6 Auto Fulfillment Processing

This chapter contains the following topics:

-

Section 6.4, "Running the Auto Fulfillment Processing Report (R4277701)"

-

Section 6.5, "Running the Auto Fulfillment Load Balance Report (R4277711)"

-

Section 6.6, "Running the Purge Fulfillment Plan ID Report (R4277710)"

6.1 Understanding Auto Fulfillment Processing

The sales order process, without fulfillment, does not provide a way to match high priority sales order lines with available inventory. During sales order processing, the system fulfills inventory on a first-come-first-serve basis. This method can cause the system to backorder critical order lines when item availability is low. The JD Edwards EnterpriseOne Fulfillment Management module enables you to set up a batch process to commit inventory. Auto fulfillment is a batch process that fulfills inventory to open sales orders based upon scoring order lines. During auto fulfillment processing, the system can:

-

Completely fulfill inventory when the item availability is high.

-

Partially fulfill inventory when the item availability is low.

The system applies fulfillment rules based on safety stock for partial fulfillment.

-

Fulfill none of the inventory when item availability is at or near zero.

The Auto Fulfillment Processing report includes:

-

Sorting order lines based upon the data sequence. You can use information from the Sales Order Detail table (F4211), Sales Order Header table (F4201), and the Customer Master Line of Business (F03012) table for the sold to customer.

-

Fulfilling inventory to sales order lines in the sequence that you specify.

-

Generating a report for the system-created fulfillment plan.

6.1.1 Auto Fulfillment Processing

The Auto Fulfillment Processing report (R4277701) fills inventory to sales order lines based on:

-

Sort sequence of the batch report.

You can use data from the F4201, F4211, and F03012 tables.

-

Inventory Commitment preference percent to fill value.

-

Service level rule information

-

Fulfillment rule information.

-

Rounding rule preference information.

The report produces printed output called a Fulfillment Plant. The Fulfillment Plan provides a list of the order lines that the system considered for fulfillment and the actual results of the fulfillment. You can run the R4277701 report in both Proof and Final mode. In Proof mode, you can review the order lines that the system processed and the potential fulfillment results. The system does not update any tables when you run the report in Proof mode. In Final mode, the system produces the printed output, updates the changes to the database, and enables you to view the results in the Fulfillment Workbench program (P4277701). The system updates the following tables in Final mode:

-

Item Location File (F41021).

-

Sales Order Detail (F4211).

-

Service Level Rule Header (F4277701).

-

Service Level Rule Detail (F4277711).

-

Fulfillment Plan ID (F4277710).

The system assigns the appropriate Fulfillment Status code to each order line based on whether the line is fully filled, partially filled, not filled, or released from fulfillment.

The system issues warning if:

-

The customer does not accept partial shipments in their Customer Billing Information

-

The line does not meet the fill requirement.

-

The line could not be released, if you set the processing option to automatically call the Release from Fulfillment report (R4277703).

The system issues errors if:

-

Records are reserved by another process.

-

Records cannot be committed.

-

Transaction processing fails.

6.1.2 Reprocess Fulfillment

The Reprocess Fulfillment processing option enables you to reevaluate sales order lines through the Auto Fulfillment Processing report multiple times. You can use reprocessing with Proof or Final mode of the report. Reprocess enables you to run different scenarios of the fulfillment plan before finalizing and releasing the sales order lines from fulfillment. With reprocessing you can batch sales order lines that are in the fulfillment process and have been assigned inventory with new sales orders that just entered the fulfillment process. For example:

-

Receive orders overnight through EDI.

-

Run the R4277701 report to assign inventory to the order lines.

-

Enter expedited sales order for your top priority customer.

-

Run the R4277701 report with reprocessing to evaluate the new expedited order with the existing EDI orders.

-

Reprocess captures the new demand and reassigns inventory appropriately.

-

The system basically un-assigns the previous batch and creates new inventory assigns

-

|

Note: The auto fulfillment process skips kit item lines and does not process fulfillment for order lines on hold. |

6.1.3 Auto Fulfillment Load Balance

The Auto Fulfillment Load Balance report (R4277711) improves the overall performance of the Auto Fulfillment Processing report (R4277701)by specifying the number of concurrent processes to run. The report splits the load using item and branch combinations. The Auto Fulfillment Load Balance report:

-

Determines how many lines in the data selection are eligible for processing.

The system reserves records to ensure that only records available for processing are included in the total line count. When the system uses an order type service level rule, the system does not process any of the order lines using that same service level rule through the load balancer. Order level rules require the processing of all related lines in a single transaction. This introduces an additional concurrency constraint by which all item and branch combinations for this order rule type are required to run on a single processor, significantly limiting the value of a load balance.

Sales order lines with an associated order service level rule are not included in the total count because the order must be processed and not as individual lines. The Auto Fulfillment Processing report does not process these order lines when called from the Auto Fulfillment Load Balance report.

-

Determines how many lines the system optimally assigns to each concurrent job.

-

Determines the maximum number of lines for each concurrent job for the target tolerance percentage range.

-

Determines the number of lines the system assigns to each concurrent job and the data selection for the Auto Fulfillment Processing report.

The data selection includes item and branch. The system replaces the data selection of the Auto Fulfillment Processing report with the new data that is determined from the Auto Fulfillment Load Balance report.

For each version of the Auto Fulfillment Processing report that the system launches, you must set up a version of the Auto Fulfillment Load Balance report. The Auto Fulfillment Load Balance report does not have data selection. The system parses the data selection from the Auto Fulfillment Processing report version that you identify in the processing option of the Auto Fulfillment Load Balance report.

-

Displays the load balance information on the report.

You must activate the Print processing option.

-

Lists error messages on the report and sends them to the Work Center.

-

Launches the concurrent version of the Auto Fulfillment Processing report for each job.

You must activate the Run Auto Fulfillment processing option.

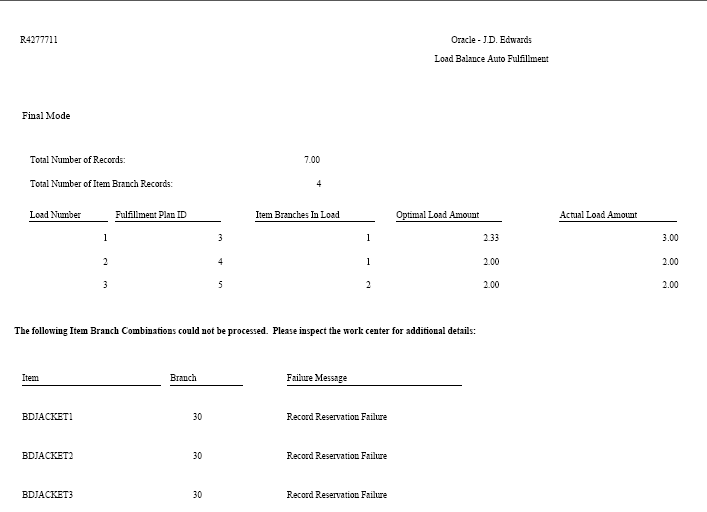

This diagram illustrates the Auto Fulfillment Load Balance report output:

Figure 6-1 Example: Auto Fulfillment Load Balance report output

Description of "Figure 6-1 Example: Auto Fulfillment Load Balance report output"

6.2 Setting Up Fulfillment Rules

This section provides an overview of fulfillment rules and discusses how to set up fulfillment rules.

6.2.1 Understanding Fulfillment Rules

The amount of safety stock that you choose to keep on hand can significantly impact your business. If you have too much safety stock, the inventory holding cost increases. Additionally, storing products for too long increases the potential of damage during the warehousing process and some products can spoil or have an expiration date. On the other hand, not having enough safety stock can result in lost sales and unsatisfied customers. Thus, efficient management of safety stock is essential.

The Fulfillment Rules program (P4277720) enables you to set up fulfillment rules that the system uses in the Auto Fulfillment Processing report. The fulfillment rules enable you to manage your safety stock by assigning inventory based on two components—score and safety stock percentage. When processing fulfillment rules, the system evaluates these components to determine whether to apply the fulfillment percentage.

6.2.1.1 Understanding Safety Stock

Safety stock is setup in the Item Branch program (P41026). If you use fulfillment rules and an item does not have a safety stock quantity, you must set up a fulfillment rule with zero percent remaining safety stock. The system uses this zero percent rule when an order line cannot be fully filled based on the limiting factor, either item availability or fulfillment percent.

If you use fulfillment rules and subtract safety stock from the on-hand balance in the availability calculation, you must set up a fulfillment rule with zero percent remaining safety stock. When you subtract safety stock in the availability calculation, the system does not hold the additional quantity from being filled to order lines.

If the system does not find an appropriate fulfillment rule during the run of the Auto Fulfillment Processing report, no inventory is filled to the sales order line.

6.2.1.2 Scenario: Understanding How the System Applies Fulfillment Rules

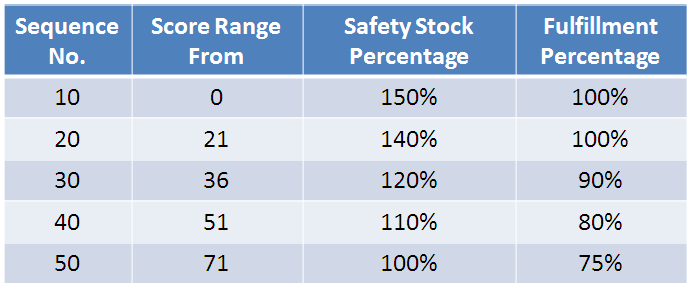

In this scenario, four customers order the same item with the same line type and order type. The available quantity for the item is 1,000 units and the safety stock quantity is 200 units. You have set up a fulfillment rule that applies to your item and the customers who order it. This diagram illustrates the fulfillment rule setup:

Figure 6-2 Example of fulfillment rule setup

Description of "Figure 6-2 Example of fulfillment rule setup"

During the fulfillment process, the system retrieves the score from the Sales Order Detail table (F4211).

|

Note: In this scenario, the lower the priority score, the more important the priority for the order line. |

This table lists the customer, the order line score, and the quantity that each customer ordered:

| Customer | Score | Quantity Ordered |

|---|---|---|

| 4242 | 15 | 150 |

| 4243 | 40 | 400 |

| 4244 | 75 | 200 |

| 4245 | 10 | 100 |

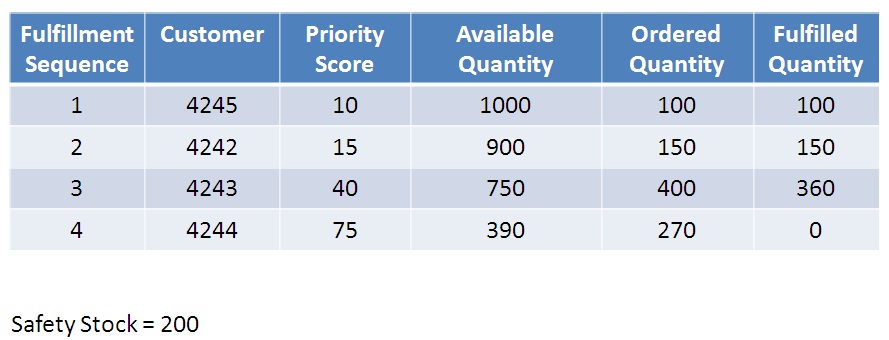

During run of the Auto Fulfillment Processing report, the system assigns inventory to the order lines based upon priority score. This diagram illustrates the results and the sequence in which the system assigns inventory:

Figure 6-3 Results and sequence in which the system assigns inventory

Description of "Figure 6-3 Results and sequence in which the system assigns inventory"

The system processes the order lines in sequence based on the priority score. This table explains how the system processes order lines for each customer during auto fulfillment processing in this scenario:

| Customer | Comments |

|---|---|

| 4245 | The system determines whether 150 percent of the safety stock remains available after assigning 100 percent (100 units) of the requested quantity to the order line for customer 4245. After the system assigns quantity to the order line, the remaining quantity is 900 units, which is more than 150 percent of the safety stock.

The system fulfills 100 percent of the quantity ordered for customer 4245 based upon the priority score (10). |

| 4242 | After fulfilling quantity for customer 4245, the system:

|

| 4243 | After fulfilling quantity for customers 4245 and 4242, the system:

|

| 4244 | After fulfilling quantity for customers 4245, 4242, and 4243, the system:

|

6.2.2 Form Used to Set Up Fulfillment Rules

| Form Name | Form ID | Navigation | Usage |

|---|---|---|---|

| Fulfillment Rules - Add Rule | W4277720B | Fulfillment Management Setup (G4277710), Fulfillment Rules Setup.

Click Add. |

Set up fulfillment rules. |

6.2.3 Setting Up Fulfillment Rules

Access the Fulfillment Rules - Add Rule form.

Figure 6-4 Fulfillment Rules - Add Rule form [Release 9.1 Update]

Description of "Figure 6-4 Fulfillment Rules - Add Rule form [Release 9.1 Update]"

- Fulfillment Rule

-

Enter a code that represents the name of the fulfillment rule.

- Sequence No. (number)

-

Enter the sequence in which you want the system to evaluate the fulfillment rule.

- Score Range From

-

Enter the beginning score in the safety stock rule range. When evaluating the safety stock rule, if a number is greater than or equal to the beginning score and less than the next highest beginning score, then the system applies this rule.

- Safety Stock Percentage

-

For the system to apply the safety stock fulfillment rule, enter the minimum percentage of safety stock that must exist after the system completely fulfills inventory to an order.

- Fulfillment Percentage

-

Enter a numeric value that determines the percentage of the order quantity that the system fulfills based upon the fulfillment rule. The system does not permit values greater than 100 percent.

6.3 Setting Up Fulfillment Rounding

This section provides an overview of fulfillment rounding and discusses how to set up preference detail values for fulfillment rounding.

6.3.1 Understanding Fulfillment Rounding

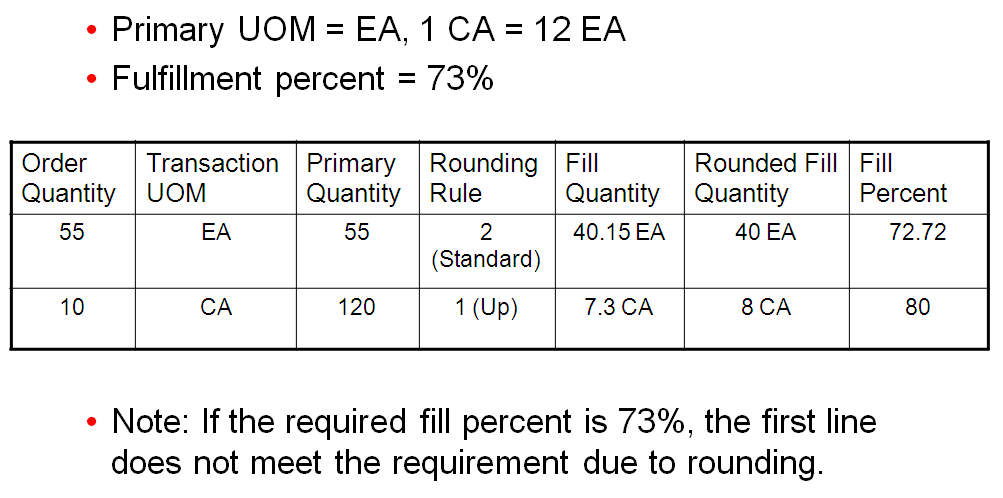

The Fulfillment Rounding advanced preference enables you to set up rounding rules to specify how the system rounds the fulfillment quantity when assigning inventory when you run the Auto Fulfillment Processing report. For example, you can define rounding amounts to the nearest whole number (up or down) or round to the next whole number. You can also specify that the system not perform rounding, thereby enabling the system to use fractions of a unit of measure in fulfillment quantities. You can set up rounding rules based on a combination of item, item group, customer, and customer group. Where rounding occurs depends on the sequence in which the rounding adjustment appears on the advance preference schedule. This example illustrates fulfillment rounding:

Figure 6-5 Example that illustrates fulfillment rounding

Description of "Figure 6-5 Example that illustrates fulfillment rounding"

|

Note: You must set up the Fulfillment Rounding Preference Type with the Level Break Radio Button set to none in the Preference Names (P4071) program. The Auto Fulfillment Processing report (R4277701) does not round quantities to the nearest whole number unless the Level Break Radio Button is set to none. |

6.3.2 Form Used to Set Up Fulfillment Rounding

| Form Name | Form ID | Navigation | Usage |

|---|---|---|---|

| Preference Values Revisions | W4072D | Advanced Preferences (G40311), Advanced Preferences Detail Revisions

On the Work with Preference Detail form, locate and select a preference name. On the Preference Detail Revisions form, select the record. Select Pref Details from the Row menu. |

Set up preference detail values. |

6.3.3 Setting Up Preference Detail Values for Fulfillment Rounding (45)

Access the Preference Values Revisions form.

Figure 6-6 Preference Values Revisions form for Fulfillment Rounding (45)

Description of "Figure 6-6 Preference Values Revisions form for Fulfillment Rounding (45)"

- Sequence

-

Enter a number that specifies the sequence of information.

- Business Unit

-

Enter an alphanumeric code that identifies a separate entity within a business for which you want to track costs.

- Transaction Primary

-

Specify the advanced preference for fulfillment rounding. Values are:

1: Transaction equals primary.

2: Transaction is not equal to primary.

- Fulfillment Rounding Rule

-

Specify the rounding rule that the system uses for the Auto Fulfillment Processing report (R4277701). Values are:

1: Round up. The system rounds the fulfillment quantity to the next whole number.

2: Standard rounding. The system rounds the fulfillment quantity to the nearest whole number (either up or down).

3: No rounding. The system does not round the fulfillment quantity. If you do not round, the system can fulfill fractions of a unit of measure.

6.4 Running the Auto Fulfillment Processing Report (R4277701)

This section discusses how to:

-

Run the Auto Fulfillment Processing report.

-

Set processing options for the Auto Fulfilment Processing report (R4277701).

6.4.1 Running Auto Fulfillment Processing (R4277701)

Select Fulfillment Processing (G4277710), Auto Fulfillment Processing.

6.4.2 Setting Processing Options for Auto Fulfillment Processing (R4277701)

Use these options to process orders through the fulfillment process.

6.4.2.1 Process

- 1. Proof or Final Mode.

-

Specify whether the system runs the Auto Fulfillment Processing report in Proof or Final mode. In Proof mode, the system assigns inventory to sales order lines without modifying the sales order lines, and does not update the status of the lines. In Final mode, the system commits the output, creates the fulfillment plan, and updates the order statuses. Values are:

Blank: Run Auto Fulfillment in Proof mode.

1: Run Auto Fulfillment in Final mode.

Note (Release 9.1 Update):

When you run this version of Auto Fulfillment in proof mode, the system does not launch the Release from Fulfillment report (R4277703). When you run this version of Auto Fulfillment in final mode, the system launches the Release from Fulfillment report. However, if the system launches this version of Auto Fulfillment from the Load Balancer report (R4277711), the system does not run the Release from Fulfillment report regardless of whether you set this version to run in proof mode or in final mode. - 2. Fulfillment Plan Description.

-

Enter a value that defines the fulfillment plan. In Final mode, the system writes the fulfillment plan to the Fulfillment Plan ID table (F4277710). This description is informational only.

- 3. Include Backordered Quantity as Available Quantity.

-

Specify whether the system adds back-ordered quantity to available quantity. Use this processing option depending on how you set up the availability calculation. Values are:

Blank: Do not add back-ordered quantity to available quantity.

1: Add back-ordered quantity to available quantity.

- 4. Release the fulfillment after orders are fulfilled.

-

Specify whether the system runs the Release from Fulfillment report (R4277703). Values are:

Blank: Do not run the Release from Fulfillment report.

1: Run the Release from Fulfillment report.

Note:

The system runs the Release from Fulfillment report only when you run the Auto Fulfillment Processing report in Final mode. However, if the system launches this version of Auto Fulfillment from the Load Balancer report (R4277711), the system does not run the Release from Fulfillment report regardless of whether you set this version to run in proof mode or in final mode - 5. Fulfillment Rule Name

-

Enter the rule name that you set up in the Fulfillment Rules program (P4277720). This functionality enables inventory assignments based on the scores and remaining percentage of the safety stock.

- 6. Reprocess Fulfillment

-

Indicate whether the system reprocesses the existing fulfillment. Reprocessing enables you to un-commit previous inventory assignments and run the process from the beginning. Values are:

Blank: The system does not reprocess the fulfillment.

1: The system reprocesses the fulfillment.

- 7. Record Reservation Error

-

Specify whether you want the Auto Fulfillment Processing report to provide error messaging on all reserved records, or only on the first reserved record that the system encounters. When record reservation is active, the Auto Fulfillment Processing report runs through all the data selection and determines whether the system has reserved any of the records. If the system has reserved records, the system issues errors, stops the Auto Fulfillment Processing report, and does not process any order lines. Values are:

Blank: Set record reservation error and continue looking for additional reservations.

1: Stop processing the program when the first record reservation error occurs.

- 8. Override Advanced Preference

-

Specify the advanced preference schedule that the system uses when resolving the Fulfillment Rounding preference. If you leave this processing option blank, the system uses the schedule from the system constants.

6.4.2.2 Versions

These processing options specify the versions of programs that the system calls from the Auto Fulfillment Processing report. When you choose a version, review the version's processing options to ensure that the version meets your needs. You can define different versions in accordance with business processes. If you leave any of the processing options blank, the system uses version ZJDE0001, which is the default version for each respective program.

- 1. Release from Fulfillment (R4277703)

-

XJDE0001

- 2. Sales Order Entry (P4210)

-

ZJDE0001

6.5 Running the Auto Fulfillment Load Balance Report (R4277711)

This section discusses how to:

-

Run the Auto Fulfillment Load Balance report.

-

Set processing options for the Auto Fulfillment Load Balance report (R4277711).

6.5.1 Running Auto Fulfillment Load Balance

Select Fulfillment Processing (G4277710), Auto Fulfillment Load Balance.

6.5.2 Setting Processing Options for the Auto Fulfillment Load Balance Report (R4277711)

Use the following processing options to process orders through the fulfillment process.

6.5.2.1 Process

- 1. Number of Concurrent Jobs

-

Specify the number of times that the system runs a version. Typically this number corresponds to the number of processors on a system. You can run the version concurrently on different processors to reduce processing time. The Auto Fulfillment Load Balance report (R4277711) launches a version of the Auto Fulfillment Processing report (R4277701) multiple times, and distributes the sales detail records over the versions.

- 2. Version of Auto Fulfillment

-

Specify the version of the Auto Fulfillment Processing report (R4277701) that the system runs. If you leave this processing option blank, the system uses version XJDE0001.

- 3. Run Auto Fulfillment

-

Specify whether the Auto Fulfillment Load Balance report (R4277711) runs the Auto Fulfillment Processing report (R4277701). Values are:

Blank: Do not run the Auto Fulfillment Processing report (R4277701).

1: Run the Auto Fulfillment Processing report (R4277701).

Note (Release 9.1 Update):

When you set the Load Balancer report to run Auto Fulfillment, the system does not run the Release from Fulfillment report (R4277703) regardless of whether you set the version of Auto Fulfillment report to run in proof or final mode. This eliminates record reservation conflicts for the sales orders potentially being processed by both the Load Balancer for Auto-Fulfillment and the Release from Fulfillment report.

6.5.2.2 Print

- 1. Print Load Balance Information

-

Specify whether the system prints load balance information in a report. Values are:

Blank: Do not print load balance information.

1: Print load balance information.

6.6 Running the Purge Fulfillment Plan ID Report (R4277710)

This section discusses how to run the Purge Fulfillment Plan ID report.

The Fulfillment Plan is a set of order lines that the system designates to be fulfilled. The Auto Fulfillment Processing report produces an initial fulfillment plan and assigns a Fulfillment Plan ID to all of the order lines that the system considers. You can use the Fulfillment Workbench program (P4277701) to validate and change the order lines in the fulfillment plan.

The Purge Fulfillment Plan ID report (R4277710) determines whether a Fulfillment Plan ID exists within the specified data selection for the Fulfillment Plan ID table (F4277710) and in the Sales Order Detail table (F4211). The system does not purge the record from the F4277710 table if records exist in the F4211. If no records match the specified data selection, the system displays a message indicating that no data has been selected.

6.6.1 Running Purge Fulfillment Plan ID

Select Fulfillment Management Advanced & Technical Ops (G4277730), Purge Fulfillment Plan ID.

|

Note: This report does not have processing options. |