Maintaining BOMs

To create and maintain BOMs, use the BOM Maintenance (BOM_MAINTENANCE) component.

You can create and maintain the product structure for a manufactured item at a detailed level. You can define multiple outputs and add text, documents, or attachments for an assembly or for the components associated with an assembly. You can also create reference designators and component item substitutes.

You can create BOMs only for existing assembly items that are either owned or consigned and approved and whose source code is set to either Make or Buy. Additionally, you can maintain BOMs only for assemblies or end items if the Used in MFG check box is selected for them on the Define Business Unit Items - General: Costing page.

All assembly, output, and component items must use a standard cost profile for all of their books. Components can be owned or non-owned or non-owned and consigned with a source code of Make, Buy, Floor Stock, or Expense.

In addition to creating a primary BOM (with a BOM code equal to 1), you can specify up to 98 alternate BOMs by entering additional BOM codes (greater than 1) in the dialog box that appears when you access the Manufacturing BOMs component.

When you need to do additional or repair work on a completed assembly, you can create rework BOMs. This is especially useful if you have a standard rework process that requires additional components. As with manufacturing BOMs, you can define a primary rework BOM and up to 98 alternates using BOM codes. You create rework BOMs by selecting Rework as the production type when adding a BOM on the Manufacturing BOMs component. Rework BOMs are always single-level BOMs. Also, PeopleSoft Cost Management does not include rework BOMs in cost maintenance. The rework BOM does not include the assembly being reworked as a component. In PeopleSoft Manufacturing, when you firm up or release the rework production ID, the system copies the rework BOM to create a component list and automatically adds the assembly being reworked. Rework BOMs cannot include multiple outputs; the system automatically includes the assembly being reworked as an output when production is created.

When you add a BOM for an item or change any attribute of an existing BOM, you can have the system send a workflow notification to the selected roles that you've defined—such as engineering manager or cost accountant.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

EN_BOM_MAINT |

Maintain all components that make up a particular manufacturing BOM for an assembly in a specified business unit. You can create and maintain a rework BOM to define a standard kit of components for use in repair. You can also indicate which components can be recovered if the assembly can be torn down into component parts. You'll maintain BOMs one level at a time. |

|

|

Header: Assembly Text Page |

EN_BOM_TEXT |

Associate text with an assembly. |

|

Header: Assembly Attachments Page |

EN_BOM_ATT |

Associate attachments with BOMs. |

|

Header: Assembly Documents Page |

EN_BOM_DC |

Associate, access, and manage pertinent assembly BOM documents in the document management system that is embedded in the PeopleSoft system. You must have PeopleSoft Engineering installed to access this page. |

|

EN_BOM_OUTPUTS |

Enter output information. |

|

|

EN_SS_BOMVND_LST |

Access a current list of Suppliers who have access to a specific item. You must have PeopleSoft Engineering installed to access this page. |

|

|

EG_IC_EMAIL |

Send email to Suppliers. You must have PeopleSoft Engineering installed to access this page. |

|

|

EN_COMP_MAINT |

Add details for each assembly BOM component. |

|

|

Components: Text Page |

EN_COMP_TEXT |

Attach and maintain component text. |

|

Components: Attachments page |

EN_COMP_ATT |

Associate attachments with components. |

|

Components - Documents Page |

EN_COMP_DC |

Associate, access, and manage pertinent component documents in the embedded document management system. You must have PeopleSoft Engineering installed to access this page. |

|

EN_COMP_DESIG |

Associate designators to a component of an assembly item.

|

|

|

EN_COMP_DIM |

Specify and maintain BOM component dimensions. |

|

|

EN_COMP_SUB |

Add substitute components. Substitutes must be defined and approved in PeopleSoft Inventory. |

|

|

EN_BOM_SUB_ITEM_SP |

View valid substitutes for the component, and copy the substitutes to the BOM. |

Field or Control |

Description |

|---|---|

BOM State |

Select a BOM state. Values are:

|

Verify BOM |

Indicates whether the system performs online loop checking. Set this option at the manufacturing business unit level on the MFG Business Unit Options page. On the MFG Business Unit Options page, you can elect to always verify online or never verify online. The check box on the Engineering BOM Summary page reflects the manufacturing option that you select. If you select to always verify online, the system checks for looping BOMs as you maintain the assembly's or end item's bill. This prevents you from adding the end item as one of its own components at this level or any lower levels. If you select Never Verify Online, loop-checking runs as a deferred process. |

Use the Manufacturing BOMs - Summary page (EN_BOM_MAINT) to maintain all components that make up a particular manufacturing BOM for an assembly in a specified business unit.

You can create and maintain a rework BOM to define a standard kit of components for use in repair. You can also indicate which components can be recovered if the assembly can be torn down into component parts.

Navigation:

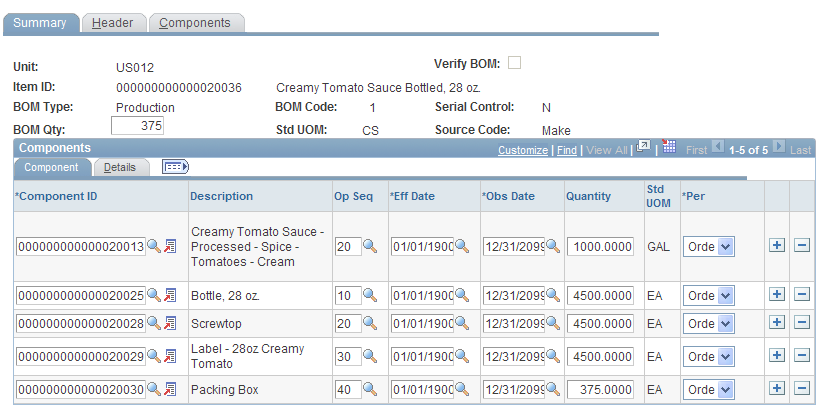

This example illustrates the fields and controls on the Manufacturing BOMs - Summary page: Components tab. You can find definitions for the fields and controls later on this page.

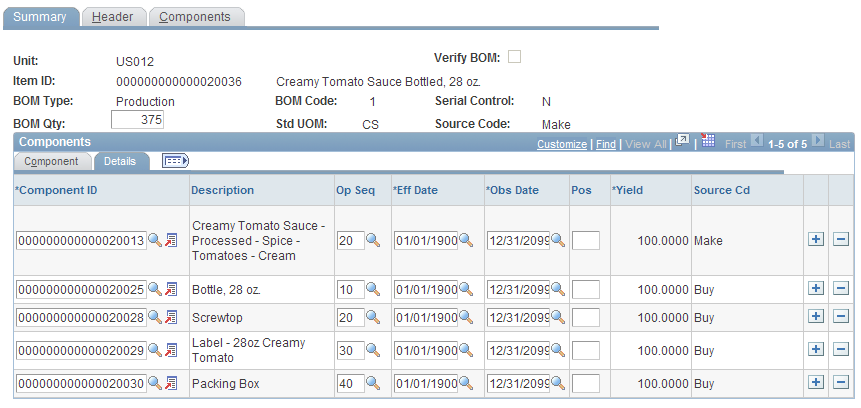

This example illustrates the fields and controls on the Manufacturing BOMs - Summary page: Details tab. You can find definitions for the fields and controls later on this page.

Note: When BOMs are complex and deep, run the BOM Verification process and set BOM verification to Never Verify Online to improve BOM maintenance performance. Use the batch BOM Verification Request page.

Header Information

Field or Control |

Description |

|---|---|

BOM Type |

Select the type of BOM you're creating. Values are:

Note: You cannot add the end item to the rework BOM as a component. The system assigns the reworked item as a component when you release a rework production ID in PeopleSoft Manufacturing. |

BOM Qty (BOM quantity) |

When BOMs contain a single-item output, you can use the BOM quantity in a particular way. The BOM quantity acts a scaling device that enables you to enter a product structure when the end item's specifications are in a base greater than 1 unit. The BOM quantity is the expected output quantity after all operation yield loss occurs. You determine the assembly quantity to which the system applies the components' quantity per assembly or per order. If the BOM quantity is greater than 1, enter the component quantity for the BOM quantity. If you set the BOM quantity to 1, the component quantity is the amount of the component required to make one unit. When BOMs contain multiple outputs, you use the field differently. If a primary item and its co-products are specified as output items on the BOM, the BOM quantity must match the primary item's average order quantity (AOQ) as defined in the Define Business Unit Item - Manufacturing: General page. If you change the BOM quantity, the system prompts you to update the AOQ with the newly entered BOM quantity. Keeping the two quantities in sync ensures correct costing of the output items. For serial-controlled items, the BOM quantity must be a whole number. The PeopleSoft system supports a calculated QPA precision of four to ten places to the right of the decimal point, depending on the installation setting on the Manufacturing Installation Options page in Set Up Financials/Supply Chain. |

Sort Option |

Select one of these values:

|

Component ID |

Select the component that you want to add to the BOM. |

|

Click the View Related Links button to access the Item Search Criteria page to locate a different item. Note: A component cannot be the same as its parent, and you cannot have overlapping effectivity dates for the same component. Furthermore, you cannot add staged date-controlled items and configured items as components on BOMs. When you add a component with item status of Hold or Discontinue, the system displays a warning message. Similarly, when updating components with item status of Hold or Discontinue, you will receive a warning message when saving the page. In both cases, the warning message does not prevent you from performing the action. Note: You cannot add an item with the status Inactive. |

Comp Rev (component revision) |

Indicates whether any component on the bill is under revision control. For items under revision control, you can associate a specific component revision with the assembly item. Depending on how you set business unit-level manufacturing options on the MFG Business Unit Options page, the system allows you to leave the Comp Rev blank, select a default value, or select a different component revision for each revision-controlled component. If the system is set up to default component revision, the Comp Rev column initially displays the current revision. When you enter effective dates, the revision is updated with the component revision effective on the date specified. |

Op Seq (operation sequence) |

Indicate where in the manufacturing or rework process you need the component. The operation sequence refers to an operation on the assembly item's routing. For manufacturing BOMs, this is the item's production routing, and for rework BOMs, it's the item's rework routing. The default operation sequence is 0 which is the first operation of the manufacturing or rework process. If you set the operation sequence for all items to 0, the system treats all items as required at the beginning of production. Therefore, the items need to be issued at the start of the first operation. You define operation sequence on the item's routing by using the Routing Definition Summary page. When maintaining the BOM, you can select any operation on the assembly item's routing. Once the routing has been established, the system lists the valid operation sequences for all corresponding routing codes and routing types in the operation sequence Detail column. For production BOMs, the system displays operation sequences only for production routings. For rework BOMs, the system displays operation sequences only for rework routings. Note: If a master routing is in use, then valid operation sequences include all manufacturing sequences associated with the item's master routing. Because a work center is associated with the routing's operation, PeopleSoft Manufacturing uses the operation information to determine the work center to which the component must be delivered. When the component's issue method is Issue or Replenish, the component is issued to the work center, and it is stocked in and consumed from the work center's WIP location storage area. When the component's issue method is Kit, the work center is still used as the indicator for material delivery. The production ID, however, is charged directly for the component and is not consumed from the WIP location. If the operation sequence specified for the component is 0 or does not exist on the routing, the system treats the material as required for the start of production. It issues the material to the work center associated with the production area where the item is being built. When the operation sequence is set to 0, it is assumed that the component item is used at the first operation. If you enter the BOM before the routing, you can return to the BOM Summary page and add the relevant operation sequence after entering the routing. |

Eff Date (effective date) and Obs Date (obsolete date) |

Enter dates for the components of the assembly item. When replacing a discontinued (use-up) item on the BOM, the obsolete date of the discontinued item and the effective date of the replacement item must be manually set to the same date. Use the projected use-up date generated in PeopleSoft Supply Planning as the suggested obsolete date. If you are using revisions, enter valid revisions in the Eff Rev (effective revision) and Obs Rev (obsolete revision) fields. Note: These fields refer to the effective and obsolete revisions of the assembly, not the component in the assembly. The obsolete date or revision must be later than the effective date. The component is effective from the start date (or beginning time) of the effective revision through the end date (or end time) of the obsolete revision. |

Quantity |

Displays the quantity of the component required for the BOM. You can override this value if necessary. |

Std UOM (standard unit of measure) |

The system displays the standard UOM for this BOM component. |

Per |

Values are:

This field determines the number of each component that is needed in the parent assembly to manufacture or rework the specified batch quantity. If the quantity is per assembly, the quantity represents the number of that component required to manufacture one end item. If the quantity is per order, it indicates that the component quantity is a fixed amount, regardless of the production quantity. Additionally, if the component is serial-controlled, the Quantity Per field must be a whole number. To provide greater flexibility when defining MBOMs, the system doesn't require the Quantity field to follow the quantity precision rules defined for the item. The system displays a warning if you define a decimal quantity value for an item whose quantity precision value is a whole number. For example, if one B0004 component is required to make two assemblies called A0001, when you define the BOM, the QPA for B0004 would be 0.5. When the system applies the rounding rules to the QPA, it rounds the QPA for B0004 to 1, thereby inflating production costs. While the Quantity Per field can be maintained with a precision of four places to the right of the decimal, a calculated QPA can be defined with a precision from four to ten decimal places. Calculated QPA is determined as (Component QPA) ÷ (BOM Qty). This calculated QPA is used to determine the assembly items' cost and to plan and schedule components. |

Details tab

Field or Control |

Description |

|---|---|

Pos (position) |

(Optional) Enter a position number. This can be a number associated with a component on a BOM drawing or on a list of all components that appear on a BOM. |

Yield |

Displays the expected yield for the BOM component. If you are adding a new component, you can enter the expected yield. |

Source Cd (source code) |

Displays the source code associated with the component. |

Engineering Considerations

If you are using PeopleSoft Engineering and outstanding ECOs are pending for the item, the system displays the ECO button next to the assembly item ID if you've checked the ECO Pending Alert check box on the ECO Item Status page. Click the ECO button to view information about the pending ECOs associated with the item.

Use the Header: Assembly Attachments page (EN_BOM_ATT) to associate attachments with BOMs.

Navigation:

Field or Control |

Description |

|---|---|

Document ID |

Enter the file name for the attachment. |

File Ext (file extension) |

Select the type of media that you want to attach. |

|

Click the Attachments button to launch the multimedia object attached to the revision. |

Note: You must set up file extensions on the File Locations page in Set Up Financials/Supply Chain, Common Definitions.

Use the Header: Outputs page (EN_BOM_OUTPUTS) to enter output information.

Navigation:

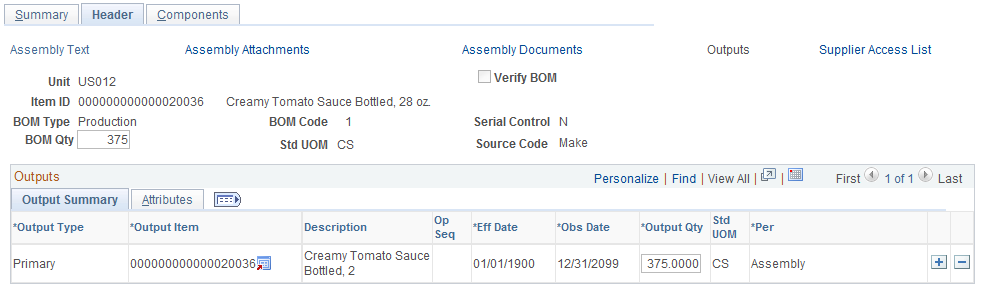

This example illustrates the fields and controls on the Header - Outputs page: Output Summary tab. You can find definitions for the fields and controls later on this page.

Output Summary Tab

Field or Control |

Description |

|---|---|

BOM Qty (BOM quantity) |

Displays the default information from the Manufacturing BOMs- Summary page, but you can change the quantity here. The detail portion of the page contains the end item as the item with the Primary output type, and this cannot be deleted. If you are not maintaining multiple outputs, you can simply bypass this page and the primary item is defined as the only output. When there is only one output for a BOM (the primary output), all fields in the row are unavailable, with default settings of the beginning time to the end time for the effectivity dates, 100 percent for the percentage fields, and output quantity set to 1. However, if another co-product is inserted, the primary item's allocation percentage and cost percentage fields are accessible. Conversely, if all the co-products are deleted from the BOM, all the fields on the primary item, except the output quantity, are unavailable for input and set back to the defaults. If you are maintaining a rework BOM, this page lists only the reworked item as the end item. Note: You cannot define co-products or by-products with rework. |

Adding Outputs

Field or Control |

Description |

|---|---|

Output Type |

Select the type of output that you are adding. Values are:

Note: You cannot add more than one primary product. If you have only one output on this BOM, then it is automatically the primary output. A co-product is an item that is produced as part of the manufacturing process along with the primary output. It shares the cost of the process, and there may be independent demand in Planning for this item. Examples of co-products are orange juice and orange concentrate in drink-processing. If the item is a co-product, the system checks to see whether the item's associated primary item is the item itself. (This is the default.) The system then prompts you to update the co-product's associated primary to this primary assembly item. A by-product can be a waste product that needs to be disposed of, or it can be a recycle by-product that can be used as an input to other processes (for example, orange pulp). The by-product is incidental to the process and has either a relief (negative) cost for recycle by-products or a disposal (positive) cost for waste by-products. Waste by-products might also have no cost associated with them. There would probably not be independent demand for by-products. Examples of recycle by-products are orange pulp. |

Output Item |

The item must be an existing, inventory, and standard costed item. Output items cannot be floor stock or expense items. |

|

Click the Item Search button to access the Item Search Criteria page to locate a different item. |

A number of restrictions apply to the Output Type and Output Item fields:

An item cannot be a co-product and by-product on the same BOM.

A primary item cannot be added to or deleted from a BOM.

The system always automatically adds the assembly or end item for which the BOM is created as the primary output item.

By-product items must have the source code Buy.

Co-product items must have the source code Make.

Co-product items cannot be phantom or configured items.

A co-product item cannot be the same as the primary item.

An item cannot be both a co-product and a component on the same BOM.

An item can be both a by-product and a component on the same BOM.

As long as the effectivity dates do not overlap, the item can exist as a by-product more than once on the BOM—at different operations or at the same operation.

An item cannot be both a waste and a recycle by-product on the same BOM.

Additional outputs cannot be added to rework BOMs, phantom BOMs, or configured-item BOMs.

Operation Sequence

The operation sequence is inaccessible for any co-products because the co-product can be generated only at the last operation. You can specify operation sequences for by-products. If the operation sequence specified on the output doesn't exist on the routing chosen for production, then it's assumed that the by-product is generated at the last operation on the routing.

The operation sequence functions in a similar fashion for outputs as it does for the components. However, for components, an operation sequence of 0 means that it is needed at the first operation. For outputs, an operation sequence of 0 means it is generated at the last operation.

The effectivity dates and revisions behave similarly to component dates. If the assembly item is revision-controlled by revision, then the effective revision and obsolete revision are displayed. On the other hand, if the assembly item is revision-controlled by date, then the effective date and obsolete date are displayed. For the primary item and any co-products, these fields show the beginning time (01/01/1900 or ---) and the end time (12/31/2099 or ---), and they are display-only. Only by-products have editable effectivity dates.

Field or Control |

Description |

|---|---|

Output Qty (output quantity) |

Enter the quantity. The default quantity for the primary item appears, but you can change it if there are additional co-products. You must enter a quantity for each output. Primary and co-product quantities are expressed in relation to the BOM quantity. By-product output quantities are expressed in terms of the expected operation start quantity. For single-output BOMs (no co-products), the BOM quantity on the primary item needs to be the same as the output quantity. Therefore, if you change the BOM quantity, the system checks to see if the primary item is the only co-product on the BOM. If so, the system updates the primary item's output quantity to the BOM quantity. If the BOM already contains additional co-product outputs, and you delete all the additional outputs from the BOM, the system displays a warning that the primary output quantity will be reset to the BOM quantity. In addition, if the output quantity is used, it should be identical to the item's average order quantity defined in the Define Business Unit Item - Manufacturing: General page. Note: For multiple output items, the BOM quantity for the batch BOM item must match the average order quantity that is defined for the item. |

Std UOM (standard unit of measure) |

The system uses the output item's standard UOM. Note: Because co-products can have different UOM values, the quantities for all the co-products do not need to add up to the BOM Quantity. |

Output Qty Per (output quantity per) |

This display-only field is available for co-products only. Values are:

The quantity code for the co-products is based on assembly and cannot be changed. |

Attributes Tab

Field or Control |

Description |

|---|---|

Res % (resource allocation percentage) |

Use this field to determine how much of the BOM quantity each co-product represents. It is used during completions to determine the percentage of the components that is consumed for each co-product and primary item. |

Cost % (cost allocation percentage) |

Use this to distribute the cost across the co-products. The cost percentage indicates the percentage of the total batch costs to be applied to the primary item or co-products. By having two percentages, the resource allocation and cost can be distributed differently for each co-product. Note: You cannot set the Res% or Cost% field to 0. |

Resource Allocation Percentage Example

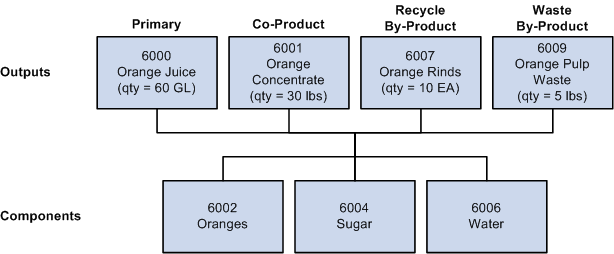

In this BOM structure, the quantity of the primary output item 6000) equals 60 gallons and quantity of the co-product (item 6001) equals 30 pounds. The resource allocation percentage for the primary and co-product does not need to be proportional to the output quantity, and it can be set to any percentage, as long as it totals 100 percent.

The following diagram illustrates the resource allocation percentage between the primary and co-products. For this structure, the percentages are set to 60 percent for item 6000 and 40 percent for item 6001.

Effect of Resource Allocation Percentages During Completions

When recording completions for co-products, the system uses the resource allocation percentage to determine what proportion of the batch quantity is consumed. For example, if you did a partial completion of 15 pounds of item 6001, the proportion of the batch quantity completed would be:

This would translate into a consumption of 20 percent of components, earned labor hours, and other related production costs. The system also uses the resource percentage on BOM inquiries to illustrate how much material each output uses when exploding down the levels.

The resource allocation percentage enables the outputs to be in different UOMs because the percentage specifies the relationship between the co-products, the primary item, and the batch quantity.

Note: For each type of percentage, the total of all primary and co-product percentages must add up to 100 percent. For a single primary item (no co-products), both of these percentages are set to 100.

Use the Header: Supplier Access List page (EN_SS_BOMVND_LST) to access a current list of Suppliers who have access to a specific item.

Navigation:

Field or Control |

Description |

|---|---|

Suppliers Associated with BOM |

Displays all suppliers that have been granted access to the specific item and its associated BOM. |

BOM Access by Supplier |

Click to access the BOM Access by Supplier page. |

Send Email to Suppliers |

Click to send email. The email message contains two URLs. One URL sends the recipient to the Manufacturing BOMs - Summary page in PeopleSoft Manufacturing, and the other URL sends the recipient to the Bill of Material inquiry page in PeopleSoft Engineering. |

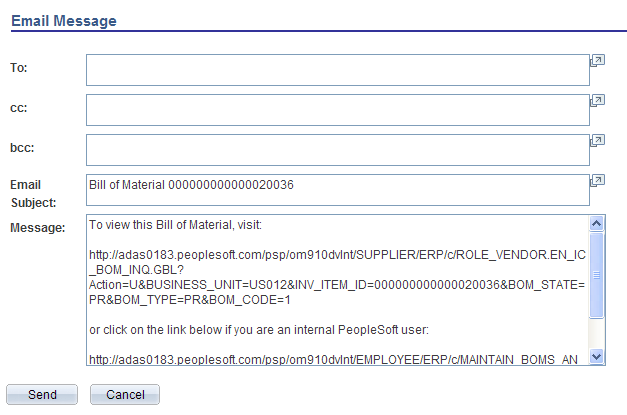

Use the Header: Send Email to Suppliers - New Message page (EG_IC_EMAIL) to send email to Suppliers.

Navigation:

Click the Send Email to Suppliers link on the Manufacturing BOMs - Header: Supplier Access List page.

Click the Send Email to Suppliers link on the Manufacturing BOMs - Header: Supplier Access List page.

This example illustrates the fields and controls on the Email Message page. You can find definitions for the fields and controls later on this page.

If you have PeopleSoft Engineering installed, the default supplier email address appears in the To field. In the case of ECRs and ECOs, the email message is sent to all suppliers who have access to the affected item. In the case of MBOMs and EBOMs, the message is sent to the item itself. You can delete email addresses from the address field if you want.

Next, enter standard recipient email information in the cc, bcc, and Email Subject fields.

If you have PeopleSoft Manufacturing and PeopleSoft Engineering installed, all email fields provide the recipient with two URLs. In many cases, one is a URL to the page from which the email was sent, and the other is to a parallel page.

If you do not have PeopleSoft Engineering installed, the system provides only one URL for the PeopleSoft Manufacturing pages.

This table displays each page from which you can send email notifications. It also describes the URL destinations provided to the recipient. If PeopleSoft Engineering is not installed, you cannot send email from a PeopleSoft Engineering page or receive a PeopleSoft Engineering URL destination.

|

Email Notification's Originating Page |

URL Destination Page |

|---|---|

|

Bill of Material inquiry page in PeopleSoft Engineering |

Bill of Material inquiry in PeopleSoft Engineering Manufacturing BOMs- Summary in PeopleSoft Manufacturing (if the BOM is a manufacturing BOM) or Engineering Manufacturing BOMs- Summary in PeopleSoft Engineering (if the BOM is an EBOM) |

|

Change Request Detail page in PeopleSoft Engineering |

Change Request Detail page in PeopleSoft Engineering ECR Maintenance - Header page in PeopleSoft Engineering |

|

Change Order Detail page in PeopleSoft Engineering |

Change Order Detail page in PeopleSoft Engineering ECO Maintenance - Header page in PeopleSoft Engineering |

|

ECO Maintenance - Header page in PeopleSoft Engineering |

ECO Maintenance - Header page in PeopleSoft Engineering Change Order Detail page in PeopleSoft Engineering |

|

ECR Maintenance - Header page in PeopleSoft Engineering |

ECR Maintenance - Header page in PeopleSoft Engineering Change Request Detail in PeopleSoft Engineering |

|

Approve ECO page in PeopleSoft Engineering |

Change Order Detail in page PeopleSoft Engineering ECO Maintenance - Header page in PeopleSoft Engineering |

|

Manufacturing BOMs- Header: Supplier Access List page in PeopleSoft Manufacturing |

Engineering Manufacturing BOMs- Summary page in PeopleSoft Engineering Bill of Material inquiry in PeopleSoft Engineering |

|

Engineering Manufacturing BOMs- Header: Supplier Access List page in PeopleSoft Engineering |

Manufacturing BOMs- Summary page in PeopleSoft Manufacturing Bill of Material inquiry page in PeopleSoft Engineering |

Note: The sender of any email notification can always edit the distribution list and the URLs in the message. Also, even though recipients may receive URLs, they must have the necessary privileges to access the system.

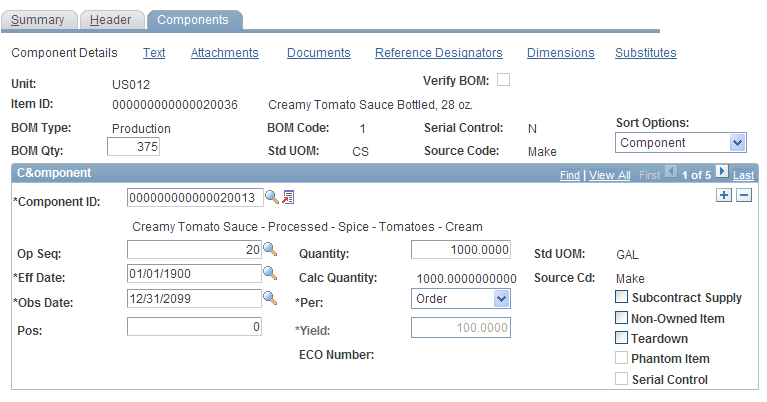

Use the Components: Component Details page (EN_COMP_MAINT) to add details for each assembly BOM component.

Navigation:

This example illustrates the fields and controls on the Components - Component Details page. You can find definitions for the fields and controls later on this page.

Note: When you add a component with the item status Hold or Discontinue, the system displays a warning message. Similarly, when you update components with the item status Hold or Discontinue, the system displays a warning when you save the page. In both cases, the warning message does not prevent you from performing the action.

Field or Control |

Description |

|---|---|

Sort Options |

Select how you want to view components. Values are:

|

Comp Rev (component revision), BOM Qty (BOM quantity), Op Seq (operation sequence), Eff Date (effective date) or Eff Rev (effective revision), Obs Date (obsolete date) or Obs Rev (obsolete revision), and Quantity |

These defaults come from the BOM Summary page, but you can change the values here at the component level. Note: If a component itself is a revision-controlled assembly, you cannot enter a revision for the item. The column is not accessible, and the current revision is always used. This ensures consistency with PeopleSoft Cost Management and PeopleSoft Supply Planning, which use the current assembly revision when exploding assemblies. |

Pos (position) |

(Optional) Indicates a position number. This can be a number associated with a component on a BOM drawing or on a list of all components that appear on a BOM. |

Per |

Select either Asy (assembly) or Ord (order). For the quantity, if you set the Per field to Asy, then when the system determines component requirements in PeopleSoft Supply Planning, it divides the quantity per by the BOM quantity and multiplies that result by the demand or order quantity. If you set the Per field to Ord, the system uses the quantity per order regardless of the demand quantity or order size. A quantity per order (QPO) is a fixed amount, regardless of the order size. If the QPO is 100, then the quantity issued to production is 100 regardless of whether an order is for 1 item or 500 items. Note: The quantity per assembly may be different for original items and their substitutes. |

QPA (quantity per assembly) |

PeopleSoft Manufacturing supports a calculated QPA precision rounded from four to ten decimal places. The calculated QPA is displayed next to the Quantity field. Calculated QPA is determined as (Component QPA) ÷ (BOM Qty). So, for example, if a calculated QPA results in 6.54321, and the installation rounding precision is set to four places, the system recognizes this as 6.5432. |

Phantom Item and Serial Control |

These display-only fields are the defaults from the PeopleSoft Inventory item definition. |

Yield |

Enter a value; the default is 100. Component yield is the expected percentage of usable components within a batch of components issued to production. If you know that components can be damaged during the issuing or assembly process, you can account for that loss here. A 100 percent yield means that the entire quantity of the component is usable and none will be scrapped. A yield of 90 percent yield means that 10 percent of the component issued will be unusable or scrapped. The system uses the component yield setting in PeopleSoft Supply Planning and PeopleSoft Cost Management processes. In PeopleSoft Supply Planning, it inflates component requirements to account for the expected loss during the assembly process. When scheduling the number of components to be used in production, the system divides the required quantity by the component yield value to derive the scheduled quantity. For example, if an assembly has a demand of 100 units, and the quantity per assembly is 1 with a component yield of 90 percent, then planning requires 111 components (100 ÷ .90). If the expected 10 percent yield loss occurs, 11 components (111 × .10) are unusable, leaving you with the original required 100 components. When calculating the cost of the assembly, the system includes the component yield loss, thereby increasing the cost contribution of the component. Note: The system doesn't support component yield for components expressed in quantity per order. |

ECO Number |

This display-only field indicates that the BOM was updated using the PeopleSoft Engineering BOM Mass Maintenance by ECO process (ENPMMAIN). The number displayed is the last ECO number that updated the component on the BOM. If no ECO has been run against this component on this BOM, this field is blank. |

Subcontracting

PeopleSoft Manufacturing can handle all subcontracting and nonsubcontracting scenarios, including those in which:

You handle manufacturing in house, and you supply all components.

A subcontractor supplies some of the components, and outside processing is performed.

The customer supplies some of the components, and you are the subcontractor.

Occasionally, you may want to maintain the full product structure of the assembly item, even though you do not provide all the components necessary to manufacture the item.

Field or Control |

Description |

|---|---|

Subcontract Supply |

Select if an outside supplier supplies part of the manufacturing process and the component is supplied by the outside supplier. |

Non-Owned Item |

Select if you do not own the component, and you want to indicate that the customer supplies the component. |

In a typical scenario, you send a partially completed assembly to a subcontractor who then adds a component and returns the altered assembly. This has planning, production, and costing implications. When exploding demand for components stemming from an assembly requirement, the system doesn't include subcontracted supplied components. Scheduling components for production also excludes subcontracted supplied components. These subcontracted components are not included in the production picking plan or issued to a WIP location storage area. For the purposes of costing, subcontracted supplied components are not included in the assembly cost.

This table describes the Subcontractor Supply and Non-Owned Item field combinations:

|

Field Selection |

Description |

|---|---|

|

Subcontract Supply and Non-Owned Item are both selected. |

A subcontractor supplies the component. |

|

Subcontract Supply is deselected, and Non-Owned Item is selected. |

You are the subcontractor, and the customer supplies the component. |

|

Subcontract Supply and Non-Owned Item are deselected. |

You supply the component. |

|

Subcontract Supply is selected and Non-Owned Item is deselected. |

This is not a valid combination. |

Field or Control |

Description |

|---|---|

Teardown |

Select to indicate whether the component is an output from a teardown order. When you select the check box, the system designates the component as a teardown output. If you do not select the check box, this indicates the component will not be an output of a torn-down assembly. The Teardown check box applies only to teardown orders. When you create a teardown order based on a BOM for this item, the system copies the teardown components on the BOM to the teardown output list when released to production. This enables the system to keep teardown outputs in sync with component changes in the manufacturing BOM. However, the Teardown check box on the BOM is also copied down to the component list for regular production IDs (as the original production ID). That way, if you tear down based on an original production ID, the system can determine which components are used as outputs. The Teardown check box on the component list on the original production ID determines the structure of the teardown output list for the teardown production ID. If you selected the Default Teardown BOM Component option on the Manufacturing Business Unit Options page, the system designates all components as teardown outputs on all BOMs for all items in the business unit. For all items where this default is in place, the system selects the Teardown check box when you add a component to a BOM. Teardown components cannot be subcontractor-supplied because those components are not tracked within PeopleSoft Manufacturing. Note: Only items with a source code of Make or Buy can be teardown components. |

Use the Components: Reference Designators page (EN_COMP_DESIG) to associate designators to a component of an assembly item.

Navigation:

Field or Control |

Description |

|---|---|

Reference Designators |

You can associate an unlimited number of reference designators with a component of an assembly item. The designator is any alphanumeric code that you can use to determine where a component is placed in an assembly. The electronics industry often uses reference designators for positioning components on circuit boards. Enter a reference designator up to 20 characters long. You can use it in relation to quantity per assembly. For example, if five pegs need to be placed in a board, you can give each its own reference designation to aid in positioning. |

Use the Components: Dimensions page (EN_COMP_DIM) to specify and maintain BOM component dimensions.

Navigation:

Field or Control |

Description |

|---|---|

Production Specifications |

These default values come from the item definition in PeopleSoft Inventory, but you can change them for the component. |

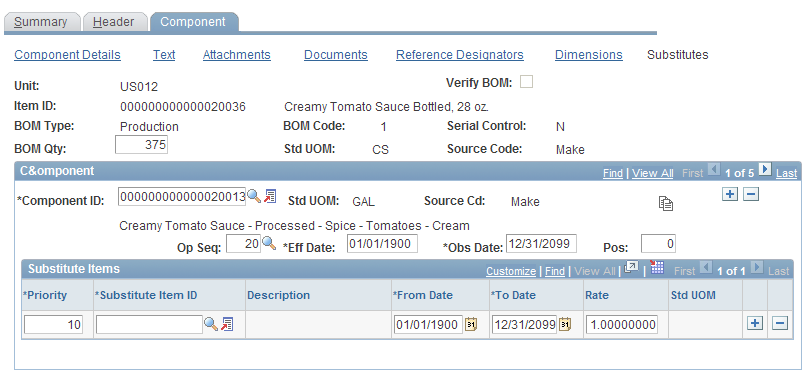

Use the Components: Substitutes page (EN_COMP_SUB) to add substitute components.

Navigation:

This example illustrates the fields and controls on the Components - Substitutes page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Substitute Item ID |

Select the component that you want to add. Substitute items must be unique for the item. You cannot enter the same item twice as a substitute with different dates. For example, substitute A with effective dates from 01/01/99 to 02/01/99 and Substitute A with effective dates from 02/01/00 to 08/30/00 could not be substitutes for the same item. In this example, you would need to define a different substitute for the second set of effective dates. |

Priority, Rate, From Date, and To Date |

Enter values for the new component. Enter the conversion rate in the Rate field. |

Std UOM (standard unit of measure) |

Enter the UOM, which can be different for the substitute and the original component. |

Note: A substitute item cannot be a phantom or a component of a phantom. Also, if substitutes exist, the item cannot be changed to a phantom.

Note: If no substitute items are defined for an item that has been designated as Discontinued, there may be a shortage of that item if demand exceeds the existing quantity on hand. If a substitute has been defined for that item, the PeopleSoft system automatically selects the substitute when the quantity on hand for the discontinued item runs out.

Use the Components: Copy Business Unit Substitute Items page (EN_BOM_SUB_ITEM_SP) to view valid substitutes for the component, and copy the substitutes to the BOM.

Navigation:

Click the Copy BU Substitute Items button.

Field or Control |

Description |

|---|---|

OK and Yes |

Click to copy business unit-level substitutes to the BOM level. |

Note: Changes to the BOM maintenance substitute list in PeopleSoft Supply Planning are not transferred back to the transaction system.