Understanding Production Options

Understanding Production Options

This chapter provides an overview of production options, lists prerequisites, and discusses how to:

Define the items that are to use production options.

Create production options.

Use the autocreate production options process.

Copy production options.

View component and output mix and production options.

Use production options with other PeopleSoft applications.

Note. In the documentation, the term PeopleSoft Supply Planning refers to both PeopleSoft Supply Planning Multi-Site Material and Advanced Multi-Site Planner, unless stated otherwise.

Understanding Production Options

Understanding Production Options

Some companies' products have either cyclical or seasonal variations in their method of producing an item. They need the ability to define different effective-dated BOM and routing combinations at different times of the year and, at the same time, have planning recommend those combinations based on production order due dates. For the discrete user, the main advantage in using this functionality is that you can link a BOM and routing code together, specify which BOM and routing combinations can be extracted to PeopleSoft Supply Planning, and use these predefined combinations in PeopleSoft Manufacturing. Optionally, you can ensure that the production ID maintenance users select only valid combinations.

Production options are effective-dated BOM and routing combinations that can be extracted to PeopleSoft Supply Planning and used in production. Once you have defined the BOMs and routings, you can link individual production BOM codes to specific production routings, enabling you to define sets of valid BOM and routing combinations for an item. By specifying an effective and obsolete date for each combination, you can take into account seasonal variations in production. You can also indicate whether the production option is to be included in PeopleSoft Supply Planning, which determines whether the combination is valid in the planning instance and considered in the optimization process. During the optimization process, PeopleSoft Supply Planning recommends a production option based on the due date of the planned order.

During the production option definition, you can:

Assign individual production options to specific production areas.

List all production areas where an item can be built.

Attach text and documents to production options.

A set of inquiries enables you to view all the data related to the production options, including component and output mix through which you can view, by operation, the components used and the outputs from that operation. In addition, you can copy production options within or between business units and automatically create production options for all or a range of items or production areas.

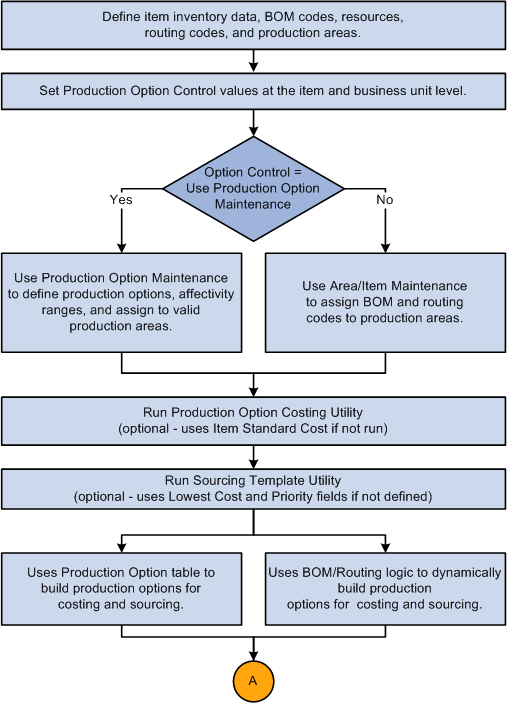

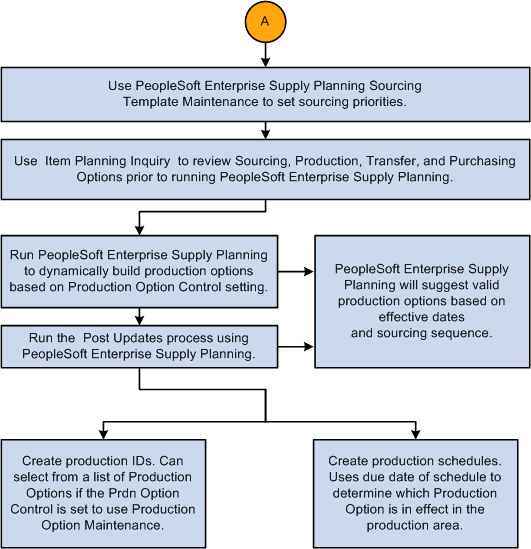

This flowchart provides a top-level view of how you can use production options:

Production option business process overview (1 of 2)

Production option business process overview (2 of 2)

Prerequisites

Prerequisites

Before you begin defining and maintaining production options, you must perform several setup tasks:

Decide which items will use production options.

Define BOMs and routings for items using production options.

If you plan to associate production options with production areas, then production areas must already be defined within PeopleSoft Manufacturing using the Area - Summary page.

See Also

Defining Items that Are to Use Production

Options

Defining Items that Are to Use Production

Options

This section discusses how to define items that will use production options.

Page Used to Define Items that Are to Use

Production Options

Page Used to Define Items that Are to Use

Production Options|

Page Name |

Definition Name |

Navigation |

Usage |

|

GEN_ATTRIB_INV |

Items, Define Items and Attributes, Define Business Unit Item, Manufacturing, General |

Define production option control information for an item. |

Defining Items Using Production Options

Defining Items Using Production Options

Access the Define Business Unit Item - Manufacturing: General page (Items, Define Items and Attributes, Define Business Unit Item, Manufacturing, General).

Production Option Control

|

Use BOM/Routing Defaults |

Use to create specific BOM and routing combinations for PeopleSoft Supply Planning. If you select Use BOM/Routing Defaults, you cannot access the production option maintenance pages for the item, but you can limit the production options that are created in PeopleSoft Supply Planning by using the BOM Code and Routing Code fields. |

|

Use Prdn Option Maintenance (use production option maintenance) |

If you select Use Prdn Option Maintenance for a specific item ID, you can access the specified item using the Production Option Maintenance component. With these pages, you can define specific BOM and routing combinations that can be extracted to PeopleSoft Supply Planning and used in PeopleSoft Manufacturing. You can define effective start and end dates for the combinations in addition to assigning the combinations to valid production areas. If you select Use Prdn Option Maintenance, select Valid Production Options only to use only predefined production options when creating production IDs. If any BOM or routing combination is valid, leave this blank. |

Note. You can only select Use Prdn Option Maintenance if no area or items have been defined for the specific item. If you have already assigned an item to a production area in PeopleSoft Manufacturing, you cannot select Use Prdn Option Maintenance for that same item on the Define Business Unit Item - Manufacturing: General page. You can, however, create production options by running the Autocreate Production Options process, which sets the item's Production Options group box to Use Prdn Option Maintenance rather than Use BOM/Routing Defaults.

Note. If you have marked an item to Use Prdn Option Maintenance, you must set the planning rates to be based on routings; you cannot select them to be based on lead time. If the item is already going to be produced based on lead times, you cannot select the Use Prdn Option Maintenance option on the Define Business Unit Item - Manufacturing: General page.

This table outlines the production options that you can create by entering various values in the BOM Code and Routing Code fields:

|

BOM Code and Routing Code Setting |

Production Option Created |

|

If both are blank. |

System creates a production option for every possible BOM and routing combination. |

|

If BOM Code field is not blank and Routing Code field is blank. |

System creates a production option for all routing codes with the specific BOM code selected. |

|

If Routing Codefield is not blank and BOM Code field is blank. |

System creates production options for all BOMs with the specific routing code selected. |

|

If both are not blank. |

System creates one production option for the single, specified BOM and routing combination. |

By selecting a specific BOM and routing code, you can limit the number of BOM and routing combinations that are extracted by PeopleSoft Supply Planning. For example, by selecting a specific BOM code and routing code, you eliminate all but this specific combination from consideration by PeopleSoft Supply Planning. At the other extreme, if you leave both fields blank, then PeopleSoft Supply Planning extracts all possible combinations.

This example illustrates various BOM and routing values and the production options that would be created by various BOM code and routing code settings.

If a specific item has BOM codes 1, 2, and 3 and routing codes 1 and 2, here are the numbers of production options created in PeopleSoft Supply Planning, based on the BOM Code and Routing Code field settings:

|

BOM Code |

Routing Code |

Production Options Created |

Total Combinations |

|

Blank |

Blank |

1-1, 1-2, 2-1, 2-2, 3-1, 3-2 |

6 |

|

1 |

Blank |

1-1, 1-2 |

2 |

|

Blank |

2 |

1-2, 2-2, 3-2 |

3 |

|

1 |

2 |

1-2 |

1 |

The number of production options created in PeopleSoft Supply Planning depends on the BOM and routing default values.

Note. Only routing codes that have the Copy Routing to Planning check box selected in the Routing Definition - Header: Description page are copied to PeopleSoft Supply Planning.

Note. You can only select Use BOM/Routing Defaults if there are no production options defined for the item. If production options exist, you must manually delete them first.

Also, if you select Use BOM/Routing Defaults, use the Production Area Maintenance set of pages to define area BOM and routing combinations.

|

Production Option Control Setting |

Steps Based on Control Setting |

|

Select Use Prdn Option Maintenance to:

|

|

|

Select Use BOM/Routing Defaults, if specific BOM and routing combinations are not required. Additionally, it's possible to limit the number of BOM and routing combinations extracted to PeopleSoft Supply Planning using the BOM and routing fields. |

|

See Also

Defining Generation of Item Supply Information

Defining Routing Header Information

Defining Manufacturing Information for an Item

Creating Production Options

Creating Production Options

To create production options, use the Define Production Options (EN_PDO_MAINT) component.

The Production Option Maintenance pages enable you to specify multiple production variations for an item and control the variations by effectivity dates. You do this by linking specific production BOM codes with specific production routings at the item level.

This section discusses how to:

Define production options.

Associate production areas.

Manage production option attachments.

Common Elements in This Section

Common Elements in This Section|

|

Click the Item Search button to access any of these pages:

|

Pages Used to Create Production Options

Pages Used to Create Production Options|

Page Name |

Definition Name |

Navigation |

Usage |

|

EN_PDO_BR |

Manufacturing Definitions, Production Options, Define Production Options, Definition |

Define production options and effective-dated BOM and routing combinations that can be extracted to PeopleSoft Supply Planning. |

|

|

EN_PDO_BR_PA |

Manufacturing Definitions, Production Options, Define Production Options, Production Area |

Associate production areas with each production option. |

|

|

EN_PDO_BR_TXT |

Manufacturing Definitions, Production Options, Define Production Options, Text |

Add production option text. |

|

|

EN_PDO_BR_DC |

Manufacturing Definitions, Production Options, Define Production Options, Documents |

Associate documents with production options. Note. You must have PeopleSoft Engineering installed to access this page. |

|

|

EN_PDO_BR_ATT |

Manufacturing Definitions, Production Options, Define Production Options, Attachments |

Attach multimedia objects or files that relate directly to the production option. Once attached, you can view these objects directly from this page. |

Defining Production Options

Defining Production Options

Access the Define Production Options - Definition page (Manufacturing Definitions, Production Options, Define Production Options, Definition).

|

Rtg Itm (routing item) |

Displays the master routing item if the item selected is linked to a master routing. |

|

BOM and Routing |

If you are adding a new production option, select the BOM code and routing code that you want to define as a production option for the item that you selected. |

|

Eff Date (effective date) and Obs Date (obsolete date) |

Enter the effectivity dates of the production option. |

|

Incl Plan (include in planning) |

Select if you want to make the production option available for extraction to PeopleSoft Supply Planning. This field appears by default from the Copy to Routing check box in Routing Maintenance. If the Copy to Routing check box is selected, then this field is automatically selected. |

|

|

Click the Select All or Deselect All buttons to control the Incl Plan field. |

See Also

Viewing Component and Output Mix and Production Options

Associating Production Areas

Associating Production Areas

Access the Define Production Options - Production Area page (Manufacturing Definitions, Production Options, Define Production Options, Production Area).

The BOM, Routing, Description, Eff Date (effectivity date), and Obs Date (obsolete date) fields appear by default from the Production Option - Definition page. For each production option, you can add one or more production areas using the Production Area field.

Note. You can select only one primary production area. Also, only one BOM and routing combination can be in effect in a production area at one time.

Because the same fields are being updated, the Revision, Primary, Maintain PID (maintain production ID), Method, Status, and Rate Qty per Shift (rate quantity per shift) fields operate identically to those fields on the Production Area Maintenance pages in PeopleSoft Manufacturing.

See Also

Managing Production Option Attachments

Managing Production Option Attachments

Access the Production Option Maintenance - Attachments page (Manufacturing Definitions, Production Options, Define Production Options, Attachments).

Attachments

|

File Ext (file extension) |

Select the type of media that you want to attach. Set up file extensions using the File Locations page. |

|

Document ID and Description |

Enter the file name and description of the multimedia file that you are attaching. |

|

|

Click the Attachments button to launch the multimedia object attached to the production option. |

Using the Autocreate Production Options

Process

Using the Autocreate Production Options

Process

You can automatically create production options by item ID or by production area. By using the autocreate production options process, you can quickly convert items that are currently not using production options to use production options.

Page Used to Create Production Options Automatically

Page Used to Create Production Options Automatically|

Page Name |

Definition Name |

Navigation |

Usage |

|

EN_PDO_AUTOCREATE |

Manufacturing Definitions, Production Options, Autocreate Production Options |

Create production options automatically by item ID or by production area. |

Creating Production Options Automatically

Creating Production Options Automatically

Access the Autocreate Production Options page (Manufacturing Definitions, Production Options, Autocreate Production Options).

This page is useful for users who are new to the production option functionality. You can use it to create production options quickly for all or a range of items or production areas. Begin by selecting either Item ID or Production Area. Then, depending on your choice, the Item ID or Prdn Area (production area) fields become available for selection.

When you click the Save button, the system converts all items that are currently not using production options to using production options. For all items converted to production options, the item's Production Option Control value on the Define Business Unit Item - Manufacturing: General page is set to Use Prdn Option Maintenance. You can then access the item on the Production Option maintenance pages. This function automatically adds the BOM and routing combination defined in the production area as a production option.

Note. If an item is going to be produced based on lead times rather than routings, the item is not converted, because items set to Use Prdn Option Maintenance cannot use lead times.

Note. If you have already assigned an item to a production area in PeopleSoft Manufacturing, then you cannot select Use Production Option for that same item on the Define Business Unit Item - Manufacturing: General page. You can, however, create production options by using the autocreate functionality.

See Also

Defining Generation of Item Supply Information

Copying Production Options

Copying Production Options

You can copy production options from one item to another and across business units, if needed. This section lists common elements and discusses how to copy production options.

Common Elements Used in This Section

Common Elements Used in This Section|

|

Click the View Related Links button to access any of these pages:

|

Page Used to Copy Production Options

Page Used to Copy Production Options|

Page Name |

Definition Name |

Navigation |

Usage |

|

EN_PDO_COPY |

Manufacturing Definitions, Production Options, Copy Production Options |

Copy production options from one item to another. |

Copying Production Options

Copying Production Options

Access the Copy Production Options page (Manufacturing Definitions, Production Options, Copy Production Options).

Source

|

Unit and Item ID |

Select the business unit and item ID whose production option you want to copy. Note. If the source item has been identified as using production options, but has no actual production options defined, then the system displays an error message, because there are no options to copy. |

|

Search |

Click to display the production options for the source item. |

Target

|

Unit and Item ID |

Select the business unit and item ID. The target item ID cannot be identical to the source item ID. If the target item already has production options defined, the system provides the option either to not continue or to overwrite the existing production options on the target; you cannot overwrite any production option that is already in use on a production order. |

|

Copy Prdn Area (copy production area), Copy Text and Copy Att (copy attachment) |

Select to copy production areas, text, and attachments to the target item. |

|

Same As Except |

Select the production options to be copied by using this field. Values are:

|

|

View Source and View Target |

Click to view the production options for the respective items. |

|

Copy |

Select the rows that you want to copy to the target item. Note. You must select at least one production option to copy or the system displays an error message. |

|

Save |

Click and the system completes the copy. |

See Also

Defining Production Area Summaries

Viewing Component and Output Mix and Production

Options

Viewing Component and Output Mix and Production

Options

This section discusses how to:

Select component and output mix information.

View component and output mix information.

View production option definitional data.

View production option production areas.

View production option selections.

Pages Used to View Component and Output

Mix and Production Options

Pages Used to View Component and Output

Mix and Production Options|

Page Name |

Definition Name |

Navigation |

Usage |

|

EN_PDO_INQ_SUM |

Manufacturing Definitions, Production Options, Review Component/Output Mix, Operation |

Enter the search for the component and output mix, and view the routing operation sequences associated with BOM and routing combinations. You can view operation information such as tasks and work centers. |

|

|

EN_PDO_INQ_DTL |

Manufacturing Definitions, Production Options, Review Component/Output Mix, Component/Output |

View the component and output mix by routing operation for a BOM and routing combination at a particular time. This inquiry displays the inputs and outputs at each operation for a specific BOM and routing combination. |

|

|

EN_PDO_BR_INQ |

Manufacturing Definitions, Production Options, Review Production Options, Definition |

View production option data. |

|

|

EN_PDO_BR_INQ_PA |

Manufacturing Definitions, Production Options, Review Production Options, Production Area |

View the production area data that is defined for the production option. |

|

|

EN_PDO_BR_INQ_TXT |

Manufacturing Definitions, Production Options, Review Production Options, Text |

View production option text. |

|

|

EN_PDO_BR_INQ_DC |

Manufacturing Definitions, Production Options, Review Production Options, Documents |

View documents that are associated with the production option. Note. You must have PeopleSoft Engineering installed to access this page. |

|

|

EN_PDO_BR_INQ_ATT |

Manufacturing Definitions, Production Options, Review Production Options, Attachments |

View attachments that are associated with the production option. |

|

|

EN_PDO_SEL_SP PL_SRC_PROD_SP |

|

View and select existing production options. |

Selecting Component and Output Mix Information

Selecting Component and Output Mix Information

Access the Component/Output Mix - Operation page (Manufacturing Definitions, Production Options, Review Component/Output Mix, Operation).

|

Unit and Item ID |

Select the business unit and item ID for the BOM and routing combination that you want to view. |

|

|

Click the View Related Links button to select one of these pages:

|

|

BOM, Routing, Revision and Eff Date (effectivity date) |

Select the desired BOM, routing, effectivity date, and revision. If the item is revision-controlled, the system pulls the BOM revision data. If it's not revision-controlled, the system sets the effectivity date to today's date. In addition, the system displays the BOM Qty. |

|

Prdn Opt Cntl (production option control) |

Displays the production option control, which indicates whether the item has been defined as using production options with the Define Business Unit Item - Manufacturing: General page. Therefore, it displays either Prdn Opt (use production option maintenance) or BOM/Rtg (BOM and routing combination defaults). |

|

Rtg Itm (routing item) |

Displays the item's reference routing. All of the data that appears is for the item's reference routing, if one exists. Note. All of the data that appears is for the item's reference routing, if one exists. |

|

Search |

Click to populate the operation list. This section displays the operation sequence for the BOM and routing combination that you selected. The page also indicates whether the operation sequence is subcontracted, and displays the work center and its description. In addition, clicking the Search button populates the Component/Output page in this component. |

Note. A production option does not have to exist for you to view the BOM and routing combination data. You view the same information in either case. In addition, use this inquiry for multiple what-if scenarios.

See Also

Defining Production Area Summaries

Defining Manufacturing Information for an Item

Viewing Component and Output Mix Information

Viewing Component and Output Mix Information

Access the Component/Output Mix - Component/Output inquiry page (Manufacturing Definitions, Production Options, Review Component/Output Mix, Component/Output).

|

Yield % |

This display-only field indicates the percentage of manufacturing items expected at the end of the operation sequence. |

Note. If the BOM component and output operation sequence do not match the header operation sequence, an asterisk appears in front of the number. The header operation that appears against the output or component is an operation assigned when defining the BOM and might not match the routing operation. For components, the component appears as part of the first operation sequence. For outputs, the output appears as part of the last operation sequence.

Viewing Production Option Definitional Data

Viewing Production Option Definitional Data

Access the Production Option - Definition inquiry page (Manufacturing Definitions, Production Options, Review Production Options, Definition).

|

|

Click the Item Search button to view the components and outputs at each routing operation for a specific BOM and routing combination. |

Viewing Production Option Production Areas

Viewing Production Option Production Areas

Access the Production Option - Production Area inquiry page (Manufacturing Definitions, Production Options, Review Production Options, Production Area).

|

|

Click the Item Search button to view the components and outputs at each routing operation for a specific BOM and routing combination. |

Viewing Production Option Selections

Viewing Production Option Selections

Access the Production Option Selection page (Production Control, Production IDs/Schedules, Production Area, Summary, Summary. Click the Item Search button next to the Item) .

|

Select |

Select this check box to populate the production option data on the page that called this page. |

Using Production Options with Other PeopleSoft

Applications

Using Production Options with Other PeopleSoft

Applications

You define production options in PeopleSoft Manufacturing, but they also are present in PeopleSoft Supply Planning and PeopleSoft Cost Management. While the specifics of these impacts are discussed in the respective pieces of application documentation, this is a high-level discussion of the cross-product use of production options.

This section discusses how to:

Use production options with PeopleSoft Supply Planning.

Use production options with PeopleSoft Manufacturing.

Using Production Options with PeopleSoft

Supply Planning

Using Production Options with PeopleSoft

Supply Planning

The Production Option Control check box (set at the item and business unit level on the Define Business Unit Item - Manufacturing: General page) determines how production options (formerly build options) are created in PeopleSoft Supply Planning.

There are two production option control options:

Use Prdn Option Maintenance (production option maintenance).

Use BOM/Routing Defaults.

Use Production Option Maintenance Setting

There are two different settings for the Production Option Control flag. If you select Use Prdn Option Maintenance, you can define specific BOM and routing combinations with effective dates assigned to each combination. You make these definitions with the Production Option Maintenance pages. All BOM and routing combinations with the Incl Plan (include in planning) check box are visible to PeopleSoft Supply Planning.

Use BOM and Routing Defaults Setting

If you select Use BOM/Rtg Defaults as the production option, you cannot define and maintain specific effective BOM and routing combinations, but you can still limit the number of production options created in PeopleSoft Supply Planning. For example, suppose that you have BOM codes 1, 2, and 3 and routing codes 1 and 2, then there are potentially six production options that can be created in PeopleSoft Supply Planning, if there is no way to limit that number. However, you can limit that number by using the BOM Code and Routing Code fields on the Define Business Unit Item - Manufacturing: General page. For example, if you select one specific BOM code and one specific routing code, then only one combination is extracted by PeopleSoft Supply Planning.

Other Production Option Planning Information

Regardless of the setting, it's possible to view the PeopleSoft Supply Planning production options before running PeopleSoft Supply Planning by using the Item Planning Inquiry.

It's also possible to cost production options using the Production Option Costing Utility, so that an accurate build cost is sent to PeopleSoft Supply Planning for each production option. This utility effectively rolls up the costs for all production options in the range of items selected. Both the batch cost (total cost) and the unit cost can be viewed through the Item Planning Inquiry.

Using the sourcing template function, you can prioritize the production, transfer, and purchase options for an item and business unit, so that you have full control over how PeopleSoft Supply Planning creates new supply for the item.

Since PeopleSoft Supply Planning has visibility into the effective dates defined against the production option, the PeopleSoft Supply Planning application recommends new planned production orders based on the current, effective BOM and routing combinations.

See Also

Defining Manufacturing Information for an Item

PeopleSoft Supply Planning PeopleBook

Using Production Options with Production

Using Production Options with Production

This section discusses how the manufacturing process uses production options.

If you select Use Prdn Option Maintenance for an item on the Define Business Unit Item - Manufacturing: General page, then any production options that you have predefined are available for selection in production ID maintenance. In addition, if the Valid Production Only check box is selected, only those BOM and routing combinations that have been set up in production option maintenance can be selected. If the check box is deselected, then any combination of BOM and routing codes can be entered for the item. The BOM and routing fields automatically change to the current BOM and routing combination that is effective for that item in the selected production area.

Production Schedule Maintenance

The item, production area, and the due date for each production schedule determine which BOM and routing combination is assigned to that schedule.

Although different BOM and routing combinations can be assigned to the same production area and item, there can be only one combination in effect at any one time. The due date of the schedule determines which BOM and routing combination is selected for that production schedule.

When completing against a production schedule, the BOM and routing effective date on the Record Completions/Scrap page determines the particular BOM and routing to be used for the production schedule. The BOM and routing effective date automatically changes to the current system date, and this field determines which combinations will be selected and appear in the BOM Code and Routing Code fields. For non-revision controlled items, this date is used to decide which BOM and routing combination will be used. A second effective date is used for the components and outputs. If the item is revision-controlled, then both the revision code and BOM and routing effective date must be selected. The revision code determines the components and outputs in effect for this revision, and the BOM and routing effective date determines the BOM and routing combination to use.

See Also

Completing Operations and Recording Scrap