Creating Orders Using Data From a Third-Party System

Using the Enterprise Integration Points (EIPs) available through the PeopleSoft Integration Broker, you can create materials stock requests (MSR) based on data from a third-party source. Use the following service operations to create a new MSR or add a new demand line to an existing MSR in PeopleSoft Inventory:

Inventory_Create_Stock_Request: Using transaction code 0360 (Create Stock Request), your message transaction can create an MSR in the Unfulfilled state. For non-soft reserve, non-ATP items, you can have the new MSR demand line placed in the Releasable state by:

Selecting the Auto Stock Approval check box on the Setup Fulfillment page.

Selecting the value of Releasable in the Non-Soft Reserved State field of the Setup Fulfillment page.

Inventory_Front_End_Shipping: Using the transaction code 0365 (Front-end Ship), your message transaction can create an MSR and then place it in the Shipped state. This EIP is commonly used to move existing MSRs from the Unfulfilled or Releasable states to the Shipped state. To use this EIP to create an MSR, you must enter Y (yes) in the Create Demand field (IN_CREATE_DMD_FLG) of your transaction. In addition you can enter 70 (advance to depleted) in the Auto Release Option field (AUTO_RELEASE_OPT) of your transaction to move your new MSR to the Depleted state.

Inventory_Shipping: Using the transaction code 0366 (Ship), this message transaction can create an MSR and then place it in the Shipped state. This EIP is commonly used to move existing MSRs from the Unfulfilled, Releasable, or Confirmed states to the Shipped state. To use this EIP to create an MSR, you must enter Y (yes) in the Create Demand field (IN_CREATE_DMD_FLG) of your transaction. In addition you can enter 70 (advance to depleted) in the Auto Release Option field (AUTO_RELEASE_OPT) of your transaction to move your new MSR to the Depleted state.

The third-party data is processed as follows:

The PeopleSoft Integration Broker receives an inbound XML message into the INVENTORY_FULFILLMENT queue. The Fulfillment Request Handler, a PeopleTools application class, formats the incoming data and populates the staging tables. For each request, the Fulfillment Request Handler assigns a unique ID called the EIP_CTL_ID. Some validations are performed by the Fulfillment Request Handler, if the inbound message fails these validations then an error is generated and the message is not inserted into the staging tables.

The Fulfillment Requests process (IN_FUL_BCT) retrieves the transaction requests from the staging tables, processes them, and applies them to the PeopleSoft Inventory demand tables. You can:

Run this process manually.

Schedule this process to run in the background on a regular basis.

Have the system automatically launch the process when transaction requests are posted to the staging tables. To automatically launch the Fulfillment Requests process, select the Auto Schedule Processing check box on the Setup Fulfillment-Fulfillment Tasks page.

If the transaction requests are successfully processed, then they are set to a status of complete. If the transaction requests are not processed successfully, they are given an error status, and the appropriate error message is provided. The Maintain Transactions component enables you to view and correct requests that contain errors. Once corrected, you can relaunch the Fulfillment Requests process. This is an optional step, you can choose to have the request errors canceled automatically, and then you could create another request.

The Inventory_Create_Stock_Request, Inventory_Front_End_Shipping, and Inventory_Shipping EIPs can create all four types of orders:

External Order: Creates an MSR for an external order. While this request type enables you to identify the individual receiving the stock by using a ship-to customer rather than a location, it is not intended to replace the features of a sales order. To complete a full billing and invoice transaction, create a sales order in PeopleSoft Order Management.

InterUnit Transfer: Creates an MSR that transfers stock from one PeopleSoft Inventory business unit to another. This includes the ability to create an intercompany transfer. For an interunit transfer, if you have selected the Allow Price/Markup Overrides check box on the Setup Fulfillment page of the source business unit, you can use this EIP to override the transfer price calculated from the Transfer Pricing Definition component. When you enter an override value for the price markup percentage, the system records the markup using the cost element in the Default Markup Cost Element field in the Setup Fulfillment page. PeopleSoft Cost Management does not support interunit pricing for non-cost items.

Internal Issue: Creates an MSR for an internal order (an order for a department or location within your organization). This includes the ability to create an interunit expensed issue. For an interunit expensed issue, if you have selected the Allow Price/Markup Overrides check box on the Setup Fulfillment page of the source business unit, you can use this EIP to override the transfer price, price markup percentage, or the transfer at zero price check box. When you enter an override value for the price markup percentage, the system records the markup using the cost element in the Default Markup Cost Element field in the Setup Fulfillment page.

Supplier Returns: Creates an MSR for a return-to-vendor (RTV) order. Based on your setup, the Inventory_Create_Stock_Request EIP and the Inventory_Shipping EIP can be launched when the RTV transaction is saved in PeopleSoft Purchasing.

The following rules apply when creating MSRs using these service operations:

The transaction request can be used to add a new demand line to an existing stock request, but it cannot be used to update data on an existing demand line; for example, it cannot update an item ID, a date, or a quantity on an existing line. If the transaction request contains an MSR demand line that already exists, then the transaction is given a status of error.

You can only create MSRs with a demand source of IN (inventory) or RT (return to vendor). These EIPs cannot be used to generate orders with a demand source of OM, PL, PR, or WM. For example, you cannot create sales order from PeopleSoft Order Management, work orders from PeopleSoft Maintenance Management, orders based on requisitions from PeopleSoft Purchasing, or planning updates from PeopleSoft Supply Planning.

You cannot enter a parent product ID, for product kits, on the transaction request. The Create Stock Requests application engine program does not process a parent product ID and explode it into the individual kit component demand lines.

You can pre-allocate a demand line that is being created in the unfulfilled state using the Inventory_Create_Stock_Request service operation. To create a pre-allocation, you can either:

Enter the material storage location (MSL) on the header, group, or detail level of the transaction.

Define an LLS level of the transaction; entering the material storage location (MSL) or lot ID.

You cannot create new MSRs or new demand lines to existing MSRs using the Inventory_Reservation EIP or the Inventory_Pick_Confirm EIP.

You cannot create a pegged demand line.

When the Inventory_Create_Stock_Request, Inventory_Front_End_Shipping, or Inventory_Shipping EIP is used to create a material stock request or new demand lines, the system uses the pass-through level of Request. The Request level insures that any errors in the transaction request prevent the entire request from being processed. However, pass-through processing does not apply to pre-allocation errors; any demand line that fails pre-allocation is still created and no other segments of that demand line's request will error. For complete information on the pass-through feature and the default hierarchy of these fields, see the PeopleSoft Inventory documentation, "Utilizing the Fulfillment Engine" topic, "Setting Up the Fulfillment Engine Processing Options" section.

The transaction requests do not use the processing feature (processing count and processing level) and the commit feature (commit count and commit level).

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

Service Operations-General Page |

IB_SERVICE |

Define and activate a service operation. Before transmitting data, you must perform the setup steps to activate the service operations. This is a setup step that is not repeated for each transaction request. See Using the Inventory Create Stock Request Message in PeopleSoft Integration Broker |

|

Message Definition Page |

IB_MESSAGE_BUILDER |

View the fields to be used by the service operation within PeopleSoft Integration Broker. In order to correctly populate the incoming data, review the message definition. This is a setup step that is not repeated for each transaction request. See Using the Inventory Create Stock Request Message in PeopleSoft Integration Broker |

|

BCT_INV_REQFUL |

Establish run control parameters for the Fulfillment Requests process to retrieve the transaction requests from the staging tables, process them, and apply them to the PeopleSoft Inventory demand tables. |

|

|

BCT_CTL_UPD |

View all electronic transactions in the transaction log (inbound staging tables) and access the detail pages that enable you to correct transaction errors. See also, Viewing the Transaction Requests |

|

|

Transaction Maintenance - Create Stock Request Page |

BCT_INV_UPD_MSR |

View header-level information of a create stock request transaction. You can view the status of the entire transaction request and view any error messages found during the Fulfillment Requests process. See Correcting Errors in a Create Stock Request Transactions. |

|

Transaction Maintenance - Create Stock Request: Group Records Page |

BCT_INV_UPD_MSRGRP |

Displays the MSRs (orders) within this transaction request. Using the group-level, you can view or edit fields related to the order header; such as, order number or customer ID. See Correcting Errors in a Create Stock Request Transactions. |

|

Transaction Maintenance- Create Stock Request: Detail Records Page |

BCT_INV_UPD_MSRDTL |

Displays a single order line within this transaction request. Using the detail-level, you can view or edit information related to one order line within an MSR on the transaction request. See Correcting Errors in a Create Stock Request Transactions. |

|

Transaction Maintenance- Create Stock Request: Location, Lot, Serial Records Page |

BCT_INV_UPD_MSRLLS |

Displays the LLS levels of a single order line within a transaction request. Using the LLS-level, you can view or edit information related to lot ID, serial ID, or material storage locations (MSL) along with container IDs and stage dates. See Correcting Errors in a Create Stock Request Transactions. |

|

Transaction Maintenance- Create Stock Request: Group Level User-Defined Fields Page |

BCT_INV_UPD_MSRGUD |

Displays the user-defined field of the MSR. See Correcting Errors in a Create Stock Request Transactions. |

|

Transaction Maintenance- Create Stock Request: Detail Level User-Defined Fields Page |

BCT_INV_UPD_MSRDUD |

Displays the user-defined fields of the order line. See Correcting Errors in a Create Stock Request Transactions. |

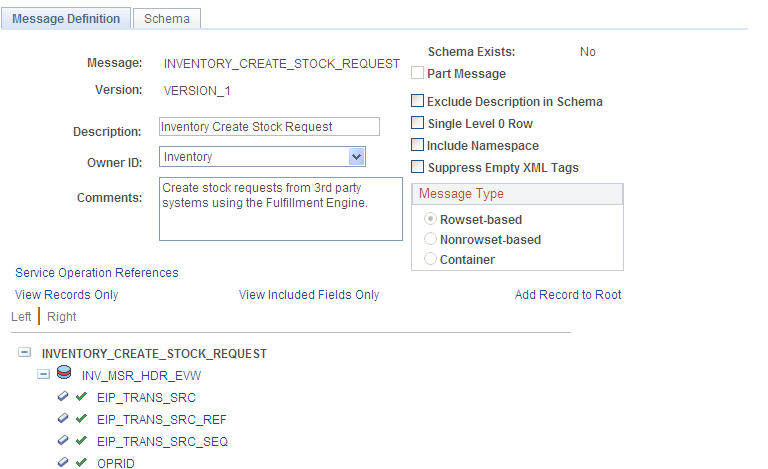

Use the Message Definition page (IB_MESSAGE_BUILDER) to view the fields to be used by the service operation within PeopleSoft Integration Broker.

In order to correctly populate the incoming data, review the message definition. This is a setup step that is not repeated for each transaction request.

Navigation:

This example illustrates the fields and controls on the View the fields included in the message used by the INVENTORY_CREATE_STOCK_REQUEST service operation (1 or 2). You can find definitions for the fields and controls later on this page.

This example illustrates the fields and controls on the View the fields included in the message used by the INVENTORY_CREATE_STOCK_REQUEST service operation (2 of 2, partial page). You can find definitions for the fields and controls later on this page.

In order to correctly populate the incoming data, review the message definition. Message definitions provide the physical description of the data that is being sent, including; fields, field types, and field lengths. Messages do not contain any processing logic. All processing logic is defined in service operations, using service operation handlers. In this section, consider some important fields in the INVENTORY_CREATE_STOCK_REQUEST message.

This message structure contains:

INV_MSR_HDR_EVW: The header level containing fulfillment transaction request header information.

INV_MSR_GRP_EVW: The group level containing order (MSR) level information.

INV_MSR_DTL_EVW: The detail level containing the order line information.

INV_MSR_LLS_EVW: The LLS level containing the location/lot/serial of a demand line. You can pre-allocate a demand line by using the LLS level of the transaction request to specify the picking location or lot ID.

The following fields are required on the incoming transaction request:

Business Unit (BUSINESS_UNIT)

Request Type (REQUEST_TYPE)

Item ID (INV_ITEM_ID)

Quantity Requested (QTY_REQUESTED)

Unit of Measure (UNIT_OF_MEASURE) Enter a unit of measure defined as an ordering UOM for this item ID on the Units of Measure page (Items, Define Items and Attributes, Units of Measure).

One of the following:

Destination Business Unit (DESTIN_BU) for interunit transfers, including intercompany transfers.

Customer (CUST_ID), Ship-To Customer (SHIP_TO_CUST_ID), and Address Sequence Number (ADDRESS_SEQ_NUM) for external orders.

Location (LOCATION) for internal issues.

Location and GL Business Unit Override (DESTIN_GL_BU) for interunit expensed issues.

Purchasing Business Unit (BUSINESS_UNIT_PO), RTV ID (RTV_ID), RTV Line Number (RTV_LN_NBR), and RTV Distrib Number (RTV_DISTRIB_NUM) for supplier returns.

If the fields are left blank on the detail level and the same fields are populated at the group level, then the values will default to the detail level. For example, if the Carrier ID field is populated at the group level but left blank at the detail level, then all of the detail lines are populated with the group level value.

For more information, see the "Managing Messages" topic of the PeopleTools: PeopleSoft Integration Broker.

Use the Message Definition page (IB_MESSAGE_BUILDER) to view the fields to be used by the service operation within PeopleSoft Integration Broker.

In order to correctly populate the incoming data, review the message definition.

Navigation:

This example illustrates the fields and controls on the View the fields included in the message used by the INVENTORY_SHIPPING service operation (1 or 2). You can find definitions for the fields and controls later on this page.

This example illustrates the fields and controls on the View the fields included in the message used by the INVENTORY_SHIPPING service operation (2 of 2, partial page). You can find definitions for the fields and controls later on this page.

In order to correctly populate the incoming data, review the message definition. Message definitions provide the physical description of the data that is being sent, including; fields, field types, and field lengths. Messages do not contain any processing logic. All processing logic is defined in service operations, using service operation handlers. In this section, consider some important fields in version 2 of the INVENTORY_SHIPPING message. These same fields are also on version 2 of the INVENTORY_FRONT_END_SHIPPING message.

Field or Control |

Description |

|---|---|

IN_CREATE_DMD_FLG |

To create an MSR, you must enter Y (yes) in the Create Demand field of your transaction. |

AUTO_RELEASE_OPT |

To advance the demand line to the Depleted state, enter 70 (advance to depleted) in the Auto Release Option field of your transaction. |

The following fields are required on the incoming transaction request:

Create Demand flag (IN_CREATE_DMD_FLG) must be Y (yes).

Business Unit (BUSINESS_UNIT)

Request Type (REQUEST_TYPE)

Item ID (INV_ITEM_ID)

Quantity Requested (QTY_REQUESTED)

Unit of Measure (UNIT_OF_MEASURE)

One of the following:

Destination Business Unit (DESTIN_BU) for interunit transfers, including intercompany transfers.

Customer (CUST_ID), Ship-To Customer (SHIP_TO_CUST_ID), and Address Sequence Number (ADDRESS_SEQ_NUM) for external orders.

Location (LOCATION) for internal issues.

Location and GL Business Unit Override (DESTIN_GL_BU) for interunit expensed issues.

Purchasing Business Unit (BUSINESS_UNIT_PO), RTV ID RTV_ID), RTV Line Number (RTV_LN_NBR), and RTV Distrib Number (RTV_DISTRIB_NUM) for supplier returns.

For more information, see the "Managing Messages" topic of the PeopleTools : PeopleSoft Integration Broker.

See the product documentation for PeopleTools: Integration Broker

Use the Fulfillment Requests page (BCT_INV_REQFUL) to establish run control parameters for the Fulfillment Requests process to retrieve the transaction requests from the staging tables, process them, and apply them to the PeopleSoft Inventory demand tables.

Navigation:

This example illustrates the fields and controls on the Fulfillment Requests process page using the 0360 transaction code. You can find definitions for the fields and controls later on this page.

The Fulfillment Requests process retrieves the transaction requests from the staging tables, processes them, and applies them to the PeopleSoft Inventory demand tables. Within the Fulfillment Request process, the Create Stock Requests application engine is launched when the following transaction requests are found; the transaction code 0360 (Create Stock Request), the transaction code 0365 (Front-end Ship) with Y in the Create Demand field, and the transaction code 0366 (Ship) with Y in the Create Demand field. The Create Stock Request application engine validates the transaction, creates the new demand lines, and applies any default values to the new demand lines.

Field or Control |

Description |

|---|---|

|

Click the Add a New Row icon to add another request to this run control ID. A new row enables you to add requests for additional transaction codes (0360, 0365, and 0366) to the same run control page. |

Use the Transaction Maintenance page (BCT_CTL_UPD) to view all electronic transactions in the transaction log (inbound staging tables) and access the detail pages that enable you to correct transaction errors.

Navigation:

The Transaction Maintenance page displays transactions from the inbound staging tables and is used to view the status of the incoming transactions. If errors are found during the Fulfillment Request process, the transaction status in the transaction log is changed to Error, and rows are inserted into error tables for each error message.

Field or Control |

Description |

|---|---|

Unit |

Select the Inventory business unit for your search. |

Transaction |

Select the type of transaction to be viewed in your search results. Leave the field blank to view all transaction types within an Inventory business unit. Use the value Create Stock Request to view transaction requests creating MSRs. |

Status |

Select the status of the transaction requests to be viewed in your search results. Leave the field blank to select all statuses. Your options are:

|

Search |

Click the search button to display results in the Transaction Details group box. |

EIP Control ID |

When displaying a Create Stock Request transaction, click this link to access the Transaction Maintenance- Create Stock Request page. |

Trans Code and Description |

Displays the transaction code and description for the transaction request. In order to create an MSR or a new demand line for an existing MSR, you must use one of the following transaction codes:

|

Status |

Displays the current status of the transaction request. You can edit this field and change the status. The rules for changing a transaction status are:

|

Error |

Displays the number of errors within the transaction request. |

Use the Transaction Maintenance- Create Stock Request component to view and correct any errors within a transaction request for creating stock request. All fulfillment transaction requests have this structure:

Header Level: Contains fulfillment transaction request header information.

Group Level: Contains fulfillment transaction request group level information. For the create stock request transaction, this represents the order.

Detail Level: Contains fulfillment transaction request detail level information within a group. For the create stock request transaction, this represents the order line.

LLS Level: Contains picking location, lot ID, serial ID, and staged-date information. For the create stock request transaction, this represents the location/lot/serial of a demand line.

Errors can occur at any level of the transaction request. For example, if a create stock request transaction is loaded with an item ID that does not exist, then the file generates an error. The item ID is located at the detail level so you can use the Transaction Maintenance- Create Stock Request: Detail Records page to correct the error. Once you have corrected the information and saved the component, the transaction request is ready to be reprocessed using the Fulfillment Requests process.

The Transaction Maintenance pages for the Inventory_Front_End_Shipping transaction and the Inventory_Shipping transaction have a similar format to the Inventory_Create_Stock_Request transaction.

Header Level

Use the Transaction Maintenance- Create Stock Request page (BCT_INV_UPD_MSR) to view header-level information of a create stock request transaction.

You can view the status of the entire transaction request and view any error messages found during the Fulfillment Requests process.

Navigation:

Transaction Maintenance-Create Stock Request page displays header-level information of a create stock request transaction. You can view the status of the entire transaction request and view any error messages found during the Fulfillment Requests process.

The Transaction Details group box displays the MSRs (orders) within this transaction request. There could be one or more MSRs within a transaction request.

Field or Control |

Description |

|---|---|

Status |

For the transaction request, this field displays the current BCT detail status on INV_MSR_HDR_VW record. The statuses are:

|

Group Recs in Error |

Displays the number of groups (that is, MSRs) within this transaction request that are in error status. |

Group Level

Use the Transaction Maintenance- Create Stock Request: Group Records page (BCT_INV_UPD_MSRGRP) to displays the MSRs (orders) within this transaction request.

Using the group-level, you can view or edit fields related to the order header; such as, order number or customer ID.

Navigation:

Displays the MSRs (orders) within this transaction request. Using the group-level, you can view or edit fields related to the order header; such as, order number or customer ID.

Detail Level

Use the Transaction Maintenance- Create Stock Request: Detail Records page (BCT_INV_UPD_MSRDTL) to displays a single order line within this transaction request.

Using the detail-level, you can view or edit information related to one order line within an MSR on the transaction request.

Navigation:

The Transaction Details group box displays one order line within this transaction request. Use the Transaction Details scroll bar to view another order line within the same MSR. Using this page, you can view or edit information related to one order line within an MSR on the transaction request.

LLS Level

Use the Transaction Maintenance- Create Stock Request: Location, Lot, Serial Records page (BCT_INV_UPD_MSRLLS) to displays the LLS levels of a single order line within a transaction request.

Using the LLS-level, you can view or edit information related to lot ID, serial ID, or material storage locations (MSL) along with container IDs and stage dates.

Navigation:

The Transaction Maintenance- Create Stock Request: Location, Lot, Serial Records page displays the LLS levels of a single order line within a transaction request. Using the LLS-level, you can view or edit information related to lot ID, serial ID, or material storage locations (MSL) along with container IDs and stage dates.

You can pre-allocate a demand line by using the LLS level of the transaction request to specify the picking location or lot ID.

User Defined Fields

Enter values in the user-defined fields for the material stock request. These fields are stored in the IN_DEMAND_USER table, a child table of IN_DEMAND. If a backorder is created, these fields are propagated to the backorder. You can view and edited user-defined fields at the:

Group Level

Detail Level

Use the Transaction Maintenance- Create Stock Request: Group Level User-Defined Fields page (BCT_INV_UPD_MSRGUD) to displays the user-defined field of the MSR.

Navigation:

Use the Transaction Maintenance- Create Stock Request: Detail Level User-Defined Fields page (BCT_INV_UPD_MSRDUD) to displays the user-defined fields of the order line.

Navigation:

(Add a New Row)

(Add a New Row)