Understanding Electronic Data Collection

Understanding Electronic Data Collection

This chapter provides an overview of electronic data collection and discusses how to:

Use electronic data collection transactions.

Use background transaction processes.

Purge transactions.

Generate labels.

Manage files.

Understanding Electronic Data Collection

Understanding Electronic Data Collection

Electronic data collection enables you to:

Increase the accuracy of data entry.

Decrease the amount of time spent on data entry.

You can use the electronic data collection components to capture data from:

Bar code devices.

External feeds.

Direct data entry.

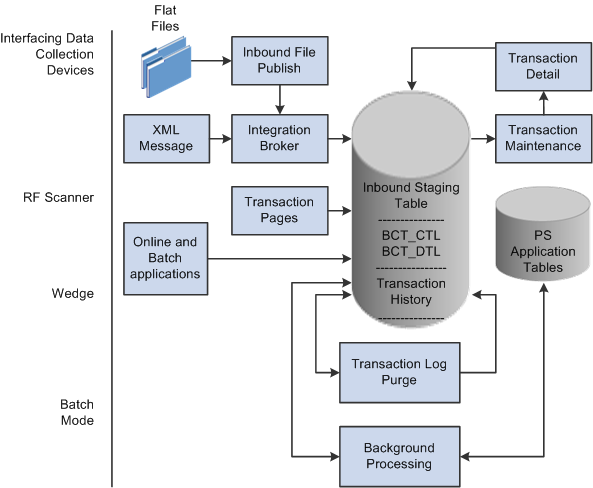

The following diagram shows the data flow for electronic data collection. Data from flat files or XML messages are placed in the inbound staging tables by the PeopleSoft Integration Broker system. Online or batch applications can also place data directly into the inbound staging tables. Background processes apply the data to the PeopleSoft production tables. Any errors are handles by the Transaction Maintenance component. The Purge process will delete all transactions with a status of Complete or Confirmed from the transaction log:

Electronic data collection data flow

See Also

Device Selection

Device Selection

The first step in designing an electronic data collection system is to select the data collection devices you will use to process bar code material movement transactions. PeopleSoft provides support for three bar code technologies:

Radio Frequency

Radio frequency (RF) systems are used when immediate access to the database is required. This technology requires RF terminals and controllers. RF data collection applications, developed in-house or by third-party vendors, produce transactions that are passed to the PeopleSoft applications through PeopleSoft Integration Broker using XML messages.

Batch

Batch systems are used when real-time updates are not needed. Batch-oriented data collection applications, developed in-house or by a third-party vendor, produce transactions that are collected in an ASCII text file. The text file is loaded into the PeopleSoft system using the Inbound File Publish utility.

Keyboard Wedge

Keyboard wedges can be used when the person collecting the bar-coded information has access to a workstation running the PeopleSoft application. A wand or a laser gun connects to the keyboard wedge that inputs the bar-coded information directly into the transaction pages. The computer interprets information entered using the keyboard wedge in the same manner as information entered using the keyboard.

See Also

Using Electronic Data Collection Transactions

Using Electronic Data Collection Transactions

Data collection transactions received through XML messages, batch oriented flat files, and the transaction pages are loaded into the transaction log. Background processes pick up these transactions, validate them, and then update the appropriate PeopleSoft application tables. If an error is found, the system does not process the transaction. The transaction's status on the transaction log is changed to Error, and the system inserts a row into the error table for each error message.

The BCt Errors Workflow process (IN_WFBCTERRS) checks for electronic data collection transactions that have an error status and generates a worklist entry. Once you process the worklist entry, the PeopleSoft system displays the Transaction Maintenance page, where you can view the errors and fix them.

Once you have modified the transaction and saved the Transaction Maintenance Detail page, the transaction can be reprocessed. Transactions that have been processed to the Complete status or that have been canceled in the Transaction Maintenance page can be archived and purged from the transaction log using the transaction purge process.

The background processes validate all information before performing any updates. However, when you enter the transactions through the data collection transaction pages, selected pieces of information on the page have edits to verify the data that is entered.

For technical details about individual EIPs, use the Interactive Services Repository (ISR) in the My Oracle Support website located at https://support.oracle.com/CSP/ui/flash.html.

Using Background Transaction Processes

Using Background Transaction Processes

You set up electronic data collection background processes to scan the transaction log continuously as long as there are transactions in the log with the status New or Reprocess. If no transactions with the status New or Reprocess are in the log when a process scans the log, the process shuts down. If the process shuts down, you can restart it with PeopleSoft Process Scheduler. Because you can set up Process Scheduler to automatically restart the background processes at predefined intervals, transaction processing can occur continuously or at set periods throughout the day.

|

Transaction |

Page Name |

Process Name |

Tables Accessed |

Tables Updated |

|

Inventory Adjustments |

BCT_INV_REQIADJ |

INPVIADJ |

BCT_INV_REQIADJ |

BCT_INV_REQIADJ |

|

Interunit Receiving |

BCT_INV_REQIURV |

INPJIURV |

BCT_INV_REQIURV |

BCT_INV_REQIURV |

|

Inventory Picking and Shipping |

BCT_INV_REQPICK |

IN_FUL_PFB |

BCT_INV_REQPICK |

BCT_INV_REQPICK |

|

Inventory Putaway |

BCT_NV_REQPWFB |

INPZPTWY |

BCT_NV_REQPWFB |

BCT_NV_REQPWFB |

|

Inventory Transfers |

BCT_INV_REQTRFR |

INPTTRFR |

BCT_INV_REQTRFR |

BCT_INV_REQTRFR |

|

Physical Inventory |

BCT_INV_REQPHYS |

INPIPHYS |

BCT_INV_REQPHYS |

BCT_INV_REQPHYS |

|

Ship Containers and Serial IDs |

BCT_INV_REQSHPM |

INPFSHPM |

BCT_INV_REQSHPM |

BCT_INV_REQSHPM |

|

Shipping Request |

BCT_INV_REQFUL |

INV_FUL_BCT |

RUN_CNTL_IN_FUL |

RUN_CNTL_IN_FUL |

|

Production Picking |

BCT_MG_REQPIK |

SFPEPICK |

BCT_MG_REQPIK |

BCT_MG_REQPIK |

|

Kanban Replenishment Requests |

BCT_MG_REQREPL |

FPPAREPL |

BCT_MG_REQREPL |

BCT_MG_REQREPL |

|

Production and Completions Scrap |

BCT_MG_REQCOMP |

SFPDCDRV |

BCT_MG_REQCOMP |

BCT_MG_REQCOMP |

|

Kit Issues and Returns |

BCT_MG_REQMISC |

SFPFMISC |

BCT_MG_REQMISC |

BCT_MG_REQMISC |

|

Actual Hours |

BCT_MG_REQACT |

SFPGACTH |

BCT_MG_REQACT |

BCT_MG_REQACT |

|

Load Purchase Order Receipts |

RUN_RECVLOAD |

PO_RECVLOAD |

RUN_CNTL_RECVLD |

RUN_CNTL_RECVLD |

See Also

Making Stock Quantity Adjustments and Transfers Within the Business Unit

Working with Shipping Containers and Shipping Serial IDs Using an Electronic Data Collection System

Creating Replenishment Requests Using Electronic Data Collection

Processing Picking Plans Using Electronic Data Collection

Processing Electronic Data Collection Completions Transactions

Processing Kit Issues and Returns

Running the Actual Hours Data Collection COBOL/SQL Process

Purging Transactions

Purging Transactions

You can periodically purge data collection transactions. The data collection architecture uses the standard purge process for PeopleSoft Supply Chain Management inbound transactions.

See Also

Generating Labels

Generating Labels

To generate bar code labels, you must first set up the attributes for each label type on the Label Setup page. Next, you generate a flat file containing the label data by running a PeopleSoft Process Scheduler Structured Query Report (SQR) program from the label-specific run control page. Use the Generate Labels component to create this flat file. Finally, you pass the flat file to an in-house or a third-party bar code label product to print the labels.

The PeopleSoft system can print 10 types of labels:

|

Purchasing Receipt labels |

Use these labels to track items that are received by the business unit. Receiving labels are generated for each item on a receipt. To print these labels, you must have PeopleSoft Purchasing installed. |

|

Production Completion labels |

Apply these labels to items that have been manufactured. To print these labels, you must have PeopleSoft Manufacturing installed. |

|

Pull Ticket labels |

Use these labels to track material replenished from online replenishment requests. To print these labels, you must have PeopleSoft Flow Production installed. |

|

Kanban Card labels |

Use these labels to track material replenished by Kanban Card. To print these labels, you must have PeopleSoft Flow Production installed. |

|

Storage Location labels |

Use these labels on storage locations, such as aisles, rows, and bins, in a business unit. To print these labels, you must have PeopleSoft Inventory installed. |

|

Item Storage labels |

Use these labels to identify items in a carton or storage location. To print these labels, you must have PeopleSoft Inventory installed. |

|

Storage Container labels |

Use these labels to identify storage containers at a storage locations. To print these labels, you must have PeopleSoft Inventory installed. |

|

Shipping Carton labels |

Apply these labels to each carton before shipping to provide shipping information to shipping personnel and carriers. You can also use them to build shipping containers, and to provide customer-specific information that identifies items within the cartons. To print these labels, you must have PeopleSoft Inventory installed. |

|

Shipping Serial labels |

Use these labels to identify a serial ID assigned to items at the time the items are shipped. To print these labels, you must have PeopleSoft Inventory installed. |

|

Shipping Container labels |

Use these labels to identify shipping containers. Shipping container labels can be used to provide shipping information to shipping personnel, carriers, and customers. To print these labels, you must have PeopleSoft Inventory installed. |

|

Item Usage labels |

Use these labels to identify medical supplies used for patients. To print these labels, you must have PeopleSoft Inventory installed. |

See Also

Managing Files

Managing Files

This section discusses how you work with files when generating labels.

Override File

To specify a file directory and file name for the extraction file, select the Override File check box, and enter the file directory and file name. Deselect the Override File check box to create the extraction file in the default directory with the default file name.

File Directory

Enter a directory path for the label file.

If you do not select the Override File check box, on any label except the Carton Label, the directory is selected according to the following hierarchy:

The directory name is the FILEPREFIX that was specified in SETENV.SQC during the initial system setup.

For information on setting the FILEPREFIX in the SETENV.SQC, refer to the PeopleTools Installation and Administration for the platform.

If no FILEPREFIX was specified during system setup, the directory name is by default the current work directory on the server running the label program.

File Name

Enter a file name for the label file.

If you do not select the Override File check box, on any label except the carton label, the file is named according to the following hierarchy:

The file name is the file prefix that is defined for the format ID (on the Data Collection Label Setup page in the Generate Labels window) combined with the last five digits of the process ID; the file name suffix is the file suffix defined for the format ID.

If no format ID is specified on the Data Collection Label Setup page, the last five digits of the process ID are used as the file name, and the file name suffix is the file suffix defined on the Data Collection Setup page in Process Transactions.

If no file suffix is defined on the Data Collection Setup page, the last five digits of the process ID are used as the file name, and the file name suffix is the FILESUFFIX that you specified in SETENV.SQC when you initially set up the system.

For information on setting the FILESUFFIX in the SETENV.SQC, refer to the installation documentation.

If no file suffix was specified in SETENV.SQC when you initially set up the system, the last five digits of the process ID are used as the file name, and no suffix is appended.

The following table indicates the sequence of defaults that the system uses when assigning file names:

|

File Prefix |

File Name |

File Suffix |

|

Override |

Override |

Override |

|

From format ID specified on the Data Collection Label Setup page. |

The last five digits of the process ID. If multiple requests can be entered on the label request page, then an additional two-digit sequential number starting with 01 is appended to the end of the file name. |

From format ID specified on the Data Collection Label Setup page. |

|

None |

The last five digits of the process ID. If multiple requests can be entered on the label request page, then an additional two-digit sequential number starting with 01 is appended to the end of the file name. |

The file suffix defined on the Data Collection Setup page. |

|

None |

The last five digits of the process ID. If multiple requests can be entered on the label request page, then an additional two-digit sequential number starting with 01 is appended to the end of the file name. |

The FILESUFFIX that you specified in SETENV.SQC. |

|

None |

The last five digits of the process ID. If multiple requests can be entered on the label request page, then an additional two-digit sequential number starting with 01 is appended to the end of the file name. |

None. |

See Also

Printing Shipping Carton Labels

Common Elements Used in This Section

Common Elements Used in This Section|

Language |

Select a language for the legible portion of the labels. |

|

Business Unit or Unit |

Select the unit for which to print labels. |

|

Format ID |

Enter a label format ID. Label formats are defined on the Data Collection Label Setup page. If you set up a default label format, its ID appears in this field. |

|

Copies |

Enter the number of copies of each label to print. When printing serial or sequential labels, if you increase the number in this field, the system multiplies the number of labels that you print. For example, if you are printing six labels in a sequence, and the number of copies is 1, then six labels print. However, if the number of copies is 2, then two copies of each label print, for a total of 12 labels. |

Pages Used to Print Labels

Pages Used to Print Labels|

Page Name |

Definition Name |

Navigation |

Usage |

|

RUN_PO_RECEIPT |

|

If you have PeopleSoft Purchasing installed, select the process request parameters for purchasing receipt labels. Purchasing receipt labels are used to track items that are received by the business unit. Receiving labels can be generated for each item on a receipt. |

|

|

RUN_SFS7004 |

SCM Integrations, Barcode Labels, Completion Label, Production Select |

Select the business unit for which to print labels. You can also indicate whether printed labels are based on a production ID or production schedule. |

|

|

RUN_SFS7004B |

SCM Integrations, Barcode Labels, Completion Label, Completion Labels |

Select the number of labels to print. |

|

|

RUN_FPS6500 |

|

Indicate how you want to print pull tickets and pull lists. |

|

|

RUN_FPS6500A |

|

Make the printing selection. |

|

|

RUN_FPS6510 |

|

Print Kanban Card labels. |

|

|

RUN_FPS6510A |

|

Select the kanban card label range. |

|

|

RUN_INS9025 |

SCM Integrations, Barcode Labels, Storage Location Label |

Select the process request parameters for printing bar code labels for storage locations. |

|

|

RUN_INS9010 |

SCM Integrations, Barcode Labels, Item Storage Label |

Select the process request parameters for printing bar code labels for items in storage. |

|

|

RUN_INS9015 |

SCM Integrations, Barcode Labels, Storage Container Label |

Select the process request parameters for printing container labels for storage container IDs. |

|

|

RUN_INS6025 |

SCM Integrations, Barcode Labels, Shipping Carton Label |

Select the process request parameters for shipping carton labels. The shipping carton labels can be automatically printed during picking. |

|

|

RUN_INS6035 |

SCM Integrations, Barcode Labels, Serial Label |

Select the process request parameters for shipping serial labels. If you assign a shipping serial label ID at shipping time, you can track items after they have been shipped. |

|

|

RUN_INS6030 |

SCM Integrations, Barcode Labels, Shipping Container Label |

Select the process request parameters for shipping container labels. |

|

|

RUN_INS6040 |

SCM Integrations, Barcode Labels, Item Usage Label |

Select the process request parameters for item usage labels. |

Printing Purchasing Receipt Labels

Printing Purchasing Receipt Labels

Access the Purchasing Receipt Labels page (SCM Integrations, Barcode Labels, PO Receipt Label, PO Receipt Labels).

To print all receiving labels staged by the user ID:

Select the Reprint Labels check box to reprint receiving labels.

The Business Unit, Receiver ID Number and Receiver Line Number fields will become available for entry if the Reprint Labels check box is selected.

Select the receiver ID number for which you want to reprint labels.

Enter the receiver line number for the item and quantity for which you want to reprint labels.

Process Type

SQR Report

Tables Accessed

BCT_LABEL_FS

BCT_SETUP_FS

RECV_RUN_CNTL

RECV_LABEL_TBL

SET_CNTRL_REC

SET_CNTRL_TREE

RECV_LN

RECV_LN_ASSET

BU_ITEMS_INV

Tables Updated

RECV_LABEL_TBL

Printing Completion Labels

Printing Completion Labels

Access the Completion Labels page (SCM Integrations, Barcode Labels, Completion Label).

To print completion labels by production ID or by production schedule:

To print completion labels by production ID, enter the production ID.

To print completions labels by production schedule, enter the production area and item ID.

If the item is revision controlled, select a revision code if the revision is required on the labels.

Once the process request parameters are entered, click the Search button to access the Completion Labels page.

Note. If the conversion rate between the standard unit of measure (UOM) and the standard pack UOM is not set up for this item, the page produces an error message, and the system does not display the Completion Labels page.

Tables Accessed

MASTER_ITEM_TBL

INV_ITEMS

BCT_LABEL_FS

BCT_SETUP_FS

RUN_CNTL_SF

Tables Updated

RUN_CNTL_SF

Printing Pull Ticket Labels

Printing Pull Ticket Labels

Access the Pull Ticket/Pull List Options page (Manufacturing Definitions, Kanban, Electronic Kanbans, Print Pull Ticket/Pull List, Pull Ticket/Pull List Options).

|

WIP Replenishment Output Opt |

Choose one of the three options for the WIP Replenishment Output Options.

Note. PeopleSoft delivers printer settings for all SQR output to a generic line printer. However, when printing bar coded information on reports on a PCL printer (HP Laser Jet), you must first define the printer type accordingly. You may do this by changing the printer type settings delivered in SETENV.SQC from LINEPRINTER to HPLASERJET. |

|

Format ID |

Select a Format ID for the extract file. You set up format IDs on the Data Collection Label Setup page. |

|

File Directory and File Name |

Enter the File Directory and File Name to which you want to save the pull ticket file extract. |

|

Request Print Status Option |

Select a Request Print Status Option: Not Printed, Previously Printed, or Both Printed and Unprinted. |

See Also

Setting Up WIP Replenishment Item Attributes

Understanding Kanban Cards and Production Replenishment Requests

Printing Kanban Card Labels

Printing Kanban Card Labels

Access the Print Kanban Cards page (SCM Integrations, Barcode Labels, Kanban Card Label, Print Kanban Cards).

|

WIP Repl Kanban Card Output |

Choose one of the three options for the WIP Replenishment Kanban Card Output options.

Note. PeopleSoft delivers printer settings for all SQR output to a generic line printer. However, when printing bar coded information on reports on a PCL printer (HP Laser Jet), you must first define the printer type accordingly. You may do this by changing the printer type settings delivered in SETENV.SQC from LINEPRINTER to HPLASERJET. |

|

Format ID |

Select a Format ID for the extract file. You set up format IDs on the Data Collection Label Setup page. |

|

File Directory and File Name |

Enter the File Directory and File Name to which you want to save the Kanban card file extract. |

|

Request Print Status Option |

Select a Request Print Status Option: Not Printed, Previously Printed, or Both Printed and Unprinted. |

If you print Kanban cards that haven't been previously printed, the system changes the Kanban ID status to Open from New. Cards that were previously printed display Reprint on the card.

See Also

Setting Up WIP Replenishment Item Attributes

Understanding Kanban Cards and Production Replenishment Requests

Selecting the Kanban Card Label Range

Selecting the Kanban Card Label Range

See Understanding Kanban Cards and Production Replenishment Requests.

Printing Storage Location Labels

Printing Storage Location Labels

Access the Storage Location Label page (SCM Integrations, Barcode Labels, Storage Location Label).

To print storage location labels:

Select the storage areas for which you want to print labels in the storage area fields.

If you select only the first level, the system prints labels for all the storage locations in that area down to the lowest level.

If you want to print labels for all the locations in your warehouse, then you would enter the area fields only to the warehouse level.

If you want to print labels for all the bins in an aisle, then you would enter the storage area fields down to the aisle level.

Tables Accessed

BCT_LABEL_FS

BCT_SETUP_FS

STOR_LOC_INV

Tables Updated

RUN_CNTL_IN

Printing Item Storage Labels

Printing Item Storage Labels

Access the Item Storage Label page (SCM Integrations, Barcode Labels, Item Storage Label).

To print item storage labels:

Select the Autogenerate Labels check box to have the system automatically generate all the item labels that you need for a storage location.

The Stor Loc (storage location) fields are required only if you use the Autogenerate Labels option.

Use these fields if you want to print labels for all the items in a specific storage location.

If you select Autogenerate Labels and enter a storage area, you can enter the unit of measure by which you want to print the labels in the Group UOM (group unit of measure) field.

For example, Location B01 has a quantity of 100 EA (each). You select group UOM of CS (case). If there are 25 each per case, then the system generates four labels. If you select a group UOM of EA (each), then the system generates 100 labels.

If you select a serial-controlled item, the Group UOM field automatically appears with the standard unit of measure for the item and is unavailable for entry.

One label per serial ID is printed.

If you enter a storage area for a lot-controlled, serial-controlled, staged date tracked, or actual costed item, the system verifies that the item exists in the specified storage area.

Tables Accessed

BCT_LABEL_FS

BCT_SETUP_FS

BU_ITEMS_INV

INV_ITEMS

INV_STCK_UOM_VW

MASTER_ITEM_TBL

PO_RECEIVED_INV

Tables Updated

RUN_CNTL_IN

Printing Storage Container Labels

Printing Storage Container Labels

Access the Storage Container Labels page (SCM Integrations, Barcode Labels, Storage Container Label).

To print storage container labels:

Select a storage container prefix in the Beg Seq (beginning sequence) field.

The storage container prefixes are defined on the Automatic Numbering page.

Enter the number of labels that you want to print in the Nbr in Seq (number in sequence) field.

The next sequence of labels for the storage container prefix that you entered are printed. The last sequence number used for the storage container prefix that you entered is saved in the system.

Tables Accessed

BCT_LABEL_FS

BCT_SETUP_FS

AUTO_NUM_TBL

Tables Updated

AUTO_NUM_TBL

RUN_CNTL_IN

Printing Shipping Carton Labels

Printing Shipping Carton Labels

Access the Shipping Carton Label page (SCM Integrations, Barcode Labels, Shipping Carton Label).

If the format ID is not entered, it automatically appears first from the ship to location, then from the sold to location, or then from the Label Setup page, in that order, depending on which of these values exist.

To specify a file directory and file name for the label extraction file, select the Override File check box, and enter the file directory and file name. Deselect the Override File check box to create the extraction file in the default directory with the default file name.

To select the directory for the carton label file, use the following hierarchy:

The path you specify for the file directory takes precedence.

If you do not specify a file directory, the directory automatically appears the Pick Plan Bar Coding Options page in the Setup Fulfillment component (ORDER_FULF_SETUP).

If no directory is specified on the Pick Plan Bar Coding Options page in the Setup Fulfillment component, the directory name is the FILEPREFIX that was specified in SETENV.SQC during the initial system setup.

For information on setting the FILEPREFIX in the SETENV.SQC, refer to the installation documentation.

If no FILEPREFIX was specified during system setup, the directory name defaults to the current directory where the label program is running.

To name the file for the carton label file, use the following hierarchy:

The file name specified in the File Name field takes precedence.

If you don't specify a file name, the file name is the file prefix defined on the Pick Plan Bar Coding Options page in the Setup Fulfillment component combined with the last five digits of the process ID and the file suffix defined on the Pick Plan Bar Coding Options page.

If nothing is specified on the Pick Plan Bar Coding Options page, the last five digits of the process ID are used as the file name and the file name suffix is the FILESUFFIX that you specified in SETENV.SQC when you initially set up the system.

For information on setting the FILESUFFIX in the SETENV.SQC, refer to the installation documentation.

If no FILESUFFIX was specified in SETENV.SQC when you initially set up the system, the last five digits of the process ID are used as the file name and no suffix is appended.

|

File Prefix |

File Name |

File Suffix |

|

Override |

Override |

Override |

|

The file prefix defined on the Pick Plan Bar Coding Options page in the Setup Fulfillment component. |

The last five digits of the process ID. If multiple requests can be entered on the label request page, then an additional two-digit sequential number starting with 01 is appended to the end of the file name. |

The file suffix defined on the Pick Plan Bar Coding Options page in the Setup Fulfillment component. |

|

None |

The last five digits of the process ID. If multiple requests can be entered on the label request page, then an additional two-digit sequential number starting with 01 is appended to the end of the file name. |

The FILESUFFIX that you specified in SETENV.SQC. |

|

None |

The last five digits of the process ID. If multiple requests can be entered on the label request page, then an additional two-digit sequential number starting with 01 is appended to the end of the file name. |

None. |

Tables Accessed

BCT_LABEL_FS

BCT_SETUP_FS

BU_ITEMS_INV

CARRIER_ID

CUST_ADDRESS

CUST_SHIPTO_OPT

CUST_SOLDTO_OPT

IN_DEMAND

DF_SETUP_INV

DF_SETUP_IT_INV

INV_ITEM_UOM

INV_ITEMS

ISSUE_HDR_INV

LOCATION_TBL

MASTER_ITEM_TBL

ORD_LINE

Tables Updated

RUN_CNTL_IN

Printing Shipping Serial Labels

Printing Shipping Serial Labels

Access the Shipping Serial Labels page (SCM Integrations, Barcode Labels, Serial Label).

Tables Accessed

AUTO_SERIAL_NUM

BCT_LABEL_FS

BCT_SETUP_FS

Tables Updated

AUTO_SERIAL_NUM

RUN_CNTL_IN

Printing Shipping Container Label

Printing Shipping Container Label

The UCC/EAN manufacturer ID is included in the extract file for the shipping container labels. The UCC/EAN manufacturer ID along with the shipping container serial ID provide a unique identifier to create a unique shipping ID for the shipping container.

Note. You cannot print shipping container labels for more than one location at a time. If the criteria that you specify include multiple ship to locations, a warning message appears requesting that you narrow the criteria until only one ship to location is included.

Tables Accessed

BCT_LABEL_FS

BCT_MFGID_SETUP

BCT_SETUP_FS

CARRIER_ID

CUST_ADDRESS

CUST_SHIPTO_OPT

CUST_SOLDTO_OPT

IN_DEMAND

ISSUE_HDR_INV

LOCATION_TBL

ORD_LINE

Tables Updated

BCT_MFGID_SETUP

IN_DEMAND

RUN_CNTL_IN

See Also

Setting Up the UCC/EAN Manufacturer ID

Understanding Shipping Containers and Packing Sessions