Defining and Maintaining Tasks

To define and maintain tasks, use the Task Definition (TASKS1) component.

You can create and maintain, by business unit, the master list of jobs or tasks that can be performed in the manufacturing process. You can also define the tasks' intensity and associated work centers, resources, operation times, conversion codes, attachments, and text information. You can associate multiple tasks with the same work center.

The use of tasks is optional, but it reduces duplication of maintenance within routings. If you perform the same task on multiple items, define the task only once and then reference that task on each item's routing. The system copies the associated task information into the item's routing. At the routing level, you can change any attribute of the task that is specific to the item without affecting the task definition.

If each item requires unique processes or operations, you do not have to define task information. However, you do need to define the work center, resources, times, and conversion codes on the routing for each item.

When you add a new task or when you change any attribute in an existing task, the system optionally sends the Task Change workflow notification to the selected roles that you've defined, such as an engineering manager or cost accountant.

This section discusses how to:

Define task attributes.

(Optional) Define task resources.

Define task operation times.

(Optional) Define task conversion codes.

View task where-used data.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

EN_TASKS |

Define task information such as the time required to complete the task, the resources used for the task, and the task intensity. |

|

|

Text Page |

EN_TASK_TXT |

Enter text about a task. Use this page to enter up to 254 characters of text. Use the Attachments page for larger blocks of text. |

|

Attachments Page |

EN_TASK_ATT |

Specify task attachments. |

|

EN_TASK_RESOURCE |

(Optional) Define task resources. |

|

|

EN_TASK_TIME |

Define task operation times and run rates. |

|

|

EN_TASK_CONCODE |

(Optional) Define conversion codes associated with the labor and machine rates for a task. |

|

|

Conversion Overhead Code Page |

EN_TASK_CONOHCODE |

(Optional) Define task conversion overhead codes. You can select up to four overhead codes. The system displays data from the current production overhead rates. |

|

Tasks Where Used - Used on Routings |

EN_TASK_WHERE_RTG |

View all routings on which the task is specified. |

|

Tasks Where Used - Used in Production |

EN_TASK_WHERE_PRD |

View all production that is associated with a specific task. |

|

RUN_ENS1006B |

View the routings and production associated with either a selected task or a range of tasks within a particular business unit. |

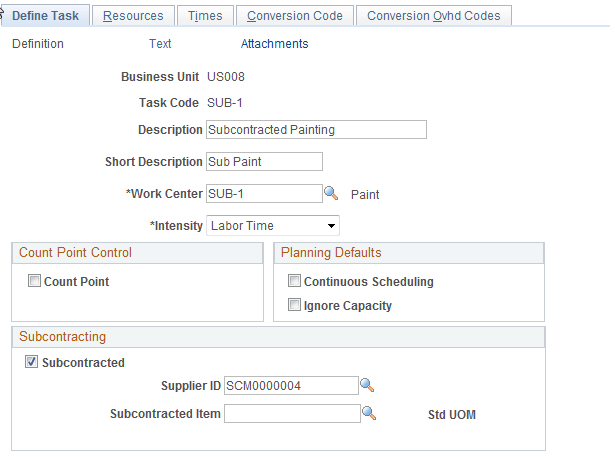

Use the Define Task - Definition page (EN_TASKS) to define task information such as the time required to complete the task, the resources used for the task, and the task intensity.

Navigation:

This example illustrates the fields and controls on the Define Task - Definition page. You can find definitions for the fields and controls later on this page.

Before defining routings, you can define a master dictionary of tasks or jobs that can be performed at work centers.

After entering the business unit and task code, associate the task with a work center. You can associate multiple tasks with the same work center, but tasks can only take place in one work center.

Field or Control |

Description |

|---|---|

Intensity |

Select to determine the basis of your scheduling. You can base the start and end date of the operation on the operation's labor time (if it is labor intensive) or machine time (if it is machine intensive). Alternately, you can base the start and end date on the longer of the two times or on the sum of the labor time and the machine time (that is, the cumulative time). Note: If you define a task as subcontracted, the system sets the intensity to Labor Time. |

Count Point |

Select to make the task a count point operation. A count point indicates the operations on a routing that record completions and scrap. You can define count points on the Define Routings - Summary page. Note: Count points are optional and are used on only production IDs. |

Planning Defaults |

Select either or both of these options:

|

Note: If you change a task by using one of these pages and the task is already associated with a routing operation, it does not change the routing information. Go to the Define Routings - Summary page to change the routing.

Subcontracting

Field or Control |

Description |

|---|---|

Subcontracted |

Select to specify a task this is performed by an outside subcontractor rather than in house. PeopleSoft Purchasing uses this information when creating subcontracted purchase orders. If you select this check box, the Supplier and Subcontracted Item fields appear. |

Supplier |

(optional) Select the supplier who will provide subcontracted services for this task. PeopleSoft Purchasing uses this information when creating subcontracted purchase orders. |

Subcontracted Item |

(optional) Select the subcontracted item. If you select the subcontracted item and if you are using PeopleSoft Purchasing, then PeopleSoft Purchasing will generate a subcontracted purchase order for this specific subcontracted item. Note: Subcontracted items are defined at a SetID level. See Defining Items at the SetID Level. See Understanding Subcontracting Using PeopleSoft Manufacturing. |

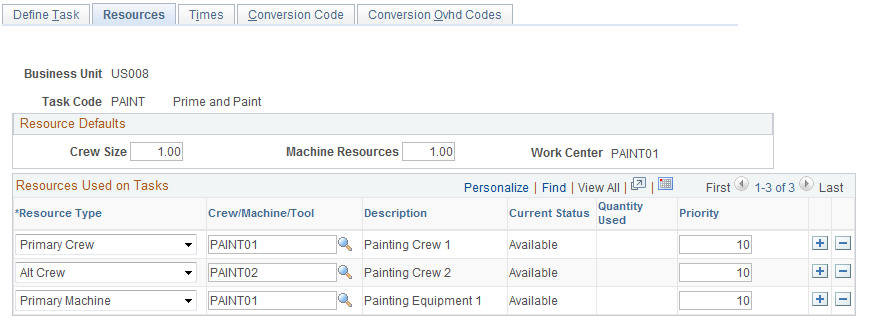

Use the Define Task - Resources page (EN_TASK_RESOURCE) to (Optional) Define task resources.

Navigation:

This example illustrates the fields and controls on the Define Task - Resources page. You can find definitions for the fields and controls later on this page.

Resource Defaults and Resources Used on Tasks

The system copies the resource defaults, as well as the information from the Resources Used on Tasks field associated with the work center into the task information.

Field or Control |

Description |

|---|---|

Resource Type and Crew/Machine/Tool |

Edit resources (crews, machines, and tools) by selecting a resource type and the specific crew, machine, and tool, provided that you have already associated the resource with the task's work center. For example, on the Work Center pages, you can specify primary and alternate machines for the work center. On the Define Task - Resources page, you can change those selections for the particular task. |

Qty Used (quantity used) |

When you select a Primary or Alternate tool as a resource type, the quantity used field becomes available for entry. Enter the tool quantity required to perform the task. This field is for informational purposes only. |

Priority |

You can manually specify a priority for the task resource. The priority is an integer ranging from 1 to 999. The primary resource for a tool, crew, and machine automatically changes to a priority of 10. Other resources of like type automatically change to a priority of 20. Using the priority factor, choose between a crew and a machine, irrespective of their resource type. The priority appears by default on the routing. |

Note: Only one primary crew and one primary machine can be associated with the task. You can, however, have unlimited primary tools and alternate crews, machines and tools.

Note: You cannot associate crew and machine resources with subcontracted tasks.

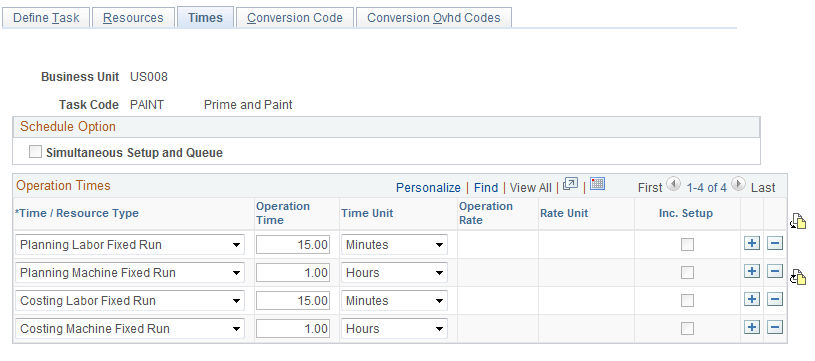

Use the Define Task - Times page (EN_TASK_TIME) to define task operation times and run rates.

Navigation:

This example illustrates the fields and controls on the Define Task - Times page. You can find definitions for the fields and controls later on this page.

Task times are divided into labor and machine setup, run, fixed run, and post production. Additionally, you can have separate sets of times and run rates for planning and costing purposes. You can define in-transit and queue time for planning purposes only. When defining time and run rates, define only the types that apply to the task.

Setting Schedule Options

Field or Control |

Description |

|---|---|

Simultaneous Setup and Queue |

Select if setup for an operation can occur during the defined queue period. If this check box is selected, the system uses the longer of the two times when determining the lead time of an operation. When you associate a task with a routing operation, this option is not valid if the task is the first operation on the routing. |

|

The function of the Planning to Costing Rate Copy and the Costing to Planning Rate Copy buttons depends on existing planning or costing values on the page. |

Note: If you are using PeopleSoft Supply Planning, you cannot select the Simultaneous Setup and Queue option.

Setting Operation Times and Rates

In the Operation Times group box, define the manufacturing times or rates:

Field or Control |

Description |

|---|---|

Setup |

This is the amount of time required to prepare an item, machine, or work center for production. This might involve calibration of a machine or running samples before the start of production. Express setup time in minutes, hours, or days. When the time is expressed in days, the system determines the number of operational hours in a day by using the average daily hours for the work center assigned to the task. When determining an operation's lead time, the scheduling function uses the setup time and does not factor in the number of units that must be processed. You can also specify that setup can be done during a work center's queue time or that operation setup can take place anytime after the start of production, except at the first operation. |

Run |

This is the amount of time necessary to process one unit, with the rate expressed in minutes, hours, or days. Alternatively, the number of units that can be processed in one time period, with the rate expressed in units per minute, units per hour, or units per day. When determining the lead time of an operation, the scheduling function calculates the total run time by factoring in the number of units to be produced. |

Fixed Run |

This is the amount of time necessary to complete the task, regardless of the number of units processed. For example, if it takes 24 hours to burn in a board, and the process must run for 24 hours if it's burning in 1 board or 10 boards, you can express this time as fixed run. Fixed run time is added to the total lead time of the operation. You can express it in minutes, hours, or days. |

Post Production |

This is the amount of time required to clean up, flush, or break down a machine, a work center or an area, once production has been completed. The system does not include post-production time in the operation lead time calculation because it is assumed that this occurs when the units have moved on to the next operation. The system includes it in the item's cost. You can express post-production time in minutes, hours, or days. |

Queue |

Used in operation scheduling, this is the amount of time that units must wait at an operation before setup or processing can begin. You cannot define queue time for the first operation. For subsequent operations, however, you can define a queue time and whether or not setup can occur during the queue time. You can express queue time in minutes, hours, or days. The system does not include queue time in the operation's cost nor is it considered in PeopleSoft Supply Planning. |

Intransit |

Used in operation scheduling, this is the amount of time required to transport completed units from one operation to the next. Express in-transit time in minutes, hours, or days. In-transit time is not included in the operation's cost nor is it considered in PeopleSoft Supply Planning. |

When setting up the task times and rates, you can designate a set of times and rates for planning purposes and a set of times and rates for costing purposes. You do not need to include all the planning times for scheduling the operation or task, nor do you need to include all the costing times in the item's cost. Simply select the time types that are appropriate for the task. The system displays this data on the Routing Operations - Times page when you select the task code that you want to associate with the operation sequence.

Note: If you define a task as subcontracted, you can only maintain queue, in-transit, and labor times.

You can make changes to the task times on an item-by-item basis on the Routing Operations - Times page without affecting the task master data. Conversely, if you change task information on the Task Times page after the task has been assigned to a routing, the item's routing information is not automatically changed.

Field or Control |

Description |

|---|---|

Op Time (operation time) and Op Rate (operation rate) |

After selecting the operation type, enter an operation time or operation rate. |

Time/Rate Unit |

If you enter an operation time, then the values are:

For example, if you enter 5 in the Op Time field and Days in the Time/Rate Unit field, one unit would be completed every five days for the operation. You express setup, fixed run, post-production, queue, and in-transit times in terms of operation times. You can define a run in terms of operation time or a run rate. If you enter an operation rate, then the values are:

For example, suppose that you enter 3 in the Op Rate field and Units/Day in the Time/Rate Unit field. Then, three units are completed every day for the operation. Use only operation rates to define run times. |

Note: If a task is already linked to a routing, and you change any times and rates for the task with this page, the system does not update the routing data. If you want the data to be identical, make the change using the Routing Time page.

Including Setup

You can only select the Inc. Setup (include setup) check box for the Planning Labor Setup and Planning Machine Setup operation types. In all other cases, the Inc. Setup check box is deselected and is unavailable for selection. If you do not select include setup, setup can begin before any production units arrive at the work center. Setup can occur at any time after the start of production, and the system does not include it as part of the item's lead time, except at the first operation. If you include setup, the setup time is factored into the task or operation's lead time. The system always includes setup in the lead time calculation of the first operation, if setup is specified, regardless of the check box setting.

PeopleSoft Supply Planning Considerations

If you are using PeopleSoft Supply Planning, be aware that:

If, in the item planning attributes, you've elected to maintain rates based on routings and resources as opposed to a lead time, then you must define labor or machine planning times (such as setup, run, or fixed run).

Do this so that PeopleSoft Supply Planning can schedule operations and determine work center or resource capacity.

PeopleSoft Supply Planning does not consider labor or machine post-production time as a requirement on the work center or the work centers resources.

PeopleSoft Supply Planning does not consider queue and in-transit times, even if you have specified them for the task.

Costing Considerations

To calculate costs for a given item, operation, and time type, you must have a corresponding costing rate type defined for a given cost version. For example, if you have a costing fixed run time of five hours defined on the task here, you should define a fixed run conversion rate (for example, 100.00 USD per hour) on the Costing Conversion Rates page.

If you intend to cost the operation using a fixed amount per unit, as opposed to a rate per hour, you must include a corresponding costing operation time type. The costing operation time can represent the amount of time to complete the task, and the system uses it to calculate earned hours. However, the system uses the amount per unit in calculating the cost, regardless of the time specified. If you do not specify a costing time, the system does not include the per unit cost, even if there's a rate defined for the code assigned to the task.

Use the Define Task - Conversion Code page (EN_TASK_CONCODE) to (Optional) Define conversion codes associated with the labor and machine rates for a task.

Navigation:

Conversion costs are optional, but you define them so the system can calculate labor, machine, and overhead costs that are associated with manufactured items during cost roll-ups. The system uses these costs within PeopleSoft Manufacturing to calculate earned labor, machine, and overhead costs that are added to work in process inventory value when operation or assembly completions are recorded.

After you enter the task's conversion code, the system displays the conversion rate type, as well as labor and machine data from the current production rates.

The rates that appear are from the frozen conversion rates and costs updated during the last cost update and revaluation.

If the labor or machine rate is in cost per unit, and you want to include the cost in the cost roll-up calculation, select a corresponding costing rate type. For example, suppose that labor run rate is .50 per unit, the task, or ultimately the routing, must have an entry for costing labor run time in order for the .50 to be included in the operation's cost.

Use the Tasks Where Used page (RUN_ENS1006B) to view the routings and production associated with either a selected task or a range of tasks within a particular business unit.

Navigation:

Field or Control |

Description |

|---|---|

Routing Code |

On the routing inquiry, the routing code indicates whether this routing is the primary (routing code 1) or alternate (routing codes 2-99) routing for the routing type. |

Production Area |

On the production inquiry, the system displays all production on which the task is performed. It segregates the production information by those items in a production area using production IDs and those items that are managed by production schedules. |

Production ID |

In the case of production ID, it displays the production IDs that have an operation that uses the task. For all other production, the system displays the item and the production area in which it is produced. In both cases, it displays the operation sequence, along with the operation's start time and date and due date and time. |