Re-Exploding Product Kits

The Kit Re-Explode process gives you to ability to synchronize the product kits on a sales order or material stock request with the latest product kit definition on the Product Kit Summary page. For example, assume that you have a Cyclist Starter Kit that includes a bicycle helmet. If you decide to change that component to another type of helmet, the Kit Re-Explode process could report on all current orders for the Cyclist Starter Kit. You could then decide whether or not to run the Kit Re-Explode process to alter all the current orders to match the new kit configuration. In addition, you can setup the Message Dashboard functionality to generate warning messages when the Kit Re-Explode process finds differences in a particular inventory business unit.

The Kit Re-Explode process can:

Generate an online inquiry page to identify all differences between the current product kit and the orders.

Generate an online inquiry page and also change the current orders to match the latest product kit definition.

Changes to the kit definition are applied to the order by adding or deleting demand lines containing kit components. If item quantities are reduced or removed, the Kit Re-Explode process may remove a soft-reserve, ATP promise, peg, or hard-allocation to the demand line. Once the Kit Re-Explode process has completed, it is important to reprocess the modified orders through reservations, order release, and so on, in order to re-apply these fulfillment conditions. In addition, any new demand lines added to the order need to be processed to the correct fulfillment state.

Any demand lines of a product kit that you have canceled before running the Kit Re-Explode process could be added back to the product kit as part of the re-explode process.

Note: The Kit Re-Explode process does not select configured product kits.

The Kit Re-Explode process works with the complete product kit and does not select demand lines that are:

Backordered.

If one demand line of the product kit is backordered, then all demand lines of the product kit are excluded from the Kit Re-Explode process.

Protected from change by the Kit Protected check box.

For new demand lines with a kit component, this check box is clear (default value of no). The Kit Protected check box can be manually selected by the user or is automatically selected when the user changes the Quantity Per field or OK to Ship Without check box on the order line. These values can be changed on the Quantity/Date Detail page of the Create/Update Stock Request component, the Update Kits page within the Maintain Stock Requests component, the Correct Demand Errors component, and Kit Component Quantity Detail page in the Order Entry Form (PeopleSoft Order Management).

If one demand line of the product kit is kit protected, then all demand lines of the product kit are excluded from the Kit Re-Explode process.

On an active TMS (transportation management system) instance.

Past the fulfillment state designated on the Allow INV Change Thru column and the Batch Kit Re-Explode row (IN_KIT_REEXPLODE) in the Demand Change Configuration component.

Only one demand line has to be past this fulfillment state in order for the entire product kit to be considered past the state. This restriction works in conjunction with fulfillment state check boxes on the Kit Re-Explode process page. For example, the Demand Change Configuration component could allow inventory changes through the fulfillment state of Confirmed, however if the Kit Re-Explode process page only selects the fulfillment state of Releasable, then you are restricted to the Releasable state for the process instance.

(For sales orders only) Not yet past the fulfillment state designated on the Allow OM Changes Thru column and the Batch Kit Re-Explode row (IN_KIT_REEXPLODE) in the Demand Change Configuration component.

At least one sales order demand line of the product kit must be past this fulfillment state.

In a situation where the re-explode process would violate the quantity precision calculation.

This can happen if a user modifies the kit definition, setting the Quantity Per field to a decimal value for a component, which in turn makes the Quantity Requested field for that component a decimal value, when that component's quantity precision requires a whole number.

Inconsistent with the product kit. The Kit Re-Explode process expects certain fields to be the same across all component kit demand lines within the same product kit.

If the data is not consistent, then the re-explode process is not performed.

Including an item ID that is not defined for the inventory business unit.

Note: The Kit Re-Explode process is part of the fulfillment engine but can only be launched from the Kit Re-Explode process page.

Working with the Message Dashboard

When the Kit Re-Explode process finishes, if it has generated results for a particular inventory business unit, then the system can issue an EWN message to inform the user that there are results to review for that business unit. You must set up the Message Dashboard functionality to use this feature. In addition, if the EMP_SERVLET URL is defined in PeopleTools, Utilities, Administration, URLs, then the EWN messages will contain a link to the Kit Re-Explode Results page.

Using the Defer Depletions Feature with the Kit Re-Explode Process

At the demand line level, the Defer Depletions field that can have the value of Y (yes), N (no), or blank. This field must have the same value across all demand lines within a product kit. The value in the Defer Depletions field will be blank for the whole kit until shipping when the default value or overrides are applied. If a new demand line is added to the kit during the Kit Re-Explode process, then the system uses the same value used on the other components in the kit (Y, N, or blank). If the existing demand lines within a kit contain different values, then an error is issued and the kit is not re-exploded.

See Delaying the Billing and Costing of Inventory Shipments.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

RUN_IN_FULFILL_XPL |

Run the Kit Re-Explode process (IN_KIT_EXPL) to review and change any differences between the product kit on an order and the product kit definition. This process enables you to change the order to match the current definition of the product kit. |

|

|

IN_KIT_EXPL_INQ |

View the results of the Kit Re-Explode process. |

|

|

IN_KIT_EXPL_MSG |

View the messages that detail the actions of the Kit Re-Explode process by demand line. |

|

|

IN_KIT_EXPL_PUR |

Select to purge report data generated by the Kit Re-Explode process. |

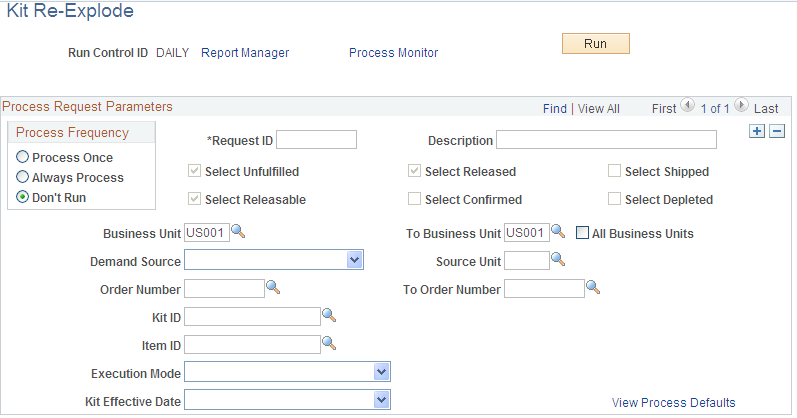

Use the Kit Re-Explode page (RUN_IN_FULFILL_XPL) to run the Kit Re-Explode process (IN_KIT_EXPL) to review and change any differences between the product kit on an order and the product kit definition.

This process enables you to change the order to match the current definition of the product kit.

Navigation:

This example illustrates the fields and controls on the Kit Re-Explode process page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Select Unfulfilled, Select Releasable, Select Released, Select Confirmed, Select Shipped, and Select Depleted |

Select one or more fulfillment states of the kit component demand lines. When selecting fulfillment states, keep in mind that this process works with the complete product kit. For example, if the user only checks the Select Unfulfilled check box, then the Kit Re-Explode process performs a second pass and brings in all kit component demand lines that are siblings of those demand lines matching the selection criteria, even if the demand lines are not in the unfulfilled state. The process re-explodes the product kit only if all the kit component demand lines have the selected fulfillment states. For example, if a product kit includes demand lines within the unfulfilled and releasable states, yet you have only selected the Select Unfulfilled check box here, then the system does not re-explode the product kit. The default selections in these check boxes are defined on the From States tab on the Setup Fulfillment-Fulfillment Task Options page (inventory business unit level) or the Fulfillment Engine Options component (SetID level). The selection is further limited by restrictions placed on the Demand Change Configuration component for the Batch Kit Re-Explode row. |

Business Unit and To Business Unit |

Enter the Inventory business unit or range of units for the demand lines to be processed. |

Demand Source and Source Unit |

Enter the source of the order and the business unit of the originating PeopleSoft application in order to limit the demand lines selected to one source. For example, entering OM and US001 limits the selection to sales order demand lines created in the PeopleSoft Order Management business unit US001. |

Order Number and To Order Number |

Enter the order number or a range of order numbers to limit the selection to specific orders. These fields can only be used if you have also populated the Business Unit, Demand Source, and Source Unit fields. When the run control record is saved, the Order Number and To Order Number fields are checked to make sure that they are valid for the entered Business Unit, To Business Unit, Demand Source, and Source Unit fields. The order number fields are not checked against the fulfillment state check boxes; Select Unfulfilled, Select Releasable, and so on. |

Kit ID |

Enter a product kit ID to limit the selection to demand lines containing components of this Kit ID. |

Item ID |

Enter the inventory item ID of one component of the product kit and the system selects all demand lines containing this component and any other components to the same product kit. If the item ID belongs to multiple kits, then all product kits are considered. |

Execution Mode |

Choose the action to be performed by the Kit Re-Explode process. The option are:

|

Kit Effective Date |

Select the date of the component kit demand lines to be compared to the date range (effective date and obsolete date) on the Product Kit Summary page. The demand line dates are:

|

View Process Defaults |

Select this link to view the defaults established for the Kit Re-Explode process. The Execution Mode and Kit Effective Date fields on this process page can only be changed if the Allow Kit Re-Explode Overrides check box has been selected on the Setup Fulfillment-Fulfillment Task Options page (inventory business unit level) or the Fulfillment Engine Options component (SetID level). |

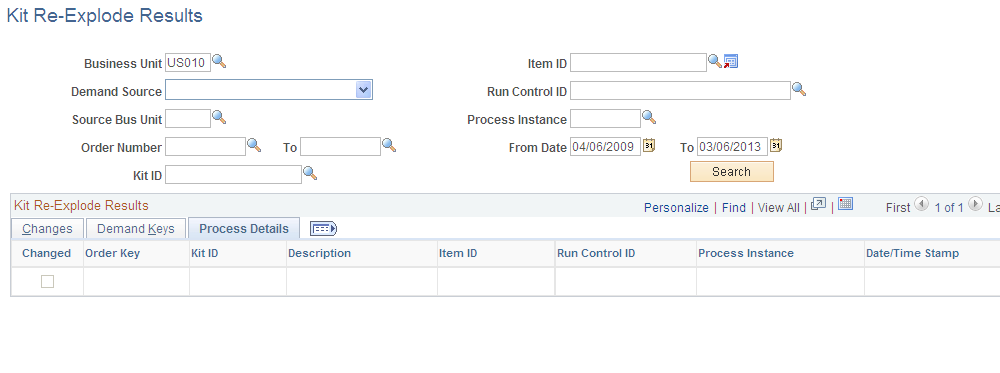

Use the Kit Re-Explode Results page (IN_KIT_EXPL_INQ) to view the results of the Kit Re-Explode process.

Navigation:

This example illustrates the fields and controls on the Kit Re-Explode Results page. You can find definitions for the fields and controls later on this page.

This example illustrates the fields and controls on the Demand Keys tab of the Kit Re-Explode Results page. You can find definitions for the fields and controls later on this page.

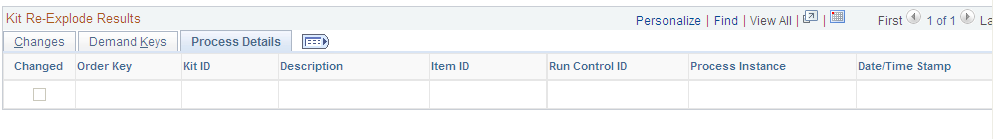

This example illustrates the fields and controls on the Process Details tab of the Kit Re-Explode Results page. You can find definitions for the fields and controls later on this page.

The Kit Re-Explode Results page enables you to view the changes needed to the demand lines to reflect the current product kit definition. This page can display:

Potential changes to the demand lines if you selected Report Only Execution Mode on the Kit Re-Explode process page.

Actual changes to the demand lines if you selected Report and Re-Explode Execution Mode on the Kit Re-Explode process page.

When the orders are changed to match the current product kit definition, demand lines can be added or deleted. The quantities on the changed demand lines could be unreserved, unallocated, and unpegged.

Use the three tabs in the Kit Re-Explode Results group box to view the demand lines that do not match the current product kit.

The Changes tab is a summary page, with the order key of the demand line, product kit ID, item ID, the action taken, and the number of messages for this line.

The message field is a link to the Kit Re-Explode Messages page where you can view the reasons for the demand line changes.

The Demand Keys tab identifies the exact demand lines to be changed.

The inventory unit, demand source, source business unit, order number, line number, schedule number, demand line number, and the item ID are displayed.

The Process Details tab displays the run control and process instance of the Kit Re-Explode process that has produced these results, as well as the date and time that the process was run.

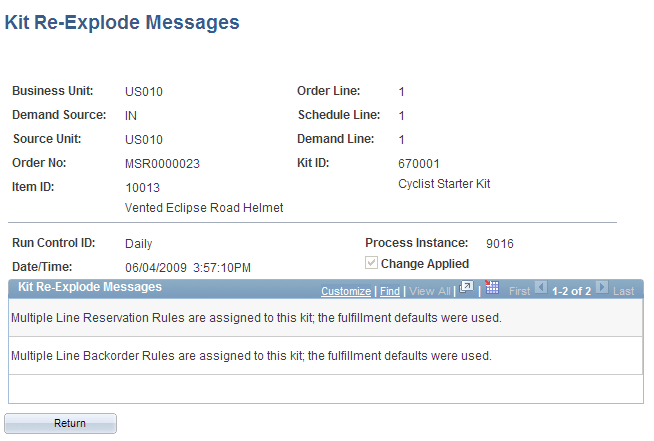

Use the Kit Re-Explode Messages page (IN_KIT_EXPL_MSG) to view the messages that detail the actions of the Kit Re-Explode process by demand line.

Navigation:

Select the Messages link on the Kit Re-Explode Results page.

This example illustrates the fields and controls on the Kit Re-Explode Messages page. You can find definitions for the fields and controls later on this page.

The Kit Re-Explode Messages page enables you to see, for each demand line, the reasons for the Kit Re-Explode action performed or just reported by the process. This page enables you to evaluate the detailed changes on each demand line.

Field or Control |

Description |

|---|---|

Run Control ID, Process Instance, and Date/Time |

Displays the run control ID, process instance, and the date and time of the Kit Re-Explode process that produced these results. |

Change Applied |

Displays if the change was applied to the demand line. If this check box is selected, then the Kit Re-Explode process has changed the demand line based on the reasons detailed on this page. If this check box is clear, then the Kit Re-Explode process has not changed the demand line and is just reporting. The demand line might not be changed because:

|

Kit Re-Explode Messages group box |

This group box displays the reasons for the Kit Re-Explode action on this demand line. Messages include:

|

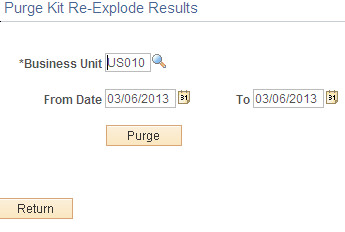

Use the Purge Kit Re-Explode Results page (IN_KIT_EXPL_PUR) to select to purge report data generated by the Kit Re-Explode process.

Navigation:

Select the Purge Kit Re-Explode Results link on the Kit Re-Explode Results page.

This example illustrates the fields and controls on the Purge Kit Re-Explode Results page. You can find definitions for the fields and controls later on this page.

Based on inventory business unit and process date range, erase Kit Re-Explode report data that is no longer needed.

Field or Control |

Description |

|---|---|

Business Unit |

Enter the Inventory business unit. This is a required entry. |

From Date and To |

Enter the data range to select the reports to purge. This date is the system date of the process instance that generated the report data. |

Purge |

Click to erase the report data based on the business unit and date range entered. When you click the Purge button, a secondary page asked you to confirm or cancel the purge. |