Recording Completed Operations and Scrap for Subcontracted Operations

Once you've processed the end items through receiving and inspection, you can record the operation as complete in PeopleSoft Manufacturing. If the subcontracted operation is the last operation on the routing, you can also indicate that production is completed.

When you record scrap for the end item, the system optionally sends a workflow notification to selected roles defined by you. These roles might include a quality manager or a production control manager.

If you are integrating with a Manufacturing Execution System (MES), you can receive subcontracted operation completions from the MES to the PeopleSoft system. The end items need to be received in PeopleSoft Purchasing before you can record the completion transaction in PeopleSoft Manufacturing. The MES sends the same information for a subcontracted completion as with completions for regular operations.

Note: If you have set up your environment to perform subcontract streamlining then the recording of subcontracted operations is unnecessary.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

SF_SUBREC |

Record completed operations and scrap by subcontracted operation. You must receive the subcontracted end items through PeopleSoft Purchasing before using this page. |

|

|

SF_COMPL_PRDN |

Indicate that production is completed for production IDs with subcontracted operations. |

|

|

SF_RECEIPT_INFO |

View receipt and completions information about the subcontracted operation. |

|

|

SF_COMPL_ID |

(Optional) Enter completions and scrap information for production IDs. In addition, use this page to move end items for production IDs with a single output or multiple outputs. |

|

|

Production Scrap Details Page |

SF_COMPL_SCRAP |

Enter scrap quantities, if applicable. |

|

Apply Defaults Page |

SF_COMPL_DEFAULTS |

Select the default putaway or alternate storage locations for the completed end items. |

|

AUTO_SERIAL_WRK |

(Optional) Automatically generate serial numbers for production end items that are serial-controlled. You must define serial-controlled items in PeopleSoft Inventory. |

|

|

Lot/Serial Number Selection scroll area Page |

SF_ED_CMP_SBP_GRD |

(Optional) Identify the lots from which you want to consume lot-controlled components. You must enter a pending quantity greater than zero for a lot-controlled component before the Lot/Serial scroll area is available. |

|

SF_TRANSHIST |

View production transaction history for production IDs. |

|

|

Production History - Detail inquiry Page |

SF_TXN_HIST_SP |

View production transaction history details based on:

|

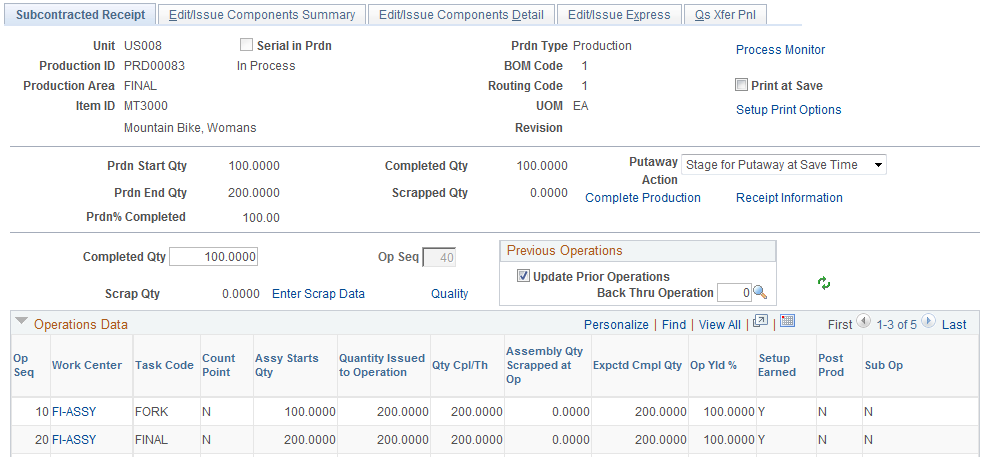

Use the Subcontracted Receipt page (SF_SUBREC) to record completed operations and scrap by subcontracted operation.

Navigation:

This example illustrates the fields and controls on the Subcontracted Receipt page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Print at Save |

Select this check box if you want to print production documents at save time. |

Setup Print Options |

Click this link to access the Process/Output Options page to select different print criteria for the production documents. |

Completed Qty (completed quantity) |

Enter the number of end items being completed. |

Quality |

Click this link to initiate a data entry session and to access either the Data Entry - Subgroup Method page or the Data Entry - Sample Method page in PeopleSoft Quality, depending on the data entry method that you specified when creating the quality control plan. |

Operations Data

View display-only production data such as assembly start quantities, number of assemblies scrapped, expected completed quantities, and yield percentages for each operation sequence.

Use the Receipt Information page (SF_RECEIPT_INFO) to view receipt and completions information about the subcontracted operation.

Navigation:

Field or Control |

Description |

|---|---|

Recv Rejected Qty (received rejected quantity) |

Displays the quantity that Receiving rejected from the supplier and that was recorded in PeopleSoft Purchasing. Receiving assigns one of these indicators to the rejected quantity:

Only received quantities that have a status of Return for Credit appear in this field. |

Prdn Accepted Qty (production accepted quantity) |

Displays the quantity that was actually recorded as a completion using the Subcontract Receipt page. |

Prdn Rejected Qty (production rejected quantity) |

Displays the quantity that was actually recorded as scrap using the Subcontract Receipt page. |

Note: Use the Edit Components page if you want to modify or view the components that will be consumed based on the quantity completed or scrapped, or if you need to select the serial or lot numbers for those serial- or lot-controlled components that were consumed when you recorded the completion.