

10.2.9 Creating Parts Lists for Master Work Orders for Style Items

Access the Master Work Order Parts List Details for Style Items form.

Figure 10-5 Master Work Order Parts List Details for Style Items form: Parts List tab

Description of "Figure 10-5 Master Work Order Parts List Details for Style Items form: Parts List tab"

To create parts lists for master work orders for style items:

-

Select Copy BOM from the Form menu to copy the bill of material for the style item root level 0 and batch quantity 0.

Note:

You cannot create a parts list without copying a bill of material. After you copy the bill of material for the style item root level 0, you can add, modify, or delete components on the parts list. -

Enter a value in the Branch/Plant field on the Copy BOM to Work Order for Style Items form.

-

Enter a value in the Bill Revision Level field, if applicable.

-

Click OK.

-

Review the parts list on the Master Work Order Parts List Details for Style Item form.

-

Click OK to validate the parts list.

10.2.10 Revising Parts Lists for Master Work Orders for Style Items

Access the Master Work Order Parts List Details for Style Items form.

To revise parts lists for master work orders for style items:

-

To delete all components on the parts list, select Delete Parts List on the Form menu.

-

To delete one component on the parts list, select a line, click Delete, and then click OK.

The component is removed from the parts lists of all child work orders.

-

To modify the quantity of one component, enter a value in the Quantity Ordered field.

The quantity of the component is changed only for that particular work order where this components is used and not in all parts list of child work orders where it exists. The quantity follows the same ratio between the quantity before and after the change.

-

To add a new component:

-

Enter the item number and quantity.

-

Enter the line number of the component from which you want to inherit information and split in the Line No (line number) field.

The quantity ordered of the new component is split among individual child work orders based on the same ratio as the original component that you are pointing to.

-

-

Click OK.

10.2.11 Creating Routing Instructions for Master Work Orders for Style Items

Access the Work Order Routing for Style Items form.

Figure 10-6 Work Order Routing for Style Items form

Description of "Figure 10-6 Work Order Routing for Style Items form"

To create routing instructions for master work orders for style items:

-

Enter routing instructions or review the existing routing on the master work order.

Note:

The routing is automatically copied to the master work order when a routing for the ordered quantity, or zero or non-zero batch quantity exists for the item, branch plant, and type of routing combination. The system automatically creates the routing when you copy a bill of material. -

Click OK.

10.2.12 Processing Master Work Orders for Style Items

Select Shop Floor Management (G41F17), Work Order Processing for Style Items (R31F410).

The Work Order Processing for Style Items program is used to create the parts list and routing instructions for the master work order as well as the child work orders.

10.2.13 Issuing Inventory to a Master Work Order for Style Items

Access the Master Work Order Parts List Details for Style Items form.

Figure 10-7 Master Work Order Parts List Details for Style Items form: Issues tab

Description of "Figure 10-7 Master Work Order Parts List Details for Style Items form: Issues tab"

To issue inventory to a master work order for style items:

-

On the Work with Master Work Orders for Style Items form, select a master work order and select Inventory Issues from the Row menu.

-

On the Issues tab of the Master Work Order Parts List Details for Style Items form, review the values in the Quantity Ordered and Quantity Issued fields for each item on the parts list.

-

Enter a value in the Issues field for each item on the parts list, if applicable.

If the Issue Material for processing option on the Display Options tab of the Master Work Order Processing for Style Items program (PCW49) is set to a value of 1, then the system populates the Issues field with the quantity to issue for each item on the master work order.

-

Click OK.

- Issues

-

Enter a value that represents the available quantity, which might consist of the on-hand balance minus commitments, reservations, and backorders. You enter this value in the Branch/Plant Constants program (P41001).

10.2.14 Reversing Inventory on a Master Work Order for Style Items

Access the Master Work Order Parts List Details for Style Items form.

Figure 10-8 Master Work Order Parts List Details for Style Items form: Issues tab

Description of "Figure 10-8 Master Work Order Parts List Details for Style Items form: Issues tab"

To reverse inventory on a master work order for style items:

-

On the Work with Master Work Orders for Style Items form, select a master work order and select Inventory Issues from the Row menu.

-

On the Issues tab of the Master Work Order Parts List Details for Style Items form, review the values in the Quantity Ordered and Quantity Issued fields for each item on the parts list.

-

Select a record.

-

Select Reversal from the Row menu.

The system automatically reverses the quantity that was originally issued to the master work order. The system reverses the quantity previously issued to the current parts list location.

Note:

You cannot perform a reversal for a quantity that is less than or greater than the issued quantity. You can only reverse the original quantity to the same location and lot. -

Click OK.

10.2.15 Completing Master Work Orders for Style Items

Access the Work Order Completions Matrix Entry form.

Figure 10-9 Work Order Completions Matrix Entry form

Description of "Figure 10-9 Work Order Completions Matrix Entry form"

To complete master work orders for style items:

-

Complete fields in the master work order completions header, as required.

The system displays a matrix, which enables you to enter completed quantities.

Note:

The system populates the Country of Origin field with the default value from the Address Book master of the Header Business unit.If you are completing a work order for a new lot, and the item/branch requires a country of origin, the system uses the value of country of origin through this field. The system displays an error if you leave the field blank. If you are completing the work order for an existing lot, and the value of country of origin in the form is different from the value in Lot Master, the system displays an error.

-

Enter a value in the Qty Completed (quantity completed) and Qty Scrapped (quantity scrapped) fields for each child style item.

-

Click OK to validate the master work order completion.